Documente Academic

Documente Profesional

Documente Cultură

Truck Tire Construction PDF

Încărcat de

willupowers0 evaluări0% au considerat acest document util (0 voturi)

24 vizualizări17 paginiTitlu original

Truck-Tire-Construction.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

24 vizualizări17 paginiTruck Tire Construction PDF

Încărcat de

willupowersDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 17

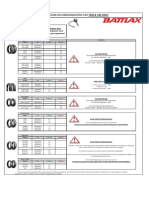

Welcome to

Truck Tire Construction

Truck Tire Construction

Tread “Cap”

For the part of the tread

that touches

the road, Bridgestone’s

innovative two-layer

design uses rubber

specially compounded to

deliver slow wear, long

tread life and

high traction.

Tread “Base”

Between the tread

“cap” and the casing,

Bridgestone uses a

special cool-running

rubber compound to

insulate the casing

from tread heat,

saving fuel and

improving

retreadability.

Undertread

Special layer of tough

rubber compounded by

Bridgestone to protect

belt package from

penetrations while

simultaneously

providing a powerful

bond between tread

and casing.

Mini-sidewalls

Specially compounded

rubber is designed by

Bridgestone to bond the

tread rubber

layers and the sidewall

rubber compound,

forming a solid

connection between

them.

Belt edge inserts

and fillers

Designed by Bridgestone

to separate, orient and

position the edges of belts

for optimum effectiveness

as support for the tread,

while protecting belt cords

from damaging

mechanical stress.

Belts

Bridgestone uses

multiple belts with angled

steel cords to create a

foundation for the tread,

pressing it flat against

the road for slow, even

wear, high traction and

responsive handing.

Transition Ply

1st Belt

The ply that forms the

bridge between the

flexible sidewall and the

more stable crown area.

The transition ply also

assists in changing the

profile of the tire from a

more rounded shape to a

“flatter” footprint.

Stabilizer Ply

2nd & 3rd Belts

These plies help to

keep the tread in

contact with the road.

Improving the flat

contact provides better

traction and improved

treadwear.

Protector Ply

4th Belt

The protector ply is the

last in the series

of the belt package.

It lies just above the

stabilizer plies and

just under the tread.

It helps to protect the

crucial working belts

(stabilizer plies) from

penetration injuries. Not

all radial tires have

protector plies.

Innerliner

For defense against air

loss, Bridgestone

employs a liner of

rubber with as many as

three separate rubber

layers and special

additives to keep air

inside the tire and away

from the steel cords.

Sidewalls

Bridgestone combines

heat-resistant, highly

resilient rubber – for solid

control – with special

additives to fight damage

from oxygen, ozone and

UV radiation from the

sun.

Casing Ply

Bridgestone embeds

precisely aligned, high

tensile strength steel

cables in specially

compounded rubber to

create the architecture

that gives “radial” tires

their name.

Soft bead filler

Designed by Bridgestone

engineers to provide a

strong, flexible, resilient

junction between the

relatively thin and flexible

sidewalls and the much

thicker, more rigid bead

area.

Hard bead filler

Bridgestone employs a

thick, relatively stiff rubber

compound to encase the

bead bundle and position

it tightly against the wheel

flange – while minimizing

flexing and movement.

Bead bundle

Bridgestone coils tough,

rubber-coated steel wire

into continuous, hexagon-

shaped rings that provide

a rigid, yet resilient

interface –

and a tight seal – between

the tire and wheel flange.

Chafer

A layer of steel cords

embedded in a special

Bridgestone rubber

compound wraps around

the bead and body ply,

helping to protect both

from mechanical strain

and abrasion.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- VG H4connectorsDocument7 paginiVG H4connectorsJeganeswaranÎncă nu există evaluări

- En 12604 (2000) (E)Document7 paginiEn 12604 (2000) (E)Carlos LanzillottoÎncă nu există evaluări

- Final App - FlsDocument9 paginiFinal App - Flsjunebug172100% (1)

- BS TBR TTL Brochure 2012 BSEU PDFDocument2 paginiBS TBR TTL Brochure 2012 BSEU PDFwillupowersÎncă nu există evaluări

- BS TBR Regionals Brochure BSEU PDFDocument8 paginiBS TBR Regionals Brochure BSEU PDFwillupowersÎncă nu există evaluări

- DHL Glo DSC Helps Bridgestone Integrate SC For Greater Efficiency PDFDocument2 paginiDHL Glo DSC Helps Bridgestone Integrate SC For Greater Efficiency PDFwillupowersÎncă nu există evaluări

- BS TBR Rangebrochure 2020 PDFDocument88 paginiBS TBR Rangebrochure 2020 PDFwillupowersÎncă nu există evaluări

- TBR Regionals InfoSheet PDFDocument2 paginiTBR Regionals InfoSheet PDFwillupowersÎncă nu există evaluări

- Premium Winter Tyre Range 2017-2018Document20 paginiPremium Winter Tyre Range 2017-2018willupowersÎncă nu există evaluări

- Dayton PDFDocument13 paginiDayton PDFwillupowersÎncă nu există evaluări

- Bridgestone Loadtables PDFDocument39 paginiBridgestone Loadtables PDFwillupowersÎncă nu există evaluări

- OE Guide: Updated May 2014Document32 paginiOE Guide: Updated May 2014willupowersÎncă nu există evaluări

- Bridgestone 2019 Tire & Tube Price List PDFDocument30 paginiBridgestone 2019 Tire & Tube Price List PDFwillupowersÎncă nu există evaluări

- 2016 Bridgestone Tyre Specifications PDFDocument33 pagini2016 Bridgestone Tyre Specifications PDFwillupowersÎncă nu există evaluări

- Tyre Range 2017: Bridgestone Truck, Bus & VanDocument48 paginiTyre Range 2017: Bridgestone Truck, Bus & VanwillupowersÎncă nu există evaluări

- Reprinted From Real Answers: Should You Stop Putting Air in Your Tires? Volume 8, Issue 3Document5 paginiReprinted From Real Answers: Should You Stop Putting Air in Your Tires? Volume 8, Issue 3willupowersÎncă nu există evaluări

- The Premium Cranes Tyre RangeDocument4 paginiThe Premium Cranes Tyre RangewillupowersÎncă nu există evaluări

- The Next Generation of Fuel-Smart Retreads.: Introducing Bandag FueltechDocument2 paginiThe Next Generation of Fuel-Smart Retreads.: Introducing Bandag FueltechwillupowersÎncă nu există evaluări

- The University of Chicago PressDocument38 paginiThe University of Chicago PresswillupowersÎncă nu există evaluări

- A PDF of This Article - Bridgestone Commercial Truck Tires PDFDocument5 paginiA PDF of This Article - Bridgestone Commercial Truck Tires PDFwillupowersÎncă nu există evaluări

- Bridgestone Americas, Inc. Procurement Supplier GuideDocument17 paginiBridgestone Americas, Inc. Procurement Supplier GuidewillupowersÎncă nu există evaluări

- The Premium Industrial Tyre RangeDocument6 paginiThe Premium Industrial Tyre RangewillupowersÎncă nu există evaluări

- Bridgestone Service Centre Document PDFDocument40 paginiBridgestone Service Centre Document PDFwillupowersÎncă nu există evaluări

- Bridgestone's View On Circular EconomyDocument13 paginiBridgestone's View On Circular EconomywillupowersÎncă nu există evaluări

- Bridgestone Price List 2019 2020 PDFDocument105 paginiBridgestone Price List 2019 2020 PDFwillupowersÎncă nu există evaluări

- Warranty PDFDocument8 paginiWarranty PDFwillupowersÎncă nu există evaluări

- The 2016 Premium Tyre Range: For Cars, Suv/4X4S and VansDocument21 paginiThe 2016 Premium Tyre Range: For Cars, Suv/4X4S and VanswillupowersÎncă nu există evaluări

- Bridgestone PDFDocument1 paginăBridgestone PDFwillupowersÎncă nu există evaluări

- Winter Tyres Pamphlet PDFDocument2 paginiWinter Tyres Pamphlet PDFwillupowersÎncă nu există evaluări

- Pt. Partono Fondas: Company ProfileDocument34 paginiPt. Partono Fondas: Company Profileiqbal urbandÎncă nu există evaluări

- 2011 TH 18205 Awad Nassib PdfaDocument95 pagini2011 TH 18205 Awad Nassib PdfahafosaamrÎncă nu există evaluări

- LMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceDocument2 paginiLMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceTrong Hung NguyenÎncă nu există evaluări

- Project Presentation SurveyingDocument14 paginiProject Presentation SurveyingSACHIN MEENAÎncă nu există evaluări

- 1.5SMC Series-1864824 PDFDocument8 pagini1.5SMC Series-1864824 PDFRizwan RanaÎncă nu există evaluări

- Content Beyond SyllabusDocument3 paginiContent Beyond SyllabusRahul PolÎncă nu există evaluări

- Seamless Fiux Fored Wire - Megafil250Document1 paginăSeamless Fiux Fored Wire - Megafil250SungJun ParkÎncă nu există evaluări

- MOTOR Brushless ss2814 Xiii 1000kvDocument1 paginăMOTOR Brushless ss2814 Xiii 1000kvsalah eddineÎncă nu există evaluări

- (Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)Document66 pagini(Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)양종렬Încă nu există evaluări

- CP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Document52 paginiCP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Honda almagrorepuestosÎncă nu există evaluări

- SECTION 1213, 1214, 1215: Report By: Elibado T. MaureenDocument19 paginiSECTION 1213, 1214, 1215: Report By: Elibado T. MaureenJohnFred CativoÎncă nu există evaluări

- Vertical Take Off and LandingDocument126 paginiVertical Take Off and LandingMukesh JindalÎncă nu există evaluări

- Student Manual of Damped & Un DampedDocument3 paginiStudent Manual of Damped & Un DampedaqibÎncă nu există evaluări

- .Preliminary PagesDocument12 pagini.Preliminary PagesKimBabÎncă nu există evaluări

- SunstarDocument189 paginiSunstarSarvesh Chandra SaxenaÎncă nu există evaluări

- Bomba FlightDocument2 paginiBomba FlightGustavo HRÎncă nu există evaluări

- Ilovepdf Merged MergedDocument209 paginiIlovepdf Merged MergedDeepak AgrawalÎncă nu există evaluări

- Planning For Information NetworkDocument32 paginiPlanning For Information NetworkChandraAdsenubiiÎncă nu există evaluări

- Drive ConfigDocument136 paginiDrive ConfigGiangDoÎncă nu există evaluări

- Hyundai Robex 220LC-9A SpecificationsDocument14 paginiHyundai Robex 220LC-9A SpecificationsKundan DhurveÎncă nu există evaluări

- As4e-Ide-2 7 0 851-ReadmeDocument10 paginiAs4e-Ide-2 7 0 851-ReadmeManoj SharmaÎncă nu există evaluări

- Design Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsDocument11 paginiDesign Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsAnonymous osfiXqUkÎncă nu există evaluări

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Document2 paginiSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaÎncă nu există evaluări

- REE Copy PDFDocument9 paginiREE Copy PDFJake ZozobradoÎncă nu există evaluări

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiDocument818 paginiFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Shock AbsorberDocument0 paginiShock AbsorberSahaya GrinspanÎncă nu există evaluări

- Building 16 PrintDocument112 paginiBuilding 16 PrintNALEEMÎncă nu există evaluări