Documente Academic

Documente Profesional

Documente Cultură

Magneto-inductive position sensor detects cylinder positions

Încărcat de

Mohamed ReyadDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Magneto-inductive position sensor detects cylinder positions

Încărcat de

Mohamed ReyadDrepturi de autor:

Formate disponibile

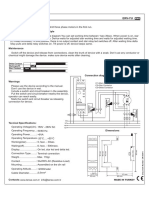

MAGNETO-INDUCTIVE Series

881

POSITION DETECTORS Type

2 wires

APPLICATION

This four-wire proximity sensor will monitor stroke end and intermediate positions

of pneumatic cylinders equipped with built-in permanent magnets.

Do not use near welding areas.

OPERATING SYSTEM

The permanent magnet is mounted in the piston head. On getting closer, its own

magnetic field generates variations of the current within the detector oscillator.

An amplifier converts them into switch signals.

B

GENERAL CHARACTERISTICS

Function : closing

Switching voltage : 10 to 65 V DC

Residual ripple : < 10%

Residual current (opening) : < 0.8 mA

Max. switching current : 100 mA

Min. switching current : 3 mA

IL max. voltage drop : <5V

Hysteresis : < 1 mm

Ambient temperature : -10°C ; +70°C CONNECTION DIAGRAM

Housing : circuit protected by an aluminium box No serial connection can be performed with

External protection : IP65 several detectors.

Electrical protection : non-polarised detector protected against + (-)

10 / 65 V =

short circuits and overcharges (100 mA)

: Load

Connection (three possibilities) : ● 0.8 m cable + four-pin male connector Ø 12 mm,

- (+)

CNOMO E03.62.520.N

● 2 m cable with stripped ends

● integrated male connector Ø 12 mm (for different extension cords available, see overleaf)

Indicator lamp : diode (yellow LED) which lights up when the contact is closed

Mounting direction : any way - Do not use near welding areas

Mounting on cylinder : ● ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552, type PES series 450 Ø 32 to 200 mm with tie rods

and Ø 32 to 125 mm with profiled barrel.

● ISO 6431 Ø 32 to 200 mm with tie rods, type PIS series 436

● CNOMO 06.07.02/03 - NFE 49001/002 Ø 32 to 200 mm with tie rods, type PCN series 437

CHOICE OF EQUIPMENT Adaptation for CNOMO PCN Ø 25 mm cylinder : consult us

Can be mounted CODE of one detector

DESCRIPTION on cylinders with bracket on its own

Inductive magnetic position detector, with wire 0.8 m long and

four-pin male connector Ø 12 mm type conprox (1) to CNOMO with tie rods Ø 32 to 100 mm 88143676❉

E03.40.150.N and E03.62.520.N, CNOMO cutting oil resistant wire, 88143672❉

delivered with mounting bracket for cylinders: with tie rods Ø 125 to 200 mm 88143678

Inductive magnetic position detector, with wire 2 m long, stripped ends with tie rods Ø 32 to 100 mm 88143677❉

without connector, CNOMO cutting oil resistant wire, delivered with

mounting bracket for cylinders: 88143673❉

with tie rods Ø 125 to 200 mm 88143679

Availability, design and specifications are subject to change without notice. All rights reserved.

with tie rods Ø 32 to 100 mm 88143617❉

Inductive magnetic position detector, with integrated four-pin male

connector Ø 12 mm (2) type conprox, delivered with mounting bracket with tie rods Ø 125 to 200 mm 88143680 88143616❉

for cylinders:

with profiled barrel

Ø 32 to 125 mm 88143618❉

(1) Wires connected to pins 1 and 4 of the connector (car industry applications) Marking male connectors

(2) Wires connected to pins 3 and 4 of the connector view from contact side

❉ In the case of use of a BIM magnetic detector on PES series 450 Ø 32, it is necessary

to add the option code = 995125 (1) 2 1 (2) 2 1

3 4 3 4

Mounting on U or H guiding units:

! The forward position detector support is specified (consult us)

00237GB-2006/R01

Detector with wire Detector with integrated connector Extension cord (see Accessories overleaf)

All leaflets are available on: www.asconumatics.eu

P297-1

MAGNETO-INDUCTIVE DETECTORS

ACCESSORIES-MOUNTINGS

DESCRIPTION CODE

CNOMO extension cord, cutting oil resistant

4 wire conductors, 0.5 mm2 with 1 five-pin straight socket connector Ø 12 5 m long 88143675

EXTENDING CORDS

mm, CNOMO E03.62.520.N (1) (other end of wire stripped)

Standard PVC extension cord, 4 wire conductors, 0.5 mm2

with 1 four-pin straight socket connector Ø 12 mm (2) 5 m long 88143619

(other end of wire stripped)

Standard PVC extension cord, 4 wire conductors, 0.5 mm2

with 1 four-pin curved socket connector Ø 12 mm (2) 5 m long 88143620

(other end of wire stripped)

Mounting device type KLI 1 for cylinders with tie rods Ø 32 to 100 mm 88143625

MOUNTING

DEVICES

Mounting device type KLI 3 for cylinders with tie rods Ø 125 to 200 mm 88143674

Mounting device type KLI 2 for cylinders with profiled barrels Ø 32 to 125 mm 88143626

(1) Wires connected to pins 1 (brown) and 4 (black) of the connector

(2) Wires connected to pins 3 (blue) and 4 (black) of the connector

DIMENSIONS AND WEIGHTS

It is possible to install magnetic detectors Detectors may be mounted on any MOUNTING ON CYLINDER MOUNTING ON CYLINDER

to monitor stroke end or intermediate positions of the 4 tie rods or profiled barrels WITH TIE RODS WITH PROFILED BARREL

M2 M4

* M1 M3

30

Dimensions cylinder Ø (mm) Weight*

(mm) 32 40 50 63 80 100 125 160 200 (in g)

M1 46 50 54 58 65 72 84 97 111

M2 39 41 48 52 60 68 78 96 110

67

M3 46 50 55 60 67 75 88 - -

* Weight of detector + bracket M4 38 42 46 50 56 65 76 - -

MOUNTING ON CYLINDERS

MOUNTING ON CYLINDERS WITH TIE RODS Ø 32 TO 200 mm

Mounting Connection by compound-filled wire

Screw bracket LED or male connector Ø 12 mm

3 Mounting instructions

1 - Install mounting bracket on detector

2 - Start screwing in the detector

Availability, design and specifications are subject to change without notice. All rights reserved.

3 - Position at measuring point

4 - Check that the detector is in contact with the

2 4 tube and tighten on cylinder, screwing down

1

moderately with key (2.5 mm hexagonal)

MOUNTING ON CYLINDERS WITH PROFILED BARREL Ø 32 TO 125 mm

Mounting Connection by male

bracket Screw LED connector Ø 12 mm

3

Mounting instructions

2

1 - Install mounting bracket on detector

2 - Start screwing bracket on detector

3 - Position at measuring point

1

00237GB-2006/R01

4 - Check that the detector is in contact with the

tube and tighten on cylinder, screwing down

4

moderately with key (2.5 hexagonal)

All leaflets are available on: www.asconumatics.eu

P297-2

S-ar putea să vă placă și

- JCB 8080 Midi Excavator Service Repair Manual SN1024000 Onwards PDFDocument17 paginiJCB 8080 Midi Excavator Service Repair Manual SN1024000 Onwards PDFhfjksekmmdm44% (9)

- Examined: Item Sub-System Customer Identification Remark Drawing Description Drawing Type Drawing Number RevisionDocument51 paginiExamined: Item Sub-System Customer Identification Remark Drawing Description Drawing Type Drawing Number RevisionWagdy KhaterÎncă nu există evaluări

- Hico SF Gas Circuit Breaker: Power Systems PUDocument6 paginiHico SF Gas Circuit Breaker: Power Systems PUSubir ChattopadhyayÎncă nu există evaluări

- Cylinders Actuators Mountings and Sensors 494 CAT 01418GBDocument2 paginiCylinders Actuators Mountings and Sensors 494 CAT 01418GBMiyka'el PaunÎncă nu există evaluări

- Inductive Sensor BI5-M18-AN6XDocument3 paginiInductive Sensor BI5-M18-AN6Xrimmer boyÎncă nu există evaluări

- Art b22 DXXXXX SeriesDocument12 paginiArt b22 DXXXXX Seriesrica_alvesÎncă nu există evaluări

- M12 Series DC 2-Wire SN 8mm: Inductive Sensors FeaturesDocument1 paginăM12 Series DC 2-Wire SN 8mm: Inductive Sensors Featuresany3000Încă nu există evaluări

- Inductive Sensor BI2-Q10S-AZ31XDocument2 paginiInductive Sensor BI2-Q10S-AZ31Xgracy2288Încă nu există evaluări

- SolenoidesDocument3 paginiSolenoidesMarcosÎncă nu există evaluări

- Ehr 4Document4 paginiEhr 4jorgeÎncă nu există evaluări

- Hawkeye Prox SwitchDocument1 paginăHawkeye Prox SwitchAlejandro A Ochoa VargasÎncă nu există evaluări

- Series: General DescriptionDocument23 paginiSeries: General Descriptionwever85Încă nu există evaluări

- Wpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document4 paginiWpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Sathish J EceÎncă nu există evaluări

- Automotive Power Relay Features and ApplicationsDocument3 paginiAutomotive Power Relay Features and ApplicationsJesus HernadezÎncă nu există evaluări

- Half Size Crystal Can Relay 2 Ampere Sensitive Series KA: Product DescriptionDocument2 paginiHalf Size Crystal Can Relay 2 Ampere Sensitive Series KA: Product Description邹光奎Încă nu există evaluări

- Hioki CLAMP ON POWER LOGGER PW3365E14Document16 paginiHioki CLAMP ON POWER LOGGER PW3365E14rubenÎncă nu există evaluări

- Capteurs Magnetiques Pour Les VerinsDocument8 paginiCapteurs Magnetiques Pour Les VerinsLadhari AliÎncă nu există evaluări

- Erv-Yu Star Delta Relay: GeneralDocument1 paginăErv-Yu Star Delta Relay: GeneralMai Văn BáchÎncă nu există evaluări

- Wpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document4 paginiWpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Gopal HegdeÎncă nu există evaluări

- Inductive Sensor with Increased Switching DistanceDocument3 paginiInductive Sensor with Increased Switching Distanceasmir_aganovic8119Încă nu există evaluări

- Emboss Tape and Radial Tape Connector SpecsDocument5 paginiEmboss Tape and Radial Tape Connector SpecspaulpuscasuÎncă nu există evaluări

- NJ15-30GM-N - P&F - 106491 - EngDocument2 paginiNJ15-30GM-N - P&F - 106491 - EngNCÎncă nu există evaluări

- LTC 3103Document20 paginiLTC 3103Audre Maren DayadayÎncă nu există evaluări

- Magnetostrictive Level Meters: For LiquidsDocument2 paginiMagnetostrictive Level Meters: For LiquidsJonathan TengÎncă nu există evaluări

- 2057 Series: Features ApplicationsDocument4 pagini2057 Series: Features Applicationsricahard61Încă nu există evaluări

- KET Catalog Electronic ConnectorDocument40 paginiKET Catalog Electronic ConnectorAraceli OrtizÎncă nu există evaluări

- Avionics/Mil: Cable Mounted Plug 7007 SeriesDocument1 paginăAvionics/Mil: Cable Mounted Plug 7007 Seriessaeedmahboob05Încă nu există evaluări

- LY2N RelaysDocument3 paginiLY2N RelaysAnh PhamÎncă nu există evaluări

- Speed Monitor PDFDocument4 paginiSpeed Monitor PDFTony IbraÎncă nu există evaluări

- 1155 TMFDocument2 pagini1155 TMFNixon Quispe SanchezÎncă nu există evaluări

- Proximity SwitchDocument4 paginiProximity SwitchMohamed MekkyÎncă nu există evaluări

- AS 603PC Photoelectric Smoke Detector User ManualDocument1 paginăAS 603PC Photoelectric Smoke Detector User ManualDonald OUedraogoÎncă nu există evaluări

- Connector: 1.2mm Pitch/disconnectable Crimp Style ConnectorsDocument2 paginiConnector: 1.2mm Pitch/disconnectable Crimp Style ConnectorsTrần Long VũÎncă nu există evaluări

- Caudalimetro Maquina de CaféDocument21 paginiCaudalimetro Maquina de CaféetjorgeÎncă nu există evaluări

- PLL FM Multiplexer Stereo Demodulator: DescriptionsDocument4 paginiPLL FM Multiplexer Stereo Demodulator: DescriptionsIvan F SantosÎncă nu există evaluări

- Capteur Angulaire NovotechnikDocument4 paginiCapteur Angulaire NovotechnikLeonorÎncă nu există evaluări

- Automotive Power Relay: Technical Data For Contact SideDocument3 paginiAutomotive Power Relay: Technical Data For Contact SideRakesh SutharÎncă nu există evaluări

- Automotive Power Relay: Technical Data For Contact SideDocument3 paginiAutomotive Power Relay: Technical Data For Contact SideRakesh SutharÎncă nu există evaluări

- Magnetschalter Fenster - Magnetic Switches For Windows Magnetschalter Fenster - Magnetic Switches For WindowsDocument1 paginăMagnetschalter Fenster - Magnetic Switches For Windows Magnetschalter Fenster - Magnetic Switches For WindowsAdmirMadzakÎncă nu există evaluări

- 08 Inductive Sensor Bi10 p30sr Fz3x2 enDocument3 pagini08 Inductive Sensor Bi10 p30sr Fz3x2 enShariq KhanÎncă nu există evaluări

- Inductive Sensor With Extended Temperature Range BI5-M18-AZ3X/S120Document3 paginiInductive Sensor With Extended Temperature Range BI5-M18-AZ3X/S120Kamitkumar PatelÎncă nu există evaluări

- Vishay-F17725222230-datasheetDocument3 paginiVishay-F17725222230-datasheetJesusSeijasÎncă nu există evaluări

- Varactor Diode: Single Varactor Diode for VCO 16V, 50nA, CR=6.0, rs=0.8Ω, MCPH3Document6 paginiVaractor Diode: Single Varactor Diode for VCO 16V, 50nA, CR=6.0, rs=0.8Ω, MCPH3alfatÎncă nu există evaluări

- Connector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocument3 paginiConnector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsЕвгений ИвановÎncă nu există evaluări

- Of Block Cylinders and Pneumatic Swing Clamps: Magnetic Sensors For Position MonitoringDocument2 paginiOf Block Cylinders and Pneumatic Swing Clamps: Magnetic Sensors For Position MonitoringDaniel Gutierrez JailletÎncă nu există evaluări

- 7-10GHz AntennaDocument2 pagini7-10GHz Antennayi zhouÎncă nu există evaluări

- ug-1safe-enDocument4 paginiug-1safe-enJernej SevšekÎncă nu există evaluări

- 2SC3928A Transistor for Low Frequency AmplificationDocument2 pagini2SC3928A Transistor for Low Frequency AmplificationFernando José Luzardo FernándezÎncă nu există evaluări

- Digital/Analog Insulation and Continuity Testers: MIT200 SeriesDocument4 paginiDigital/Analog Insulation and Continuity Testers: MIT200 SeriessaadÎncă nu există evaluări

- XCL223/XCL224: General DescriptionDocument20 paginiXCL223/XCL224: General DescriptionSarah Joy ManimtimÎncă nu există evaluări

- Electrostatic Field Meter User ManualDocument3 paginiElectrostatic Field Meter User ManualOrbán NorbertÎncă nu există evaluări

- Dse 7110-20 UkDocument4 paginiDse 7110-20 UkAnas BasarahÎncă nu există evaluări

- Technical Data: NJ15-30GK-E2-T-5MDocument1 paginăTechnical Data: NJ15-30GK-E2-T-5MrajanarenderÎncă nu există evaluări

- Capacitor For Power Electronics: R Tanδδδδ CxrDocument6 paginiCapacitor For Power Electronics: R Tanδδδδ Cxrraza239Încă nu există evaluări

- Relative Pressure Transmitter Type 520Document8 paginiRelative Pressure Transmitter Type 520DaveÎncă nu există evaluări

- Cylindrical proximity sensorsDocument6 paginiCylindrical proximity sensorsMin ZayarÎncă nu există evaluări

- JST Connector Catalogue Vol 120eDocument535 paginiJST Connector Catalogue Vol 120etiago alexandreÎncă nu există evaluări

- Miniline Ml30.102 With DC 10-12V / 30W: Data SheetDocument2 paginiMiniline Ml30.102 With DC 10-12V / 30W: Data SheetHong Khuyen ThaiÎncă nu există evaluări

- Dse8661 Data Sheet (Usa)Document2 paginiDse8661 Data Sheet (Usa)top stm32Încă nu există evaluări

- Voltage Transducer LV 25-400 Measures AC and DC Voltage Up to 600VDocument3 paginiVoltage Transducer LV 25-400 Measures AC and DC Voltage Up to 600Vtichtruong77Încă nu există evaluări

- SCT9320Document20 paginiSCT9320Charith PereraÎncă nu există evaluări

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10De la EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10Încă nu există evaluări

- MTP50P03HDL Power MOSFET 50 Amps, 30 Volts, Logic LevelDocument8 paginiMTP50P03HDL Power MOSFET 50 Amps, 30 Volts, Logic LevelMohamed ReyadÎncă nu există evaluări

- TN3050H-12WY: 30 A, 1200 V Automotive Grade SCR ThyristorDocument10 paginiTN3050H-12WY: 30 A, 1200 V Automotive Grade SCR ThyristorSohail AhmedÎncă nu există evaluări

- 10fhy RSM1 Gan TF (LF) (SN)Document11 pagini10fhy RSM1 Gan TF (LF) (SN)Mohamed ReyadÎncă nu există evaluări

- FQB20N06 / FQI20N06: 60V N-Channel MOSFETDocument9 paginiFQB20N06 / FQI20N06: 60V N-Channel MOSFETMohamed ReyadÎncă nu există evaluări

- 1N4007 888322Document7 pagini1N4007 888322JohnMax TehÎncă nu există evaluări

- Thyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeDocument5 paginiThyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeMohamed ReyadÎncă nu există evaluări

- Auirfz44Vzs: Automotive GradeDocument13 paginiAuirfz44Vzs: Automotive GradeMohamed ReyadÎncă nu există evaluări

- MTP50P03HDL Power MOSFET 50 Amps, 30 Volts, Logic LevelDocument8 paginiMTP50P03HDL Power MOSFET 50 Amps, 30 Volts, Logic LevelMohamed ReyadÎncă nu există evaluări

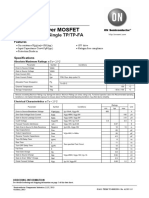

- N-Channel Power MOSFET: 600V, 1.0A, 13, Single TP/TP-FADocument5 paginiN-Channel Power MOSFET: 600V, 1.0A, 13, Single TP/TP-FAMohamed ReyadÎncă nu există evaluări

- C106 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 paginiC106 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsOmarÎncă nu există evaluări

- BSM150GT120DN2Document1 paginăBSM150GT120DN2Mohamed ReyadÎncă nu există evaluări

- Precision Potentiometer: Model 7280 SeriesDocument5 paginiPrecision Potentiometer: Model 7280 SeriesMohamed ReyadÎncă nu există evaluări

- 10fhy RSM1 Gan TF (LF) (SN)Document11 pagini10fhy RSM1 Gan TF (LF) (SN)Mohamed ReyadÎncă nu există evaluări

- BSM150GT120DN2Document1 paginăBSM150GT120DN2Mohamed ReyadÎncă nu există evaluări

- Thyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeDocument5 paginiThyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeMohamed ReyadÎncă nu există evaluări

- Thyristor Product CatalogDocument224 paginiThyristor Product CatalogMohamed ReyadÎncă nu există evaluări

- Enda Ec442 Up/Down CounterDocument5 paginiEnda Ec442 Up/Down CounterMohamed ReyadÎncă nu există evaluări

- VS-30TPS16-M3: Vishay SemiconductorsDocument7 paginiVS-30TPS16-M3: Vishay SemiconductorsMohamed ReyadÎncă nu există evaluări

- En - Steval-Ihm023v3 BomDocument4 paginiEn - Steval-Ihm023v3 BomMohamed ReyadÎncă nu există evaluări

- Project Name: Bill of Materials STEVAL-IHM032V1Document2 paginiProject Name: Bill of Materials STEVAL-IHM032V1Mohamed ReyadÎncă nu există evaluări

- Magneto-inductive position sensor detects cylinder positionsDocument2 paginiMagneto-inductive position sensor detects cylinder positionsMohamed ReyadÎncă nu există evaluări

- Waukee Carburetor: User Manual - Revision 4Document20 paginiWaukee Carburetor: User Manual - Revision 4Mohamed ReyadÎncă nu există evaluări

- Precision Potentiometer: Model 7280 SeriesDocument5 paginiPrecision Potentiometer: Model 7280 SeriesMohamed ReyadÎncă nu există evaluări

- Tem Numb Quantity Part Reference Mistral Part No Value Description MFR - Name MFR - Part - NumberDocument4 paginiTem Numb Quantity Part Reference Mistral Part No Value Description MFR - Name MFR - Part - NumberMohamed ReyadÎncă nu există evaluări

- Diax 03: ELS-04VRSDocument480 paginiDiax 03: ELS-04VRSMohamed ReyadÎncă nu există evaluări

- VM05 War1Document106 paginiVM05 War1Giovanni TrinidadÎncă nu există evaluări

- Synax200 Decentralized System For The Synchronization of Machine Axes Version 06 Sy06 Wa01 Rexroth IndramatDocument89 paginiSynax200 Decentralized System For The Synchronization of Machine Axes Version 06 Sy06 Wa01 Rexroth IndramatMohamed ReyadÎncă nu există evaluări

- Sse03 FK01Document246 paginiSse03 FK01Mohamed ReyadÎncă nu există evaluări

- Synax200 Decentralized System For The Synchronization of Machine Axes Version 06 Sy06 Wa01 Rexroth IndramatDocument89 paginiSynax200 Decentralized System For The Synchronization of Machine Axes Version 06 Sy06 Wa01 Rexroth IndramatMohamed ReyadÎncă nu există evaluări

- Industrial Automation Repairs, Spares and ServiceDocument12 paginiIndustrial Automation Repairs, Spares and ServiceMohamed ReyadÎncă nu există evaluări

- Electronic Equipment Repair (EE 302) : Lectured By: Pn. Nor Kharul Aina Binti Mat DinDocument5 paginiElectronic Equipment Repair (EE 302) : Lectured By: Pn. Nor Kharul Aina Binti Mat DinSadrina MahamudÎncă nu există evaluări

- Practical No.12: Adjust Handlebar Arrangement For Precise Steering of VehicleDocument7 paginiPractical No.12: Adjust Handlebar Arrangement For Precise Steering of VehicleRohan pateÎncă nu există evaluări

- Solar Power Generator - LeafletDocument2 paginiSolar Power Generator - LeafletRajesh RaiÎncă nu există evaluări

- A Textbook of Automobile Engineering by Navy FerozDocument161 paginiA Textbook of Automobile Engineering by Navy Ferozumesh1374100% (2)

- Copper Power Cable SizingDocument2 paginiCopper Power Cable SizingAshish MÎncă nu există evaluări

- Transfer Cases Brochure Letterweb 3Document3 paginiTransfer Cases Brochure Letterweb 3Marek WyszatyckiÎncă nu există evaluări

- ABB TransformersDocument18 paginiABB TransformersEng HamiedÎncă nu există evaluări

- Surge Protection For Power SystemsDocument117 paginiSurge Protection For Power SystemsMauricio Cesar Molina ArtetaÎncă nu există evaluări

- 003-013 Rocker Lever HousingDocument7 pagini003-013 Rocker Lever HousingYè WințÎncă nu există evaluări

- Sterner Infranor Polaris-12 Series Brochure 2006Document20 paginiSterner Infranor Polaris-12 Series Brochure 2006Alan MastersÎncă nu există evaluări

- Service manual for Onkyo A-5VL integrated amplifierDocument77 paginiService manual for Onkyo A-5VL integrated amplifierAdrian NegulescuÎncă nu există evaluări

- 850Document4 pagini850Ssubrat RrudraÎncă nu există evaluări

- View Parker Pneumatic Valvair II Series Valves BookmarksDocument10 paginiView Parker Pneumatic Valvair II Series Valves Bookmarksalvaro cardenasÎncă nu există evaluări

- 600/1000V Cu/PVC cable technical data sheetDocument1 pagină600/1000V Cu/PVC cable technical data sheetCiwa DoankÎncă nu există evaluări

- Product Information Packet: 7.5HP, 1770RPM, 3PH, 60HZ, 213T, 3738M, TEFC, FDocument11 paginiProduct Information Packet: 7.5HP, 1770RPM, 3PH, 60HZ, 213T, 3738M, TEFC, FJose Luis RocanoÎncă nu există evaluări

- Chapter 7 Notes Computer OrganizationDocument20 paginiChapter 7 Notes Computer OrganizationsriÎncă nu există evaluări

- Parallel Operation of Synchronous GeneratorDocument7 paginiParallel Operation of Synchronous Generatorfahrid mudoriÎncă nu există evaluări

- Data Manual: PCI2050BDocument88 paginiData Manual: PCI2050BapurvÎncă nu există evaluări

- Downloaded From Manuals Search EngineDocument47 paginiDownloaded From Manuals Search EngineAan DharmawanÎncă nu există evaluări

- Betonieră Imer MINIBETADocument1 paginăBetonieră Imer MINIBETAdiconÎncă nu există evaluări

- Amended Technical Bulletin on Engine Oil ConsumptionDocument9 paginiAmended Technical Bulletin on Engine Oil ConsumptionSeepa Rakkar100% (1)

- Phase Antiphase Boost Control PDFDocument2 paginiPhase Antiphase Boost Control PDFNugrahaÎncă nu există evaluări

- Mechatronics Project FinalDocument21 paginiMechatronics Project FinalAklesh GuptaÎncă nu există evaluări

- DIY Modular Hydroponic Tower SystemDocument14 paginiDIY Modular Hydroponic Tower SystemconsultoriaALFAÎncă nu există evaluări

- Hägglunds CB motor data and dimensionsDocument1 paginăHägglunds CB motor data and dimensionsThiago SilvaÎncă nu există evaluări

- Computer Based ControllerDocument44 paginiComputer Based Controllerksjanarthanan_sriÎncă nu există evaluări

- 1.1 KV Cable Voltage Drope CalculationDocument3 pagini1.1 KV Cable Voltage Drope CalculationParmod SainiÎncă nu există evaluări