Documente Academic

Documente Profesional

Documente Cultură

Internship Report RAK

Încărcat de

AnithaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Internship Report RAK

Încărcat de

AnithaDrepturi de autor:

Formate disponibile

Internship Report 2019-20

INTRODUCTION

An internship is a period of work experience offered by an organisation for a specific period of

time. Once confined to engineering graduates, the term is now used for a wide range of

placements in business, non-profit organizations and government agencies. They are typically

undertaken by students and graduates looking to gain relevant skills and experience in a

particular field. Employers benefit from these placements because they often recruit employees

from their best interns, who have known capabilities, thus saving time and money in the long

run.

Internships for professional careers are similar in some ways, but not as rigorous as

apprenticeships for professions, trade and vocational jobs. The lack of standardization and

oversight leaves the term “internship” open to broad interpretation. Interns may be high school

students, college and university students or post-graduate adults.

Typically, an internship consists of an exchange of services for experience between the intern

and the organization. Internships are used to determine if the intern still has an interest in that

field after the real-life experience. In addition, an internship can be used to create a professional

network that can assist with letters of recommendation or lead to future employment

opportunities. The benefit of bringing an intern into full-time employment is that they are already

familiar with the company, their position and they typically need little to no training. Internships

provide current college students the ability to participate in a field of their choice to receive

hands on learning about a particular future career, preparing them for full-time work following

graduation.

Department of Civil Engineering GEC, Kushalnagar Page 1

Internship Report 2019-20

COMPANY PROFILE

Raksha Engineers began as a general works contractor in 2010. Over the years, the group as

undertaken many challenging projects and accumulated skills, know-how and experiences in

design and build solutions, project management services, building trades and related engineering

works.

Today, Raksha Engineers take the role of main contractor for small to medium size projects and

performs project management services to coordinates specialist trades for residential or

commercial projects. We also provide design inputs and engineering solutions as value-add

services to our clients.

Our objective is to provide our clients with an “I am assured” experience when we are chosen to

execute their projects. Our emphasis on clear communication and follow through procedures

ensures that client’s objectives are top priority in the planning and execution of all our processes.

Our project management and execution philosophy is:

Create detail schedule and resources plan to meet client’s project objective.

Communicate clearly with all project stakeholders.

Track project progress and fine-tune deviations.

Supervise closely on quality of work done.

Complete the project on time.

Our Vision:

To be a respectable building contractor delivering beyond expectation, always.

Our Mission:

To procure projects at competitive pricing, provide safe working conditions and deliver quality

work within reasonable time frame.

Department of Civil Engineering GEC, Kushalnagar Page 2

Internship Report 2019-20

CHAPTER-1

SITE-1: CONSTRUCTION OF COMMERCIAL BUILDING AT BOGADI,

MYSURU

Table 1: Project description

Name of the site Commercial building at Bogadi 2nd stage

Mysore

Construction company Raksha Engineers

Ramakrishna Nagar Mysore

Type of the infrastructure Commercial Building

Total area of site 4000sq.ft

Total budget of the project 3 Crore

Fig.1.1: Bogadi Site

1.1 Reading and Interpreting Drawings

Department of Civil Engineering GEC, Kushalnagar Page 3

Internship Report 2019-20

Drawings are the means by which the designer conveys the physical, quantitative and

visual description of the project to the contractor. The drawings are a two-dimensional

representation of the physical structure that meets the objectives of the owner. They are also

known as plans or blueprints.

Drawings at the construction site include:

1. Architectural drawing

2. Structural drawing

3. Sanitary drawing

4. Electrical and installation drawing.

. The basic rules in reading a drawing involve:

Read the cover sheet which contains the project name, the architect’s name, address

and contact information, project location and date.

Go through the index of plan sheets and their contents, abbreviation key, a scale bar

with and plan scale indicated.

Understand the architectural sheets that will be numbered in the approximate order of

construction.

Civil engineering drawings (C) include plot or site plans, utilities, grading, and

landscape details.

Structural drawings (S) include foundation, structural steel, building support system,

and roof framing system along with sections and details.

Architectural drawings (A) include floor plans, elevations, building sections, door and

window schedules, and room finishes. The floor plan is an important drawing because

it provides the most important information and acts as a reference for the location of

additional sections and details. The floor plan shows floor finishes, walls, doors,

stairways, fire places, built‐ in cabinets and mechanical equipment. Elevations are

views of the exterior features of the building.

The Electrical drawings (E) include the electrical wiring, lighting plan etc.

Department of Civil Engineering GEC, Kushalnagar Page 4

Internship Report 2019-20

Department of Civil Engineering GEC, Kushalnagar Page 5

Internship Report 2019-20

Department of Civil Engineering GEC, Kushalnagar Page 6

Internship Report 2019-20

SAFETY PRECAUTIONS AT THE SITE

Department of Civil Engineering GEC, Kushalnagar Page 7

Internship Report 2019-20

Safety of all the people at the site is of at most importance to company. Hence, each person

entering the site will be briefed about the safety request and preventive measure to be taken for

safe and efficient operation.

And social accountability.

Providing and ensuring safety for people lives, environment, property, machinery and

equipment, products and services.

Provisions of necessary information, awareness and training to all the employees.

Prevention of Environment, Health, Safety, Incidents, Injury and ill health through pro-

active measure like contractors in order in order to carry out their task in a safe and

responsible manner. Periodic assessments and audits, organize health check for

employees.

Avoid engaging child labour, forced and compulsory labour, discrimination and follow

the practice of freedom of association and right to collective.

Fig.1.6 Safety precautions at site for labours

INTERNSHIP ACTIVITIES

Department of Civil Engineering GEC, Kushalnagar Page 8

Internship Report 2019-20

Site work

In this section of my report, I will try to describe activities and practices that were done in my

hosting company during my internship time I was able to see the practical works starting from

excavation to some superstructure working. I used to observe all the methods of working as well

as participate in all the activities that have done in the site to achieve my task and to find out the

practical knowledge. I will try to describe the activities in my intern time into two parts:

Substructure working and

Superstructure working

Substructure works

Substructure is a part of the building located below the ground level. By the time I arrived at the

site, the setting out had already been completed. Different works had been carried out, these

works include in this sub topic. Firstly, preparation of the project site is done. This is the first

stage in construction work and then further works like as follows are carried on.

Earthwork excavation

Excavation is the first and major activity of the construction project. Excavation is done

to required depth such that hard strata are available to bear the load from structure.

First and foremost work in excavation work is marking, the location and width of footing

or excavation is marked in site as shown in figure as per in the column drawing provided

by designer.

Marking can be done either by using survey equipments or manually by knowing the

distance between the footings using tape.

Equipment generally used for excavation is necessary excavation is done with man

power.

The depth of foundation that would excavated in our internship site is 1.5m for isolated

footing.

Chemical is sprayed on surface of excavated ground to prevent the attack of termites.

Foundation

Department of Civil Engineering GEC, Kushalnagar Page 9

Internship Report 2019-20

Foundation is the lowest part of the structure which transmits the load of the

structure, together with the effect of live loads and pressure, to the material on which the

structure rest, soil strata, in such manner that the underlying material is not stressed beyond its

safe bearing capacity . Generally, the foundation is placed below the ground level to increase the

stability of a structure or building. Thus the objective of providing foundations may be outlined

as follows

To distribute and transmit the total load coming on the structure or building to a large

area of underlying support.

To prevent excessive settlement and differential settlement of the structure

To provide stability to the structures against many disturbing dynamic forces, i.e., wind,

rain, earth quake, etc.

The type of structure and the nature of the underlying soil are two main governing factors in

selection of the material and type of foundation. In our site the foundation type consist of

isolated footings and the material used for construction of this foundation is reinforced concrete.

Fig.1.7 Footing marking

Department of Civil Engineering GEC, Kushalnagar Page 10

Internship Report 2019-20

1.2 FOOTING REINFORCEMENT

Fig.1.8 Footing Reinforcement

Footing shall be designed to sustain the applied loads, moments and forces and the induced

reactions and to ensure that any settlement which may occur shall be as nearly uniform as

possible. Size is calculated based on the load on the column and safe bearing capacity of soil.

Here SBC of soil is 200KN/m2

In this isolated square footing, reinforcement in each direction is distributed uniformly

across the full width of the footing.

PPC was laid on the ground before the reinforcement for footing mat. This was provided

to give a firm solid base for footing. PCC of grade M15 (1:4:8) thickness of 6 inches was

laid.

Concrete cover blocks were used to provide clear cover of 40mm

to the reinforcement.

A cover block is essentially a spacer that is used to lift the rebar

matrix off the ground so that the concrete may flow underneath the

rebar and also, to protect the steel reinforcement bars from

environmental effects to prevent the corrosion.

Department of Civil Engineering GEC, Kushalnagar Page 11

Internship Report 2019-20

Fig.1.9 Cover block

1.3 COLUMN REINFORCEMENT

Fig.1.10 Column reinforcement

RCC column is a vertical structural member which transfers superimposed loads from beam and

slab directly to the footing.

When marking of column location is done, the reinforcement of columns are placed according to

the structural drawing. The reinforcement of the column, to be built above the footing was tied to

footing reinforcement using binding wires. Initially a master ring was laid and tied to the footing

mat using the binding wires. Verticality was checked using the plumb bob.

Longitudinal reinforcement

Minimum area of cross-section of longitudinal reinforcement bars must be at least 0.8%

of the gross section area of the column.

Maximum area of cross-section of longitudinal reinforcement bars must not exceed 6% of

the gross section area of the column.

The bars should not be less than 12mm in diameter.

Department of Civil Engineering GEC, Kushalnagar Page 12

Internship Report 2019-20

Minimum number of longitudinal bars must be four in rectangular column and six in

circular column.

Spacing of longitudinal bars measures along the periphery of a column should not exceed

300mm.

Transverse Reinforcement

It may be in the form of lateral ties or spirals.

The diameter of the lateral ties should not be less than 1/4th of the diameter of the largest

longitudinal bar.

6mm.

Pitch of Lateral Ties

The least lateral dimension of the compression members.

Sixteen times the smallest diameter of longitudinal bars

300mm

48 times diameter of lateral ties.

1.3 SHUTTERING

Fig.1.11 Footing shuttering Fig.1.12 Column shuttering

Footing Shuttering:

Department of Civil Engineering GEC, Kushalnagar Page 13

Internship Report 2019-20

Formwork (shuttering) is a temporary mould to provide support to fresh concrete when placed in

structural member until the concrete has set. Formwork size and shape depends on the type and

dimension of the footing.

For example: Footing size of 1.5mx1.5m and depth of 1.3m.

=1.5 x 1.3

=1.950m2

Four sides area = 4 x 1.950

= 7.80m2

Column Shuttering:

Formwork for column is done after tieing the reinforcements. The type of Formwork used for

columns is partial shuttering. In this type, four different plates of shuttering is arranged in proper

manner with the help of clamps and Tie rods.

Procedure

Initially clean the plywood members and apply oil to them.

Based on the starter concrete the plywood members should be placed.

Proper bracing at equal intervals should be done. So, that the members are stiff and hold

together.

At last in order to prevent the sway of the columns proper support should be given on all

sides of the formwork.

Checks Should Be Made Are

The formwork should be well placed and firm i.e. no movement should be there.

The shuttering should satisfy the plumb.

The diagonals should be equal for the column formwork.

Department of Civil Engineering GEC, Kushalnagar Page 14

Internship Report 2019-20

Department of Civil Engineering GEC, Kushalnagar Page 15

Internship Report 2019-20

CONCRETE CASTING:

Concrete was placed in its final position well before initial setting time, so as to leave sufficient

time for proper compaction. Concrete from the RMC was unloaded from transit mixer on to the

receiving platform and if any visible segregation of concrete was remixed manually by spade &

shovel before placement. The concrete was then pumped into the footing shuttering.

Fig.1.13 Concrete from RMC mixer

Before laying any subsequent layer of concrete, the previous layer was fully compacted using

needle vibrator. The vibrations cause the mixture to liquefy, reducing the internal friction of the

mix components of cement, aggregate, and water. This allows the mix to move around more

easily. This helps to ensure that enough concrete gets into every little nook and cranny and

eliminate voids. Furthermore, the vibrations and liquefaction help to allow air bubbles to escape.

Fig.1.15.Concrete pouring and vibrating

Department of Civil Engineering GEC, Kushalnagar Page 16

Internship Report 2019-20

3.7 COLUMN STARTER

A starter for a column is the lowest part of a column, which is cast before the casting of the

whole column. It has same width and length of column section and relatively smaller height of

around 50 mm as shown in Fig.1.16.This starter helps mainly to adjust the form work of a

column vertically and ultimately sufficiently gap is remained between column reinforcement and

shuttering.

The advantages of having a starter are:

1. It is easier to establish & verify the center line of the starter than that of the column.

2. It is easier to fix the column shuttering if the starter is already in place.

3. The chances of column formwork becoming skew are eliminated.

Fig.1.16. Column Starter

COLUMN CONCRETING:

Concreting of RCC column should start from the centre of vertical bars and go towards the ends.

After placement of sufficient quantity, concrete should be vibrated at regular intervals so that the

concrete spreads evenly on all sides.

Over vibration of concrete should be avoided. Over vibration of concrete leads to segregation of

coarse aggregate which settles at the bottom making the mix weak. If the concreting has to be

stopped for the day, all upper surface of column should be made rough by wire brush after initial

setting of concrete for joints with later pour of concrete.

Department of Civil Engineering GEC, Kushalnagar Page 17

Internship Report 2019-20

DE- SHUTTERING:

After the concrete has attained the required strength; the reinforcements are removed from

the hardened concrete for the next items of work to be conducted such as chiseling and plastering

works. Slab and beam formworks are removed after the 21st day while column formworks are

removed after twenty four hours. When removing formworks great attention is given for safe

removal of formwork components as they are reused again. Most of the time; formwork

components are disconnected when preparing formwork for the next floor above the existing one

since the members have similar dimensions and hence are easy to use. Another activity

conducted following the demolishing of formworks is chiseling work which is pre requisite for

the plastering work. Chiseling works are conducted sub contract workers who perform these

activities after form work removal. They use hand tools to chisel the surfaces of structural

members such as slab ceilings, beams and columns. The following steps were used in formwork

removal (de-shuttering) and chiseling work.

First; the vertically supporting formwork members are removed.

The horizontal members together with the beam formworks are removed giving attention

to minimize occurrence of accidents.

The top formwork material is then taken down by ensuring they are removed safely

without deformation and breaks.

After the formwork is taken away; chiselers will start their activity by separating their

specific tasks and identifying structural components to be chiseled.

CURING:

Curing shall start 24hrs after finishing the de-shuttering. Curing shall be continued depending on

the temperature. In case of normal temperature curing shall be done for 7 days. In case moderate

temperature curing should be done for 10 days. In case of high temperature curing should be

done for 15 days.

Department of Civil Engineering GEC, Kushalnagar Page 18

Internship Report 2019-20

FORMWORK FOR BEAM AND SLAB:

Formwork for reinforced concrete slabs depends on the type of slabs to be constructed. The slabs

can be structural slabs supported on a steel or concrete structural frame.

Formwork should be strong enough to resist the pressure or the weight of fresh concrete

plus any constructional live loads.

Rigid enough to retain the shape without undue deformation.

Economical in terms of the total cost of the forms and the concrete surface finishing

when required.

Sufficiently watertight to avoid leakage at the joints.

Formwork materials:

1. Timber.

2. Metals.

3. Plastics.

Fig.1.17 Formwork for slab and beams

Department of Civil Engineering GEC, Kushalnagar Page 19

Internship Report 2019-20

SLAB AND BEAM REINFORCEMENT:

The reinforcement work for the slab, beam and mechanical, electrical, plumbing

works are carried simultaneously.

Proper cover should be maintained for the slab bottom and sides.

The electrical pipe lines should be laid as per the drawings by the MEP

department.

Where ever the reinforcement crosses one over another it should be tied with the

binding wire of 18 gauge.

Chairs:

Chairs in RCC structures are provided to ensure the correct spacing between the top mat

and bottom mat of the reinforcement during placing of concrete, as per the bar bending schedule/

reinforcement plans.

Department of Civil Engineering GEC, Kushalnagar Page 20

Internship Report 2019-20

CHAPTER-2

BAR BENDING SCHEDULE

Bar bending schedule, commonly referred as BBS is a comprehensive list that describes the type,

size, length, number and bending details of each bar in a reinforcement drawing of a structure.

This process of listing the type, size, length and number of bar is called “Scheduling”. This leads

to an estimation of the quantity of steel, which translates the cost requirements for steel work.

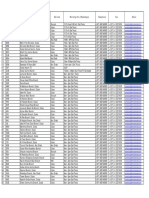

Sl.No Description Dia(mm) Numbers Number Cutting Total length of Total

of rods length rod in metre weight

1 Footing

F1(x-x) 12 4 15 2.13 145.80 129.470

F1(y-y) 12 4 15 2.13 145.80 129.470

F2(x-x) 12 6 16 2.28 249.60 221.645

F2(y-y) 12 6 16 2.28 249.60 221.645

F3(x-x) 12 2 18 2.6 104.40 92.707

F3(y-y) 12 2 18 2.6 104.40 92.707

2 Column

C1 20 3 2 5.50 33 81.51

20 3 2 6.50 39 96.33

16 3 2 5.50 33 52.14

16 3 2 6.50 39 61.62

Lateral ties 8 3 28 0.98 82.32 32.516

8 3 28 0.98 82.32 32.516

Master ring 8 3 4 1.42 17.04 6.7308

C2 20 1 2 5.50 11 27.17

20 1 2 6.50 13 32.11

16 1 2 5.50 11 17.38

16 1 2 6.50 13 20.54

Lateral ties 8 1 28 0.98 27.44 10.8388

8 1 28 0.98 27.44 10.8388

Master ring 8 1 4 1.42 5.68 2.2436

C3 25 1 2 5.50 11 42.46

25 1 2 6.50 13 50.18

20 1 2 5.50 11 27.17

20 1 2 6.50 13 32.11

Lateral ties 10 1 28 0.98 27.44 16.930

10 1 28 0.98 27.44 16.930

Master ring 8 1 4 1.42 5.68 2.243

Department of Civil Engineering GEC, Kushalnagar Page 21

Internship Report 2019-20

C4 25 1 2 5.50 11 42.46

25 1 2 6.50 13 50.18

20 1 2 5.50 11 27.17

20 1 2 6.50 13 32.11

Lateral ties 10 1 28 0.98 27.44 16.930

10 1 28 0.98 27.44 16.930

Master ring 8 1 4 1.42 5.68 2.243

C5 25 4 2 5.50 44 169.84

25 4 2 6.50 52 200.72

20 4 2 5.50 44 108.68

20 4 2 6.50 52 128.44

Lateral ties 10 4 28 0.98 109.76 67.72

10 4 28 0.98 109.76 67.72

Master ring 8 4 4 1.42 22.72 8.9744

CHAPTER 3

ESTIMATION AND COSTING

For all engineering works it is required to know beforehand the probable cost of construction

known as the estimated cost. In preparing an estimate, the quantities of different items of works

are calculated and cost of quantities are calculated. The rates in estimate provide for the complete

work, which consists of the cost of materials, cost of transport, cost of labours, cost of

scaffolding, cost of tools and plants, cost of water, taxes, reasonable profit of contractor etc..

Example:

Department of Civil Engineering GEC, Kushalnagar Page 22

Internship Report 2019-20

Centre line: (Wall thickness=0.3m)

CL (x-x) = 0.3/2 + 2.28 + 0.125 + 1.2 + 0.3 +1.2 + 0.125 + 2.28 + 0.3/2

= 7.8m

= 7.8 * 2 = 15.6m

CL(y-y) = 0.3/2 + 3.65 + 0.3/2

= 3.95 * 3 = 11.85m

Total = 15.6 + 11.85

= 27.45m

Centre line: (Partition wall = 0.125m)

CL (x1-x1) = 0.125/2 + 1.2 + 0.3/2

= 1.41 * 2 = 2.82m

CL (y1-y1) = 0.3/2 + 1.82 + 0.125/2

= 2.032 * 2 = 4.065m

Total = 2.82 + 4.065

= 6.885m

Sl.n PARTICULARS No. L B D Quantity Remarks

o

1 Earthwork

Department of Civil Engineering GEC, Kushalnagar Page 23

Internship Report 2019-20

a)Main wall 1 26.25 1.2 1.5 47.25m3

b)Partition wall 1 5.08 0.9 0.6 2.74 m3

2 PCC

a)Main wall 1 26.45 1 0.15 3.96 m3

b)Partition wall 1 5.485 0.7 0.15 0.575m3

3 Footing

a)Concrete 7 1 1 1 7 m3

b)Steel 417.6Kg

4 SSM (MW)

a)1st coarse 1 26.55 0.9 0.45 10.75 m3

b)2nd coarse 1 26.75 0.7 0.45 8.42 m3

c)3rd coarse 1 26.95 0.5 0.45 6.06 m3

SSM (PW)

1.317 m3

a)1st coarse 1 5.855 0.5 0.45

5 Column

a)Concrete 7 0.3 0.3 4.65 2.929 m3

b)Steel 229.92Kg

6 Plinth beam

a) Concrete 1 32.805 0.5 0.1 1.640m3

b)Steel 522.8Kg

7 Brick wall

a)Main wall 1 27.15 0.3 3 24.43 m3

b)Partition wall 1 6.635 0.125 3 2.488 m3

Department of Civil Engineering GEC, Kushalnagar Page 24

Internship Report 2019-20

Department of Civil Engineering GEC, Kushalnagar Page 25

S-ar putea să vă placă și

- Call Center - GrameenPhoneDocument39 paginiCall Center - GrameenPhoneNazim Sharif Tonmoy67% (3)

- 1554557144502-Final Rushi SIP PDFDocument39 pagini1554557144502-Final Rushi SIP PDFTarun AilaniÎncă nu există evaluări

- Internship Report On Pakistan Telecommunication Company LTDDocument67 paginiInternship Report On Pakistan Telecommunication Company LTDbbaahmad89Încă nu există evaluări

- Intern Report FinalDocument28 paginiIntern Report FinalGaneshkumarÎncă nu există evaluări

- Company ProjectDocument9 paginiCompany ProjectAMARNATH KÎncă nu există evaluări

- Internship Report On Hakkani Apparels LTDDocument40 paginiInternship Report On Hakkani Apparels LTDAsiful HaiderÎncă nu există evaluări

- Pearl Global Industries LimitedDocument9 paginiPearl Global Industries LimitedAnisha NandaÎncă nu există evaluări

- Iip 1Document2 paginiIip 1Praval SaiÎncă nu există evaluări

- Project Report On Ask Automotive in Customer Satisfaction and BrandlolityDocument77 paginiProject Report On Ask Automotive in Customer Satisfaction and Brandlolitydebprit100% (2)

- Mini ProjDocument27 paginiMini ProjMekhajith MohanÎncă nu există evaluări

- DukeDocument100 paginiDukelimbasiyahirenÎncă nu există evaluări

- Haroon - Internship ReportDocument45 paginiHaroon - Internship Reportmuhammad kaleemÎncă nu există evaluări

- Intenship ReportDocument43 paginiIntenship ReportManoj KumarÎncă nu există evaluări

- SACHIN KUMAR Project Report Final Ready 1 PDFDocument37 paginiSACHIN KUMAR Project Report Final Ready 1 PDFaditya sharmaÎncă nu există evaluări

- IDLC Finance LTD OverviewDocument13 paginiIDLC Finance LTD OverviewKhan Mohammad ShahadatÎncă nu există evaluări

- BCG Matrix of A Audit FirmDocument1 paginăBCG Matrix of A Audit FirmBizness Zenius HantÎncă nu există evaluări

- Report On Operation of KapcoDocument45 paginiReport On Operation of KapcoZunaira RasheedÎncă nu există evaluări

- Presentation On IIFLDocument36 paginiPresentation On IIFLrajendra_783Încă nu există evaluări

- Internship Report MTMDocument45 paginiInternship Report MTMusmanaltafÎncă nu există evaluări

- Final Presentation On Ambuja Cements LTDDocument25 paginiFinal Presentation On Ambuja Cements LTDRocky SyalÎncă nu există evaluări

- Bajaj AutoDocument14 paginiBajaj Autoravi_hi48Încă nu există evaluări

- Internship Report of Mughal Brothers TechnologiesDocument19 paginiInternship Report of Mughal Brothers Technologiesbbaahmad89Încă nu există evaluări

- HR Policies of SharekhanDocument13 paginiHR Policies of SharekhanShivam GuptaÎncă nu există evaluări

- A Report On Industrial Training at PDFDocument28 paginiA Report On Industrial Training at PDFgauravkumar bhandariÎncă nu există evaluări

- HaldiramDocument72 paginiHaldiramGuman SinghÎncă nu există evaluări

- SAED International Profile (ENGLISH)Document24 paginiSAED International Profile (ENGLISH)Mohammad BokhariÎncă nu există evaluări

- Aircel Human Resource ReportDocument57 paginiAircel Human Resource Reportdeeksha50% (2)

- Cost of Capital NumericalsDocument9 paginiCost of Capital Numericalsckcnathan001Încă nu există evaluări

- INTERNSHIP REPORT ON Human Resource Policies of Shova Enterprise LimitedDocument56 paginiINTERNSHIP REPORT ON Human Resource Policies of Shova Enterprise LimitedNafiz FahimÎncă nu există evaluări

- Nikita Sip Project.-1Document52 paginiNikita Sip Project.-1priyanka shethÎncă nu există evaluări

- Jobs in QatarDocument5 paginiJobs in QatarYorymaoÎncă nu există evaluări

- Inplant Training ReportDocument48 paginiInplant Training ReportyogeshÎncă nu există evaluări

- Pratiksha Final Project PDFDocument53 paginiPratiksha Final Project PDFruishekesh neheteÎncă nu există evaluări

- MHC Group I Dewan Distillery Report Format Ver.2-2Document21 paginiMHC Group I Dewan Distillery Report Format Ver.2-2Sabah19Încă nu există evaluări

- Employment Agencies in BangladeshDocument23 paginiEmployment Agencies in BangladeshMd Abdur Rahman Bhuiyan0% (1)

- A Project Report ON "HR Policies" OF "Himachal Futuristic Communication LTD"Document72 paginiA Project Report ON "HR Policies" OF "Himachal Futuristic Communication LTD"Parveen Kumar67% (3)

- Internship Project Report of Nayana PaulsonDocument20 paginiInternship Project Report of Nayana PaulsonSiril muhammed100% (1)

- Ankur SUMMER INTERNSHIP REPORTDocument38 paginiAnkur SUMMER INTERNSHIP REPORTSaurav ReyanshÎncă nu există evaluări

- Jai 1391014 PDFDocument56 paginiJai 1391014 PDFSindhu SidÎncă nu există evaluări

- Branches New List PDFDocument2 paginiBranches New List PDFKaran Thakur SnghÎncă nu există evaluări

- Internship Report DivyaDocument58 paginiInternship Report DivyaDivya gondesiÎncă nu există evaluări

- NPTEL POMS Week 6 A06 - Final SolutionsDocument3 paginiNPTEL POMS Week 6 A06 - Final SolutionsAnurag SharmaÎncă nu există evaluări

- Summer Training Report200Document25 paginiSummer Training Report200amarsinghchawlaÎncă nu există evaluări

- Treebo SIP ReportDocument44 paginiTreebo SIP ReportDivyaÎncă nu există evaluări

- Software Houses in PakistanDocument8 paginiSoftware Houses in PakistanMuhammad Aneek RehmanÎncă nu există evaluări

- Consultancies in ChennaiDocument9 paginiConsultancies in ChennaiporurÎncă nu există evaluări

- Customer Satisfaction in Health Care SectorDocument21 paginiCustomer Satisfaction in Health Care SectorRaju Sporsher BaireÎncă nu există evaluări

- Internship Report On ESMLDocument43 paginiInternship Report On ESMLZaighum AliÎncă nu există evaluări

- Welfare Activities of Employees NewDocument66 paginiWelfare Activities of Employees NewLohit SahniÎncă nu există evaluări

- HavellsindiaDocument70 paginiHavellsindiawasimkhanforyouÎncă nu există evaluări

- Project Ginning FactoryDocument28 paginiProject Ginning FactoryGirish Agarwal0% (1)

- Profile SEMS Foundation PDFDocument4 paginiProfile SEMS Foundation PDFAtul gargÎncă nu există evaluări

- Internship Report MTMDocument79 paginiInternship Report MTMasjadm143Încă nu există evaluări

- Polycab Final ReportDocument97 paginiPolycab Final ReportAnjali PandeÎncă nu există evaluări

- Project HRMDocument47 paginiProject HRMKishoreAgarwalÎncă nu există evaluări

- Recruitment, SelectionDocument63 paginiRecruitment, SelectionAkshay Shah100% (1)

- TVS MOTORS-group 6 CS Final ProjectDocument19 paginiTVS MOTORS-group 6 CS Final ProjectShubham MaggoÎncă nu există evaluări

- Report 123 PDFDocument51 paginiReport 123 PDFPramod Kumar HTÎncă nu există evaluări

- INTERNSHIPDocument31 paginiINTERNSHIPStalan JonathanÎncă nu există evaluări

- PP423 - RSW MT 02 - Marquez John Mark L.Document62 paginiPP423 - RSW MT 02 - Marquez John Mark L.Julie Ann QuimingÎncă nu există evaluări

- Long Wall & Short Wall Method PDFDocument5 paginiLong Wall & Short Wall Method PDFAnithaÎncă nu există evaluări

- Specification Complete Assembly 17.02.2020Document45 paginiSpecification Complete Assembly 17.02.2020AnithaÎncă nu există evaluări

- Proceedings of VC 18.4.20 On LetterheadDocument5 paginiProceedings of VC 18.4.20 On LetterheadAnithaÎncă nu există evaluări

- Concrete Construction Article PDF - Precast Concrete Forms The Backbone of The Channel TunnelDocument2 paginiConcrete Construction Article PDF - Precast Concrete Forms The Backbone of The Channel TunnelAnithaÎncă nu există evaluări

- ChannelTunnel RETC 1989Document20 paginiChannelTunnel RETC 1989AnithaÎncă nu există evaluări

- Seminar PDFDocument27 paginiSeminar PDFAnithaÎncă nu există evaluări

- Function of Soil-Based On-Site Wastewater Treatment Systems - Biological and Chemical Treatment CapacityDocument70 paginiFunction of Soil-Based On-Site Wastewater Treatment Systems - Biological and Chemical Treatment CapacityAnithaÎncă nu există evaluări

- Ground Water HydraulicsDocument25 paginiGround Water HydraulicsAnitha100% (1)

- Fig 1.1 Proposals Presented in 1985. Left: Eurobridge, Middle: Euroroute, Right: Channel TunnelDocument17 paginiFig 1.1 Proposals Presented in 1985. Left: Eurobridge, Middle: Euroroute, Right: Channel TunnelAnithaÎncă nu există evaluări

- Ecc DoddaDocument18 paginiEcc DoddaAnithaÎncă nu există evaluări

- 1.1 General: Dept. of Civil Engineering GeckDocument16 pagini1.1 General: Dept. of Civil Engineering GeckAnithaÎncă nu există evaluări

- Vision and Mission of The Department of Civil Engineering VisionDocument2 paginiVision and Mission of The Department of Civil Engineering VisionAnithaÎncă nu există evaluări

- Sheet Pile Wall, With Tieback Anchors, Design Based On AASHTO (HB-17), 2018 IBC & ACI 318-19Document3 paginiSheet Pile Wall, With Tieback Anchors, Design Based On AASHTO (HB-17), 2018 IBC & ACI 318-19afvilavilanoriegaÎncă nu există evaluări

- Westock - Ultra Slim Floor Beam (USFB) DesignDocument20 paginiWestock - Ultra Slim Floor Beam (USFB) Designalberto5791Încă nu există evaluări

- Calculation Report Conveyor Structure T 1022 PDFDocument29 paginiCalculation Report Conveyor Structure T 1022 PDFAnonymous ahdhFMaÎncă nu există evaluări

- Bridge Pier Seismic Strengthening Using Uhpfrc CoverDocument13 paginiBridge Pier Seismic Strengthening Using Uhpfrc CoverSebastian Contreras ContrerasÎncă nu există evaluări

- Sifcon Seminar ReportDocument27 paginiSifcon Seminar Reportshivukumar75% (4)

- Midas Civil Application in Box Girder LRT 3Document48 paginiMidas Civil Application in Box Girder LRT 3milkcÎncă nu există evaluări

- Example PROGRESS Report of A High Rise BuildDocument3 paginiExample PROGRESS Report of A High Rise BuildMehmet Akif Cirit100% (1)

- SOR For Rural RoadsDocument189 paginiSOR For Rural RoadsDebajit ChakravartyÎncă nu există evaluări

- Integrated Approach To Concrete DesignDocument64 paginiIntegrated Approach To Concrete DesignJason GuzmanÎncă nu există evaluări

- Formulario Vigas MATLABDocument29 paginiFormulario Vigas MATLABLeonardo ZambranoÎncă nu există evaluări

- Sheet Piling ExampleDocument12 paginiSheet Piling Exampleshravan38Încă nu există evaluări

- Solved Example On MasonryDocument53 paginiSolved Example On MasonrysanketÎncă nu există evaluări

- Structural Drawings g+2 1Document34 paginiStructural Drawings g+2 1Syed Arman AlamÎncă nu există evaluări

- Notaton X Foreword X 1 Introducton 1: Istructe Manual For The Design of Concrete Building Structures To Eurocode 2Document7 paginiNotaton X Foreword X 1 Introducton 1: Istructe Manual For The Design of Concrete Building Structures To Eurocode 2Lim Wee BengÎncă nu există evaluări

- 3.0 - Calculation Omis Profex - 2 SideDocument9 pagini3.0 - Calculation Omis Profex - 2 SideMuhammad ZuhayrÎncă nu există evaluări

- Proroc Bracing Manual09Document12 paginiProroc Bracing Manual09JonoÎncă nu există evaluări

- BS 06100-9-2007Document56 paginiBS 06100-9-2007Al JameelÎncă nu există evaluări

- IJCRT1892221Document6 paginiIJCRT1892221Niva R ChandraÎncă nu există evaluări

- ASMDMDocument2 paginiASMDMJhundel Factor PajarillagaÎncă nu există evaluări

- WIS DOT Bridge Manual Retaining Wall PDFDocument260 paginiWIS DOT Bridge Manual Retaining Wall PDFPrashant JhaÎncă nu există evaluări

- Civil PE Sample Examination LindeburgDocument6 paginiCivil PE Sample Examination Lindeburghassaniqbal8460% (5)

- Anchorbolt (318 08)Document26 paginiAnchorbolt (318 08)Anonymous 9MDGo2jÎncă nu există evaluări

- List of Completed Bridges June 2016-May 2019Document50 paginiList of Completed Bridges June 2016-May 2019RapplerÎncă nu există evaluări

- 2 08P17 PDFDocument60 pagini2 08P17 PDFMike2322Încă nu există evaluări

- 4.shear Stress in Beam PDFDocument10 pagini4.shear Stress in Beam PDFharshdeepÎncă nu există evaluări

- Mini ProjectDocument17 paginiMini ProjectLuq ManÎncă nu există evaluări

- Clubhouse Structural NotesDocument17 paginiClubhouse Structural NotesCarlo Doragos100% (1)

- Pag-Ibig Foreclosed Properties For Auction On July 18 and 19, 2013Document27 paginiPag-Ibig Foreclosed Properties For Auction On July 18 and 19, 2013Cherry Vi Saldua Castillo50% (6)

- Design in Etabs As Per IS CodeDocument24 paginiDesign in Etabs As Per IS CoderohitÎncă nu există evaluări