Documente Academic

Documente Profesional

Documente Cultură

Understanding Non-Linear Load Sequencing: Lets Look at Loading Sequencing

Încărcat de

Darren KamDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Understanding Non-Linear Load Sequencing: Lets Look at Loading Sequencing

Încărcat de

Darren KamDrepturi de autor:

Formate disponibile

Understanding Non-Linear Load Sequencing

Typical loadings are Deadweight applied then pressure then system heated up.

i.e. Gr -> P1 -> T1. Many pipe stress programs lump all these loadings

together. AutoPIPE non-linear analysis applies these loadings in a sequence

with Gravity always first as expected.

Note: There is no load sequencing for a Linear analysis.

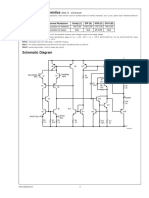

Lets look at Loading Sequencing

Guide , gap left & right = 0.2”

8’

2’

V-Stop

10’

2’

8” STD WT, A106-B

8’ P = 0psi, 550F

Static Seimic loading, E1 =

0.6g in the +Z direction

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

Example 1

No friction, load sequence = OP1 for occasional loads like

Seismic, Wind, User etc

OP1 = hot operating condition GR -> T1, since no pressure

analysis. So case E1 is applied in the hot condition after

Gravity and temperature are applied.

Create User combination: GrE1 = Gr + E1 [This is to illustrate how

this combination is inconsistent with the load sequence]

S U P P O R T F O R C E S

( Force - lb , Moment - ft-lb , Tran. - in , Rot. - deg )

Point/ Connect/ Load L O C A L G L O B A L

Supp. ID Type Combination Dirn Force Deform Dirn Force Deform

-------- -------- ----------- ---- -------- -------- ---- -------- --------

Tag No.: <None>

A04 GR down 727 0.000 X 0.000

A04 1 Guide left 0.000 Y -727 0.000

Stiff :RIGID back 0.000 Z 0.000

T1 down 0.000 X 0.737

left 232 0.200 Y 0.000

forw 0.737 Z -232 -0.200

E1 down 0.000 X 0.000

rght 232 0.306 Y 0.000

forw 0.000 Z 232 0.306

GT1 down 727 0.000 X 0.737

left 232 0.200 Y -727 0.000

forw 0.737 Z -232 -0.200

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

Notice default non-code combination is GT1E1

which is consistent with the load sequence Notice combined

movement =0.106” in +Z

direction

GT1E1 down 727 0.000 X 0.737

rght 0.106 Y -727 0.000

forw 0.737 Z 0.106

GRE1 down 727 0.000 X 0.000

rght 232 0.306 Y -727 0.000

forw 0.000 Z 232 0.306

Inconsistent User Combination GrE1

2. Thermal Loading (GT1)

2 (hot condition)

T1, Dz= -0.2, gap is

closed so load

generated = 232 lb

3. Seismic E1 Loading (GT1E1)

2 (hot condition)

0.2” E1, Dz= 0.306”, Seismic

0.306” load moves the pipe is

1 opposite direction. However

3 gap is not closed on +Z side

since did not travel 0.4” (2 x

gap = 0.2”)

Hence GT1E1 = 0

Sequence

Gr -> T1 -> E1

1 -> 2 -> 3

However notice User combination GrE1 = Gr + E1, GrE1 Load at A04 guide, Fz =

232lb. However this does not make sense because the load sequence was Gr then

T1 then E1, so this combination GrE1 does not consider movement due to T1. It

thinks the E1 is applied after Gravity case which is not correct. If it was for E1,

expect Dz = 0.2” instead of 0.306” and gap closed.

Note: Gr -> P1 -> T1 -> E1 gives the same result as Gr -> T1 -> P1 -> E1

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

Also refer to Analysis Summary

A N A L Y S I S S U M M A R Y

Current model revision number : 6

Static - Date and Time of analysis ............. Apr 16, 2007 9:46 AM

Model Revision Number ................. 6

Number of load cases .................. 3

Load cases analyzed ................... GR T1 E1

Gaps/Friction/Soil considered ......... Yes

Tolerance - Force, Displacement ....... 1.00 lb 0.0162 in

Friction - Scale Factor, Tolerance .... 1.00 0.10

Ignore friction for cases E1,E2,E3 .... Yes

Ignore friction for gravity case ...... No

Hanger design run ..................... No

Cut short included .................... No

Thermal bowing included ............... No

Include Bourdon rotational effect ..... No

Pipe radius for Bourdon calculation ... Mean

Occasional load analysis type ......... Nonlinear

Non-linear analysis summary file ...... LOADSEQ_1.LOG

Use default load sequence ............. Yes

Base load cases for nonlinear analysis

GR = None

T1 = GR

E1 = T1

Actual load sequence:

GR -> T1 -> E1

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

Example 2

No friction, load sequence = GR for occasional loads like

Seismic, Wind, User etc

GR = cold operating condition GR -> E1, since no pressure

analysis. So case E1 is applied in the cold condition after

Gravity so temperature is not considered.

S U P P O R T F O R C E S

( Force - lb , Moment - ft-lb , Tran. - in , Rot. - deg )

Point/ Connect/ Load L O C A L G L O B A L

Supp. ID Type Combination Dirn Force Deform Dirn Force Deform

-------- -------- ----------- ---- -------- -------- ---- -------- --------

Tag No.: <None>

A04 GR down 727 0.000 X 0.000

A04 1 Guide left 0.000 Y -727 0.000

Stiff :RIGID back 0.000 Z 0.000

T1 down 0.000 X 0.737

Notice default non-code

left 232 0.200 Y 0.000

combination is GE1 which is

consistent with the load forw 0.737 Z -232 -0.200

sequence

i.e. no temperature case E1 down 0.000 X 0.000

considered rght 450 0.200 Y 0.000

forw 0.000 Z 450 0.200

GT1 down 727 0.000 X 0.737

left 232 0.200 Y -727 0.000

forw 0.737 Z -232 -0.200

GE1 down 727 0.000 X 0.000

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

rght 450 0.200 Y -727 0.000

forw 0.000 Z 450 0.200

GRE1 down 727 0.000 X 0.000

rght 450 0.200 Y -727 0.000

forw 0.000 Z 450 0.200

Notice combined movement =0.2” in +Z

direction, i.e. gap distance

Also refer to Analysis Summary

A N A L Y S I S S U M M A R Y

Current model revision number : 6

Static - Date and Time of analysis ............. Apr 16, 2007 9:14 AM

Model Revision Number ................. 6

Number of load cases .................. 3

Load cases analyzed ................... GR T1 E1

Gaps/Friction/Soil considered ......... Yes

Tolerance - Force, Displacement ....... 1.00 lb 0.0162 in

Friction - Scale Factor, Tolerance .... 1.00 0.10

Ignore friction for cases E1,E2,E3 .... Yes

Ignore friction for gravity case ...... No

Hanger design run ..................... No

Cut short included .................... No

Thermal bowing included ............... No

Include Bourdon rotational effect ..... No

Pipe radius for Bourdon calculation ... Mean

Occasional load analysis type ......... Nonlinear

Non-linear analysis summary file ...... LOADSEQ_1.LOG

Use default load sequence ............. No

Base load cases for nonlinear analysis

GR = None

T1 = GR

E1 = GR

Actual load sequence:

GR -> T1

GR -> E1

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

Summary

Recommendations

It is recommended to evaluate the maximum support loads and movements by

analyzing both GR and OP1 default sequence. Also remember to include + ve

and –ve Seismic and wind loadings for ‘worst-case’ evaluation of occasional

loads and stresses.

© Bentley Systems Inc 4/20/2007 Load_Sequencing5.doc

S-ar putea să vă placă și

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Load Case CAESAR IIDocument6 paginiLoad Case CAESAR IIshakasspÎncă nu există evaluări

- TSCDocument23 paginiTSCKriti Srivastava100% (3)

- Exercises in Electronics: Operational Amplifier CircuitsDe la EverandExercises in Electronics: Operational Amplifier CircuitsEvaluare: 3 din 5 stele3/5 (1)

- Presentation Hot TappingDocument59 paginiPresentation Hot TappingSagar Naduvinamani83% (6)

- Ground Fault CurrentDocument5 paginiGround Fault Currentjsrplc7952Încă nu există evaluări

- Load Case Definition in CAESAR IIDocument8 paginiLoad Case Definition in CAESAR IINilesh Gohel100% (1)

- Technical Note No. TN S02 Second Order Effects Safe and EtabsDocument9 paginiTechnical Note No. TN S02 Second Order Effects Safe and EtabsVance KangÎncă nu există evaluări

- Load CasesDocument8 paginiLoad Casestebodin_319100% (1)

- WELL CONTROL METHODS FOR SAFELY MANAGING KICKSDocument90 paginiWELL CONTROL METHODS FOR SAFELY MANAGING KICKSMike Ross100% (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- STAAD Pro - PDelta AnalysisDocument9 paginiSTAAD Pro - PDelta Analysisswe_maniÎncă nu există evaluări

- Fatigue ScreeningDocument13 paginiFatigue ScreeningNama Peja100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- Coagulation and Floculation - 062 - Part 2Document18 paginiCoagulation and Floculation - 062 - Part 2Joce8888100% (1)

- Zuellig Building Written ReportDocument15 paginiZuellig Building Written ReportJohn Rhey Almojallas BenedictoÎncă nu există evaluări

- Pump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Document295 paginiPump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Noel Dunn75% (4)

- Field Civil Inspection & Test PlanDocument9 paginiField Civil Inspection & Test PlanChristian Albert Sinaga RumajarÎncă nu există evaluări

- Technical Note No. TN S02 Second Order Effects PDFDocument9 paginiTechnical Note No. TN S02 Second Order Effects PDFKhushroo LankerÎncă nu există evaluări

- Finite Element Analysis of Stress Factors in Pipe BendsDocument7 paginiFinite Element Analysis of Stress Factors in Pipe BendsSteve IpÎncă nu există evaluări

- Pipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Document8 paginiPipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Ton PhichitÎncă nu există evaluări

- PSV Back PressureDocument2 paginiPSV Back PressureTon PhichitÎncă nu există evaluări

- RMC Rate AnalysisDocument100 paginiRMC Rate AnalysisSasanka SekharÎncă nu există evaluări

- Perf CalcDocument7 paginiPerf CalcDevdatt SondeÎncă nu există evaluări

- 0387 1301 FINAL CEPA Surface Loading Calculator User ManualDocument43 pagini0387 1301 FINAL CEPA Surface Loading Calculator User ManualTon Phichit100% (2)

- Calculation CCR (RC)Document123 paginiCalculation CCR (RC)bonnicoÎncă nu există evaluări

- Boardwalk DesignDocument20 paginiBoardwalk Designsameh100% (1)

- Calculate Heat Loss from Insulated PipeDocument8 paginiCalculate Heat Loss from Insulated PipeTon PhichitÎncă nu există evaluări

- Pipe NoiseDocument10 paginiPipe NoiseRoshin99Încă nu există evaluări

- Bs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes FDocument13 paginiBs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes Fcelsocarvalh100% (1)

- Previous-Load Cases Definition CII PDFDocument8 paginiPrevious-Load Cases Definition CII PDFAnonymous 5ICLRl100% (1)

- Electronics 3 Checkbook: The Checkbooks SeriesDe la EverandElectronics 3 Checkbook: The Checkbooks SeriesEvaluare: 5 din 5 stele5/5 (1)

- Tapcon 240 TrainingDocument6 paginiTapcon 240 TrainingAhmedKhaledSalahÎncă nu există evaluări

- LP Bypass SystemDocument25 paginiLP Bypass SystemTon Phichit100% (1)

- 9C304 19Document37 pagini9C304 19SHEKHAR100% (1)

- Feedforward ControlDocument7 paginiFeedforward Controlnilanjana89Încă nu există evaluări

- Turbulent Flow ModelingDocument11 paginiTurbulent Flow ModelingGhada OrabiÎncă nu există evaluări

- SCT= Static Conductor Tension Load: 1000 NDocument2 paginiSCT= Static Conductor Tension Load: 1000 NSafi Zabihullah SafiÎncă nu există evaluări

- Load Evaluation PDFDocument9 paginiLoad Evaluation PDFMois DanielÎncă nu există evaluări

- R6134E Setting Guide OPNDocument5 paginiR6134E Setting Guide OPNrajinipre-1Încă nu există evaluări

- Electrical Characteristics: Thermal Resistance Cerdip (J) Dip (N) HO8 (H) SO-8 (M)Document1 paginăElectrical Characteristics: Thermal Resistance Cerdip (J) Dip (N) HO8 (H) SO-8 (M)naveedhalamzaiÎncă nu există evaluări

- Pilot/Flight Engineer Open Book Gouge: Cover PageDocument7 paginiPilot/Flight Engineer Open Book Gouge: Cover PagepepeÎncă nu există evaluări

- Cascaded PIDDocument14 paginiCascaded PIDTatenda BizureÎncă nu există evaluări

- Ascó Temperature-Stress Analysis Above 200ºCDocument63 paginiAscó Temperature-Stress Analysis Above 200ºCJMÎncă nu există evaluări

- TCS3P125 PDFDocument10 paginiTCS3P125 PDFJuan José Tovar PérezÎncă nu există evaluări

- MARLOW Datasheet InstructionsDocument4 paginiMARLOW Datasheet InstructionsLutionnnÎncă nu există evaluări

- AN1353 Application Note: ASD ST62000C Software Description For Cooling Thermostat ApplicatonsDocument17 paginiAN1353 Application Note: ASD ST62000C Software Description For Cooling Thermostat ApplicatonsDan EsentherÎncă nu există evaluări

- An Serv 005 PDFDocument20 paginiAn Serv 005 PDFSyafrizalÎncă nu există evaluări

- Hotwire Calibration ProceduresDocument5 paginiHotwire Calibration ProceduresRohanSrinivasÎncă nu există evaluări

- EKC312Document12 paginiEKC312bmw72Încă nu există evaluări

- Quads On Fire 1 EnglishDocument4 paginiQuads On Fire 1 EnglishMarko ŠimićÎncă nu există evaluări

- Manual 08Document15 paginiManual 08AliEjazÎncă nu există evaluări

- Directional Overcurrent Relay ModelDocument13 paginiDirectional Overcurrent Relay ModelAlen JefryÎncă nu există evaluări

- Electrical Drives ReportDocument100 paginiElectrical Drives ReportFrank DillaneÎncă nu există evaluări

- 09 Testing Procedures CP_ENDocument95 pagini09 Testing Procedures CP_ENandersson benito herreraÎncă nu există evaluări

- School of Physics and Astronomy: File Topic07 PDFDocument3 paginiSchool of Physics and Astronomy: File Topic07 PDFEbert AroneÎncă nu există evaluări

- 25 Parámetros OBD IIDocument11 pagini25 Parámetros OBD IImongongoÎncă nu există evaluări

- Pnalty Fctor 1Document12 paginiPnalty Fctor 1nadra_arÎncă nu există evaluări

- Simulation ToolDocument6 paginiSimulation ToolRaja ReddyÎncă nu există evaluări

- New ratio control structure improves transient responseDocument6 paginiNew ratio control structure improves transient responseBOMBE45Încă nu există evaluări

- Comp Vs Op AmpDocument15 paginiComp Vs Op AmpDedi Irwan Eka PutraÎncă nu există evaluări

- M 05 0596Document10 paginiM 05 0596Jehuty88Încă nu există evaluări

- Temperature InversionDocument1 paginăTemperature Inversionfaris_qutaishatÎncă nu există evaluări

- School of Physics and Astronomy Junior Honours ThermodynamicsDocument4 paginiSchool of Physics and Astronomy Junior Honours ThermodynamicszjnsrbtÎncă nu există evaluări

- Thermal Overload Protection 2Document5 paginiThermal Overload Protection 2Anonymous DKv8vpÎncă nu există evaluări

- Motor Load MonitorDocument4 paginiMotor Load MonitorRenghat RumahorboÎncă nu există evaluări

- Software Verification: EXAMPLE 6-004Document7 paginiSoftware Verification: EXAMPLE 6-004Sushil DhunganaÎncă nu există evaluări

- Servo FundamentalsDocument11 paginiServo Fundamentalsapi-3797895Încă nu există evaluări

- Traditional Advanced Control Approaches - Feedforward, Cascade and Selected ControlDocument42 paginiTraditional Advanced Control Approaches - Feedforward, Cascade and Selected Controljricardo01976Încă nu există evaluări

- JLD614 ManualDocument8 paginiJLD614 ManualJ.R. VincentÎncă nu există evaluări

- Selection of MotorDocument28 paginiSelection of MotorGURSIMRAN SINGHÎncă nu există evaluări

- Derating of ConnectorsDocument4 paginiDerating of ConnectorsCeasar CapunoÎncă nu există evaluări

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe la EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesÎncă nu există evaluări

- Control TechnologyDocument104 paginiControl TechnologyTon PhichitÎncă nu există evaluări

- Insert Flanges For Jacketed PipingDocument4 paginiInsert Flanges For Jacketed PipingTon PhichitÎncă nu există evaluări

- Abb Review 2000Document9 paginiAbb Review 2000Ton PhichitÎncă nu există evaluări

- Steam TurbinesDocument24 paginiSteam Turbinesrt_sendhilÎncă nu există evaluări

- Aquarium PumpsDocument1 paginăAquarium PumpsTon PhichitÎncă nu există evaluări

- 66 Lateral PDFDocument7 pagini66 Lateral PDFGerman ToledoÎncă nu există evaluări

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDocument4 paginiTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitÎncă nu există evaluări

- 390Document9 pagini390Ton PhichitÎncă nu există evaluări

- Engineering Standard for Piping Material Selection (On Plot PipingDocument431 paginiEngineering Standard for Piping Material Selection (On Plot PipingpradeepÎncă nu există evaluări

- VibrationDocument10 paginiVibrationAHMEDSAEED013Încă nu există evaluări

- ML 070260376Document25 paginiML 070260376Ton PhichitÎncă nu există evaluări

- 12 Ernie Sturtz Pumping Facility Design StandardsDocument41 pagini12 Ernie Sturtz Pumping Facility Design StandardsTon PhichitÎncă nu există evaluări

- 21 5 1710Document31 pagini21 5 1710Ton PhichitÎncă nu există evaluări

- Load SequencingDocument7 paginiLoad SequencingTon PhichitÎncă nu există evaluări

- System DesignDocument16 paginiSystem DesignTon PhichitÎncă nu există evaluări

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDocument4 paginiTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitÎncă nu există evaluări

- Viibratiion DiiagnostiicsDocument113 paginiViibratiion DiiagnostiicsDanielAvellanedaÎncă nu există evaluări

- KU-11-6 FinalDocument208 paginiKU-11-6 FinalTon PhichitÎncă nu există evaluări

- Thermal Considerations in Pipe FlowsDocument11 paginiThermal Considerations in Pipe FlowsWaqas AhmadÎncă nu există evaluări

- Hurricane-2006 12 46-53Document8 paginiHurricane-2006 12 46-53Ton PhichitÎncă nu există evaluări

- Tension and Sag 07-25-06Document7 paginiTension and Sag 07-25-06Ton PhichitÎncă nu există evaluări

- SECUDRAIN 131C WD - Ficha TécnicaDocument1 paginăSECUDRAIN 131C WD - Ficha TécnicaVitalidad ivdaÎncă nu există evaluări

- Radiator Design and OptimizationDocument12 paginiRadiator Design and Optimizationspandan shahÎncă nu există evaluări

- London Olympic StadiumDocument3 paginiLondon Olympic StadiumPranav SamdadiyaÎncă nu există evaluări

- Bar Bending ScheduleDocument4 paginiBar Bending ScheduleTayyub SiddiquiÎncă nu există evaluări

- Stress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionDocument16 paginiStress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionAndrucruz CruzÎncă nu există evaluări

- Ground ImprovementDocument17 paginiGround Improvementpatelahmad77Încă nu există evaluări

- S-OIL HYDRO FLUID AW Antiwear Industrial Hydraulic FluidDocument1 paginăS-OIL HYDRO FLUID AW Antiwear Industrial Hydraulic FluidJonhÎncă nu există evaluări

- Chersterton Arc S2 PDFDocument1 paginăChersterton Arc S2 PDFMohamed NouzerÎncă nu există evaluări

- STRUCTURES INFLUENCE LINESDocument5 paginiSTRUCTURES INFLUENCE LINESChristian Paul RamosÎncă nu există evaluări

- NDT Request - RT DTD 06.05.19Document81 paginiNDT Request - RT DTD 06.05.19Kushal PraviraÎncă nu există evaluări

- Steel-Concrete Composite Slab Design Using ExcelDocument9 paginiSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulÎncă nu există evaluări

- BarrageDocument29 paginiBarrageTaha UsamaÎncă nu există evaluări

- Newirpwm PDFDocument416 paginiNewirpwm PDFPiyush MauryaÎncă nu există evaluări

- Bio HomesDocument6 paginiBio HomesNandha Palani DoraiÎncă nu există evaluări

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 paginiPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahÎncă nu există evaluări

- KNS3643 Tutorial 1 1617 1Document2 paginiKNS3643 Tutorial 1 1617 1Nur Hazirah SadonÎncă nu există evaluări

- Sika Rapid Technology BrochureDocument2 paginiSika Rapid Technology BrochuredipinnediyaparambathÎncă nu există evaluări

- WaterproofingDocument2 paginiWaterproofinghoney4747Încă nu există evaluări

- Hydro 1 - Open ChannelsDocument28 paginiHydro 1 - Open ChannelsJericho Alfred Rullog SapitulaÎncă nu există evaluări

- Static and Fatigue Simulation of Automotive Anti Roll Bar Before DBTTDocument6 paginiStatic and Fatigue Simulation of Automotive Anti Roll Bar Before DBTTSliim AmiriÎncă nu există evaluări

- Abstracts Structural EnggDocument371 paginiAbstracts Structural EnggbishalÎncă nu există evaluări