Documente Academic

Documente Profesional

Documente Cultură

LT Panel PDI SOP

Încărcat de

Shrikanth SolaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LT Panel PDI SOP

Încărcat de

Shrikanth SolaDrepturi de autor:

Formate disponibile

Title: SOP (Standard operating Procedure) for LT Panel PDI

FOURTH PARTNER ENERGY PVT. LTD

Fourth Partner House, Plot No: N46, House No: 4-9-10, HMT Nagar, Hyderabad – 500 076. India

T: +91-40-64631123| E-mail: info@fourthpartner.co | Website: www.fourthpartner.co

CIN No: U40108AP2010PTC070806

✓ Following are the tests which were performed in LT Panel PDI:

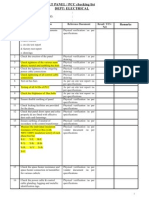

Visual & Mechanical Checks:

● Check switchgear & all the components for any physical damage / defects.

● Check nameplate of panel with the actual/Approved design.

● Inspect enclosure’s for proper alignment, foundation and grounding.

● Inspect all covers, panel sections & doors for fixing along with painting.

● Check for proper alignment of primary and secondary contacts.

● Check components of the panel with the actual designs & BOM.

● Check for the Size of Busbar & verify Current carrying capacity.

● Check for operation of all mechanical interlocks.

● Check for tightness of all the bolted connections.

● Check for phasing connection of bus bar with the drawings.

● Perform mechanical check and visual inspection for breaker / Contractor as

per section.

● Perform mechanical check and visual inspection for instrument transformers

(CT’s) as per section.

● Perform mechanical check and visual inspection on all disconnect /

grounding switches as per section.

● Dimensional checks of Panel, Bus bars & Phase to Phase & Phase to ground

clearances.

● Check for Galvanizing thickness of panel as per standards & designs.

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

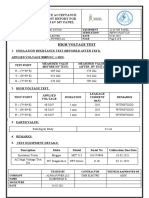

Insulation Resistance Test

The insulation resistance test is a DC evaluation test of the insulation and gives

a reliable indication of the presence of moisture, contamination or breakdown in

the insulation. This test also establishes a benchmark for future comparative tests.

It includes panel enclosure, busbar, CT and circuit breaker. The following

precautions should be taken care, before starting the testing.

● A visual inspection to ensure the surface dust and moisture removal/ clear from

the component under test.

● Make sure the section is isolated from other joined system, which may feed to

other sections or circuits which aren’t under test.

● On testing, voltage shall be applied between one phase and other phases

connected with ground, testing shall be repeated for other phases as mentioned

above.

● Test voltage limits mentioned in table below:

Rated voltage Test Voltage

100-1000V AC/DC 1000V DC

>1000 to <5000V AC 2500V DC

> 5000V AC 5000V DC

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

High Voltage Test

● To determine the equipment is in proper condition to put in service, as it was

designed and to predict the healthy status or if deterioration is underway which

can shorten.

● To conduct the test all connections to the earth circuit should be removed.

● Furthermore, electronic equipment for control/ signal/ electronic instrument or

DC control equipment which are included in the control circuit, shall be

disconnected or removed during the test.

Voltage to be applied=2xOperating Vol., + 1KV (For 60 sec)

● IR Test after HV:

• Same must be repeated after the HV Test to the LT panel

• To check break down’s in the Insulation due to HV test.

✓ Functional Checks of Panel:

• Verify all the Connections & Terminations

• Check for Functional tests by using Indicational lamps

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

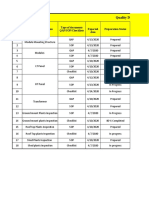

General checks Acceptance Applicable/Not

A Type of check criteria Applicable

1 Visual inspection Physical Witness

Measuremen

2 Dimensional check t Witness

3 BOM check Verification Witness

Measuremen

4 Paint thickness check t Witness

5 verification of type test certificates Verification Witness

verification of brought items test

6 certificates Verification Witness

7 Bus bar calculation sheet Verification Witness

8 Wiring check (Ferrules & connections) Verification Witness

9 Recommended protection relay settings Verification Witness

B Routine tests

1 Mechanical & Dimensional checks Verification Witness

2 Insulation resistance test (Before HV test) Verification Witness

Measuremen

3 HV test t Witness

Measuremen

4 Insulation resistance test (After HV test) t Witness

Breaker operational tests (Electrical &

5 Mechanical) Physical Witness

6 Functional tests Physical Witness

Numerical relay configuration & Functional

7 check Physical Witness

8 Review all the Type & RMTC’s Certificates Review

Summary of testing:

● Testing reduces your business risks by meeting your requirements as well as

standards.

● Testing helps to Increase quality and safety of your products and processes.

● Shorten your time & increase market access by partnering with experts in

regulatory requirements and standards.

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

S-ar putea să vă placă și

- SOP for LT Panel PDI Tests (39Document4 paginiSOP for LT Panel PDI Tests (39Shrikanth SolaÎncă nu există evaluări

- Panel Inspection Report FormatDocument5 paginiPanel Inspection Report Formatp mahesh goud100% (1)

- LT Panel SOP For Test ProcedureDocument5 paginiLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- HT Panel ChecklistDocument1 paginăHT Panel ChecklistMahfuza MansuraÎncă nu există evaluări

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 paginiLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Commissioning Standard Test Formats for ACDB PanelsDocument4 paginiCommissioning Standard Test Formats for ACDB PanelsDinesh Pitchaivel0% (1)

- Commissioning Standard Test FormatsDocument7 paginiCommissioning Standard Test FormatsAmr ElkadyÎncă nu există evaluări

- Masibus-8208 Manual PDFDocument36 paginiMasibus-8208 Manual PDFfaisal2106Încă nu există evaluări

- Contact Resistance Test FormatDocument1 paginăContact Resistance Test Formatrudra abhiÎncă nu există evaluări

- High Voltage Test: Site Acceptance Test Report For 22 KV MV PanelDocument2 paginiHigh Voltage Test: Site Acceptance Test Report For 22 KV MV PanelGajendran Sriram100% (1)

- HT Panel & Transmission Line ChecklistDocument1 paginăHT Panel & Transmission Line Checklisttango member0% (1)

- SEC-EOA Site Test ReportDocument9 paginiSEC-EOA Site Test ReportmaheshknmÎncă nu există evaluări

- Transformer Check ListDocument2 paginiTransformer Check ListKanhiya Prasad100% (2)

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 paginiCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarÎncă nu există evaluări

- Insulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)Document2 paginiInsulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)MD JAHANGEER0% (1)

- RSP-PROJ - ELEC - CABLE - 03 - Hipot Test Report of CableDocument1 paginăRSP-PROJ - ELEC - CABLE - 03 - Hipot Test Report of CableKatik Xalxo100% (2)

- Is 3043Document4 paginiIs 3043Jeya KannanÎncă nu există evaluări

- Auxiliary Contactors Test FormatDocument1 paginăAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- ACB Maintenance ProcedureDocument1 paginăACB Maintenance ProcedureMartono Abu HanifÎncă nu există evaluări

- 1.6 Kva Transformer Testing ReportDocument5 pagini1.6 Kva Transformer Testing ReportVikrant DeshmukhÎncă nu există evaluări

- Uss 105Document12 paginiUss 105Soumya BhowmickÎncă nu există evaluări

- Standard Procedure for Megger Testing TransformersDocument3 paginiStandard Procedure for Megger Testing TransformersLincoln DsouzaÎncă nu există evaluări

- Checklist For Erection of USSDocument3 paginiChecklist For Erection of USSsasikumarÎncă nu există evaluări

- Check List of Protection Relays TestsDocument2 paginiCheck List of Protection Relays TestsAnonymous dH3DIEtz67% (3)

- Dry Type Transformer Test Report: Page 1 of 2Document2 paginiDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryanaÎncă nu există evaluări

- Standard Operating Procedure for LT PanelDocument5 paginiStandard Operating Procedure for LT PanelKarthik Mandya100% (3)

- Test Report For Protection Relay and Current Transformer: Schneider Vamp 50Document2 paginiTest Report For Protection Relay and Current Transformer: Schneider Vamp 50RamaÎncă nu există evaluări

- DCDB Panel Functional Test FormDocument5 paginiDCDB Panel Functional Test FormAmr ElkadyÎncă nu există evaluări

- Check List LT PanelDocument1 paginăCheck List LT PanelAnil PatelÎncă nu există evaluări

- Operation & Maintenance of TransformersDocument46 paginiOperation & Maintenance of TransformersAbhinav TewariÎncă nu există evaluări

- Switch Yard & Protection SystemDocument48 paginiSwitch Yard & Protection SystemDharmendra GargÎncă nu există evaluări

- ACB VCB OCB LT Panel ChecklistDocument7 paginiACB VCB OCB LT Panel ChecklistAnonymous mNQq7oj100% (1)

- Checklist For Erection of Control & Relay Panel-Busbar Protection.Document2 paginiChecklist For Erection of Control & Relay Panel-Busbar Protection.sasikumarÎncă nu există evaluări

- QAP - LT Panel PDFDocument8 paginiQAP - LT Panel PDFAkshay Ajay100% (2)

- Electrical Panel SOPDocument10 paginiElectrical Panel SOPRiyaZ55100% (1)

- Switch Gear Commissioning ChecklistDocument27 paginiSwitch Gear Commissioning ChecklistRAM SHANMUGAMÎncă nu există evaluări

- Testing Procedure For Potential Transormer: Prepared byDocument1 paginăTesting Procedure For Potential Transormer: Prepared byGuru MishraÎncă nu există evaluări

- Erection Procedure For 415 V LCC, LDBS, LPS, SPDocument40 paginiErection Procedure For 415 V LCC, LDBS, LPS, SPAnmohieyÎncă nu există evaluări

- Appendix-2 (POWER PANEL Test Report)Document2 paginiAppendix-2 (POWER PANEL Test Report)hafed baccoucheÎncă nu există evaluări

- AOH checklist for LT and HT motorsDocument8 paginiAOH checklist for LT and HT motorsElectrical Team100% (1)

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 paginiFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005Încă nu există evaluări

- Ac Panel Test ReportDocument14 paginiAc Panel Test ReportUtku Can KılıçÎncă nu există evaluări

- 4 Ammeter Test ReportDocument1 pagină4 Ammeter Test ReportJayaprakash M PÎncă nu există evaluări

- Motor Maintenance GuideDocument22 paginiMotor Maintenance GuidechinnaraoÎncă nu există evaluări

- Electrical Panel SOPDocument3 paginiElectrical Panel SOPShah SaadÎncă nu există evaluări

- Rmu Visual Inspection ChecklistDocument1 paginăRmu Visual Inspection ChecklistJoe_Average100% (2)

- Inspection Report Electrical Power TransformerDocument9 paginiInspection Report Electrical Power Transformerprotecciones100% (1)

- VCBDocument19 paginiVCBmadan_153Încă nu există evaluări

- HT Panel Test ReportDocument4 paginiHT Panel Test ReportItx Adi0% (1)

- L & T Construction - PT & D Ic: Safe Operating ProcedureDocument20 paginiL & T Construction - PT & D Ic: Safe Operating Procedurearvindsarkar100% (1)

- Standard Operating Procedure - HT Panel - V01 - 022.04.2011Document5 paginiStandard Operating Procedure - HT Panel - V01 - 022.04.2011Karthik MandyaÎncă nu există evaluări

- Feeder Protection Test Report FormatDocument2 paginiFeeder Protection Test Report FormatHari haran100% (1)

- Capacitor Step Size Selection Guidelines in APFC PanelsDocument4 paginiCapacitor Step Size Selection Guidelines in APFC PanelsAditya Pandey100% (1)

- Motor Test FormDocument1 paginăMotor Test FormArie Yantoe100% (1)

- CNCEC-QF-06-E006 - MV LV Switchgear Installation Inspection ChecklistDocument1 paginăCNCEC-QF-06-E006 - MV LV Switchgear Installation Inspection ChecklistTahir2016100% (1)

- HV Cable Test Report 1Document3 paginiHV Cable Test Report 1prabhumanoc100% (1)

- Checklist Control PanelDocument2 paginiChecklist Control PanelAnjar AjjaÎncă nu există evaluări

- Grid Code TestingDocument52 paginiGrid Code TestingYahya DarÎncă nu există evaluări

- Siemens Internship ReportDocument17 paginiSiemens Internship ReportmirfanbilalÎncă nu există evaluări

- Et 0000 97 Toc 001bDocument5 paginiEt 0000 97 Toc 001bGLEDSONÎncă nu există evaluări

- Is 2720 29 1975Document14 paginiIs 2720 29 1975biswashree10Încă nu există evaluări

- Electrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Document5 paginiElectrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Shrikanth Sola100% (1)

- Is 2720 28 1974 PDFDocument27 paginiIs 2720 28 1974 PDFsunitkghoshÎncă nu există evaluări

- List of Is Standards For Substation EquipmentsDocument9 paginiList of Is Standards For Substation EquipmentsRajj Pruthivi100% (1)

- Disclosure To Promote The Right To InformationDocument22 paginiDisclosure To Promote The Right To InformationSandeep ReddyÎncă nu există evaluări

- Is 1077 1992Document10 paginiIs 1077 1992Prakash SharmaÎncă nu există evaluări

- Is 2720 28 1974 PDFDocument27 paginiIs 2720 28 1974 PDFsunitkghoshÎncă nu există evaluări

- Is 516 1959 PDFDocument30 paginiIs 516 1959 PDFannie3456789Încă nu există evaluări

- Is 2386 2 1963 PDFDocument21 paginiIs 2386 2 1963 PDFsherlin100% (1)

- SL - No SL - No Action ItemsDocument3 paginiSL - No SL - No Action ItemsShrikanth SolaÎncă nu există evaluări

- Is 2720 29 1975Document14 paginiIs 2720 29 1975biswashree10Încă nu există evaluări

- Is 3495 1-4 1992 PDFDocument13 paginiIs 3495 1-4 1992 PDFmanuvthampyÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument22 paginiDisclosure To Promote The Right To InformationSandeep ReddyÎncă nu există evaluări

- Is 2386 2 1963 PDFDocument21 paginiIs 2386 2 1963 PDFsherlin100% (1)

- Generation Detail of Last One Year-19Document232 paginiGeneration Detail of Last One Year-19Shrikanth SolaÎncă nu există evaluări

- Is 2720 28 1974 PDFDocument27 paginiIs 2720 28 1974 PDFsunitkghoshÎncă nu există evaluări

- Trafo Oil Testing TypesDocument10 paginiTrafo Oil Testing TypesShrikanth SolaÎncă nu există evaluări

- Project DetailsDocument1.325 paginiProject DetailsShrikanth SolaÎncă nu există evaluări

- ErpDocument3 paginiErpShrikanth SolaÎncă nu există evaluări

- Transformer Oil & Its EvolutionDocument7 paginiTransformer Oil & Its EvolutionShrikanth SolaÎncă nu există evaluări

- Quality Department Document StatusDocument3 paginiQuality Department Document StatusShrikanth SolaÎncă nu există evaluări

- KRA KPI DepartmentDocument6 paginiKRA KPI DepartmentShrikanth Sola100% (1)

- CELL-TO-MODULE LOSS SIMULATION FOR SHINGLED-CELL CONCEPTDocument5 paginiCELL-TO-MODULE LOSS SIMULATION FOR SHINGLED-CELL CONCEPTShrikanth SolaÎncă nu există evaluări

- Installation Instructions: Mico Basic 8.6Document2 paginiInstallation Instructions: Mico Basic 8.6Servizio TecnicoÎncă nu există evaluări

- New Holland Engine F4ge Backhoe en Service ManualDocument10 paginiNew Holland Engine F4ge Backhoe en Service Manualenrique100% (47)

- 1 PDFDocument60 pagini1 PDFdexterÎncă nu există evaluări

- ABB Terminal BlocksDocument236 paginiABB Terminal BlocksBenoit LefebvreÎncă nu există evaluări

- IGBTDocument22 paginiIGBTumeshgangwar100% (1)

- Test RDCDocument88 paginiTest RDCWan SahÎncă nu există evaluări

- Fire Pump Installation GuideDocument3 paginiFire Pump Installation GuideJeff D. AgustinÎncă nu există evaluări

- Rectification ProcessDocument5 paginiRectification ProcessDilnaz TegispayÎncă nu există evaluări

- KRYPTOSPHERE TechnologyDocument20 paginiKRYPTOSPHERE TechnologySoniale Sánchez GómezÎncă nu există evaluări

- Question Paper Code:: Reg. No.Document2 paginiQuestion Paper Code:: Reg. No.tamilarasi87thulasiÎncă nu există evaluări

- 6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Document18 pagini6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Stefan IstratescuÎncă nu există evaluări

- MANUAL Vdocuments - Site FG Wilson P88e1Document287 paginiMANUAL Vdocuments - Site FG Wilson P88e1eletronica55100% (2)

- New Tutorial 2 Solution On ThermodynamicsDocument7 paginiNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadÎncă nu există evaluări

- Fabric Expansion JointsDocument28 paginiFabric Expansion Jointswarmachine269889Încă nu există evaluări

- Design and Generating Energy As A Car Alternator TDocument7 paginiDesign and Generating Energy As A Car Alternator TJohnny TestÎncă nu există evaluări

- Module 4 (3) Collection, Transport, TransferDocument32 paginiModule 4 (3) Collection, Transport, TransfervanilivaniliÎncă nu există evaluări

- Amcor 2016Document69 paginiAmcor 2016Romulo AlvesÎncă nu există evaluări

- Measuring Instrument Accuracy LimitsDocument2 paginiMeasuring Instrument Accuracy LimitsDan DanubiusÎncă nu există evaluări

- Kiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerDocument1 paginăKiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerMohamed SelimÎncă nu există evaluări

- New Holland Cargador w170 B Tier III Na RepuestosDocument555 paginiNew Holland Cargador w170 B Tier III Na Repuestosarmando vara chavez100% (2)

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 paginăBomba Electrica 1500gpm 300HP (Medidas)Fire ChileÎncă nu există evaluări

- FAI Services Overview SHORTDocument58 paginiFAI Services Overview SHORTMariela CarrilloÎncă nu există evaluări

- Method of Lighting CalculationsDocument3 paginiMethod of Lighting CalculationsSpencer Josh RegedorÎncă nu există evaluări

- Unit 1Document36 paginiUnit 1MonishÎncă nu există evaluări

- Overhead Phil MC KeownDocument30 paginiOverhead Phil MC KeownAditya AoleÎncă nu există evaluări

- 39CQ Iom 06302014Document20 pagini39CQ Iom 06302014Non Etabas GadnatamÎncă nu există evaluări

- Specialist Water Supply Systems PP-R pipe system Ensure reliabilityDocument16 paginiSpecialist Water Supply Systems PP-R pipe system Ensure reliabilitymabj68Încă nu există evaluări

- Principle Heat TransferDocument34 paginiPrinciple Heat TransferZick HaziqÎncă nu există evaluări

- SGMF Hose BunkeringDocument15 paginiSGMF Hose BunkeringFilipÎncă nu există evaluări

- Control of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysDocument14 paginiControl of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysKaushik SenguptaÎncă nu există evaluări