Documente Academic

Documente Profesional

Documente Cultură

PC18, PC20, PC27, PC30, PC35, PC45, PC55MR-3

Încărcat de

prasetyo nugrohoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PC18, PC20, PC27, PC30, PC35, PC45, PC55MR-3

Încărcat de

prasetyo nugrohoDrepturi de autor:

Formate disponibile

OPERATING WEIGHT

PC18MR-3 1,780 kg 3,920 lb

PC20MR-3 2,160 kg 4,760 lb

PC27MR-3 2,890 kg 6,370 lb

PC30MR-3 3,140 kg 6,920 lb

PC35MR-3 3,580 kg 7,890 lb

PC45MR-3 4,760 kg 10,490 lb

PC55MR-3 5,160 kg 11,380 lb

H YDRAULIC E XCAVATOR

C OMPACT

Photo may include optional equipment

LBSSP45300.indd 1 2/19/2016 10:15:26 AM

C OMPACT H YDRAULIC E XCAVATOR

WALK-AROUND

BEBERAPA KEUNGGULAN

Performance and Versatility Operator Comfort

• Komatsu HydrauMind hydraulic system • Large operator platform

• Automatic load sensing two-speed travel • Pilot proportional joystick controls

• Standard auxiliary hydraulics • Large monitor panel

• Integrated counterweight and tight tail swing • Easy entry and egress

Prestasi dan Fleksibilitas • Low noise

• Komatsu HydrauMind hidrolik sistem Kenyamanan operator

• Load sensing otomatis dua-kecepatan travel • Ruang operator luas

• Standard auxiliary hydraulics • Proposional pilot dengan joystick controls

• Counterweight yang terintegrasi dan ayunan bagian belakang • Monitor panel besar

yang kokoh • Akses masuk dan keluar yang mudah

• Kebisingan yang rendah

Service and Maintenance

• Wide opening engine hood and side covers

• Side-by-side radiator and oil cooler are easy to inspect and clean

• Extended lubrication and engine oil replacement intervals reduce maintenance and down time

• Tilt-forward operator’s station provides full access to engine

Perawatan dan Perbaikan

• Kap Engine dan side covers dapat dibuka lebar

• Radiator dan oil cooler saling berdampingan untuk memudahkan pengecekan dan pembersihan

• Jarak waktu penggantian oli engine dan pelumas diperpanjang untuk mengurangi waktu perawatan

dan perbaikan

• Station operator yang dapat dimiringkan ke depan menyediakan akses penuh ke engine

LBSSP45300.indd 2 2/19/2016 10:15:27 AM

COMPACT HYDRAULIC EXCAVATOR

OPERATING WEIGHT

PC18MR-3 1,780 kg 3,920 lb

PC20MR-3 2,160 kg 4,760 lb

PC27MR-3 2,890 kg 6,370 lb

PC30MR-3 3,140 kg 6,920 lb

PC35MR-3 3,580 kg 7,890 lb

PC45MR-3 4,760 kg 10,490 lb

PC55MR-3 5,160 kg 11,380 lb

Value, Durability, and Strength

• High strength X-track frame

• Castings are used for boom foot, tip, and swing yoke

• Single large diameter swing pin

• Three track options: rubber, steel, and Roadliner

• O-ring face seal hydraulic fittings

• Moisture/dust resistant electrical connectors

Nilai, Daya tahan, dan Kekuatan

• Track frame-X berkekuatan tinggi

• Boom foot, tip, dan swing yoke menggunakan bahan casting

General Features • Pin swing berdiameter besar

• Two-post ROPS canopy or ROPS cab • Tiga pilihan track shoe : karet, besi dan roadliner

ROPS (ISO 3471) : Roll-Over Protective Structure • O-ring face seal hydraulic fittings

• Neutral engine start system • Konektor listrik yang tahan terhadap debu dan embun

• Excellent visibility enhances job site awareness

• Low emission Komatsu engine with dual element air cleaner

• One key operates the ignition and all machine locks

General Features

• 2-post ROPS canopy atau ROPS cab

ROPS (ISO 3471) : Roll-Over Protective Structure

• Neutral engine start system

• Jarak pandang yang baik meningkatkan kesadaran akan lingkungan sekitar

• Engine Komatsu beremisi rendah dengan dua elemen penyaring udara

• Satu kunci dapat dipakai untuk menghidupkan dan mengunci semua alat

LBSSP45300.indd 3 2/19/2016 10:15:33 AM

C OMPACT H YDRAULIC E XCAVATOR

PRODUCTIVITY FEATURES

FITUR-FITUR PRODUKTIVITAS

Tight Tail Swing

Operator is able to focus on the work in front of them and worry less about a

rear swing impact, even in confined areas with only an 80mm 3” projection

over the tracks.

Ayunan bagian belakang yang kokoh

Operator dapat fokus pada pekerjaan di bagian depan mereka dan tidak

perlu khawatir dengan dampak ayunan belakang, bahkan di area yang

terbatas dengan perkiraan hanya 80mm 3” dari track.

Automatic Two-speed Travel

The travel speed selector switch installed on the blade control allows the

operator to engage high speed

travel. Once engaged the

system automatically senses

the travel load and shifts

between high speed and low

Confined Job Site Advantage speed travel.

Operator can focus on digging and improve productivity, because they can Dua-Kecepatan Travel

worry less about obstacles to the rear of the machine, such as parked cars, Otomatis

walls and trees. Saklar pemilih kecepatan travel

Kondisi kerja jobsite yang menguntungkan yang dipasang pada kontrol

Operator dapat fokus pada aplikasi menggali dan meningkatkan blade memungkinkan operator

produktivitas, karena mereka tidak perlu khawatir dengan hambatan di untuk mengaktifkan travel kecepatan tinggi. Ketika sudah diaktifkan, sistem

belakang mesin, seperti mobil yang diparkir, dinding dan pohon. secara otomatis mendeteksi beban travel dan mengubah setting kecepatan

travel antara travel kecepatan tinggi dan travel kecepatan rendah.

PC18MR-3 2,070mm 6’9”* Expandable Undercarriage (PC18MR-3)

The PC18MR-3 can pass through narrow space due to narrow width and

PC20MR-3 2,250mm 7’5”*

undercarriage can be expanded for good stability during excavation.

PC27MR-3 2,515mm 8’3”*

PC30MR-3 2,415mm 7’11”* Undercarriage yang dapat diperlebar (PC18MR-3)

PC18MR-3 dapat melewati area sempit karena memiliki ukuran lebar yang

PC35MR-3 2,550mm 8’4”*

lebih kecil dan undercarriage dapat diperlebar untuk kestabilan yang baik

PC45MR-3 2,830mm 9’3”* selama penggalian.

PC55MR-3 2,800mm 9’2”*

* : When boom swing

Closed-center Load Sensing System (CLSS)

HydrauMind Hydraulic System

When two or more actuators are operated simultaneously, the pressure-

compensated CLSS system ensures each actuator works according to its

control input, regardless of the size of the load. This gives the operator

precise control at all times.

Closed-center Load Sensing System (CLSS)

HydrauMind Hydraulic System

Ketika dua atau lebih aktuator dioperasikan secara bersamaan, sistem CLSS

dengan tekanan yang diseimbangkan akan memastikan setiap aktuator

bekerja sesuai dengan masukan pada kontrol, tanpa memperhatikan

besarnya beban. Hal ini memberikan operator kontrol yang tepat setiap saat.

LBSSP45300.indd 4 2/19/2016 10:15:37 AM

COMPACT HYDRAULIC EXCAVATOR

Working Range

mm ft.in.

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3

Max.digging height 3615 11’10’’ 4000 13’1’’ 4480 14’8’’ 4840 15’11’’

Max.digging dept 2160 7’1’’ 2280 7’6’’ 2550 8’4’’ 2760 9’1’’

Max.digging reach at

3935 12’11’’ 4000 13’1’’ 4550 14’11’’ 4910 16’1’’

ground level

Loading height 1220 4’0’’ 1430 4’8’’ 1650 5’5’’ 1700 5’7’’

PC35MR-3 PC45MR-3 PC55MR-3

Max.digging height 5000 16’5’’ 5515 18’1’’ 5945 19’6’’

Max.digging dept 3110 10’2’’ 3350 12’0’’ 3800 12’6’’

Max.digging reach at

5170 17’0’’ 5575 18’3’’ 6070 19’11’’

ground level

Loading height 1805 5’11’’ 1945 6’5’’ 1930 6’4’’

Digging Force

kg lb

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3

Max.crowd force: Arm 1010 2230 1390 3065 1500 3310 1800 3970 Stability

Max.crowd force: Bucket 1620 3570 1920 4235 2230 4920 3000 6610 The MR-3 series offers exceptional lifting capacity and stability

in a tight tail machine.

PC35MR-3 PC45MR-3 PC55MR-3 Kestabilan

Max.crowd force: Arm 2100 4630 2200 4850 2440 5380 Seri MR-3 menawarkan kapasitas angkat yang luar biasa dan

kestabilan dalam alat yang kecil.

Max.crowd force: Bucket 3050 6720 3460 7630 3980 8770

Lifting capacity comparation

kg lb

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3

3m 10’ 220 480 285 630 370 820 365 800

Rating at max.reach 185 410 240 530 245 540 220 480

PC35MR-3 PC45MR-3 PC55MR-3

3m 10’ 580 1280 995 2190 1005 2220

Rating at max.reach 345 760 505 1110 435 960

The conditions of this comparison are a standard arm, sideways, blade on ground, and at a height

of 0m (Ground level).

Auxiliary Flow

L/min USgal/min

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3

Auxiliary flow 35 9.2 35 9.5 50 13.2 70 18.5

PC35MR-3 PC45MR-3 PC55MR-3

Auxiliary flow 70 18.5 70 18.5 70 18.5

Drawbar Pull

kg lb

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3

Max.drawbar pull 1700 3750 2060 4540 3200 7050 3400 7500

PC35MR-3 PC45MR-3 PC55MR-3

Max.drawbar pull 3400 7500 4280 9440 4280 9440

LBSSP45300.indd 5 2/19/2016 10:15:39 AM

C OMPACT H YDRAULIC E XCAVATOR

OPERATOR ENVIRONMENT

LINGKUNGAN OPERATOR

Large Entrance and Foot Space Fully Adjustable Operator’s Seat

The two-post canopy design allows the MR-3 series to have larger entrance The spacious operator’s compartment provides outstanding ride quality.

for entry and egress. The large operator’s seat enhances operator comfort.

Akses masuk dan area kaki yang luas Kursi operator yang dapat disesuaikan

Desain 2-post kanopi memungkinkan seri MR-3 memiliki akses masuk Kompartemen operator yang luas menyediakan kualitas berkendara yang

dan dan keluar yang lebih besar. luar biasa. Kursi operator yang besar meningkatkan kenyamanan operator.

Joystick Controls

Pressure Proportional Control (PPC) joystick controls are low effort and

provide fine control.

Joystick Controls

Pressure Proportional Control (PPC) joystick controls memberikan

kemudahan dan kontrol yang baik.

PC18MR-3

Pattern Change Valve (Optional Equipment)

Pattern change valve allows the operator to change easily between ISO

control pattern (ISO 10968) or backhoe control pattern.

Excellent Visibility Pattern Change Valve (Peralatan Pilihan)

The operator’s station design allows the operator to maintain 360˚ field Pattern Change Valve mengijinkan operator untuk mengubah dengan

view. mudah antara pola kontrol ISO (ISO 10968) atau pola kontrol backhoe.

Jarak pandang yang baik

Desain alat yang memungkinkan operator untuk melihat dengan

pandangan 360˚.

LBSSP45300.indd 6 2/19/2016 10:15:43 AM

COMPACT HYDRAULIC EXCAVATOR

Large Operator’s Cab (Optional Equipment) (Not Available for PC18MR-3)

The cab provides outstanding foot space. Ergonomic design helps reduce fatigue.

The large rear glass provides the operator excellent rear visibility.

Kabin operator luas (Peralatan Pilihan) (Tidak Tersedia untuk PC18MR-3)

Kabin menyediakan ruang kaki yang luas. Desain ergonomis membantu

mengurangi kelelahan. Kaca belakang yang besar menyediakan jarak pandang

yang baik.

Upper-rail Type Sliding Door

Upper-rail Type Sliding Door

Large Rear Glass

Kaca Belakang Besar

Large-capacity Air Conditioner

(Optional Equipment) (Not

Available for PC20MR-3)

Provides comfortable operator

environment throughout the year.

Air Conditioner berkapasitas

besar (Peralatan Pilihan) (Tidak

Tersedia untuk PC20MR-3)

Menyediakan lingkungan operator

yang nyaman sepanjang tahun.

Cup Holder

Large cup holder is standard equipment.

Cup Holder

Cup holder besar sebagai peralatan standar.

LBSSP45300.indd 7 2/19/2016 10:15:45 AM

C OMPACT H YDRAULIC E XCAVATOR

EASY MAINTENANCE

PERAWATAN MUDAH

Tilt-up Operator Compartment

Operator’s compartment floor tilts forward providing easy access

to hydraulic compartments.

Operator Kompartemen yang dapat dimiringkan keatas

Lantai kompartemen operator yang dapat dimiringkan kedepan

menyediakan akses mudah ke kompartemen hydraulic.

Fully Opening Engine Door and Side Cover

Allow easy access for daily checks and regular maintenance.

Pintu Engine dan Side Cover yang dapat terbuka penuh

Memungkinkan akses mudah untuk pemeriksaan harian dan

pemeliharaan rutin.

High Strength X-track Frame

X-track frame is a large hydraulic excavator concept and deters dirt and

debris build up saving the operator valuable Wide opening

time when cleaning the machine. Larger Diameter Swing Pin

Track Frame-X berkekuatan tinggi Has high durability and

Kerangka Track-X adalah sebuah maintains suitable clearances

konsep hydraulic excavator between pin and bushing after

besar yang dapat mengurangi long-term operation.

jumlah kotoran sehingga Diameter Swing Pin yang

menghemat waktu operator lebih besar

yang berharga saat Memiliki daya tahan tinggi dan

membersihkan mesin. menjaga ukuran clearances

yang sesuai antara pin dan

bushing setelah operasi jangka panjang.

Sealed Connector

Sealed connectors are

moisture and dust resistant.

Konektor berseal

O-ring Face Seal Konektor berseal tahan

O-ring face seals are highly terhadap kelembaban dan

reliable. debu.

O-ring Face Seal

O-ring face seals yang sangat

handal.

LBSSP45300.indd 8 2/19/2016 10:15:48 AM

COMPACT HYDRAULIC EXCAVATOR

GENERAL FEATURE

FITUR- FITUR UMUM

Two-post ROPS & OPG Canopy Chevron-shaped Boom Cylinder Guard and Boom Bottom Working

ROPS (ISO 3471) [Roll-Over Protective Structure] Lamp (Not Available for PC18MR-3 and PC27MR-3).

This canopy meets the requirements of ROPS, with the advantage A chevron-shaped boom cylinder guard* is provided

of a two-post design. This design reduces damage to the cylinder caused by interference of the breaker, hitting

2-post ROPS & Kanopi OPG against the dump vessel, etc.

ROPS (ISO 3471) [Rollover Protective Structure] * The boom cylinder guard of the PC20MR-3 is a reinforced thick plate type.

Kanopi ini memenuhi persyaratan ROPS, dengan keuntungan dari Chevron-shaped Boom Cylinder Guard dan

desain 2-post. Boom Bottom Working Lamp (Tidak Tersedia

untuk PC18MR-3 dan PC27MR-3).

A chevron-shaped boom cylinder guard* disediakan

Desain ini mengurangi kerusakan silinder yang

disebabkan oleh gangguan dari breaker, menghantam

dump vessel, dll.

* Boom Cylinder Guard PC20MR-3 menggunakan tipe plat tebal yang di

reinforced.

A working lamp is provided on the boom bottom

A working lamp for work equipment is provided on the

boom bottom to prevent damage due to accidental

contact.

Sebuah lampu kerja disediakan pada bagian

bawah boom

Sebuah lampu kerja untuk peralatan kerja yang disediakan di bagian bawah boom untuk

mencegah kerusakan akibat kontak tidak disengaja.

A Travel Lamp Is Provided Near of Operator’s Seat as the Standard Equipment

(Not Available for PC18MR-3 and PC27MR-3)

Tie-Downs or Anchor Points This travel lamp provides an increased visibility both in a night operation and in the travel

Large tie-downs or anchor points in the track frame and blade allow position.

the machine to be secured quickly for transport. Sebuah Lampu Travel Disediakan Dekat Kursi Operator sebagai Peralatan Standar

Tie-Downs atau jangkar Poin (Tidak Tersedia untuk PC18MR-3 dan PC27MR-3)

Tie-downs atau titik jangkar pada track frame dan blade Lampu travel ini menyediakan jarak pandang yang lebih baik pada operasi malam hari dan di

memungkinkan alat diamankan dengan cepat saat transport. posisi travel.

Neutral Engine Start System

Locks out drives and hydraulics during machine start up.

OPTIONAL EQUIPMENT Neutral Engine Start System

PERALATAN PILIHAN Mengunci kemampuan berkendara dan hydraulic selama alat mulai dihidupkan

Roadliner (Not Available for PC18MR-3 and PC20MR-3) Power Angle Blade (Not Available for PC18MR-3, PC20MR-3

Replacement is fast, easy and cost efficient as and PC27MR-3)

individual shoes are replaced when damaged or

worn instead of replacing the entire track.

Roadliner (Tidak Tersedia untuk PC18MR-3

dan PC20MR-3)

Penggantian cepat, mudah, dan biaya yang efisien karena hanya mengganti shoe satu

per satu bila rusak atau aus bukan mengganti keseluruhan track.

Steel Shoes with Rubber Pad Optional Blade

(Bolt-On Cutting adge (B.O.C) TYPE)

LBSSP45300.indd 9 2/19/2016 10:15:51 AM

C OMPACT H YDRAULIC E XCAVATOR

SPECIFICATION

SPESIFIKASI

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3 PC35MR-3 PC45MR-3 PC55MR-3

1780 3920 2160 4760 2890 6370 3140 6920 3580 7890 4760 10490 2160 4760

Operating weight kg lb

ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe ROPS Canopy, Rubber shoe

kW/min-1 11.2/2600 15.5/2500 19.2/2600 21.4/2400 21.4/2400 28.5/2400 15.5/2500

Flywheel horsepower

HP/min-1 15/2600 20.8/2500 25.7/2600 28.6/2400 28.6/2400 38.2/2400 20.8/2500

(SAE heaped) 0.044 0.058 0.066 0.086 0.08 0.10 0.09 0.12 0.11 0.14 0.14 0.18 0.066 0.086

Bucket capacity m3 yd3

(CECE heaped) 0.04 0.052 0.06 0.08 0.07 0.09 0.08 0.10 0.10 0.13 0.13 0.17 0.06 0.08

Bucket width 400 16 430 17 430 17 430 17 530 21 530 21 430 17

mm in

(incl.side cutters) 450 18 500 20 500 20 500 20 600 24 600 24 500 20

Hi km/h MPH 4.3 2.7 4.6 2.9 4.8 3.0 4.6 2.9 4.8 3.0 4.6 2.9 4.6 2.9

Travel speed

Lo km/h MPH 2.3 1.4 2.8 1.7 2.6 1.6 2.5 1.6 2.8 1.7 2.8 1.7 2.8 1.7

Swing speed min-1 8.9 8.9 9.2 9.3 9 9 8.9

Ground pressure kg/cm2 PSI 0.32 4.6 0.27 3.9 0.32 4.6 0.30 4.3 0.36 5.1 0.25 3.6 0.27 3.9

Perfomance

Max.traction force kg lb 1700 3750 2060 4540 3200 7050 3400 7500 3400 7500 4280 9440 2060 4540

Gradeability deg. 30 30 30 30 30 30 30

Bucket digging force (ISO) kg lb 1620 3570 1920 4230 2230 4920 3000 6610 3050 6720 3460 7630 1920 4230

Arm crowd force (ISO) kg lb 1010 2230 1390 3065 1500 3310 1800 3970 2100 5630 2200 4850 1390 3065

Model --- Komatsu 3D67E-2 Komatsu 3D76E-3 Komatsu 3D82AE-6 Komatsu 3D88E-6 Komatsu 3D88E-6 Komatsu 4D88E-6 Komatsu 3D76E-3

Engine Type --- Swirl chamber Swirl chamber Direct injection Direct injection Direct injection Direct injection Swirl chamber

Piston displacement L in3 0.778 47 1.115 68 1.33 81 1.642 100 1.642 100 2.189 134 1.115 68

Operator voltage V 12 12 12 12 12 12 12

Electric Battery Ah 41 45 58 58 58 72 45

System Alternator A 40 40 40 40 40 40 40

Starter kW 1.2 1.4 2.3 2.3 2.3 2.3 1.4

990 or 1280 x 250 1450 x 300 1550 x 355 1550 x 355 1740 x 355 1960 x 355 1450 x 300

Blade Width x height mm ft.in.

3’3’’ or 4’2’’ x 10’’ 4’9’’ x 1’0’’ 5’1’’ x 1’2’’ 5’1’’ x 1’2’’ 5’9’’ x 1’2’’ 6’5’’ x 1’2’’ 4’9’’ x 1’0’’

Drive method --- Hydrostatic Hydrostatic Hydrostatic Hydrostatic Hydrostatic Hydrostatic Hydrostatic

Drive

Type of travel brake --- Hydraulic lock type Hydraulic lock type Hydraulic lock type Hydraulic lock type Hydraulic lock type Hydraulic lock type Hydraulic lock type

System

Type of travel shoe --- Rubber Rubber Rubber Rubber Rubber Rubber Rubber

Adjustment of the track tension --- Grease Grease Grease Grease Grease Grease Grease

Number of shoes (For each side) --- 35 (steel) 35 (steel) 40 (steel) 44 (steel) 44 (steel) 39 (steel) 35 (steel)

Undercarriage

Number of carrier rollers (For each side) --- 0 0 1 1 1 1 0

Number of track rollers (For each side) --- 3 3 4 4 4 4 4

Type of hydraulic pump --- Variable capacity x 1 gear x 1 Variable capacity x 1 gear x 1 Variable capacity x 1 gear x 1 Variable capacity x 1 gear x 1 Variable capacity x 2 gear x 1 Variable capacity x 2 gear x 1 Variable capacity x 1 gear x 1

L/min 41.6 x 1 + 12.7 53.4 x 1 + 15.5 70.6 x 1 + 21.4 69.8 x 1 + 19.8 36.1 x 2 + 19.8 53.5 x 2 + 33.8 53.4 x 1 + 15.5

Max. oil flow

US gal/min 11.0 x 1 + 3.4 14.1 x 1 + 4.1 18.7 x 1 + 5.7 18.4 x 1 + 5.2 9.5 x 2 + 5.2 14.1 x 1 + 8.9 14.1 x 1 + 4.1

Hydraulic (Travel) --- Variable capacity x 2 Variable capacity x 2 Variable capacity x 2 Variable capacity x 2 Variable capacity x 2 Variable capacity x 2 Variable capacity x 2

Hydraulic motor

System (Swing) --- fixed capacity x 1 fixed capacity x 1 fixed capacity x 1 fixed capacity x 1 fixed capacity x 1 fixed capacity x 1 fixed capacity x 1

Max. pressure setting kg/cm2 PS1 235 3340 250 3560 250 3560 265 3770 265 3770 270 3840 250 3560

L/min 35 35 50 70 70 70 35

Auxiliary hydraulic flow

US gal/min 9.2 9.2 13.2 18.5 18.5 18.5 9.2

Fuel tank L USgal 19 5.0 28 7.4 44 11.6 44 11.6 44 11.6 65 17.2 28 7.4

Refilling Hydraulic tank L USgal 15.2 4.0 19 5.0 14 3.7 14 3.7 14 3.7 20 5.3 19 5.0

Capacity Engine L USgal 3.3 0.9 3.4 0.9 5 3.7 6.7 1.8 6.7 1.8 7.5 2.0 3.4 0.9

Coolant L USgal 3.1 0.8 3.0 0.8 3.3 0.9 3.3 0.9 3.3 0.9 8.5 2.2 3.0 0.8

WORKING RANGE

STD Arm Working Range PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3 PC35MR-3 PC45MR-3 PC55MR-3

a Max. digging height mm ft.in. 3615 11’10’’ 4000 13’1’’ 4480 14’8’’ 4840 15’11’’ 5000 16’5’’ 5515 18’1’’ 5945 19’6’’

b Max.dumping height mm ft.in. 2610 8’7’’ 2760 9’1’’ 3190 10’6’’ 3350 11’0’’ 3530 11’7’’ 3785 12’5’’ 4230 13’11’’

c Max. digging depth mm ft.in. 2160 7’1’’ 2280 7’6’’ 2550 8’4’’ 2760 9’1’’ 3110 11’2’’ 3350 11’0’’ 3800 12’6’’

d Max. vertical digging depth mm ft.in. 1785 5’10’’ 1860 6’1’’ 2080 6’10’’ 2400 7’10’’ 2690 8’10’’ 2645 8’8’’ 3020 9’11’’

e Max. digging reach mm ft.in. 4025 13’2’’ 4150 13’7’’ 4650 15’3’’ 5050 16’7’’ 5300 17’5’’ 5735 18’10’’ 6220 20’5’’

Max. digging reach mm ft.in.

f 3935 12’11’’ 4000 13’1’’ 4550 14’11’’ 4910 16’1’’ 5170 17’0’’ 5575 13’3’’ 6070 19’11’’

at ground level mm ft.in.

Min. swing radius 1670 5’6’’ 1790 5’10’’ 1980 6’6’’ 2055 6’9’’ 2030 6’8’’ 2340 7’8’’ 2270 7’5’’

g mm ft.in.

(When boom swing) (1355 4’5’’) (1450 4’9’’) (1660 5’5’’) (1560 5’1’) (1600 5’3’) (1770 5’10’) (1740 5’9’)

h Max. blade lift mm ft.in. 280 11’’ 340 1’1’’ 360 1’2’’ 360 1’2’’ 360 1’2’’ 430 1’5’’ 430 1’5’’

i Max. blade depth mm ft.in. 255 10’’ 240 9.4’’ 310 1’0’’ 310 1’0’’ 390 1’13’’ 330 1’1’’ 430 1’5’’

Long Arm Working Range PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3 PC35MR-3 PC45MR-3 PC55MR-3

a Max. digging height mm ft.in. 3820 12’6’’ 4300 14’1’’ 4690 15’5’’ 5070 16’8’’ 5270 17’3’’ 5780 19’0’’ 6215 20’5’’

b Max.dumping height mm ft.in. 2815 9’3’’ 3020 9’11’’ 3390 11’1’’ 3580 11’9’’ 3790 12’5’’ 4060 13’4’’ 4495 14’9’’

c Max. digging depth mm ft.in. 2410 7’11’’ 2580 8’6’’ 2840 9’4’’ 3130 10’3’’ 3455 11’4’’ 3770 12’4’’ 4160 13’8’’

d Max. vertical digging depth mm ft.in. 2000 6’7’’ 2215 7’3’’ 2370 7’9’’ 2770 9’1’’ 3120 10’3’’ 3060 10’0’’ 3380 1’1’’

e Max. digging reach mm ft.in. 4270 14’0’’ 4500 14’9’’ 4930 16’2’’ 5390 17’8’’ 5640 18’6’’ 6130 20’1’’ 6570 21’7’’

Max. digging reach mm ft.in.

f 4190 13’9’’ 4350 14’3’’ 4840 15’11’’ 5215 17’1’’ 5520 18’1’’ 5980 19’7’’ 6430 21’1’’

at ground level mm ft.in.

Min. swing radius 1770 5’10’’ 1940 6’4’’ 2030 6’8’’ 2190 7’2’’ 2140 7’0’’ 2410 7’11’’ 2380 7’10’’

g mm ft.in.

(When boom swing) (1435 4’8’’) (1515 5’0’’) (1700 5’7’’) (1665 5’6’) (1710 5’7’) (1860 6’1’) (1840 6’0’)

h Max. blade lift mm ft.in. 280 11’’ 340 1’1’’ 360 1’2’’ 360 1’2’’ 360 1’2’’ 430 1’5’’ 430 1’5’’

i Max. blade depth mm ft.in. 255 10’’ 240 9.4’’ 310 1’0’’ 310 1’0’’ 390 1’13’’ 330 1’1’’ 330 1’5’’

10

LBSSP45300.indd 10 2/19/2016 10:15:55 AM

COMPACT HYDRAULIC EXCAVATOR

DIMENSIONS

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3 PC35MR-3 PC45MR-3 PC55MR-3

A Overall length mm ft.in. 3650 12’0’’ 3750 12’4’’ 4240 13’11’’ 4560 15’0’’ 4825 15’10’’ 5220 17’2’’ 5550 18’3’’

B Overall width mm ft.in. 1280 4’2’’ 1450 4’9’’ 1550 5’1’’ 1550 5’1’’ 1740 5’9’’ 1960 6’5’’ 1960 6’5’’

C Overall height mm ft.in. 2410 7’11’’ 2520 8’3’’ 2520 8’3’’ 2520 8’3’’ 2520 8’3’’ 2550 8’4’’ 2550 8’4’’

D Tail swing radius mm ft.in. 715 2’4’’ 805 2’8’’ 855 2’10’’ 855 2’10’’ 950 3’1’’ 1060 3’6’’ 1060 3’6’’

E Crawler length mm ft.in. 1555 5’1’’ 1880 6’2’’ 1950 6’5’’ 2105 6’11’’ 2105 6’11’’ 2520 8’3’’ 2520 8’3’’

F Track gauge mm ft.in. 1045 3’5’’ 1200 3’11’’ 1250 4’1’’ 1250 4’1’’ 1440 4’9’’ 1560 5’1’’ 1560 5’1’’

G Track shoe width mm in. 230 9’’ 250 9’8’’ 300 12’’ 300 12’’ 300 12’’ 400 16’’ 400 16’’

H/I Boom swing angle deg. LH70/RH50 LH75/RH50 LH85/RH50 LH80/RH50 LH75/RH55 LH85/RH50 LH70/RH50

J Bucket offset LH mm ft.in. 465 1’6’’ 510 1’8’’ 580 1’11’’ 580 1’11’’ 580 1’11’’ 630 2’1’’ 630 2’1’’

K Bucket offset RH mm ft.in. 255 2’7’’ 760 2’6’’ 845 1’0’’ 845 1’0’’ 770 1’13’’ 880 2’11’’ 880 2’11’’

LIFTING CAPACITY

Blade on Ground (With additional counterweight (X-weight) for PC18MR-3 and PC20MR-3)

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *355 *780 *355 *780

2m 6.5’ *310 *680 235 520 *315 *700 215 470

PC18MR-3

965mm 3’2’’ 1m 3.25’ *650 *1485 420 930 *365 *810 230 510 *320 *710 180 400

0m 0’ *805 *1780 395 870 *410 *900 220 480 *335 *740 185 410

-1m -3.25’ *635 *1400 400 880 *340 *750 245 540

1215mm 4’0’’ 0m 0’ *795 *1750 390 860 *400 *880 215 470 *300 *660 165 360

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *515 *1135 375 825

2m 6.5’ *525 *1155 310 685 *545 *1200 250 550

PC20MR-3

970mm 3’2’’ 1m 3.25’ *1310 *2885 550 1215 *685 *1510 295 650 *595 *1310 225 495

0m 0’ *1535 *3385 530 1170 *790 *1745 285 630 *655 *1445 240 530

-1m -3.25’ *1260 *2780 545 1200 *750 *1630 345 760

1320mm 4’4’’ 0m 0’ *1495 *3295 515 1135 *750 *1655 275 605 *555 *1220 195 430

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *650 *1430 425 940 *695 *1530 325 720

2m 6.5’ *1215 *2680 800 1760 *795 *1750 410 900 *705 *1550 250 550

PC27MR-3

1100mm 3’7’’ 1m 3.25’ *1065 *2350 385 850 *735 *1620 230 510

0m 0’ *2230 *4920 680 1500 *1185 *2610 370 820 *775 *1710 245 540

-1m -3.25’ *1820 *4010 695 1530 *1020 *2250 370 820 *810 *1790 315 690

1370mm 4’6’’ 0m 0’ *2305 *5080 660 1450 *1155 *2550 355 780 *695 *1530 295 450

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *795 *1750 435 960 *825 *1820 290 640

2m 6.5’ *1000 *2200 420 930 *825 *1820 225 500

PC30MR-3

1240mm 4’1’’ 1m 3.25’ *1320 *2910 385 850 *845 *1860 210 460

0m 0’ *2660 *5860 680 1500 *1440 *3170 365 800 *870 *1920 220 480

-1m -3.25’ *2140 *4720 695 1530 *1250 *2760 365 800 *880 *1940 275 610

1610mm 5’3’’ 0m 0’ *2820 *6220 670 1480 *1415 *3120 360 790 *780 *1720 185 410

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *705 *1550 680 1500 *690 *1520 385 850

2m 6.5’ *960 *2120 655 1440 *710 *1570 315 690

PC35MR-3

1370mm 4’6’’ 1m 3.25’ *1290 *2840 610 1350 *845 *1860 335 740

0m 0’ *2610 *5750 1100 2420 *1430 *3150 580 1280 *885 *1950 345 760

-1m -3.25’ *2245 *4950 1120 2470 *1325 *2920 580 1280 *920 *2030 415 910

1720mm 5’8’’ 0m 0’ *2735 *6030 1085 2390 *1390 *3060 675 1270 *720 *1590 275 610

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *990 *2180 *990 *2180 *1020 *2250 585 1290

2m 6.5’ *1530 *3370 1100 2430 *1060 *2340 500 1100

PC45MR-3

1375mm 4’6’’ 1m 3.25’ *2125 *4960 1025 2260 *1120 *2470 480 1060

0m 0’ *2345 *5170 995 2190 *1195 *2640 505 1110

-1m -3.25’ *3010 *6640 1965 *4330 *2195 *4840 995 2190 *1280 *2820 600 1320

1770mm 5’10’’ 0m 0’ *1250 *2760 *1250 *2760 *2275 *5020 980 2160 *1045 *2300 430 950

2m 6.5’ 3m 10’ Maximum

Arm Length

Front Side Front Side Front Side

3m 10’ *850 *1870 500 1100

2m 6.5’ *1435 *3160 1140 2510 *885 *1950 440 970

PC55MR-3

1640mm 5’5’’ 1m 3.25’ *2030 *4480 1045 2300 *930 *2050 420 930

0m 0’ *2260 *4980 1005 2220 *985 *2170 435 960

-1m -3.25’ *2790 *6150 1960 *4320 *2170 *4780 1000 2209 *1050 *2320 500 1100

2000mm 6’7’’ 0m 0’ *1285 *2830 *1285 *2830 *2205 *4860 1010 2230 *895 *1970 390 860

11

LBSSP45300.indd 11 2/19/2016 10:15:57 AM

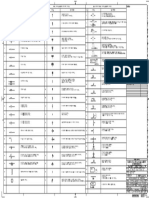

STANDARD/OPTIONAL EQUIPMENT

PC18MR-3 PC20MR-3 PC27MR-3 PC30MR-3 PC35MR-3 PC45MR-3 PC55MR-3

Arm

STD arm with aux.piping

PC18MR: 965mm 3’2’’ PC20MR: 970mm 3’2’’

PC27MR: 1100mm 3’7’’ PC30MR: 1240mm 4’1’’

PC35MR: 1370mm 4’6’’ PC45MR: 1375mm 4’6’’

PC55MR: 1640mm 5’5’’

Long arm with aux.piping

PC18MR: 1215mm 4’0’’ PC20MR: 1320mm 4’4’’

PC27MR: 1410mm 4’8’’ PC30MR: 1610mm 5’3’’

PC35MR: 1720mm 5’8’’ PC45MR: 1770mm 5’10’’

PC55MR: 2000mm 6’7’’

STD arm without aux.piping

Long arm without aux.piping

Bucket capacity Bucket width (Incl.side cutters)

0.022m3 0.029yd3 250mm 10” (300mm 12”)

0.033m3 0.043yd3 250mm 10” (320mm 13”)

0.035m3 0.046yd3 250mm 10” (320mm 13”)

0.04m3 0.052yd3 350mm 14” (400mm 16”)

0.044m3 0.058yd3 280mm 11” (350mm 14”)

0.044m3 0.058yd3 350mm 14” (420mm 17”)

0.044m3 0.058yd3 400mm 16” (450mm 18”)

0.055m3 0.072yd3 300mm 12” (370mm 14”)

0.055m3 0.072yd3 350mm 14” (420mm 17”)

0.066m3 0.086yd3 430mm 17” (500mm 20”)

0.08m3 0.10yd3 430mm 17” (500mm 20”)

0.08m3 0.10yd3 530mm 21” (600mm 24”)

0.09m3 0.12yd3 430mm 17” (500mm 20”)

0.09m3 0.12yd3 530mm 21” (600mm 24”)

0.11m3 0.14yd3 430mm 17” (500mm 20”)

0.11m3 0.14yd3 530mm 21” (600mm 24”)

0.13m3 0.17yd3 630mm 25” (700mm 28”)

0.14m3 0.18yd3 535mm 21” (600mm 24”)

0.16m3 0.21yd3 585mm 23” (650mm 26”)

Track shoes

230mm 9” rubber shoe

250mm 10” rubber shoe

300mm 12” rubber shoe

400mm 16” rubber shoe

230mm 9” steel shoe

250mm 10” steel shoe

300mm 12” steel shoe

400mm 16” steel shoe

230mm 9” steel shoe with rubber pad

250mm 10” steel shoe with rubber pad

300mm 12” steel shoe with rubber pad

400mm 16” steel shoe with rubber pad

300mm 12” road liner

400mm 16” road liner

Blade

Expandable blade aseembly

Blade assembly

Blade assembly with B.O.C

Power angle blade

Others

Standard Equipment Optional Equipment

• Air cleaner, double element • Steering pedals • Additional working light] • Suspension seat, reclining with wrist rests

• Automatic two-speed travel • Rigid seat, reclining with wrist rests • Air conditioner (For cab) • ROPS & top guard cab with heater, front window

• Rear view mirrors, RH and LH • Travel alarm (Not available for PC18MR-3 and PC20MR-3) washer/wiper, cup holder and ashtray

• Seat belt, 78mm 3” width • Two-post ROPS & top guard canopy • Cigarette lighter (For cab) (Not available for PC18MR-3)

• Pattern change valve (ISO- Backhoe) • Seat belt, 50mm 2” width

(ISO control pattern (ISO 10968))

• Radiator net • Radio (For cab)

B.O.C : Bolt-On Cutting edge

Printed in Indonesia 03-2016

LISSP45300

is a trademark of Komatsu Ltd.Japan

LBSSP45300.indd 12 2/19/2016 10:15:58 AM

S-ar putea să vă placă și

- Installation, Maintenance and User Manual For Fm200 Fire Extinguishing SystemsDocument175 paginiInstallation, Maintenance and User Manual For Fm200 Fire Extinguishing Systemsozer100% (1)

- QRF PC78UU-6 LowResDocument2 paginiQRF PC78UU-6 LowResRalf Maurer0% (1)

- 2018 - sh235x 6 t3Document10 pagini2018 - sh235x 6 t3Ralf MaurerÎncă nu există evaluări

- Hitachi EXC5 Operators Manual - oDocument252 paginiHitachi EXC5 Operators Manual - ofahim100% (1)

- SY35 Vs Competition - V2Document4 paginiSY35 Vs Competition - V2Raj Kumar V RÎncă nu există evaluări

- Pneumatic Bench Vice Project-Report PDFDocument30 paginiPneumatic Bench Vice Project-Report PDFrahul bhatt100% (4)

- PC18 55MR 3 - Cen00374 04Document12 paginiPC18 55MR 3 - Cen00374 04SabahÎncă nu există evaluări

- Pc138us-2 - Uess005701 - 0601 - Eng 1Document20 paginiPc138us-2 - Uess005701 - 0601 - Eng 1LU YO100% (2)

- PC18 20 27 30 35 45 55MR-3Document7 paginiPC18 20 27 30 35 45 55MR-3Paloma SmithÎncă nu există evaluări

- ATS - Komatsu PC78US-6Document2 paginiATS - Komatsu PC78US-6Gilnad WilsonÎncă nu există evaluări

- 329d Pump3Document2 pagini329d Pump3hydeer 13100% (1)

- Spek ZX350Document2 paginiSpek ZX350Sigit Adi P100% (1)

- PC350 8 - PC350LC 8 - Cen00222 03 PDFDocument8 paginiPC350 8 - PC350LC 8 - Cen00222 03 PDFLU YOÎncă nu există evaluări

- Sk70sr-2 Shop ManualDocument946 paginiSk70sr-2 Shop ManualHuy Tran100% (1)

- Road Roller Sakai SW880 Maint Serv MNLDocument95 paginiRoad Roller Sakai SW880 Maint Serv MNLGarick ParialpalacioÎncă nu există evaluări

- H Pump PC 100-5Document13 paginiH Pump PC 100-5eka sukandaÎncă nu există evaluări

- SH130-6 Hydraulic ExcavatorDocument14 paginiSH130-6 Hydraulic ExcavatorInhar Suwandi100% (1)

- PC45MR 3Document12 paginiPC45MR 3LU YOÎncă nu există evaluări

- Hyundai.R110 7.SMDocument496 paginiHyundai.R110 7.SMDennis aÎncă nu există evaluări

- Ebook - Komatsu Pw140-7 Shop Manual1-Đã M KhóaDocument1.144 paginiEbook - Komatsu Pw140-7 Shop Manual1-Đã M KhóaLâm Trần ngọcÎncă nu există evaluări

- Ex450lc 5Document7 paginiEx450lc 5anon_485665212100% (1)

- Operational Performance Test: Section 4Document66 paginiOperational Performance Test: Section 4Tú Xuân Lương100% (1)

- Bomag BW211-40Document1 paginăBomag BW211-40Felipe MenesesÎncă nu există evaluări

- Produksi AgustusDocument18 paginiProduksi AgustusnoviÎncă nu există evaluări

- HG Kawasaki K3VL Parts Catalog WebDocument17 paginiHG Kawasaki K3VL Parts Catalog WebPartagon PowÎncă nu există evaluări

- Salient Features:: Crawler DozerDocument4 paginiSalient Features:: Crawler DozerAnsh MishraÎncă nu există evaluări

- Standard Equipment: Hydraulic ExcavatorsDocument8 paginiStandard Equipment: Hydraulic Excavatorsvitor santos100% (1)

- Lx70 ManualDocument23 paginiLx70 Manualsrabani dashÎncă nu există evaluări

- Demo pc210lc-10Document30 paginiDemo pc210lc-10dani100% (1)

- ZOOMLION+ZE75E 10+Crawler+ExcavatorDocument2 paginiZOOMLION+ZE75E 10+Crawler+ExcavatorAlfa anag bangsawanÎncă nu există evaluări

- PC78UU 10 (v9) PDFDocument16 paginiPC78UU 10 (v9) PDFpurnomoÎncă nu există evaluări

- PC55MR3 SM ExDocument3 paginiPC55MR3 SM Exkeingar0% (1)

- Capacities For Refrigerant (Medium Wheel Loaders)Document15 paginiCapacities For Refrigerant (Medium Wheel Loaders)Susanth SukumaranÎncă nu există evaluări

- Bomba Rexroth A10v0 PDFDocument36 paginiBomba Rexroth A10v0 PDFMauricio GonzalezÎncă nu există evaluări

- Stock Valuation Report: Stock Code Description Model No Packing Group Brand UOM Qty. Cost Currency MMKDocument522 paginiStock Valuation Report: Stock Code Description Model No Packing Group Brand UOM Qty. Cost Currency MMK张宇轩Încă nu există evaluări

- Website Catalog PUMPS v2Document14 paginiWebsite Catalog PUMPS v2Wong DaÎncă nu există evaluări

- Hydraulic Parts: Supplier Name: Address: Contact: Telephone: Mobile Phone: ShowroomDocument9 paginiHydraulic Parts: Supplier Name: Address: Contact: Telephone: Mobile Phone: ShowroomTomislav1998Încă nu există evaluări

- PC400 8 - PC400LC 8 - Cen00223 03 PDFDocument24 paginiPC400 8 - PC400LC 8 - Cen00223 03 PDFhendra hardyÎncă nu există evaluări

- Excavator PC210 8Document24 paginiExcavator PC210 8Bálint Géza100% (2)

- SK380XDLC 10Document8 paginiSK380XDLC 10Bilal VURALÎncă nu există evaluări

- Pc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line R.H.) (Blade)Document1 paginăPc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line R.H.) (Blade)februÎncă nu există evaluări

- Track Adjuster - Other Makes: Part No. Brand ApplicationsDocument3 paginiTrack Adjuster - Other Makes: Part No. Brand ApplicationsNizar BrahamÎncă nu există evaluări

- Sk75sr 3e EuDocument8 paginiSk75sr 3e EuPHÁT NGUYỄN THẾÎncă nu există evaluări

- PC35Document488 paginiPC35duker zhouÎncă nu există evaluări

- SH210-6 BrochureDocument14 paginiSH210-6 Brochureapray aprayÎncă nu există evaluări

- Work Equipment PC200-7Document4 paginiWork Equipment PC200-7Ryan Abubakar Obili PakayaÎncă nu există evaluări

- PC600-8 Gen00043-02 PDFDocument117 paginiPC600-8 Gen00043-02 PDFWill Front100% (1)

- 1 Manual JjibDocument8 pagini1 Manual JjibNurulÎncă nu există evaluări

- 1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Document14 pagini1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Irwan Firmansyah100% (2)

- PC78US-8 Structure, Function and Maintenance StandardDocument238 paginiPC78US-8 Structure, Function and Maintenance StandarddatphuongÎncă nu există evaluări

- DX190W HydrDocument1 paginăDX190W HydrJuan Pablo Leon RualesÎncă nu există evaluări

- Part Book PC130F-7 Engine PDFDocument46 paginiPart Book PC130F-7 Engine PDFChimanÎncă nu există evaluări

- PC200 PC200LC: Gross: 110 KW 147 HP / 2000 Min Net: 103 KW 138 HP / 2000 MinDocument8 paginiPC200 PC200LC: Gross: 110 KW 147 HP / 2000 Min Net: 103 KW 138 HP / 2000 MinTeguhwidi YantoÎncă nu există evaluări

- SV521Series Operator ManualDocument96 paginiSV521Series Operator ManualOggy ToffyÎncă nu există evaluări

- Motor 114 PDFDocument442 paginiMotor 114 PDFEduard Gutierrez100% (1)

- Cead 000201Document216 paginiCead 000201Rodrigo GeistÎncă nu există evaluări

- Pc28uu-2 S - N 7001-Up Boom - Pin and RodDocument2 paginiPc28uu-2 S - N 7001-Up Boom - Pin and RodEUROPARTSÎncă nu există evaluări

- CAT - Excavadora - Orugas - 320D-320D L With C6.6 Engine - English - 2012 PDFDocument24 paginiCAT - Excavadora - Orugas - 320D-320D L With C6.6 Engine - English - 2012 PDFTcristomoradoÎncă nu există evaluări

- PC 18 MRDocument12 paginiPC 18 MRbudimir2310Încă nu există evaluări

- PC18MR PC20MR PC27MR PC30MR PC35MR PC45MR PC55MRDocument7 paginiPC18MR PC20MR PC27MR PC30MR PC35MR PC45MR PC55MRJimmy CordovaÎncă nu există evaluări

- PC300HD-7 Aess653-00Document6 paginiPC300HD-7 Aess653-00rmajdi2000100% (1)

- PC600/600LC PC600/600LC: - 8R1 Backhoe - 8R1 Loading ShovelDocument20 paginiPC600/600LC PC600/600LC: - 8R1 Backhoe - 8R1 Loading ShovelSabahÎncă nu există evaluări

- Pneutrainer 200Document36 paginiPneutrainer 200Faus1214Încă nu există evaluări

- Spraymec MF 050 VC 100068557 PDFDocument10 paginiSpraymec MF 050 VC 100068557 PDFAlfred UBOKOÎncă nu există evaluări

- EasiHeat - FolderDocument12 paginiEasiHeat - FolderWilianCarraÎncă nu există evaluări

- Torque Ratings - G-Series (Pneumatic) : Spring-Return ActuatorsDocument54 paginiTorque Ratings - G-Series (Pneumatic) : Spring-Return ActuatorsYuri Soverika SitepuÎncă nu există evaluări

- HKS (M-Da-H-F10 200 360º) Manual de PartesDocument17 paginiHKS (M-Da-H-F10 200 360º) Manual de Partescesar franz napaico perezÎncă nu există evaluări

- Proportional Valve: Parts ManualDocument48 paginiProportional Valve: Parts ManualDorian Cristian Vatavu0% (1)

- Learning Instrumentation and Control Engineering PDFDocument3 paginiLearning Instrumentation and Control Engineering PDFAli Raza KaisraniÎncă nu există evaluări

- Saudi Arabian Oil Company: NotesDocument1 paginăSaudi Arabian Oil Company: NotesWael ChouchaniÎncă nu există evaluări

- Control Valves PDFDocument69 paginiControl Valves PDFadel100% (2)

- Architecture of Industrial Automation Systems: Unit-1 ECE361Document20 paginiArchitecture of Industrial Automation Systems: Unit-1 ECE361anuj jainÎncă nu există evaluări

- Aktuator Diapraghm Fisher 30i-70iDocument12 paginiAktuator Diapraghm Fisher 30i-70iUntoro Adi NugrohoÎncă nu există evaluări

- Etronic Failuretree Iveco V623Document132 paginiEtronic Failuretree Iveco V623Dario MartinezÎncă nu există evaluări

- Badger Range Guard Wet Chemical Cylinder Assemblies: FeaturesDocument4 paginiBadger Range Guard Wet Chemical Cylinder Assemblies: FeaturesLee WenjianÎncă nu există evaluări

- The Very Latest Drive Technology For The World of TomorrowDocument24 paginiThe Very Latest Drive Technology For The World of TomorrowZuyeffÎncă nu există evaluări

- 03 WellDynamicsDocument54 pagini03 WellDynamicsjpolk1Încă nu există evaluări

- Pneumatic: Participant ManualDocument95 paginiPneumatic: Participant ManualMuhammad Idris SazaliÎncă nu există evaluări

- Coool Hydraulic System Design ThesisDocument235 paginiCoool Hydraulic System Design ThesisGirish Kasturi100% (1)

- Metric Industrial Polyethylene SpecificationDocument6 paginiMetric Industrial Polyethylene SpecificationAdiedh RahmanÎncă nu există evaluări

- Fuel System C7 and C9 - Caterpillar Electronic Engine - Blog - TeknisiDocument19 paginiFuel System C7 and C9 - Caterpillar Electronic Engine - Blog - TeknisiAllan LariosaÎncă nu există evaluări

- Selection Control ValvesDocument7 paginiSelection Control ValvesVeera Mani100% (1)

- Manual de Instalacion KameleonDocument33 paginiManual de Instalacion Kameleonlectomano1975Încă nu există evaluări

- Mico Master Cylindro IIDocument22 paginiMico Master Cylindro IICAR6Încă nu există evaluări

- Introduction To Robotics & Work CellsDocument20 paginiIntroduction To Robotics & Work Cellsb7663664Încă nu există evaluări

- annotated-LBYME4B EF2 Group204 Pneumatics1Document11 paginiannotated-LBYME4B EF2 Group204 Pneumatics1catalan153709Încă nu există evaluări

- A Review of Electromechanical Actuators For More/All Electric Aircraft SystemsDocument24 paginiA Review of Electromechanical Actuators For More/All Electric Aircraft SystemsCrateFXÎncă nu există evaluări

- Motion - Kinetix Selection GuideDocument170 paginiMotion - Kinetix Selection GuideNicolás A. SelvaggioÎncă nu există evaluări

- Chapter 4 - Vibration Assisted MillingDocument35 paginiChapter 4 - Vibration Assisted MillingHimanshu BisariaÎncă nu există evaluări

- Flight Control Actuation Technology For Next-Generation All-Electric AircraftDocument14 paginiFlight Control Actuation Technology For Next-Generation All-Electric AircraftwalterÎncă nu există evaluări