Documente Academic

Documente Profesional

Documente Cultură

MBrace Fibre PDF

Încărcat de

Francois-Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MBrace Fibre PDF

Încărcat de

Francois-Drepturi de autor:

Formate disponibile

MBrace®Fibre

Unidirectional Carbon Fibre sheeting Glass and Aramid sheeting used with resin lay up

method

Description MBrace®Glass

MBrace®Fibre sheet reinforcement materials are i Retrofit of masonry structures vulnerable to

enveloped in MBrace®Saturant resin to yield a range earthquake damage

of high performance features.

i Colours

MBrace®Fibre Reinforcement Systems include the - Carbon Fibre – Black

MBrace®CF640, MBrace®CF240 unidirectional tow

- Glass – White

sheet carbon fibre, MBrace®G Sheet AR Eglass and

- Aramid – Yellow

Aramid A sheets. Each Fibre Reinforcement System

within the finished MBrace®Fibre Reinforced Polymer

MBrace®Aramid

system permits high strength to cross section ratio,

i Blast proof

and structural integrity that is similar to bonding steel

i Impact resistance

plates to concrete surfaces.

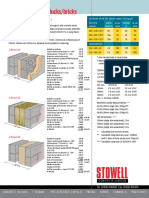

Typical physical properties

Recommended for

MBrace® CF 640

• Walls, beams and slabs

Carbon Fibre Reinforcement System

i Columns and chimneys

High Modulus CF

i Silos and tanks

i Pipes and tunnels

Technical data of fibre (unidirectional) 400g/m²

Modulus of elasticity 640kN/mm²

Features and benefits Tensile strength 2650N/mm²

Weight of C fibre (main direction) 400g/m²

MBrace®Carbon Fibre Total weight of sheet 430g/m²

i Increased strength Density 2.1g/cm³

ε Ultimate % 0.4

- Flexural

Thickness for static design weight / 0.19mm

- Shear density

Theor. Section for static design 190mm²

- Confinement 1000mm width

- Blast resistance Safety factor for static design 1.2 (recommended)

(manual lamination / UDproduct)

- Fatigue enhancement Tensile force of 1000mm width 190 x 2650 = 419.6kN

i Lightweight ultimate 1.2

Tensile force of 1000mm width at 200kN

i Durable 0.2% ε for design

i Control of crack propagation

i Strength to thickness ratio

MBrace®Fibre

MBrace®CF240

Carbon Fibre Reinforcement System

High Tensile CF

Technical data of fibre (unidirectional) 200g/m² 300g/m²

Modulus of elasticity 240kN/mm² 240kN/mm²

Tensile strength 3800N/mm² 3800N/mm²

Weight of C fibre (main direction) 200g/m² 300g/m²

Total weight of sheet 230g/m² 330g/m²

Density 1.7g/cm³ 1.7g/cm³

ε Ultimate % 1.55 1.55

Thickness for static design weight / density 0.117mm 0.176mm

Theor. Section for static design 1000mm width 117mm² 176mm²

Safety factor for static design (manual lamination / UDproduct) 1.2 (recommended) 1.2 (recommended)

Tensile force of 1000mm width ultimate 117 x 3800 = 370.5kN 176 x 3800 = 557.3kN

1.2 1.2

Tensile force of 1000mm width at 0.6% ε for design 140kN 211kN

MBrace®A Sheet120

Aramid sheet

Technical data of fibre (unidirectional) 290g/m² 420g/m²

Modulus of elasticity 120kN/mm² 120kN/mm²

Tensile strength 2900N/mm² 2900N/mm²

Weight of C fibre (main direction) 290g/m² 420g/m²

Total weight of sheet 320g/m² 450g/m²

Density 1.45g/cm³ 1.45g/cm³

ε Ultimate % 2.5 2.5

Thickness for static design weight / density 0.2mm 0.29mm

Theor. Section for static design 1000mm width 200mm² (theor fibre area) 290mm² (theor fibre area)

Safety factor for static design (manual lamination / UDproduct) 1.2 (recommended) 1.2 (recommended)

Tensile force of 1000mm width for design 200 x 2900 = 483.3kN 290 x 2900 = 700.8kN

1.2 1.2

MBrace®G SheetE 50/50 & AR 50/50

Glass Reinforcement System

Technical data of fibre (main and cross directional) EGlass ARGlass

Modulus of elasticity 73kN/mm² 65kN/mm²

Tensile strength 3400N/mm² 3000N/mm²

Sheet Weight (total 350g/m²) 175g/m² in both directions 175g/m² in both directions

Density 2.6g/cm³ 2.68g/cm³

ε Ultimate % 4.5 4.3

Thickness for static design weight / density 0.067mm 0.065mm

Cross section for static design 1000mm width 67mm² (fibre area only / each direction) 65mm² (fibre area only / each direction)

Safety factor for static design (manual lamination / 1.4 (recommended) 1.4 (recommended)

woven product)

Tensile force of 1000mm width for design 67 x 2400 = 114.86kN 65 x 1700 = 78.93kN

(impregnated) 1.4 1.4

each direction each direction

MBrace®Fibre

MBrace®G Sheet E 90/10 A & AR 90/10 A

Glass Reinforcement System

Technical data of fibre (main EGlass ARGlass

direction)

Modulus of elasticity 73kN/mm² 65kN/mm²

Tensile strength 3400N/mm² 3000N/mm²

Impregnated strand in a composite 2400N/mm² Use for the static design 1700N/mm² Use for the static design

Sheet Weight (total 440g/m²) 400g/m² in main direction 400g/m² in main direction

Density 2.6g/cm³ 2.68g/cm³

ε Ultimate % 4.5 4.3

Thickness for static design weight / 0.154mm 0.149mm

density

Theor. section for static design 154mm² (fibre area only / main direction) 149mm² (fibre area only / main direction)

1000mm width

Safety factor for static design 1.4 (recommended) 1.4 (recommended)

(manual lamination / woven product)

Tensile force of 1000mm width for 154 x 2400 = 264.0kN 149 x 1700 = 180.93kN

design impregnated 1.4 1.4

main direction main direction

Cross direction 10% of the equal fibre is used in the weft (cross section)

MBrace®G Sheet E 90/10 B & AR 90/10 B

Glass Reinforcement System

Technical data of fibre (main EGlass ARGlass

direction)

Modulus of elasticity 73kN/mm² 65kN/mm²

Tensile strength 3400N/mm² 3000N/mm²

Impregnated strand in a composite 2400N/mm² Use for the static design 1700N/mm² Use for the static design

Sheet Weight (total 880g/m²) 800g/m² in main direction 800g/m² in main direction

Density 2.6g/cm³ 2.68g/cm³

ε Ultimate % 4.5 4.3

Thickness for static design weight / 0.308mm 0.299mm

density

Theor. section for static design 308mm² (fibre area only / main direction) 299mm² (fibre area only / main direction)

1000mm width

Safety factor for static design 1.4 (recommended) 1.4 (recommended)

(manual lamination / woven product)

Tensile force of 1000mm width for 308 x 2400 = 528.0kN 299 x 1700 = 363.07kN

design impregnated 1.4 1.4

main direction main direction

Cross direction 10% of the equal fibre is used in the weft (cross section)

MBrace®Fibre

Packaging Product Material Safety Data Sheets are available

MBrace®CF640 system: and should be consulted and on hand during

Width 300mm, Length 50M application and/or whenever handling these products.

These products are for professional and industrial

MBrace®CF240 system: use only; application directions must be followed.

Width 300mm, Length 150M

Maintenance

MBrace®A Sheet120 Periodically inspect the applied material and repair

Width 300mm, Length 150M localised areas needed. Consult your BASF

Construction Chemicals SA representative for

MBrace®G Sheet E 50/50 & AR 50/50 additional information.

Width 680mm, Length 50M

MBrace® G Sheet E 90/10 A & AR 90/10 A

Width 680mm, Length 50M

MBrace®G Sheet E 90/10 B & AR 90/10 B

Width 680mm, Length 50M

Special rolls available on demand.

Precautions

Read all safety directions and warnings and refer to

material safety data sheet for handling procedures.

Store in cool, dry area 10 to 32° away from direct

sunlight, flame or other hazards.

MBrace®Fibre reinforcement materials contain

carbon and glass fibres. During application of

MBrace®Fibre materials, wear appropriate work

clothing to minimise contact. Use caution when

handling flammable liquids and eliminate all sources

of ignition from work area.

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or

implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any

labour involved in the application are beyond our control.

As all BASF’s technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

BASF Construction Chemicals South Africa (Pty) Ltd

852 Sixteenth Road, Midrand

P.O. Box 420, Westonaria, 1780

PO Box 2801, Halfway House, 1685

11 Pullinger Street, Westonaria, 1779 Tel: +27 11 203 2405

Tel: +27 11 754 1343

Fax: +27 11 754 1105 Website : basf -cc.co.za

S-ar putea să vă placă și

- 0001 CatDocument108 pagini0001 CatJorge CabreraÎncă nu există evaluări

- Peugeot 206 Fuse Diagram PDFDocument6 paginiPeugeot 206 Fuse Diagram PDFDedi dwi susanto100% (2)

- Method Statement - Masterseal 345 REV D PDFDocument17 paginiMethod Statement - Masterseal 345 REV D PDFFrancois-Încă nu există evaluări

- ASTM IndexDocument34 paginiASTM IndexJimmy Chan67% (3)

- Risk Management Report SummaryDocument61 paginiRisk Management Report SummaryIamCcj100% (1)

- Presentation On Data Integrity in PharmaDocument80 paginiPresentation On Data Integrity in Pharmaskvemula67% (3)

- Mbrace Fibre: Unidirectional Carbon Fibre Sheeting Glass and Aramid Sheeting Used With Resin Lay Up MethodDocument4 paginiMbrace Fibre: Unidirectional Carbon Fibre Sheeting Glass and Aramid Sheeting Used With Resin Lay Up MethodbudiÎncă nu există evaluări

- MBrace FibreDocument4 paginiMBrace FibreaahtagoÎncă nu există evaluări

- Mbrace Fibre v4Document3 paginiMbrace Fibre v4Abhay SuwalÎncă nu există evaluări

- Sikawrap®-300 C: Product Data SheetDocument4 paginiSikawrap®-300 C: Product Data SheetHenri DormoyÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CAlexis KarampasÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CJhune UrabaÎncă nu există evaluări

- Sikawrap 301 C Pds enDocument4 paginiSikawrap 301 C Pds enjohanes b muda100% (1)

- Sikawrap - 230 CDocument4 paginiSikawrap - 230 CNyein ZawÎncă nu există evaluări

- Sikawrap - 600 C WVDocument4 paginiSikawrap - 600 C WVIndra KusumaÎncă nu există evaluări

- Sikawrap - 300 C NW: Stitched, Carbon Fiber Fabric For Structural StrengtheningDocument4 paginiSikawrap - 300 C NW: Stitched, Carbon Fiber Fabric For Structural StrengtheningHenri DormoyÎncă nu există evaluări

- SikaWrap - 300 CDocument4 paginiSikaWrap - 300 CShadin Asari ArabaniÎncă nu există evaluări

- Sikawrap®-900 C: Product Data SheetDocument4 paginiSikawrap®-900 C: Product Data SheetnovitaapriyaniÎncă nu există evaluări

- Mbrace Mbrace Mbrace Mbrace Fibre Fibre Fibre FibreDocument2 paginiMbrace Mbrace Mbrace Mbrace Fibre Fibre Fibre FibreBabu SundararamanÎncă nu există evaluări

- SikaWrap 231 C PDS PDFDocument4 paginiSikaWrap 231 C PDS PDFMohit KohliÎncă nu există evaluări

- Sikawrap 231 C - Pds en PDFDocument4 paginiSikawrap 231 C - Pds en PDFsugi zhuangÎncă nu există evaluări

- SikaWrap®-900 CDocument4 paginiSikaWrap®-900 CN.J. PatelÎncă nu există evaluări

- Doka Birch Plywood Specs - 18 MMDocument2 paginiDoka Birch Plywood Specs - 18 MMAnupam GhoshÎncă nu există evaluări

- SikaWrap 600C PDSDocument4 paginiSikaWrap 600C PDSFranco VasquezÎncă nu există evaluări

- Sikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningDocument3 paginiSikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningBudhi KurniawanÎncă nu există evaluări

- Elephant Moistbloc Gypsum Board Product SpecificationDocument1 paginăElephant Moistbloc Gypsum Board Product SpecificationDilon Fernando0% (1)

- Alucobest Data SheetDocument4 paginiAlucobest Data SheetALI ZHANGÎncă nu există evaluări

- Carbon BD Cbd200Document1 paginăCarbon BD Cbd200Archal ShahÎncă nu există evaluări

- Concrete Midi BlocksDocument1 paginăConcrete Midi BlocksAjdinÎncă nu există evaluări

- CFRP PropertiesDocument2 paginiCFRP Propertiesswapnil gandhiÎncă nu există evaluări

- Plasterboard ImpactchekDocument3 paginiPlasterboard ImpactchekEdwardLuÎncă nu există evaluări

- Kingspan Europanel Jumbo KS100 ERO Datasheet MEATCA enDocument5 paginiKingspan Europanel Jumbo KS100 ERO Datasheet MEATCA en1BQ19AT069 PRAJWAL B KAMATHÎncă nu există evaluări

- DuFlex, Lightweight Composite PanelsDocument16 paginiDuFlex, Lightweight Composite PanelsDennys RamirezÎncă nu există evaluări

- ORI - Maxx AromourDocument4 paginiORI - Maxx Aromourjose castilloÎncă nu există evaluări

- Com Flor 225Document1 paginăCom Flor 225mgalltestÎncă nu există evaluări

- Mapletree Cost Study TableDocument2 paginiMapletree Cost Study TableKevin LowÎncă nu există evaluări

- Multi Rib Metal Roofing TileDocument1 paginăMulti Rib Metal Roofing Tilevadivel415Încă nu există evaluări

- Sikawrap 230C 01012014Document4 paginiSikawrap 230C 01012014rizone83Încă nu există evaluări

- Fiber Dowels Technical DescriptionDocument1 paginăFiber Dowels Technical DescriptionBrahim IssamÎncă nu există evaluări

- Boger Sport Flooring Catalog (2019)Document4 paginiBoger Sport Flooring Catalog (2019)Acid JayÎncă nu există evaluări

- Datasheet Cembonit EIDocument1 paginăDatasheet Cembonit EIDiana Maria GavriloiuÎncă nu există evaluări

- Plasterboard FyrchekDocument4 paginiPlasterboard FyrchekAlex ZecevicÎncă nu există evaluări

- Product Innovation, Safety Commitment & Carbon Fiber Composite SystemDocument2 paginiProduct Innovation, Safety Commitment & Carbon Fiber Composite SystemJohn Rheynor MayoÎncă nu există evaluări

- Manual Etalbond May2009Document32 paginiManual Etalbond May2009crizat00Încă nu există evaluări

- Reinforcekit Beam Fiche TechniqueDocument24 paginiReinforcekit Beam Fiche TechniqueAmel RADJEFÎncă nu există evaluări

- 3M92015 Double-Coated Tape PDFDocument6 pagini3M92015 Double-Coated Tape PDFargh112Încă nu există evaluări

- Data Sheet - HCU603 PDFDocument1 paginăData Sheet - HCU603 PDFlaxmi29Încă nu există evaluări

- Data Sheet - HCU403 PDFDocument1 paginăData Sheet - HCU403 PDFlaxmi29Încă nu există evaluări

- Bauder - InvertedRoofHotmelt - Bakor JVPM JFRI200 AP1 Bakor BL PDFDocument1 paginăBauder - InvertedRoofHotmelt - Bakor JVPM JFRI200 AP1 Bakor BL PDFdamindaÎncă nu există evaluări

- Sikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningDocument4 paginiSikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningCretu Cezar CatalinÎncă nu există evaluări

- Easy Macro - Fiber Reinforced Panel - SpecDocument1 paginăEasy Macro - Fiber Reinforced Panel - SpecMadhan MuniandyÎncă nu există evaluări

- Gerard Corona ShakeDocument1 paginăGerard Corona ShakeСузана Вујовић МарковићÎncă nu există evaluări

- GW Geoweb GW30v6 SummaryDocument1 paginăGW Geoweb GW30v6 SummaryChowdhury PriodeepÎncă nu există evaluări

- Classic Tile Specification: Technical DataDocument1 paginăClassic Tile Specification: Technical DataСузана Вујовић МарковићÎncă nu există evaluări

- Trelleborg ATP Ballast Mat BrochureDocument8 paginiTrelleborg ATP Ballast Mat BrochureÜmit KukulaÎncă nu există evaluări

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 paginiSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezÎncă nu există evaluări

- Data Teknis Hive Honeycomb KoreaDocument70 paginiData Teknis Hive Honeycomb KoreailhamhanafyÎncă nu există evaluări

- Polyfibra Tec EngDocument2 paginiPolyfibra Tec EngPedroÎncă nu există evaluări

- FRP Strengthening Systems for Concrete StructuresDocument15 paginiFRP Strengthening Systems for Concrete StructuresAnkita Baban GavadeÎncă nu există evaluări

- 05 Recycled Waste Products, Building Boards and PapersDocument61 pagini05 Recycled Waste Products, Building Boards and PapersAngel Mine AlcantaraÎncă nu există evaluări

- Masterbrace Fibers PDFDocument2 paginiMasterbrace Fibers PDFbinodÎncă nu există evaluări

- InstaLay 30 Technical SpecificationDocument2 paginiInstaLay 30 Technical SpecificationshanÎncă nu există evaluări

- Video and Camcorder Servicing and TechnologyDe la EverandVideo and Camcorder Servicing and TechnologyEvaluare: 4 din 5 stele4/5 (1)

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 paginiSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-Încă nu există evaluări

- Standard Grout PDFDocument3 paginiStandard Grout PDFFrancois-Încă nu există evaluări

- Masterflow 524: High Strength, Non Shrink Cementitious Construction GroutDocument3 paginiMasterflow 524: High Strength, Non Shrink Cementitious Construction GroutFrancois-Încă nu există evaluări

- Ferroflow 939: Iron Fortified Shrinkage Compensated GroutDocument2 paginiFerroflow 939: Iron Fortified Shrinkage Compensated GroutFrancois-Încă nu există evaluări

- Masterflow 410 PCDocument3 paginiMasterflow 410 PCFrancois-Încă nu există evaluări

- MEYCO MP 367 Foam PDFDocument2 paginiMEYCO MP 367 Foam PDFFrancois-Încă nu există evaluări

- Ferromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationDocument2 paginiFerromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationFrancois-Încă nu există evaluări

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 paginiMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-Încă nu există evaluări

- Meyco MP302 PDFDocument3 paginiMeyco MP302 PDFFrancois-Încă nu există evaluări

- FlowcableDocument4 paginiFlowcableFrancois-Încă nu există evaluări

- Meyco MP308 PDFDocument3 paginiMeyco MP308 PDFFrancois-Încă nu există evaluări

- MEYCO MP320 Questions & Answers PDFDocument12 paginiMEYCO MP320 Questions & Answers PDFFrancois-Încă nu există evaluări

- Meyco MP 357 GS PDFDocument2 paginiMeyco MP 357 GS PDFFrancois-Încă nu există evaluări

- MEYCO MP 364 Flex PDFDocument2 paginiMEYCO MP 364 Flex PDFFrancois-Încă nu există evaluări

- Meyco MP 301 PDFDocument2 paginiMeyco MP 301 PDFFrancois-Încă nu există evaluări

- Rheoface 405: (Formerly Known As Surface Retarder)Document1 paginăRheoface 405: (Formerly Known As Surface Retarder)Francois-Încă nu există evaluări

- Meyco Fix Lube 1 PDFDocument2 paginiMeyco Fix Lube 1 PDFFrancois-Încă nu există evaluări

- Primer SC PDFDocument3 paginiPrimer SC PDFFrancois-Încă nu există evaluări

- Rheocrete 222+: Organic Corrosion Inhibiting AdmixtureDocument3 paginiRheocrete 222+: Organic Corrosion Inhibiting AdmixtureFrancois-Încă nu există evaluări

- Meyco FIB 500 PDFDocument2 paginiMeyco FIB 500 PDFFrancois-Încă nu există evaluări

- Meyco MP355 1K - TDS - 07 - PDFDocument2 paginiMeyco MP355 1K - TDS - 07 - PDFFrancois-Încă nu există evaluări

- Micro Air 120 PDFDocument2 paginiMicro Air 120 PDFFrancois-Încă nu există evaluări

- MBrace RESIN SYSTEMS PDFDocument6 paginiMBrace RESIN SYSTEMS PDFFrancois-Încă nu există evaluări

- Meyco FIB 600 PDFDocument2 paginiMeyco FIB 600 PDFFrancois-Încă nu există evaluări

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 paginiPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-Încă nu există evaluări

- RheoFIT 761 PDFDocument2 paginiRheoFIT 761 PDFFrancois-Încă nu există evaluări

- Pozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteDocument2 paginiPozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-Încă nu există evaluări

- Rheobuild 1030: High Range Water ReducerDocument2 paginiRheobuild 1030: High Range Water ReducerFrancois-Încă nu există evaluări

- Protectosil CIT PDFDocument3 paginiProtectosil CIT PDFFrancois-Încă nu există evaluări

- Almond Milk Case Study Executive SummaryDocument19 paginiAlmond Milk Case Study Executive Summarygauthamsindia307Încă nu există evaluări

- Grade 9 P.EDocument16 paginiGrade 9 P.EBrige SimeonÎncă nu există evaluări

- Eltra Cs 530Document122 paginiEltra Cs 530ahalonsoÎncă nu există evaluări

- Temporomandibular Joint SyndromeDocument11 paginiTemporomandibular Joint SyndromeRahma RahmaÎncă nu există evaluări

- Chambal Cable Stayed Bridge Connecting ShoresDocument6 paginiChambal Cable Stayed Bridge Connecting Shoresafzal taiÎncă nu există evaluări

- PhilLife claims process ECQDocument18 paginiPhilLife claims process ECQNoel EboniaÎncă nu există evaluări

- Rundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967Document15 paginiRundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967nixyingboÎncă nu există evaluări

- Indian Boyhood PDFDocument316 paginiIndian Boyhood PDFHasanÎncă nu există evaluări

- Requirement & Other Requirement: 2.311 Procedure For Accessing Applicable LegalDocument2 paginiRequirement & Other Requirement: 2.311 Procedure For Accessing Applicable Legalkirandevi1981Încă nu există evaluări

- Fischer FBN II BoltDocument5 paginiFischer FBN II BoltJaga NathÎncă nu există evaluări

- EPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsDocument4 paginiEPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsHemanth DhananjayÎncă nu există evaluări

- Experiment 4 (Group 1)Document4 paginiExperiment 4 (Group 1)Webster Kevin John Dela CruzÎncă nu există evaluări

- EXPERIMENT 5 - Chroamtorgraphy GRP9 RevDocument2 paginiEXPERIMENT 5 - Chroamtorgraphy GRP9 RevMic100% (2)

- To 1 BUMN 2023 Bahasa Inggris StructureDocument5 paginiTo 1 BUMN 2023 Bahasa Inggris StructureKukuh Perkasa WirayudaÎncă nu există evaluări

- Cswip Visual Welding Inspector 3.0 BrochureDocument1 paginăCswip Visual Welding Inspector 3.0 BrochureNasfauzan100% (2)

- Impact of Dairy Subsidies in NepalDocument123 paginiImpact of Dairy Subsidies in NepalGaurav PradhanÎncă nu există evaluări

- Fiitjee JEE Adv p1 Phase II SolDocument10 paginiFiitjee JEE Adv p1 Phase II SolPadamÎncă nu există evaluări

- Olpers MilkDocument4 paginiOlpers MilkARAAJ YOUSUFÎncă nu există evaluări

- Rawat Inap Rumah Sakit Santa Elisabeth Medan Englin Moria K. Tinambunan, Lindawati F. Tampubolon, Erika E. SembiringDocument14 paginiRawat Inap Rumah Sakit Santa Elisabeth Medan Englin Moria K. Tinambunan, Lindawati F. Tampubolon, Erika E. SembiringafrilianaÎncă nu există evaluări

- Ethnobotany Manual 14th September 2016Document54 paginiEthnobotany Manual 14th September 2016Rahul0% (1)

- Heat Transfer Augmentation in Decaying Turbulent Swirl FlowDocument1 paginăHeat Transfer Augmentation in Decaying Turbulent Swirl FlowOnkar ChavanÎncă nu există evaluări

- Seguridad Boltec Cable PDFDocument36 paginiSeguridad Boltec Cable PDFCesar QuintanillaÎncă nu există evaluări

- 632 MA Lichauco vs. ApostolDocument2 pagini632 MA Lichauco vs. ApostolCarissa CruzÎncă nu există evaluări

- Overhead Set (OBC)Document19 paginiOverhead Set (OBC)MohamedÎncă nu există evaluări

- Delta C200 Series AC Drives PDFDocument5 paginiDelta C200 Series AC Drives PDFspÎncă nu există evaluări