Documente Academic

Documente Profesional

Documente Cultură

Thyssenkrupp Elevator Qatar: Risk Assessment

Încărcat de

Mahran MastouriDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Thyssenkrupp Elevator Qatar: Risk Assessment

Încărcat de

Mahran MastouriDrepturi de autor:

Formate disponibile

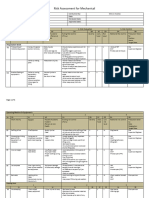

Doc Ref Nos.

tkeQ /HSE / RA / 04 /2019

thyssenkrupp Elevator Qatar Revision / Issue :

Risk Assessment Date : 02/09/2019

Discription : Risk Assessment for Elevator Maintenance

Risk

likelihood Certain Highly Likely Likely Unlikely Highly Unlikely Severity Catastrophic Substantial Moderate Minor Trivial Critical High Meduim Low Insignificant

5 4 3 2 1 5 4 3 2 1 Classification 21-25 16-20 11-15 6-10 0-5

Risk Rating Residual Risk

Effects/

Likelihood

Likelihood

Job Step Hazards Consequences

Outcome

Outcome

Severity

Severity

SL

(Sequence of working activities) (The potential to cause harm ) (The harm which could possibly Recommended Control Measures & Mitigations

No

occur).

Partially Blocked access / Uneven Follow site safety rules

1 Site Condition (Common access & Egress) Trip/fall 3 3 9 1 3 3

Suface /Loose soil Use only designated access

Barricading elevator entrances (ground, first and Safety barricade and fence to be placed in fornt of the

2 Unauthorized Entry Fall to Pit 3 3 9 1 3 3

second) landing door .

Open the landing door with emergency key when Keep an eye on floor level when exit from cabin.When

Cabin top stationed below the

3 elevator is in the correct position to access to Fall to cabin top / injury 4 3 12 cabin reach almoast 500MM ,stop the unit by means of 1 3 3

landing level.

cabin top. unlocking key.

When access to cabin top ,check and apply stop button .

Cabin top stationed below the

4 Access to cabin top Fall to cabin top / injury 3 4 12 Inspection switch and light switch ON.(Strictly follow the 1 4 4

landing level.

tkeQ access procedure).

Always station the cabin top in level to the landing doors

Cabintop stationed in improper Trip or fall from cabin top to and exit. Release the stop button, switch to normal mode

5 Egress from the cabintop 4 3 12 1 3 3

level. landing levels and switch off the lights. Never leave any tools and

materials over the cabintop.

Keep an eye on floor level when exit from cabin.When

Pit Access (Register call inside the cabin to UP Uneven cabin and landing door Slip,trip and fall on the same

6 3 3 9 cabin move and reach over the head level ,stop the unit by 1 3 3

level and exit). sills. level.

means of unlocking key.

Stop the cabin when it reached above operatives Keep a safe distance from the landing sill.Verify the cabin

7 head level height by means of door unlocking standing near to pit. Falling to pit / Fracture 4 3 12 is in correct position by opening the both landing door 1 3 3

device. 100mm.

Always keep an eye for cabin movement.Hold one hand

wrist firmly on outside shaft column.Lean carefully into the

8 Applying the stop button inside the pit. standing near to pit. Falling to pit / Fracture 4 3 12 shaft and with the other hand apply the stop button located 1 3 3

inside the pit. Switch on the shaft or pit light.

Apply the stop button

Always maintain three mode contact on fixed ladder whilst

access/egress to the pit.Never use buffer as ladder.Grip

9 Access to Pit Improper use of fixed ladder Falling to pit / Fracture 4 4 16 firmly on handrail and then step on fixed ladder 1 4 4

properly.Ensure to Pit stop ON, Keep landing door open

with a 100mm gap by means of door stopper.

Always maintained three mode contact whilst access/egress

to the pit.Never use buffer as ladder.Grip firmly on handrail

10 Egress from Pit Improper use of fixed ladder Fall to pit 3 3 9 and then step on fixed ladder properly. Release the Pit stop 1 3 3

switch and close the landing door after maintaning safe

distance form landing area.

Doc Ref Nos. tkeQ /HSE / RA / 04 /2019

thyssenkrupp Elevator Qatar Revision / Issue :

Risk Assessment Date : 02/09/2019

Discription : Risk Assessment for Elevator Maintenance

Risk

likelihood Certain Highly Likely Likely Unlikely Highly Unlikely Severity Catastrophic Substantial Moderate Minor Trivial Critical High Meduim Low Insignificant

5 4 3 2 1 5 4 3 2 1 Classification 21-25 16-20 11-15 6-10 0-5

Risk Rating Residual Risk

Effects/

Likelihood

Likelihood

Job Step Hazards Consequences

Outcome

Outcome

Severity

Severity

SL

(Sequence of working activities) (The potential to cause harm ) (The harm which could possibly Recommended Control Measures & Mitigations

No

occur).

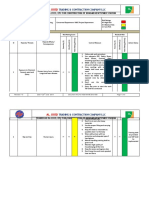

Provide signboard on the landing doors at all levels

indicating, Lift is Under Service.

Do not leave the landing doors open.

Ensure proper lighting, ventilation and housekeeping

Inadequate access Fall of person 3 4 12 Proper ladder to be provided to access to pit 1 4 4

Suitable working platform shall be installed in the pit to

access the bottom of car, especially for high speed

elevators, where the clearance from the pit bottom will be

more than 2mtr

Make sure adequate rest break and provision of drinking

11 Working in pit Humidity Heat stress 4 3 12 1 3 3

water

Loose Materials Material falling to pit 3 3 9 Maintain good housekeeping 1 3 3

Test and verify the door lock circuit and pit stop switch, or

two means of stopping operation of the elevator, before

entering the pit

Hit by cabin/counter weight in Ensure proper lighting, ventilation and housekeeping

Moving Car & Counter weight 3 4 12 1 4 4

multiplex hoist way While working in the pit, other related work on the car top

should not be carried out

Temporary barricade should be provided to prevent the

technicians from entering the running elevator pit

All works related to the car top and bottom should be

carried out keeping the car at the lower most possible floor

Hand rails should be made available on the car top while

working ,if not ensure about the full body harness and shall

hooked in acceptable points.

Working at height Person falling from car top 5 5 25 1 5 5

Existing hand rails on car top shall never be removed

Do not stand on the hand rail for any reason what so ever

Avoid loose materials(tools, nut & bolts) grease spillage

on the car top

Suitable ladders shall be provided on the car top

12 Working on Cabin top temporarily to access the rail top.

In duplex/triplex hoist way avoid jumping from one car top

to another car top.

Technicians shall not over reach beyond the hand rails

Ensure that car top light of the other elevator is switched

Working near Rotatable Parts Entanglement /Crush Injury 4 4 16 ON so that the technicians are cautioned, whenever the 1 4 4

nearby elevator crosses the work place.

Doc Ref Nos. tkeQ /HSE / RA / 04 /2019

thyssenkrupp Elevator Qatar Revision / Issue :

Risk Assessment Date : 02/09/2019

Discription : Risk Assessment for Elevator Maintenance

Certain

12 Working Highly

on Cabin top Likely Likely Unlikely Highly Unlikely Severity Catastrophic Substantial Moderate Minor Trivial Risk Critical High Meduim Low Insignificant

likelihood

5 4 3 2 1 5 4 3 2 1 Classification 21-25 16-20 11-15 6-10 0-5

Risk Rating Residual Risk

Effects/

Likelihood

Likelihood

Job Step Hazards Consequences

Outcome

Outcome

Severity

Severity

SL

(Sequence of working activities) (The potential to cause harm ) (The harm which could possibly Recommended Control Measures & Mitigations

No Working near Rotatable Parts Entanglementoccur).

/Crush Injury 4 4 16 1 4 4

All technicians should aware of the head room clearance of

car top & overhead obstructions

Before moving the car up or down, ensure the car top

person makes proper instruction.

Restrict working on live conditions to bare minimum

possible

While carrying out any maintenance activity in the control

panel, car top station & car operating panel, the power

supply should be isolated and lock out/tag out procedure to

be followed.

Proper warning signs to be displayed

Use only approved hand tools with insulation

13 Function test in live control panel Electricity Electrocution 5 4 20 No metallic ornaments shall be worn by technician 1 4 4

Change the operation of elevator to manual mode before

carrying out any maintenance adjustments in the control

unit, while carrying out function test

Use only approved and calibrated instruments

Ensure the use of proper jumpers

Check the earth resistance of elevator before attempting

any live working to ensure that the earthling is effective

Ensure the usage of good quality hand gloves

Doc Ref Nos. tkeQ /HSE / RA / 04 /2019

thyssenkrupp Elevator Qatar Revision / Issue :

Risk Assessment Date : 02/09/2019

Discription : Risk Assessment for Elevator Maintenance

Risk

likelihood Certain Highly Likely Likely Unlikely Highly Unlikely Severity Catastrophic Substantial Moderate Minor Trivial Critical High Meduim Low Insignificant

5 4 3 2 1 5 4 3 2 1 Classification 21-25 16-20 11-15 6-10 0-5

Risk Rating Residual Risk

Effects/

Likelihood

Likelihood

Job Step Hazards Consequences

Outcome

Outcome

Severity

Severity

SL

(Sequence of working activities) (The potential to cause harm ) (The harm which could possibly Recommended Control Measures & Mitigations

No

occur).

Ensure proper lighting

Before carrying out any work in motor, power supply

should be switched off and follow lock out/tag out

procedure strictly

No loose clothing shall be allowed

No metallic ornaments shall worn.

Trap between, Caught in,Pinch Guards shall not be removed unnecessarily, if the guards

14 Working on traction machine Rotating Parts 4 3 12 1 3 3

point are removed during maintenance activities, It shall be fixed

back immediately.

Ensure that there is no physical contact with moving parts

before starting any test.

Maintain a safe working distance from the rotating parts of

the motor while inspection

Beware of pinch points.

Ensure that all power tools are double insulated.

Inspect all power tools, cable, plug and socket periodically

and before each use.

Take power supply from only approved sources and

15 Use of power tools Electricity Electrocution 3 4 12 1 4 4

through ELCB

Do not use power tools in wet hand or wet environment.

Avoid loose materials, cables from rotating parts

Maintain good cable management

Do not keep any hand tools on the separator beam/call

button cut out.

Slip from hand Falling of tools 3 3 9 Use restraining strap with hand tools to avoid falling 1 3 3

hazards, make sure to carry safe load and correctly.

All hand tools should be maintained in a small tool box at

the place of work

Get mushroomed head of impact tools such as chisels,

16 Use of hand tools wedges or drift pins ground off. Otherwise the heads might

Impact tools Flying obtacts 4 3 12 shatter on impact, sending sharp fragments flying 1 3 3

Do not use screw driver as a chisel, it’s handle can break

and fly, hitting the user and others

Inspect the wrenches for worn out jaws since it might slip

while working.

Worn out tools Strike against 3 3 9 Do not use screw driver as a chisel ,it’s handle can break 1 3 3

and fly, hitting the user and others

Maintain good cable management

Use only Registered vehicle & Licensed driver

17 Transportation & Maintenance Improper securing of materials Falling of materials 4 3 12 1 3 3

Doc Ref Nos. tkeQ /HSE / RA / 04 /2019

thyssenkrupp Elevator Qatar Revision / Issue :

Risk Assessment Date : 02/09/2019

Discription : Risk Assessment for Elevator Maintenance

Risk

likelihood Certain Highly Likely Likely Unlikely Highly Unlikely Severity Catastrophic Substantial Moderate Minor Trivial Critical High Meduim Low Insignificant

5 4 3 2 1 5 4 3 2 1 Classification 21-25 16-20 11-15 6-10 0-5

Risk Rating Residual Risk

Effects/

Likelihood

Likelihood

Job Step Hazards Consequences

Outcome

Outcome

Severity

Severity

SL

(Sequence of working activities) (The potential to cause harm ) (The harm which could possibly Recommended Control Measures & Mitigations

No

occur).

17 Transportation & Maintenance Improper securing of materials Falling of materials 4 3 12 Secured the materials with ratchet binders . Never exceed 1 3 3

the S.W.L.

Conduct several run tests in normal mode by Passenger may lead to another Never allow passengers during run tests.Standby technician

18 unauthorized entry 3 3 9 1 3 3

registering all possible elevator calls. levels should be inside the cabin.

Remove the barricade from all levels (ground, Hitting of barricading with Barricade to be removed properly. Ensure good housekeeping

19 Passenger movement 4 3 12 1 3 3

first and second) passenger before leaving the area of work

Prepared By : Binu.P.Raphal (HSE ) Reviewed & Approved By :

Date : 02/09/2019 Date : 02/09/2019

S-ar putea să vă placă și

- JSA For Elevator InstallationDocument9 paginiJSA For Elevator InstallationHamid RazaÎncă nu există evaluări

- Risk Assessment For Mechanical: Preparation WorkDocument3 paginiRisk Assessment For Mechanical: Preparation Workahmedalderbi801Încă nu există evaluări

- 31.HIRA - Boom Placer OperationDocument3 pagini31.HIRA - Boom Placer OperationMMRDACA07 SAFETYÎncă nu există evaluări

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 paginiRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkÎncă nu există evaluări

- Elevator Installation RISK ASSESSMENT (0Document16 paginiElevator Installation RISK ASSESSMENT (0Goutham Vijayan100% (1)

- Shifting of Materials by Double HydraDocument1 paginăShifting of Materials by Double HydraShahid RazaÎncă nu există evaluări

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 paginiAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinÎncă nu există evaluări

- Risk Assessment:: Corresponding Permit To Work NoDocument4 paginiRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamÎncă nu există evaluări

- JSEA-ICS-004 Cable Laying and PullingDocument16 paginiJSEA-ICS-004 Cable Laying and PullingJayson EscamillanÎncă nu există evaluări

- Hira RCC Cement MillDocument2 paginiHira RCC Cement MillRajuÎncă nu există evaluări

- HIRADocument6 paginiHIRAvijay kumar singhÎncă nu există evaluări

- Risk Assessment-Pnuematic Test. DraftDocument3 paginiRisk Assessment-Pnuematic Test. DraftKono Nor AtanÎncă nu există evaluări

- 02 - Transformer (Testing)Document5 pagini02 - Transformer (Testing)Saravanan SaraÎncă nu există evaluări

- Hira - RCC Road ActivityDocument3 paginiHira - RCC Road Activitytariq1987100% (1)

- Sultan Saed Al - Zahrani Est ProfileDocument60 paginiSultan Saed Al - Zahrani Est ProfileaayasirÎncă nu există evaluări

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 paginiCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoÎncă nu există evaluări

- Risk Assessment For DemolitionDocument10 paginiRisk Assessment For Demolitionadeniyi abiolaÎncă nu există evaluări

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 paginiRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaÎncă nu există evaluări

- 9-1 Moem Hirarc Feb 2017Document1 pagină9-1 Moem Hirarc Feb 2017PHH9834Încă nu există evaluări

- JSA For SRP Instolation and DismentlingDocument17 paginiJSA For SRP Instolation and DismentlingShekh BabulÎncă nu există evaluări

- BackfillingDocument2 paginiBackfillingGyanendra Narayan NayakÎncă nu există evaluări

- Passenger Hoist LiftDocument1 paginăPassenger Hoist LiftGyanendra Narayan Nayak100% (2)

- JSA For Elevator InstallationDocument11 paginiJSA For Elevator InstallationHamid RazaÎncă nu există evaluări

- Concreting Risk AssessmentsDocument2 paginiConcreting Risk AssessmentsHSE1 SHAMNET0% (1)

- Mech-5-20-JSA - Activity For Erection of ScaffoldingDocument10 paginiMech-5-20-JSA - Activity For Erection of ScaffoldingNasrullah JanÎncă nu există evaluări

- PCC & ConcDocument4 paginiPCC & Concprasanna okÎncă nu există evaluări

- Ladders, Hop Ups Risk AssessmentDocument8 paginiLadders, Hop Ups Risk AssessmentRebecca Winter100% (1)

- 005 Civil Works PDFDocument5 pagini005 Civil Works PDFghada gattouch100% (1)

- SG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageDocument41 paginiSG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageJames HoltÎncă nu există evaluări

- Risk Assessment For Erection of Steel GirderDocument11 paginiRisk Assessment For Erection of Steel GirderNirajan MarwaitÎncă nu există evaluări

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 paginiTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- Lift Rescue SopDocument3 paginiLift Rescue Sop[X]TR3ME100% (1)

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 paginiSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- BMR - Safety PPT Apr-2023Document17 paginiBMR - Safety PPT Apr-2023shamshad ahamedÎncă nu există evaluări

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 paginiJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiÎncă nu există evaluări

- Risk Assessment For Stone WorkDocument17 paginiRisk Assessment For Stone WorkKhuda BukshÎncă nu există evaluări

- 011 Duct Lifter SWMSDocument2 pagini011 Duct Lifter SWMSJ JohnsonÎncă nu există evaluări

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 paginiHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitÎncă nu există evaluări

- JHA-Mechanical Lifting1Document2 paginiJHA-Mechanical Lifting1john jaycoh veranoÎncă nu există evaluări

- HIRA Reference Bearing & StopprtDocument51 paginiHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Ra For Hot Work (Welding & Cutting Works)Document3 paginiRa For Hot Work (Welding & Cutting Works)Abrar AhmedÎncă nu există evaluări

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 paginiM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADÎncă nu există evaluări

- Risk Assessment For PAS InstallationDocument18 paginiRisk Assessment For PAS Installationjide.atolagbe3737Încă nu există evaluări

- 003 Material HandlingpdfDocument4 pagini003 Material Handlingpdfghada gattouchÎncă nu există evaluări

- Risk Assessment Relocation Overhead LineDocument5 paginiRisk Assessment Relocation Overhead Lineghada gattouchÎncă nu există evaluări

- Risk Assessment For Blinding Concrete - 01Document6 paginiRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 paginiRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Daily JSA - Back Filling, Levelling and ComapactionDocument3 paginiDaily JSA - Back Filling, Levelling and Comapactionshoaib akhtarÎncă nu există evaluări

- ExcavationDocument3 paginiExcavationprasanna ok100% (1)

- Rope Replacement Risk AssessmentDocument53 paginiRope Replacement Risk AssessmentFrancois Johannes BrinkÎncă nu există evaluări

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 paginiRisk Assessment Construction of Lighting Pole at Site OfficeSinaÎncă nu există evaluări

- Safety Alert 304 - Unsafe MEWP's OperationDocument2 paginiSafety Alert 304 - Unsafe MEWP's OperationAbdulKatherÎncă nu există evaluări

- Risk Assessment - Tower DecommissioningDocument5 paginiRisk Assessment - Tower DecommissioningJeffery Mulei100% (1)

- Precast Erection JSWDocument6 paginiPrecast Erection JSWPrabhakaran GurunathanÎncă nu există evaluări

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 paginiCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- Method Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00Document6 paginiMethod Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00bryanÎncă nu există evaluări

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 paginiRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayÎncă nu există evaluări

- Work Permit: OCP To Be Followed For Following ActivitiesDocument2 paginiWork Permit: OCP To Be Followed For Following ActivitiesKishan MauryaÎncă nu există evaluări

- Cuplocks Scaffolding JSA UtilityDocument4 paginiCuplocks Scaffolding JSA UtilitysoubhagyaÎncă nu există evaluări

- Thyssenkrupp Elevator Qatar: Risk AssessmentDocument5 paginiThyssenkrupp Elevator Qatar: Risk AssessmentMahran Mastouri100% (4)

- MOS For Counter Weight Sheave Replacement-2552Document2 paginiMOS For Counter Weight Sheave Replacement-2552Mahran MastouriÎncă nu există evaluări

- Hydraulic Start ProblemDocument1 paginăHydraulic Start ProblemMahran MastouriÎncă nu există evaluări

- Scaffolding SketchDocument1 paginăScaffolding SketchMahran MastouriÎncă nu există evaluări

- Thyssenkrupp Elevator Qatar: Risk AssessmentDocument5 paginiThyssenkrupp Elevator Qatar: Risk AssessmentMahran Mastouri100% (4)

- Lift Controller For Machine Room-Less Installations: ManualDocument20 paginiLift Controller For Machine Room-Less Installations: ManualMahran MastouriÎncă nu există evaluări

- Seite 1 Von 2 N:/DATEN/DOC/Projekte/LM-Internet/LM Homepage 2007/AL Homepage/FAQ/Englisch/Aktuell/01 - Frequenzumrichter/faq - 01001eDocument2 paginiSeite 1 Von 2 N:/DATEN/DOC/Projekte/LM-Internet/LM Homepage 2007/AL Homepage/FAQ/Englisch/Aktuell/01 - Frequenzumrichter/faq - 01001eMahran MastouriÎncă nu există evaluări

- SIP Master Stations: Configuration GuideDocument36 paginiSIP Master Stations: Configuration GuideMahran MastouriÎncă nu există evaluări

- DCP InterfaceDocument1 paginăDCP InterfaceMahran MastouriÎncă nu există evaluări

- HATMSI47 1811 E - OPC LM1 PR - ManualDocument14 paginiHATMSI47 1811 E - OPC LM1 PR - ManualMahran Mastouri100% (1)

- RS-232/RS-485/422: UT-203 Interface Converter InstructionDocument1 paginăRS-232/RS-485/422: UT-203 Interface Converter InstructionMahran MastouriÎncă nu există evaluări

- Frenic CodeDocument8 paginiFrenic CodeMahran MastouriÎncă nu există evaluări

- Full Color 7" TFT Display Module For LiftsDocument8 paginiFull Color 7" TFT Display Module For LiftsMahran MastouriÎncă nu există evaluări

- Full Color 7" TFT Display Module For LiftsDocument8 paginiFull Color 7" TFT Display Module For LiftsMahran MastouriÎncă nu există evaluări

- A100K11013 Pulse - Getting - StartedDocument4 paginiA100K11013 Pulse - Getting - StartedMahran MastouriÎncă nu există evaluări

- A100K 10602 AlphaCom E User GuideDocument40 paginiA100K 10602 AlphaCom E User GuideMahran MastouriÎncă nu există evaluări

- Stannah Microlift Brochure PDFDocument12 paginiStannah Microlift Brochure PDFMahran MastouriÎncă nu există evaluări

- Wiring DrawingDocument8 paginiWiring DrawingMahran Mastouri100% (7)

- SWMS Worn Gear DriveDocument6 paginiSWMS Worn Gear DriveMahran MastouriÎncă nu există evaluări

- Strata Ene 2023Document8 paginiStrata Ene 2023gabyÎncă nu există evaluări

- Strain GaugeDocument7 paginiStrain GaugefahadarizkiÎncă nu există evaluări

- Chemistry Project Paper ChromatographyDocument20 paginiChemistry Project Paper ChromatographyAmrita SÎncă nu există evaluări

- G120D Getting Started 0418 en-USDocument94 paginiG120D Getting Started 0418 en-USHamadi Ben SassiÎncă nu există evaluări

- Quotation Request Form: Customer DetailsDocument1 paginăQuotation Request Form: Customer DetailsAmanda RezendeÎncă nu există evaluări

- The Logistics of Harmonious Co-LivingDocument73 paginiThe Logistics of Harmonious Co-LivingKripa SriramÎncă nu există evaluări

- Critical and Creative ThinkingDocument26 paginiCritical and Creative Thinkingjoaquinricardo20153461Încă nu există evaluări

- SThe Electric Double LayerDocument1 paginăSThe Electric Double LayerDrishty YadavÎncă nu există evaluări

- July 2014 GEARSDocument76 paginiJuly 2014 GEARSRodger BlandÎncă nu există evaluări

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocument3 paginiIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriÎncă nu există evaluări

- Catalog ITEM - Pdf4a3667894b315Document552 paginiCatalog ITEM - Pdf4a3667894b315Domokos LeventeÎncă nu există evaluări

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 paginiFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezÎncă nu există evaluări

- Getting Started in Steady StateDocument24 paginiGetting Started in Steady StateamitÎncă nu există evaluări

- Human Resource Development Multiple Choice Question (GuruKpo)Document4 paginiHuman Resource Development Multiple Choice Question (GuruKpo)GuruKPO90% (20)

- Definition, Scope and Nature of EconomicsDocument29 paginiDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarÎncă nu există evaluări

- Translated Copy of Jurnal B.inggris 41117110162 Aditya NurfajriDocument16 paginiTranslated Copy of Jurnal B.inggris 41117110162 Aditya Nurfajriaditya estimatorÎncă nu există evaluări

- Missing Person ProjectDocument9 paginiMissing Person ProjectLaiba WaheedÎncă nu există evaluări

- Straightforward Pre-Intermediate Progress Test 4: Language Section VocabularyDocument8 paginiStraightforward Pre-Intermediate Progress Test 4: Language Section VocabularyStrange BrawlerÎncă nu există evaluări

- 3949-Article Text-8633-1-10-20180712Document10 pagini3949-Article Text-8633-1-10-20180712Volodymyr TarnavskyyÎncă nu există evaluări

- Prescriptions For Closing The Seven Service Quality GapsDocument1 paginăPrescriptions For Closing The Seven Service Quality GapsReema NegiÎncă nu există evaluări

- CHEM 111 Assignment 2024Document3 paginiCHEM 111 Assignment 2024Ben Noah EuroÎncă nu există evaluări

- Student Material CN Version - 2017.11.10Document25 paginiStudent Material CN Version - 2017.11.10Jagaddeesha BRÎncă nu există evaluări

- Transient Thermal Conduction ExampleDocument14 paginiTransient Thermal Conduction ExampleDevendra BangarÎncă nu există evaluări

- RH 120eDocument8 paginiRH 120eSawadogo Gustave NapinguebsonÎncă nu există evaluări

- April 7-9 2022-WPS OfficeDocument3 paginiApril 7-9 2022-WPS OfficeAllen AntolinÎncă nu există evaluări

- A Presentation On Organizational Change ModelDocument4 paginiA Presentation On Organizational Change ModelSandeepHacksÎncă nu există evaluări

- Module-2: SolidificationDocument16 paginiModule-2: SolidificationSachin AgnihotriÎncă nu există evaluări

- (Fanuc Lad 0I-Mc) Ladder Diagram 1Document160 pagini(Fanuc Lad 0I-Mc) Ladder Diagram 1Ujang NachrawiÎncă nu există evaluări

- Class 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDocument12 paginiClass 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDiksha TÎncă nu există evaluări

- Dyn ST 70 Ser 2Document12 paginiDyn ST 70 Ser 2alexgirard11735100% (1)