Documente Academic

Documente Profesional

Documente Cultură

Method Statement for Soft Soil Improvement

Încărcat de

Tran Huy HungDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Statement for Soft Soil Improvement

Încărcat de

Tran Huy HungDrepturi de autor:

Formate disponibile

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 1 of 29

JOTUN PAINTS VIETNAM CO., LTD.

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN JOB NO. 2017-2340

TVC JOB NO. VD-156

DOCUMENT NO. VD156-CV-JOTUN-

0 June 18th 2018 Propose for bidding L.A.DUC D.X.HOANG N.C.CONG

REV. DATE DESCRIPTION PREPARED CHECKED APPROVED

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 2 of 29

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................... 3

2. SCOPE OF WORKS ..................................................................................................... 3

3. STANDARDS AND REFERENCE DOCUMENTS .................................................... 4

3.1. STANDARDS ............................................................................................................... 4

3.2. REFERENCE DOCUMENTS....................................................................................... 5

4. METHOD STATEMENT ............................................................................................. 5

4.1. SOFT SOIL TREATMENT AREA............................................................................... 5

4.2. CONSTRUCTION FLOW CHART.............................................................................. 5

4.3. PVDS INSTALLATION ............................................................................................... 5

4.4. INSTALLATION OF HORIZONTAL PIPE SYSTEM ............................................... 9

4.5. CONSTRUCTION OF GEO-MEMBRANE AND GEOTEXTILE ........................... 12

4.6. INSTALLATION AND OPERATION OF VACUUM SYSTEM ............................. 17

4.7. MONITORING............................................................................................................ 20

4.8. SURCHARGE PROCESS ........................................................................................... 20

4.9. POST SOIL INVESTIGATION .................................................................................. 21

4.10. MAIN MACHINE-EQUIPMENT AND HUMAN RESOURCE ............................... 21

4.10.1. MAIN MACHINE - EQUIPMENT............................................................................. 21

4.10.2. HUMAN RESOURCE ................................................................................................ 21

5. CONSTRUCTION PROGRESS ................................................................................. 22

6. QUALITY MANAGEMENT ...................................................................................... 22

6.1. QUALITY OF PLAN AND GOAL ............................................................................ 22

6.2. QUALITY GUARANTEE SYSTEM ......................................................................... 22

7. HEALTH, SAFETY, ENVIRONMENT AND FIRE-EXPLOSION PREVENTION

(HSE) 23

7.1. HSE GOAL .................................................................................................................. 23

7.2. HEALTH MANAGEMENT ....................................................................................... 23

7.2.1. HEALTH AND PROTECTION .................................................................................. 23

7.2.2. HEALTH ON SITE ..................................................................................................... 23

7.3. SAFETY MANAGEMENT ........................................................................................ 23

7.3.1. SAFETY MANAGEMENT SYSTEM........................................................................ 23

7.3.2. ELECTRICAL SAFETY RULES ............................................................................... 24

7.3.3. ESTIMATION OF UNSAFE ITEM AND SOLVE SOLUTIONS ............................. 24

7.4. ENVIRONMENT MANAGEMENT .......................................................................... 25

7.5. FIRE/EXPLOSION PREVENTION ........................................................................... 25

7.5.1. FIRE/ EXPLOSION SEQUENCE .............................................................................. 25

7.5.2. FIRE/ EXPLOSION PREVENTION METHOD ........................................................ 26

7.5.3. FIRE/ EXPLOSION FIGHTING METHOD .............................................................. 26

7.6. COUNTERMEASURES AGAINST UNSAFE SOURCES ....................................... 27

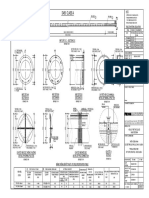

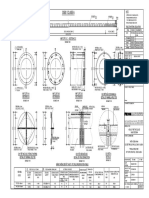

Appendix 1. Drawing of VCM

Appendix 2. Schedule of VCM

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 3 of 29

1. INTRODUCTION

This document describes the soft soil improvement works by Vacuum consolidation method

(VCM) for internal roads, yards, parking, store and pavement areas of Jotun pain factory

project at Hiep Phuoc IZ, Nha Be district, Ho Chi Minh city.

Figure 1.1 Soil improvement area layout

2. SCOPE OF WORKS

Method statement included these work items as below:

PVD installation

Install the VCM system

Operating of VCM system

Monitoring and reporting

Surcharge filling

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 4 of 29

Install protecting Larsen steel structure (if any)

Post soil investigation

3. STANDARDS AND REFERENCE DOCUMENTS

3.1. STANDARDS

Following standards and specifications are proposed to apply for these work items of soft soil

improvement works as bellow:

Table 3.1.1 Apllication and reference standard

NO. Code Specifications and standards

A Procedure and standards for application

1 TCVN 9842:2013 Prefabricated vertical drain combine vacuum pressure with

sealed membrane for soft ground improvement in transport –

Construction and acceptance

2 22TCN 262-2000 Specification for survey, investigation and design of highway

embankment on soft soil

3 TCVN 8871-2011 Geotextile – Standard test method

4 TCVN 8221-2009 Geotextile − Test method for determination of mass per unit area

5 TCVN 8220-2009 Geotextile – Test method for determination of normal thickness

Standard test method for tensile properties of geotextiles by the

6 ASTM D4595

wide-width strip method

7 ASTM D882 Tensile testing of thin plastic sheeting

Standard test method for tear strength of conventional vulcanized

8 ASTM D624

rubber and thermoplastic elastomers

Standard test method for hydrostatic pressure resistance of

9 ASTM D5385

waterproofing membranes

Standard guide for selection of test methods to determine rate of

10 ASTM D5886-95

fluid permeation through geomembranes for specific applications

Standard test methods for water permeability of geotextiles by

11 ASTM D4491

permittivity

B Process and reference standards

Ground improvement by prefabricated vertical drain (PVD)

1 TCVN 9355 2012

Code on soils – Laboratory methods of determination of grain

2 TCVN 4198-2014 size distribution

Soil for hydraulic engineering construction – Field test method

3 TCVN 8731-2012

for determination of water permeability of soil by testing of

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 5 of 29

NO. Code Specifications and standards

water pouring in the pit and boreholes.

Soil for hydraulic engineering construction - Laboratory test

method for determination of permeability coefficient of soil.

4 TCVN 8723-2012

3.2. REFERENCE DOCUMENTS

Following documents is used in this report:

Technical specification of project.

Design document of shop drawing for soil improvement work.

Other related documents

4. METHOD STATEMENT

4.1. SOFT SOIL TREATMENT AREA

The soft soil treatment area by Vacuum consolidation method (VCM) for Jotun paint factory

project is about 3.3ha.

4.2. CONSTRUCTION FLOW CHART

Figure 4.2.1 Construction flow chart

4.3. PVDs INSTALLATION

4.3.1. Specification requirement of PVDs

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 6 of 29

PVDs material shall be satisfied these specification requirements in following table as below:

Table 4.3.1 Specification requirements of PVDs

No. Item Standard Unit Requirement

PVDs

1 Thichness TCVN 8220 mm ≥4

2 Strength at break ASTM D4595 kN >1.6

3 Elongation at break ASTM D4595 % >20

4 Elongation at pressure of 0.5kN TCVN 8871-1 % <10

Discharge capacity at pressure of 10

5 ASTM D4716 10-6 m3/s 80-140

kN/m2, gradient I=0.5

Discharge capacity at pressure of 300

6 ASTM D4716 10-6 m3/s 60-80

kN/m2, gradient I=0.5

PVDs filter

1 Trapezoid tearing force TCVN 8871-2 N >100

2 Breaking resistance TCVN 8871-5 kPa >900

3 Penetration resistance TCVN 8871-4 N >100

4 A.O.S (O95) – Pore size O95 ASTM D 4751 µm ≤ 75

5 Permeability factor ASTM D 4491 m/s ≥ 1.4 x 10-4

Test samples and catalogs of PVDs shall be submitted and approved prior to purchase and

deliver to the site for construction with distance and depth as design drawings. Each

100,000m length of PVDs shall get a laboratory sample taken. PVD is stored in the warehouse

to avoid exposure to rain, sunlight and damage.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 7 of 29

4.3.2. Construction procedure of PVD installation

Material preparation Mobilize machine, Receive site, the corner

(PVDs, anchor) material, labor to the point of construction site

PVDs testing site

PVDs trial (2) (1) Setting out the PVDs points

PVDs mass

(3)

Acceptance and

(4) handover

Figure 4.3.1 Flow chart of construction procedure

(1) Setting out the PVDs points

Using Total station setting out the grid of control point follow design, from that grid,

workers shall use soft rope to identify the remaining points on the grid under the

supervision of engineers scene, all the PVDs points shall be marked with bamboo

sticks or any other material to mark. Tolerance of PVDs points allows about 15cm.

Figure 4.3.2 Illustration of PVDs marker

(2) PVDs trial

Mobilize PVDs machines to the construction site, set up PVDs to the PVDs machine.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 8 of 29

Setting out the trial PVDs points

Then, PVDs was pulled out of the direction pipe and each 1m length of PVDs shall be

marked and trial construction to check and calibrate the recording equipment.

Check the machine capacity: speed, depth

Trial construction works shall be supervised by a consultant.

(3) PVDs mass construction

All data recorded by the recording equipment shall be recorded in the form and submit

these notes with a summary report.

Figure 4.3.3 Illustration of PVDs mass

Mandrel : A mandrel (120x60x10mm), which is pushed downwards into the weak subsoil.

Set anchor plate: Set anchor plate (150x85x0.5mm) to band drain and reinsert to the casing

pipe.

Penetration:

Casing pipe will be penetrated into the ground until the designated depth.

Then, casing pipe will be returned to the ground. If vertical drain will be coming back

more than tolerance; Location within ≤ 15cm, Verticality less than 5%, the length of

PVD not higher than 1% (comparing with design), vertical drain shall be rearranged.

Splicing:

Splicing of the PVD shall be done by stapling with proper workmanship ensuring the

structural and hydraulic continuity of the drain. At the splice the jacket of the upper

part of the drain shall be external to the lower portion. A maximum of one splice per

drain will be permitted without specific permission from the Engineer.

The jacket and core shall be overlapped a minimum of 30 cm at any splice.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 9 of 29

Cut and record

When casing pipe will be set back to original position, the plastic band drain shall be

cut by knife. Vertical Drain shall be remained 30cm from the platform to wrap to

filtration pipe

At the same time, the length of each vertical drain shall be recorded in the monitoring

format. Total vertical drain length will be calculated each day, cumulated and

presented every day as a daily progress report.

Afer finishing PVD works, plan cleaning will be done

Noted:

The length of the PVDs length design is only theoretical. In fact, PVDs length shall be

adjusted depending on the actual geological conditions. During the construction

process, if marred or may not proceed to install PVDs as length design, site engineers

need to immediately notify the site manager for appropriate solutions.

(4) Inspection

Tolerance of PVD point: less than 15cm

The length of PVD: not higher than 1% (comparing with design)

Tolerance of verticality: less than 5%

Remaining length on the surface: 30cm

Quantity of PVDs points: follows design document

4.4. INSTALLATION OF HORIZONTAL PIPE SYSTEM

The horizontal pipe system includes: The main pipe UPVC D63 without punched and the

filtration pipe, PE D50 with punched, covered with non-woven geotextile and connected to

each other by 4-way connection and 3-way connection. These steps of installation of the

horizontal pipe system are indicated as below:

4.4.1. Material requirement of horizontal pipe and covered geotextile

Water and air in soft soil, ground shall be got out through a horizontal pipe under

vacuum system. The horizontal pipe might adequate hard, can be bent and without

compact under external load.

The covered geotextile might ensure filter feature, unbroken under vacuum pressure

and without a tear in the construction process.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 10 of 29

Table 4.4.1 Specification of covered geotextile

No. Item Standard Unit Requirement

1 Unit weight TCVN 8221 g/m2 ≥ 200

2 Pore size TCVN 8871-6 mm < 0.08

3 Permeability coefficient ASTM D4491 cm/s > 2 x 10-2

4.4.2. Construction procedure of horizontal pipe

Construction procedure of horizontal pipe will be indicated as flow chart below:

Setting out the position of

(1)

D50, D63

(2) Dig trench

(3) (4)

Installation D50 Installation D63

Cut and connect to D63 of

Wrap PVD to D50

Vacuum pump

(5) Wrap D50 to D63

(6)

No Check No

Yes

Carry out of next works

Figure 4.4.1 Flow chart of horizontal pipe construction procedure

(1) Setting out of position of horizontal pipe D50 and D63

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 11 of 29

Base on the construction drawing for horizontal pipe, setting out of position at the

site

(2) Dig the trench

For filtration pipe D50: Using a shovel to open trench with cross section is triangle

shape 15cm x 20cm or rectangular shape 15cm x 15cm x 20cm at PVDs rows (with

20cm depth of the trench).

For main pipe D63: The trench size of main pipe D63 is similar the trench size of

filtration pipe D50.

(3) Construction of filtration pipe D50

The filtration pipe system will be installed in the same position of PVDs rows. The

head of PVDs shall be wound to filtration pipe at least 2 cycles and tied by plastic

belt to ensure stability of connection and continuity of the permeability path during

the construction process

Figure 4.4.2 Illustration of filtration pipe installation and wrap

(4) Construction of main pipe D63

Install one (01), two (02) or more main pipes parallel the center line depend on the

cross section of the road or the influencing of the vacuum pump.

At the position of the vacuum pump, one (01) pipe D63 is connected to main pipe

D63 by 3-way connection. It is also put into the trench and connected with pipe D76

by L shape connection (this position of L shape connection have distance is about

1.0m to 1.5m away from the boundary).

(5) Wrap filtration pipe D50 to main pipe D63

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 12 of 29

The filtration pipe system shall be connected to the main pipe by 3-way connection

or 4-way connection.

The position of connection point might follow the design drawing and shop drawing

of horizontal pipe.

(6) Check the horizontal pipe installation

PVDs were wrapped and tied to the filtration pipe and guarantee constant.

The connection point will be covered with geotextile to ensure without entered of

sand during vacuum operation process. This connection point also guarantees

constant, without breaking and failure follows the construction period.

After completed, fill sand in the trench, clean the site and prepare the next steps.

Figure 4.4.3 Illustration of main pipe D63 installation and connected with pipe D50

4.5. CONSTRUCTION OF GEO-MEMBRANE AND GEOTEXTILE

4.5.1. Material requirement of Geo-membrane and Geotextile

The requirements of geo-membrane material are shown in table 4.5-1 as below:

Table 4.5.1 Specification of geo-membrane

No. Item Standard Unit Requirement

1 Thickness TCVN 8220 mm 0.14

2 Breaking pull force in curling direction ASTM D-882 MPa ≥ 15

3 Elongation when broken ASTM D-882 % ≥ 220

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 13 of 29

No. Item Standard Unit Requirement

4 Breaking pull force in dimension direction ASTM D-882 MPa ≥ 15

5 Tearing resistance in curling direction, N/mm ASTM-D624 N/mm ≥ 40

6 Tearing resistance in dimension direction ASTM-D624 N/mm ≥ 40

7 Permeability under static pressure of 100kPa ASTM –D5886 cm/s ≤ 10-11

Anti-permeability strength or hydrostatic

8 ASTM D5385 kPa ≥ 150

pressure resistance

Geotextile layers protect geo-membrane

Geotextile layers have to guarantee technical requirements as below:

Table 4.5.2 Specification of geotextile layers

No. Iteam Standard Units Level 1 Level 2

1 Unit weight TCVN 8221 g/m2 ≥ 150 ≥ 300

2 Thickness TCVN 8220 mm ≥ 1.5 ≥ 2.2

3 Strength at break ASTM D4595 kN/m ≥ 6.5 ≥ 9.5

4 Elongation at break ASTM D4595 % ≥ 50 ≥ 50

5 Trapezoid tearing force TCVN 8871-2 kN ≥ 0.1 ≥ 0.24

6 Penetration strength CBR TCVN 8871-3 kN ≥ 0.6 ≥ 1.5

Noted: Level 1 of geoxtextile is used for the first geotextile layer under geo-membrane. Level

2 of the geotextile is used for the second geotextile layer upper Geo-membrane.

4.5.2. Construction procedure of Geomembrane and Geotextile

Construction procedure of Geo-membrane layers and geotextile layers are indicated in flow

chart as below:

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 14 of 29

(1) Laying the first geotextile layer

Transfer geo-membrane to the

(2) site

(3) Laying the first geo-membrane layer

(4) Checking the first geo-membrane layer

(5) Laying the second geo-membrane layer

(6) Checking the second geo-membrane layer

bury the edge of geo-membrane

(7) into the trench or clay mixing wall

(8) Install the vacuum system

Figure 4.5.1 Flow chart of construction sequence of geo-membrane and the 1st geotextile

The construction site shall be cleaned before laying geotextile layer, particularly,

remove all strange objects, sharp objects to out of site.

(1) Laying the first geotextile layer

These rolls of geotextile shall be laid and sewn by sewing machine with overlap is

about 10cm.

Follow the treatment boundary, the edge of the geotextile is remained about 2.0m to

2.5m that shall be buried combine Geo-membrane into the trench.

Checking the sewed line to ensure enough of overlap and stable

Geotextile should be constructed in dry environment condition, if has water, It will

be heavy, these works such as transfer, laying, sewed become difficult.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 15 of 29

Figure 4.5.2 Illustration of geotextile laying and sewed

(2) Transfer geo-membrane to the site

Transfer the rolls of geo-membrane to the site, a sign of these rolls of geo-membrane

from the manufactory was corresponded these treatment zones based on the order.

(3) Laying the first geo-membrane layer

Geo-membrane layer shall be laid and covered the treatment entire area, at the

treatment boundary, the edge of the Geo - membrane have to remain about 3.0m to

4.0m to bury into the trench. If using two (02) or more Geo-membrane layers, it will

be connected by special glue, the width of overlap is not less than 10cm.

Mobilize enough workers to complete Geo-membrane laying for each time of laying

and conduct under grade 5 of wind. During Geo-membrane laying, the workers

should be equipped with the soft sole of shoes and gloves to avoid tearing of the Geo

- membrane.

(4) Checking the first geo-membrane layer

Check carefully the treatment entire area, if any lacerations or puncture that will be

mended immediately.

(5) Laying the second geo-membrane layer

After completing these works above, construct the second go-membrane layer. The

construction process and checked steps are similar the first Geo-membrane layer.

(6) Checking the second geo-membrane layer

After completed installation of two (02) geo-membrane, set up these devices such as

waiting connection point of vacuum pump, pipe of vacuum gauge, monitoring

instrumentation on surface of the second geo-membrane layer, connection points

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 16 of 29

between these devices with geo-membrane are also glued, tied carefully to ensure

airtight. Noted: Surface settlement plate has to cover by geotextile or bags when set

on the surface of geo-membrane to avoid breaking of geo-membrane.

Figure 4.5.3 Illustration of laying geo-membrane layer

(7) Bury geotextile and geo-membrane into trench

The first geotextile layer and two (02) geo-membrane layers shall be buried into

trench.

During vacuum trial, conduct to check all of treatment area, treatment boundary. If

any leakage or tearing of geomembrane layer, glue immediately to ensure airtight.

Using an excavator with 0.4m3 to 0.9m3 volume to dig a trench along treatment

boundary. The depth of trench depends on the depth of the first original clay. The

edge of the Geo - membrane has to bury at least 0.5m into the first original clay to

ensure airtight.

After burying Geo-membrane, filling the trench. On the side that located vacuum

pump system, make a drainage ditch with dimension is 0.5m width of drainage ditch

bottom, 0.5m ~ 0.7m depth during filling the trench.

Some cases, The edge of the Geo - membrane may bury previously into the trench,

after that connect it with main Geo-membrane on the surface of treatment area.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 17 of 29

Figure 4.5.4 Illustration of buried constrution of geo-membrane

(8) Vacuum system installation

This item is indicated clearly in section “Installation and operation of vacuum system”

4.6. INSTALLATION AND OPERATION OF VACUUM SYSTEM

4.6.1. Material and device parameters of vacuum system

Table 4.6.1 Material and device parameters of vacuum system

No. Item Type/capacity Note

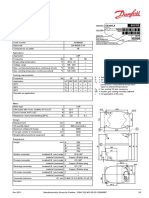

1 Vacuum pump 7.5 kW

20 switch type, with electrical leakage

2 Electric box (EB) -

protection Aptomat

3 Electric wire

4x240

3.1 From source to EB Aluminum core

(or 4x185)

From EB to vacuum

3.2 4x4 Copper core

pump

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 18 of 29

4.6.2. Constrution procedure of installation and operation vacuum system

The installation procedure and operation vacuum system are shown as flow chart below:

After competed geo-membrane

laying and buried

Set up vacuum system

(1) (vacuumpump, valve, pump box,

Supervision and checking

pipe D76, electric wire e.g…)

Set up electric system (electric wire,

(2)

EB, safe system)

(3) Opening Vacuum system

(4) Laying the second geotextile layer

Figure 4.6.1 Flow chart of construction and opening vacuum system

(1) Vacuum pump installation

These vacuum pumps with 7.5 kW capacity may create vacuum pressure ≥ 70 kPa

under geomembrane layer.

Connect valve, water bucket into the pump

Put a pump in pump box, then the pump box may place in drainage ditch or pond.

Guarantee pump box and pond always full water because these vacuum pumps are

submersible pump type.

Drainage pipe D76 is PVC pipe with steel core, it is connected to vacuum pump by

connection joint (connection head of the pump) that located nearby the treatment

boundary. To transfer water from the main pipe to pump and get out.

The length of pipe D76 must be long enough to ensure not append even embankment

construction or surcharge loading.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 19 of 29

Any connections have to ensure airtight (using rubber gasket, waterproofing tape if

necessary) to ensure no leakage of vacuum pressure during operation.

Finally, the power is connected to the pumping system: Each pump is connected to

one switch in the control EB to ensure easy switching when needed. The connection

must be performed by electricians, electrical safety during construction

Figure 4.6.2 Illustration of vacuum pump installation

(2) Electric system

The power source supplies to the site need to ensure sufficient capacity for all the

pumps running continuously and stability.

Each EB is designed to control 15 to 20 pumps with independent switches. Power

from the source to the EB through the aluminum cable system 4x185 or 4x195. 4x4

copper cable type is used to connect power from EB to each vacuum pump, each

pump uses an independent wire.

The control EB must be had aptomat electric leakage protection for electrical safety

during construction

Electricity should be provided regularly. In case of power cuts, power supply

constructor should inform planning power cuts previously at least 05 days for

contractors to prepare plans redundant power supply.

Any cases of power cuts influence effective of vacuum running and the schedule of

the project, the contractor will be updated and reported to the Client and consultant

by technical letter

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 20 of 29

(3) Vacuum system operation

After complete the vacuum system as design requirement, perform vacuum trial.

Trial time is from 7 days to 14 days, after that, vacuum pressure must be reached

higher than 70 kPa under geo-membrane layer.

Vacuum trial process is also time to check and repair all vacuum systems, including

detection and patched these punctures on the surface of Geo-membrane, check the

pump connection position, the location of the Geo - membrane buried.

After the vacuum trial process is the process of stable vacuum running. During this

process, the vacuum pressure has to achieve and remain stable follow the design

requirement. Vacuum pressure will be reached over 70kPa or 80kPa during the

construction process.

The vacuum pressure is required to be ≥ 60 kPa for soil mass improved, namely the

vacuum pressure of 60 kPa have to be retained in soil mass between PVDs.

(4) Laying the second geotextile layer

Specification requirement of the second geotextile is indicated in table 5.5-2

“Specification of geotextile layers”.

When ensured that the Geo-membrane layer satisfy the requirement, the vacuum

pressure achieved as designed, carry out of laying the second geotextile.

The spread, sewing and inspection was carried out similar to the first geotextile layer

4.7. MONITORING

The monitoring system will be used to check the suitability between construction

process and shop drawing about vacuum pressure, actual settlement compared to

predict settlement, check the slope stable during the construction process

Monitoring process will be carried out by monitoring contractor. During the

installation and monitoring, to ensure safety, without causing damage to the vacuum

system

4.8. SURCHARGE PROCESS

After the end of vacuum trial running, when vacuum pressure reached to design

requirement, surcharge process will be carried out

Surcharge or remove surcharge process shall not be effected to vacuum system,

especially clay mixing wall system, drainage trench, geomembrane, ...

Surcharge work will be carried out by filling contractor, but it follows the

requirement below

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 21 of 29

- Surcharge material: According to the filling material specification

- Construction sequence: According to Standard filling construction and

inspection

Note: The minimum thickness of compaction layer is 0.6m that shall not be effected

to vacuum system

4.9. POST SOIL INVESTIGATION

The post soil investigation must be carried out at the end of soil improvement work

to assement the properties of the soil layers. This work will be submitted by an

individual methodstatement later.

4.10. MAIN MACHINE-EQUIPMENT AND HUMAN RESOURCE

4.10.1. Main machine - equipment

Supplied machines, equipments for vacuum construction is shown in the table below:

Table 4.10.1.1 Summary of machines and equipments

No Machine name Type Unit Quantity Remark

1 PVD Machine BJ800 PCs 02

2 Excavator 0.7 m3 PCs 04

3 Vacuum pump 7,5kVA PCs 100

4 Total station Topcon – 233N PCs 01

5 Automatic elevation PCs 01

6 Transformer station 500kVA PCs 01

7 Rollers 16T PCs 2

8 Bulldozers PCs 1

9 Truck 15m3 PCs 5

4.10.2. Human resource

Manpower include manager/technical staff and worker.

Manager/techinical staff will be shown detailed in manpower document that will

submit to Consultant later.

The Worker will be mobilized following the project progress. The quantity of

worker is proposed such as:

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 22 of 29

Table 4.10.2.1 Summary of proposal manpower

No Manpower Quantity Remark

1 Manager/technical staff 05

2 Worker 20

5. CONSTRUCTION PROGRESS

The soil improvement work is proposed to carryout in six months. The detail S.I.W schedule

is shown in attachment “S.I.W schedule”, but this construction schedule must be updated and

approved by owner and supervisor.

6. QUALITY MANAGEMENT

6.1. QUALITY OF PLAN AND GOAL

A 100% acceptance upon completion.

A 100% quality acceptance. To satisfy quality requirement according to relate

standard and codes, reach or exceed the design requirement.

6.2. QUALITY GUARANTEE SYSTEM

Figure 6.2.1 Quality guarantee system

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 23 of 29

7. HEALTH, SAFETY, ENVIRONMENT AND FIRE-EXPLOSION PREVENTION

(HSE)

7.1. HSE GOAL

Health Goal: no diseases, no radioactive threats

Safety Goal: no occurrence of serious casualties, fire disasters, machinery accidents,

injury within a thousand people

Environment Goal: protect the environments at the most, no construction pollution.

Strive for a clear site upon completions

7.2. HEALTH MANAGEMENT

7.2.1. Health and Protection

Equipped with body protection apparatuses and clothes.

No use of any unhealthy and polluted material.

Increase self-protection concepts. No use of hazardous and deteriorated foods.

No smoking on site. No activity in the dorm influencing others.

Regular health examinations. Treat and cure unhealthy personnel. Back to work after

healthy restoration.

Equipped with wind and dust protections, e.g., wind protection clothes, eye

protection glasses.

7.2.2. Health on site

The toilet on site are prepared and cleaned the regularly

Discharges and disposals will be mobilized out of the site

7.3. SAFETY MANAGEMENT

7.3.1. Safety management System

Form a panel including Project Manager and HSE Manager. Project Manager takes

the principal responsibility. HSE Manager takes the direct responsibility. Special

Safety Engineer is in charge of regular safety affairs, inspection of safe actions of

personnel. Each team is equipped with Special Safety Technician and Safety

Technician

Optimize safety management rules. The rules should be department-and team-

specific, and include safety instruction, rules, safety inspection rules, accidents

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 24 of 29

processing rules, and benefit-penalty rules. The rules are carried by each tier to build

an environment of safe construction maintained by each person

Establish a safety responsibility system based on safe duties. Specify the safety

responsibilities of each tier personnel

The main safety precautions include mechanical injuries, electrical shocks, traffic

accidents, fire disasters and poisonous foods

Carry out safety examination rules stringently. Firstly, the Project Manager should

ensure they carry-out of rules. Secondly, any identified safety concern should be

subjected to reporting, reconstruction and removal. Thirdly, combine safety

examinations with rules modification

7.3.2. Electrical safety Rules

Upon constructions, examine stringently the tools and instruments. No use of unsafe

tools and instruments. Precautions on voltage, current and isolation should be abided

by. Electricians should wear protections and isolative tools.

Electricians should repair or install only if the power is switched off. Examinations

under electrical conditions should not be conducted alone, in which case, one

company should stand by and take necessary safety measures.

Temporary power lines should abide by safety specifications. Outdoor power lines

must not be exposed to bumps, mechanical ruins, chemical corrosions and rolling-

over. Connections should be protected from water and humidity and well isolated.

The open switch box must be equipped with electrical protections, whose

specifications and capacities should meet criteria. The switch box should protect

from rainfalls and wet conditions. After rainfalls, electricians should measure the

resistively of the switch box. Only if safe requirements are met, the switch box can

be used. The switch box should be used for one machine. Prohibit multiple machines

loaded by one switch box.

7.3.3. Estimation of unsafe item and solve solutions

Table 7.3.3.1 Table of Identification and assessement of unsafe source and factor

Frequency and Solution

No Actives Dangers Consequence Remark

Frequency Solution

Machine Safety training, Armed

PVD Mechanical

1 crash to Low safety equipments

Machine injuries

people when climb on the rig.

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 25 of 29

Machine driver must

to have license

Safety training, Armed

Trench Crashed Mechanical safety equipments;

2 Low

excavation into people injuries Signal when

excavation

Safety training, Armed

Vacuum Electrical safety equipments,

3 Death Low

Operation shock changed the new

wire…

7.4. ENVIRONMENT MANAGEMENT

Learn and abide by the Vietnam’s environmental protection rules. Enhance the

concept of all personnel on environmental protections.

Stipulate benefit-penalty rules. Examine and inspect stringently. Carry out

environmental protection responsibility rules. Conduct irregular examinations and

document the examinations

Abide by the rules and be easy-going. Coordinate with the owner, inspectors and

general contractor. Be friendly with the local residents.

Assign special people to clean the site 24 hours a day. Debris and dust should be

covered. Construction debris and garbage should be removed or stored tidily

Maintain a safe environment in construction and living sections. Remove garbage

timely to specified locations. Septic tanks are excavated in living areas. Sewage and

discharges should be discharged into sewage pipelines only if treated. No discharge

directly out of the site

In public facilities, reliable measures should be carried out to protect their ruins and

removed, and be presented to all personnel

Site removals, e.g., topsoil, turfs, trees, stumps, roots, bushes and debris, should be

timely disposed to specific locations, and must not impede constructions and

environmental protections

7.5. FIRE/EXPLOSION PREVENTION

7.5.1. Fire/ Explosion sequence

Inform everyone

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 26 of 29

Call phone number 114 (fire prevention and fighting force)

Rescure people, moving property, other equipment out of fire area

Carry out fire prevention on spot and fire fighting

Control fire area, keep fire area do not spread out further

Lead the way for fire fighting profesional force

Guard keep law and order, property protection

To solve the consequoence. Meeting and learn from experience

7.5.2. Fire/ Explosion prevention method

Zoning for working, material on the site

Fire forbidence on the site

Armed fire quipment on spot as: Fire extinguisher, sand, shovel, water pump,…

Phone number of fire fighting force need to placed that easy to see on the site and

office

No smoking when working, it has the smoking area on the site

To estabish the fire fighting on spot

No cooking on the site

7.5.3. Fire/ Explosion fighting method

Using water with the nornal case as geotextitle, PVD, geomembrane

Using sand to cure the fire of diesel, petrol

Using CO2 box cure the fire of electricity

Using MFZ box for all case

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 27 of 29

7.6. COUNTERMEASURES AGAINST UNSAFE SOURCES

The solve solution for emergency incident on site is such as:

Safety manager

Tel: ………….

Hospital

Tel: …………. Action to prevent

Site office accident

Victim’s

Organization of Cambodia -

Tel: …………

Contractor’s

Leader

Tel: …………

Government offices

concerned : Regional police

Tel: ………..

Figure 7.6.1 Solve solution for emergency incident

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 28 of 29

Appendix 1. METHOD STATEMENT DRAWINGS

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

JOTUN VIETNAM - GREENFIELD PROJECT

JOTUN Job No. 2017-2340

TVC Job No. VD-156

METHOD STATEMENT FOR SOFT SOIL

IMPROVEMENT WORK

Jnne 18th 2018 Rev. 0 Project Doc. No. VD156-CV-JOTUN- Page 29 of 29

Appendix 2. Schedule of VCM

FECON SOIL IMPROVEMENT AND CONSTRUCTION JSC

Add.: 19th floor, CEO tower, plot HH2-1, Pham Hung, Me Tri, Nam Tu Liem, Ha Noi

M M Ju Ju Ju Ju Ju Ju Ju Ju Ju A A A A Se Se Se Se Se O O O O N N N N D D D D D Ja Ja Ja Ja Fe Fe Fe Fe M M

Task Name Duration Start Finish

1 Soil improvment work by 180 days Sun 7/1/18 8:00 AM Thu 12/27/18 5:00 PM

Vacuum consolidation

2 Preparation: 15 days Sun 7/1/18 8:00 AM Sun 7/15/18 5:00 PM

3 Order and purchase mate15 days Sun 7/1/18 8:00 AM Sun 7/15/18 5:00 PM 7/1 7/15

4 Mobilization of 7 days Sun 7/1/18 8:00 AM Sat 7/7/18 5:00 PM 7/1 7/7

5 Methodstatment 7 days Sun 7/1/18 8:00 AM Sat 7/7/18 5:00 PM 7/1 7/7

6 Contruction: 152 days Sun 7/8/18 8:00 AM Thu 12/6/18 5:00 PM

7 PVD installation 20 days Sun 7/8/18 8:00 AM Fri 7/27/18 5:00 PM 7/8 7/27

8 Larsen installation 15 days Sun 7/8/18 8:00 AM Sun 7/22/18 5:00 PM 7/8 7/22

9 Vacuum system installat25 days Sun 7/8/18 8:00 AM Wed 8/1/18 5:00 PM 7/8 8/1

10 Monitoring installation 15 days Sun 7/8/18 8:00 AM Sun 7/22/18 5:00 PM 7/8 7/22

11 Vacuum trial running 7 days Thu 8/2/18 8:00 AM Wed 8/8/18 5:00 PM 8/2 8/8

12 Sand compensation fillin30 days Thu 8/9/18 8:00 AM Fri 9/7/18 5:00 PM 8/9 9/7

13 Vacuum running 120 days Thu 8/9/18 8:00 AM Thu 12/6/18 5:00 PM 8/9 12/6

14 Monitoring and 147 days Fri 7/13/18 8:00 AM Thu 12/6/18 5:00 PM 7/13 12/6

15 Post soil investigation 20 days Fri 12/7/18 8:00 AM Wed 12/26/18 5:00 PM 12/7 12/26

16 Site clean and Handover 1 day Thu 12/27/18 8:00 AM Thu 12/27/18 5:00 PM 12/27 12/27

Task Project Summary Manual Task Start-only Deadline

Split Inactive Task Duration-only Finish-only Progress

Milestone Inactive Milestone Manual Summary Rollup External Tasks Manual Progress

Summary Inactive Summary Manual Summary External Milestone

S-ar putea să vă placă și

- Method Statement For Plumbing Piping Works Rev.01Document46 paginiMethod Statement For Plumbing Piping Works Rev.01zenoses76% (37)

- Method Statement For Pipe Line Re-RoutingDocument6 paginiMethod Statement For Pipe Line Re-RoutingChris100% (1)

- Fluid FlowDocument88 paginiFluid FlowFren R.100% (2)

- Method Statement For Roof, Wall and Floor WorkDocument27 paginiMethod Statement For Roof, Wall and Floor WorkĐặng Quang HuyÎncă nu există evaluări

- Method Statement For Road and Paving WorkDocument32 paginiMethod Statement For Road and Paving WorkĐặng Quang Huy100% (7)

- Method Statement for RCUD ConstructionDocument9 paginiMethod Statement for RCUD ConstructionFa DylaÎncă nu există evaluări

- IRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Document100 paginiIRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Saroon Afshan76% (29)

- Singly Reinforced BeamsDocument15 paginiSingly Reinforced BeamsRhea Michelle Caballero100% (3)

- Aluminium Extrusion Process PlanningDocument10 paginiAluminium Extrusion Process PlanningHarshith Rao VadnalaÎncă nu există evaluări

- Assignment 1Document3 paginiAssignment 1Ansuman SahooÎncă nu există evaluări

- Method Statement for Internal CoatingDocument20 paginiMethod Statement for Internal CoatingNgô Trung NghĩaÎncă nu există evaluări

- GID-253-CV-GTPP-SITE-012 CMB Wall CracksDocument5 paginiGID-253-CV-GTPP-SITE-012 CMB Wall CracksAkash SharmaÎncă nu există evaluări

- HIC & SSC Test ProcedureDocument32 paginiHIC & SSC Test ProcedureMohamed FarisÎncă nu există evaluări

- Methodolgy012 Expansion JointDocument5 paginiMethodolgy012 Expansion JointMohd IrshadÎncă nu există evaluări

- Method Statement for Installing Stormwater Hume PipesDocument22 paginiMethod Statement for Installing Stormwater Hume PipesĐặng Quang Huy88% (8)

- Vol II of II 20181203 120035 PDFDocument259 paginiVol II of II 20181203 120035 PDFGilberto YoshidaÎncă nu există evaluări

- GID-253-CV-GTPP-SITE-010 RWPH RepairsDocument4 paginiGID-253-CV-GTPP-SITE-010 RWPH Repairsakash sharmaÎncă nu există evaluări

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFDocument8 paginiMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhÎncă nu există evaluări

- Methode Statement Weld & Fitup of PipeDocument14 paginiMethode Statement Weld & Fitup of PipeRio Cristovan MantiriÎncă nu există evaluări

- Trenching Procedure for Pipeline ProjectDocument5 paginiTrenching Procedure for Pipeline ProjectAkhilesh KumarÎncă nu există evaluări

- Tasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingDocument10 paginiTasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingFarhanÎncă nu există evaluări

- Tech BidDocument251 paginiTech BidAtex CertificationÎncă nu există evaluări

- Air Blowing of Piping (PTJ-Lub-Growth II-COM-008) Rev.01Document9 paginiAir Blowing of Piping (PTJ-Lub-Growth II-COM-008) Rev.01Ahmed Al SharabasyÎncă nu există evaluări

- method-statement-for-installation-of-hume-pipeDocument26 paginimethod-statement-for-installation-of-hume-pipemanishsinghqcmccÎncă nu există evaluări

- SSP Excavation Work PGRODocument23 paginiSSP Excavation Work PGROMuhammad Syazwan MuskamÎncă nu există evaluări

- General Method Statement For Epoxy Grout Rev NeilDocument9 paginiGeneral Method Statement For Epoxy Grout Rev NeilNeil JavierÎncă nu există evaluări

- MD1-0-T-030-05-00120 - ITP For UG Piping of HDPEDocument7 paginiMD1-0-T-030-05-00120 - ITP For UG Piping of HDPETran KhuynhÎncă nu există evaluări

- BRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Document21 paginiBRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Minh TruongÎncă nu există evaluări

- HFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BDocument14 paginiHFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BMohamed FarisÎncă nu există evaluări

- Method Statement Manual Loading Concrete Mixture Machine For Concrete Works - R1Document18 paginiMethod Statement Manual Loading Concrete Mixture Machine For Concrete Works - R1Shubham PatelÎncă nu există evaluări

- KOC-MP-022 Pt.1Document33 paginiKOC-MP-022 Pt.1Ravi MahetoÎncă nu există evaluări

- Method of Statement For Pipe BridgeDocument6 paginiMethod of Statement For Pipe BridgeShin thant KyawÎncă nu există evaluări

- Petrochemical Welding ProcedureDocument24 paginiPetrochemical Welding ProcedureTuan LuuÎncă nu există evaluări

- Method Statement For Erection of Scaffolding PDFDocument20 paginiMethod Statement For Erection of Scaffolding PDFChris Enyinnaya100% (1)

- Section 3 - Scope of WorkDocument14 paginiSection 3 - Scope of Worktrung nguyen tranÎncă nu există evaluări

- GID-253-CV-GTPP-SITE-016 Ironite IPS FlooringDocument6 paginiGID-253-CV-GTPP-SITE-016 Ironite IPS FlooringAkash SharmaÎncă nu există evaluări

- METHOD OF STATEMENT For HDPE Pipe InstallationDocument18 paginiMETHOD OF STATEMENT For HDPE Pipe InstallationShahzaib Shahid100% (3)

- Ml-12 Work Procedure For Hdpe Duct LayingDocument13 paginiMl-12 Work Procedure For Hdpe Duct LayingBrijesh Katariya VCSÎncă nu există evaluări

- Oe MS Ar 3082 - Rev1Document51 paginiOe MS Ar 3082 - Rev1Alvin BadzÎncă nu există evaluări

- PROCEDURE -3LPE -MSL-REV.00Document15 paginiPROCEDURE -3LPE -MSL-REV.00Suresh KrishnanÎncă nu există evaluări

- Magnetic Particle Testing Procedure for Piping and StructuresDocument22 paginiMagnetic Particle Testing Procedure for Piping and StructuresTuan LuuÎncă nu există evaluări

- MS Underground HDPE PN10, Corrugated & uPVC Pipe Installation Works Rev01Document20 paginiMS Underground HDPE PN10, Corrugated & uPVC Pipe Installation Works Rev01mieadidassÎncă nu există evaluări

- PROCEDURE - 3LPE -MSL-REV.01Document15 paginiPROCEDURE - 3LPE -MSL-REV.01Suresh KrishnanÎncă nu există evaluări

- Application - Bespoke - Non Technical SummaryDocument7 paginiApplication - Bespoke - Non Technical SummaryOsama AbbasÎncă nu există evaluări

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocument9 paginiMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- HDPE Piping Pressure Test ProcedureDocument36 paginiHDPE Piping Pressure Test ProceduretuanphamÎncă nu există evaluări

- NIT38HYDIV 52 CRDocument252 paginiNIT38HYDIV 52 CRRanjan SinghÎncă nu există evaluări

- RJE - SC - URUP - P1, P2, P3, P4&P5 (Hlawga, 33KV GIS)Document18 paginiRJE - SC - URUP - P1, P2, P3, P4&P5 (Hlawga, 33KV GIS)Htun SoeÎncă nu există evaluări

- 11-Backfiling at Station NoDocument7 pagini11-Backfiling at Station NoAkhilesh KumarÎncă nu există evaluări

- Method Statement For Hydrostatic Test & Pneumatic Test: Issue Purpose For ConstructionDocument19 paginiMethod Statement For Hydrostatic Test & Pneumatic Test: Issue Purpose For ConstructionHà HuệÎncă nu există evaluări

- Document Review Status: Sarawak Energy BerhadDocument14 paginiDocument Review Status: Sarawak Energy BerhadSaldan Mohammad HadoumiÎncă nu există evaluări

- PPR and uPVC Piping Installation Method StatementDocument46 paginiPPR and uPVC Piping Installation Method Statementjaianit8980% (5)

- RWR Method Statement-R00Document18 paginiRWR Method Statement-R00Rahul Kumar PatelÎncă nu există evaluări

- TIMOR - Specification For Rubber LiningDocument8 paginiTIMOR - Specification For Rubber Liningdimas prasetyoÎncă nu există evaluări

- 010-MS For Grouting PDFDocument33 pagini010-MS For Grouting PDFKöksal PatanÎncă nu există evaluări

- Method Statement For Geotechnical InvestigationDocument11 paginiMethod Statement For Geotechnical InvestigationRahulÎncă nu există evaluări

- Grap-Ii (2022)Document10 paginiGrap-Ii (2022)harish14586Încă nu există evaluări

- REPLICA-06-point LBC-21-06.07.2017 - UTDocument11 paginiREPLICA-06-point LBC-21-06.07.2017 - UTPham UtÎncă nu există evaluări

- SBDNITDhemajiDocument325 paginiSBDNITDhemajiAbhishek PathakÎncă nu există evaluări

- Method Statement For Trial LoadingDocument5 paginiMethod Statement For Trial LoadingPunithan PunithanÎncă nu există evaluări

- CivilWorks Design & CriteriaDocument51 paginiCivilWorks Design & CriteriaDidi QuaydiÎncă nu există evaluări

- Final Year ProjectDocument50 paginiFinal Year ProjectDanish KaiserÎncă nu există evaluări

- FreamworkDocument13 paginiFreamworkAbdullah AfifÎncă nu există evaluări

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeDe la EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeÎncă nu există evaluări

- Longwall Mining at Shallow Depth of Cover in IndiaDe la EverandLongwall Mining at Shallow Depth of Cover in IndiaÎncă nu există evaluări

- Profile of construction machine capacity for stone column & vibro compactionDocument26 paginiProfile of construction machine capacity for stone column & vibro compactionTran Huy HungÎncă nu există evaluări

- D400classa PDFDocument1 paginăD400classa PDFTran Huy HungÎncă nu există evaluări

- Soil Improvement Technology For Urban Underground Constructi...Document33 paginiSoil Improvement Technology For Urban Underground Constructi...Tran Huy HungÎncă nu există evaluări

- Technical Specification-VCMDocument18 paginiTechnical Specification-VCMTran Huy HungÎncă nu există evaluări

- D300class A PDFDocument1 paginăD300class A PDFTran Huy HungÎncă nu există evaluări

- D450class A PDFDocument1 paginăD450class A PDFTran Huy HungÎncă nu există evaluări

- D500classa PDFDocument1 paginăD500classa PDFTran Huy HungÎncă nu există evaluări

- D350class A PDFDocument1 paginăD350class A PDFTran Huy HungÎncă nu există evaluări

- FCS Novaland Presentation 2017 05 31Document40 paginiFCS Novaland Presentation 2017 05 31Tran Huy HungÎncă nu există evaluări

- 88ce40d0 4Document121 pagini88ce40d0 4Tran Huy HungÎncă nu există evaluări

- VCM MethodDocument44 paginiVCM MethodTran Huy HungÎncă nu există evaluări

- ASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsDocument80 paginiASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsJohn Henry Ramos SantosÎncă nu există evaluări

- 14.Stress-Strain Relationship in Axial Compression For EPS ConcreteDocument7 pagini14.Stress-Strain Relationship in Axial Compression For EPS ConcreteManuel GutarraÎncă nu există evaluări

- Altro Fix 15 Data SheetDocument1 paginăAltro Fix 15 Data SheetFloorkitÎncă nu există evaluări

- Para ProductsDocument12 paginiPara ProductsKyle MoolmanÎncă nu există evaluări

- Precision Steel Tube Handbook Third Edition PDFDocument218 paginiPrecision Steel Tube Handbook Third Edition PDFRohan KulkarniÎncă nu există evaluări

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument12 paginiAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Valve RatesDocument34 paginiValve RatesDeepthy VasavanÎncă nu există evaluări

- Rolling (Bulk Deformation Process)Document27 paginiRolling (Bulk Deformation Process)Kazal ArefinÎncă nu există evaluări

- DBR PDFDocument7 paginiDBR PDFrajeev shahÎncă nu există evaluări

- TN NewDocument6.322 paginiTN Newdeva nesan83% (6)

- Pump Design PresentationDocument9 paginiPump Design PresentationKayode Ijaola100% (1)

- Water Migration in Xlpe CableDocument4 paginiWater Migration in Xlpe CableSISWANTOÎncă nu există evaluări

- Cat Filtrazione 2017 enDocument80 paginiCat Filtrazione 2017 enTed ThomsonÎncă nu există evaluări

- Acoustic Materials GuideDocument110 paginiAcoustic Materials GuideMOHD AZHAR NUMANIÎncă nu există evaluări

- Group 15 : Relief Valves AccessoriesDocument4 paginiGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesÎncă nu există evaluări

- Bridge ConstructionDocument101 paginiBridge ConstructionMuhammad Nashrul FikriÎncă nu există evaluări

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocument2 paginiGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaÎncă nu există evaluări

- Fatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxDocument18 paginiFatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxSWAPNIL PATILÎncă nu există evaluări

- Static Electricity Balloon ExperimentDocument2 paginiStatic Electricity Balloon ExperimentRosalyn RechsteinerÎncă nu există evaluări

- Chapter 3: Design Principles of Embankment DamsDocument14 paginiChapter 3: Design Principles of Embankment DamsRefisa JiruÎncă nu există evaluări

- MULTIPLE CHOICE PAPER EXAMDocument2 paginiMULTIPLE CHOICE PAPER EXAMJeyakandan MarudiahÎncă nu există evaluări

- Electrical Checklist Plan Review ChecklistDocument13 paginiElectrical Checklist Plan Review ChecklistCB100% (1)

- Etm-211 Pead HMN 6060uv MarlexDocument4 paginiEtm-211 Pead HMN 6060uv Marlexnicolas yoris marcoglieseÎncă nu există evaluări

- Air Fiter - Regulator SB10Document3 paginiAir Fiter - Regulator SB10Abhishek SinghÎncă nu există evaluări

- Chapter 9 - Buckling of ColumnsDocument8 paginiChapter 9 - Buckling of ColumnswinzÎncă nu există evaluări