Documente Academic

Documente Profesional

Documente Cultură

M6 TTT Course Posters Final1 PDF

Încărcat de

JCA0 evaluări0% au considerat acest document util (0 voturi)

26 vizualizări1 paginăEnergy efficient ship operation requires implementing effective energy management plans and systems. Management systems like the International Safety Management (ISM) Code, ISO 9001 on quality, ISO 14001 on environment, and ISO 50001 on energy management all follow the continuous Plan-Do-Check-Act (PDCA) cycle for improvement. The IMO's Ship Energy Efficiency Management Plan (SEEMP) framework also uses a four step process of planning, implementation, monitoring, and self-evaluation. Shipping companies develop SEEMPs based on IMO guidelines and Company Energy Management Systems (CEnMS) based on ISO 50001 to manage ship and fleet-wide energy efficiency. Energy audits and reviews are important planning activities to identify energy efficiency measures

Descriere originală:

Titlu original

M6 TTT course Posters final1.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentEnergy efficient ship operation requires implementing effective energy management plans and systems. Management systems like the International Safety Management (ISM) Code, ISO 9001 on quality, ISO 14001 on environment, and ISO 50001 on energy management all follow the continuous Plan-Do-Check-Act (PDCA) cycle for improvement. The IMO's Ship Energy Efficiency Management Plan (SEEMP) framework also uses a four step process of planning, implementation, monitoring, and self-evaluation. Shipping companies develop SEEMPs based on IMO guidelines and Company Energy Management Systems (CEnMS) based on ISO 50001 to manage ship and fleet-wide energy efficiency. Energy audits and reviews are important planning activities to identify energy efficiency measures

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

26 vizualizări1 paginăM6 TTT Course Posters Final1 PDF

Încărcat de

JCAEnergy efficient ship operation requires implementing effective energy management plans and systems. Management systems like the International Safety Management (ISM) Code, ISO 9001 on quality, ISO 14001 on environment, and ISO 50001 on energy management all follow the continuous Plan-Do-Check-Act (PDCA) cycle for improvement. The IMO's Ship Energy Efficiency Management Plan (SEEMP) framework also uses a four step process of planning, implementation, monitoring, and self-evaluation. Shipping companies develop SEEMPs based on IMO guidelines and Company Energy Management Systems (CEnMS) based on ISO 50001 to manage ship and fleet-wide energy efficiency. Energy audits and reviews are important planning activities to identify energy efficiency measures

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

ENERGY EFFICIENT

SHIP OPERATION

ENERGY MANAGEMENT PLANS AND SYSTEMS

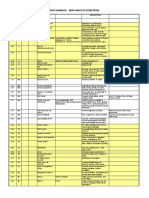

Management Systems PDCA Cycle Commonalities of Management IMO SEEMP Framework

in Shipping Plan-Do-Check-Act refers to the Systems The SEEMP works through four steps:

• ISM Code: The most continuous improvement cycle. PDCA It can be demonstrated that all the • Planning,

prominent is the most basic framework for any management standards have common • Implementation

management system management system. features in areas of: • Monitoring, and

that is already • Plan: Develop an action plan of the • Need for defining objectives and • Self-evaluation

mandatory in shipping. activities that need to be done policies

Safety is at its core. together with all relevant • Need for top management

implementation details. engagement and commitment.

• ISO 9001: Quality • Do: Implement the action plan and • PDCA cycle approach for continuous

Management System the selected efficiency measures. improvement

• ISO 14001: • Check: Monitor the results of the • Need for training of human resources

Environmental implementation via effective data • Need for monitoring and inspection

Management System analysis and assessments. SEEMP is:

• OHSAS 18001: Health • Act: Review the effectiveness of

and safety systems. the plan and set new targets. Ship- Includes a Implementation

specific number of EEM oriented

• ISO 50001: Energy Management commitment is the cornerstone of implementation of any management system including

Management System energy management plans and systems

Shipping Company Approach to Ship Energy Audit/Review

ISO 50001 Energy Management Company Energy Policy Energy Management Development of a SEEMP based on IMO

ISO 50001 is based on PDCA principle A “company energy policy” sets the agenda for the corporate- guidelines or a CEnMS based on ISO 50001

Two tier approach:

and the main aspects include: wide energy saving and reduction of GHG emissions . Based on will involve planning activities. An energy

• SEEMP for ship-level energy

• Energy policy ISO 50001, it needs to be developed and endorsed by top management according to IMO

audit or review is best for this purpose.

• Energy planning management. The energy policy would deal, inter alia, with the Guidelines

Also, audits could be used for monitoring

• Implementation following topics: • CEnMS (Company Energy Management

of SEEMP or CEnMS effectiveness.

• Checking • Aims, objectives and targets System) for fleet-level energy

Depending on the area of application, the

• Management review • A commitment to continual improvement management based on ISO 50001.

energy audit scope and objectives may be

• A commitment to ensure the availability of resources to different.

achieve objectives and targets; A CEnMS needs to deal with both shore-

• A commitment to comply with applicable legal and other A ship energy audit normally aims to

based and ship-based energy efficiency

requirements; identify a set of EEMs for implementation

aspects. In this approach, SEEMP will be a

• A framework for setting and reviewing energy objectives and purposes. As part of the audit/review, all

sub-set of the CEnMS. A CEnMS will thus

targets; aspects of the ship including hull,

be in harmony with ship-board SEEMP and

• A commitment to training staff and engaging major external propeller, engines, auxiliary machinery ,

vice a versa.

stakeholders. voyage, route, trim, training, etc. will be

• Support for purchase of energy-efficient products / services assessed.

Other aspects of the CEnMS include:

Commitment from the management at the highest level should • Energy policy development

be demonstrated via energy policy endorsement and its wide A ship energy audit/review may involve a

• Planning for ships via development and

communication to staff at all levels. number of phases.

improving SEEMPs across fleet.

• Phase I – Pre-survey activities such as

Source: ISO 50001:2011

• Planning the fleet-level energy

Data Collection and preliminary data gathering and data

Performance Monitoring management plan

Reporting reviews

The scope of the company’s performance • Gathering fleet data, monitoring and

IMO data collection system is • Phase II – Ship survey: The ship visit is

monitoring activities could include any benchmarking

currently under development • Managing the investment on capital- planned and carried out by the auditor,

aspect of the fleet/ship including voyage

and advocates the collection facilitated by ship personnel

analysis, hull and propeller condition, intensive energy saving projects such as

of ships’ fuel consumption • Phase III – Analysis of data for the

engines condition, auxiliary machinery ship technology upgrades.

and some other parameters. • Fleet-wide training of staff identified measures and reporting.

utilisation and so on.

A shipping company energy review or

• Coordination with all stakeholders such

The system aims to have audit will follow the same format but areas

Performance monitoring invariably rely on as ports, charterers, shipyards, etc.

three main elements: to be investigated will be different and the

data collection and analysis. Depending

1. Data collection by ships How to Train or Incentivize Staff concentration will be on common high-

on how data are collected and analysed,

2. Flag State functions of level issues of the fleet.

the monitoring systems can be divided Increasing awareness and incentives of

Engine Performance /

into: data verification staff are key to a successful energy Marginal Abatement Cost Curves

• Manual: Systems with manual data Condition Monitoring 3. Establishment of a management campaign. This may be

These systems are primarily (MACC).

logging, data analysis and reporting centralised database at done via a number of ways: A simple and effective way of presenting

(for example once every 24 hours); based on analysis of cylinder the IMO. • Training either direct or through

pressure data. Cylinder pressure the EEMs for a ship or a fleet is by

• Automatic: Systems with automatic distance-learning, ‘Computer Based plotting a MACC. A MACC can be

data logging, data analysis and is measured and processed for: Although not final yet, some Training (CBT)’ programs

• Maximum cylinder pressure developed through the following steps

reporting with high sampling rates; general agreement has been • Regular on-board meetings on the • Step 1 – Identify EEMs and their

• Hybrid: Hybrid systems with some • Angle of this maximum reached in areas of: subject.

• Cylinder compression pressure • Applicable to ships greater • Poster campaign and communication energy saving levels.

manual and automatic elements. • Step 2 – Calculate the cost of

Modern performance monitoring systems • Ignition angle – The angle at than 5000 GT. of energy policy.

which combustion starts implementation of the EEMs.

also utilise: • Annual reporting • Collection of ship-level seafarers • Step 3 - From fuel consumption ,

• Advanced sensors and data • Indicated power as measured • Use of the IMO number ideas, and their documentation and

on top of the piston estimate annual CO2 reductions (X

communication technologies; for ship identification implementation. axis).

• Ship-shore communication; and • Registered owner will be • Develop competition for energy • Step 4 - From steps 2 and 3 calculate,

• Big data analysis capability. In addition, current day systems responsible for submission efficiency, e.g. between ships..

collect other data such as engine the cost-effectiveness ($cost per

Hull performance monitoring of data. • Use of company magazine or other tonne CO2 reduced) (Y-axis).

brake power, scavenge pressure, • Flag Administration will be publicity documents for raising

For hull performance monitoring, various turbocharger speed, fuel injection • Step 5 – Rank the EEMs from the

techniques are used including: responsible for data awareness and interest . lowest MAC to highest MAC.

pressure diagram, etc. in support verification.

• Assessment of ship speed-power of the analysis. • Step 6 – Plot the MACC using the

curve relative to a baseline; measures according to their rank.

• Assessment of level of added Step by step approach to energy

resistance relative to a baseline; management: Diagram shows this

• Use of divers to visually inspect the approach by starting from low cost

hull and propeller conditions. measures to moving to higher cost

ones.

In practice, a combination of the above

methods will be most satisfactory.

This poster is for training purposes and developed for use within IMO capacity building activities. It is subject to change by IMO . November 2015 Source: DNV 2010

S-ar putea să vă placă și

- Accounting for sustainable development performanceDe la EverandAccounting for sustainable development performanceÎncă nu există evaluări

- Bsi0161 - 1808 - NZ - Iso 50001 Implemention Guide Web PDFDocument12 paginiBsi0161 - 1808 - NZ - Iso 50001 Implemention Guide Web PDFAnggoro AntonoÎncă nu există evaluări

- Bsi Us Iso 50001 Implementation GuideDocument12 paginiBsi Us Iso 50001 Implementation Guidejbl_100% (1)

- نموذج خطة بحث عربيDocument19 paginiنموذج خطة بحث عربيAhmed Hassan ShehataÎncă nu există evaluări

- 1.4 Energy AuditsDocument17 pagini1.4 Energy AuditsKhaled QarraÎncă nu există evaluări

- ISO 50001 EnMs (Draft)Document21 paginiISO 50001 EnMs (Draft)AgustinusDwiSusantoÎncă nu există evaluări

- ISO 50001 Implementation Guide LR - IndiaDocument7 paginiISO 50001 Implementation Guide LR - IndiaDebabrata PanigrahiÎncă nu există evaluări

- Energy ManagementDocument47 paginiEnergy ManagementUnstraightable FingerÎncă nu există evaluări

- Chapter 2 Energy Management System Part 1Document74 paginiChapter 2 Energy Management System Part 1Zafirah HanafiÎncă nu există evaluări

- Project Report 2Document18 paginiProject Report 2Arif AliÎncă nu există evaluări

- Chapter 2 - 1Document17 paginiChapter 2 - 1Hana YukiÎncă nu există evaluări

- Energy MGT & Audit TrainingDocument75 paginiEnergy MGT & Audit TrainingMaintenance marinÎncă nu există evaluări

- Exchange of Experience Energy Management System ISO 50001: 2018 General IntroductionDocument40 paginiExchange of Experience Energy Management System ISO 50001: 2018 General IntroductionCodyÎncă nu există evaluări

- Chapter 3 EbookDocument27 paginiChapter 3 EbookwongÎncă nu există evaluări

- Energy Management System 2Document13 paginiEnergy Management System 2Azmi HashimÎncă nu există evaluări

- Advisory Services Energy Management Action Plan BrochureDocument12 paginiAdvisory Services Energy Management Action Plan BrochureGys SmedaÎncă nu există evaluări

- DNV GL Adv Energy Efficiency Excellence BC 3 2017Document4 paginiDNV GL Adv Energy Efficiency Excellence BC 3 2017Gerardo AguirreÎncă nu există evaluări

- Iso 50001Document10 paginiIso 50001candhareÎncă nu există evaluări

- ISO 50001 UnidoDocument46 paginiISO 50001 Unidoiwan100% (1)

- Proving The Sustainability of Your Enterprise With ISO 50001Document2 paginiProving The Sustainability of Your Enterprise With ISO 50001Oscar GarciaÎncă nu există evaluări

- EE MethodologyDocument72 paginiEE MethodologyNitipal SinghÎncă nu există evaluări

- Comparing Actual Performance To Objectives and StandardsDocument2 paginiComparing Actual Performance To Objectives and StandardscrsitalÎncă nu există evaluări

- Energy ManagmentDocument226 paginiEnergy ManagmentEcy Yghi0% (1)

- Iso 50001 Guide and Check List UkDocument47 paginiIso 50001 Guide and Check List UkAnggoro Antono0% (1)

- ISO 50001:2018 EssentialsDocument19 paginiISO 50001:2018 Essentialscaesar bintangÎncă nu există evaluări

- A Guide To ISO 50001 2018 Energy Management SystemsDocument6 paginiA Guide To ISO 50001 2018 Energy Management Systemsphamxtien374133% (3)

- EnMS 500012018 Awareness TrainningDocument85 paginiEnMS 500012018 Awareness TrainningramanÎncă nu există evaluări

- Asset Management ISO 55000Document4 paginiAsset Management ISO 55000Roy AlonzoÎncă nu există evaluări

- ISO 50001 - 2018 Transition EssentialDocument19 paginiISO 50001 - 2018 Transition EssentialUll RullÎncă nu există evaluări

- Slides Lesson 2 - Energy AuditDocument93 paginiSlides Lesson 2 - Energy Auditzeno zenoÎncă nu există evaluări

- The Energy Management According To ISO 50001:2011 Standard and AEMAS Scheme Feasibly Implement in Viet NamDocument6 paginiThe Energy Management According To ISO 50001:2011 Standard and AEMAS Scheme Feasibly Implement in Viet NamRCM Hoc vienÎncă nu există evaluări

- Assest ManagmentDocument43 paginiAssest ManagmentÂñçhūlä SrïkâñthÎncă nu există evaluări

- Plataforma ABB ISO 50001Document11 paginiPlataforma ABB ISO 50001Francisco SalgadoÎncă nu există evaluări

- 2012 ISO 50001 Recommendations For ComplianceDocument21 pagini2012 ISO 50001 Recommendations For Compliancejcampos02Încă nu există evaluări

- Lesson No. 12 - ControllingDocument28 paginiLesson No. 12 - Controllingjun junÎncă nu există evaluări

- Enms at TPDDLDocument18 paginiEnms at TPDDLapoorva sethÎncă nu există evaluări

- 998-19978426 GmaDocument14 pagini998-19978426 GmaESSALIM ABDELHAKIMÎncă nu există evaluări

- M6 Energy Management System and Plan - IMO TTT Course Presentation Final1Document83 paginiM6 Energy Management System and Plan - IMO TTT Course Presentation Final1OdumoduChigozieUzomaÎncă nu există evaluări

- Sample Energy PlanDocument14 paginiSample Energy PlangodwanaÎncă nu există evaluări

- 6-1 Monitoring and TargetingDocument67 pagini6-1 Monitoring and TargetingShamsudin Bin Mohd FuadÎncă nu există evaluări

- Cbe495 Lecture Iv Model Predictive Control: Professor Dae Ryook YangDocument22 paginiCbe495 Lecture Iv Model Predictive Control: Professor Dae Ryook YangMark ClarkÎncă nu există evaluări

- ISO 9001/27001 Crossovers and ContrastsDocument2 paginiISO 9001/27001 Crossovers and Contrastsmilad4556Încă nu există evaluări

- ISO 50001 Checklist PDFDocument2 paginiISO 50001 Checklist PDFIka Setyaningrum100% (1)

- Fractal Solutions Fractal Solutions Fractal Solutions Fractal SolutionsDocument8 paginiFractal Solutions Fractal Solutions Fractal Solutions Fractal SolutionsJorge FracaroÎncă nu există evaluări

- 5 021 12 - SeidelDocument8 pagini5 021 12 - SeidelNur Amirah SulaimanÎncă nu există evaluări

- ISO 50001 Checklist PDFDocument2 paginiISO 50001 Checklist PDFclaudiaeandrea100% (2)

- IMS Powerpoint MaterialDocument24 paginiIMS Powerpoint Materialrhamarao100% (1)

- 2.4. Energy Auditing 50002 Khaled EL FarraDocument18 pagini2.4. Energy Auditing 50002 Khaled EL FarraerkingulerÎncă nu există evaluări

- Pilot University Lecture On The Energy Management (Auditing) of Buildings MSC Program Albin Zsebik, PHD, CemDocument60 paginiPilot University Lecture On The Energy Management (Auditing) of Buildings MSC Program Albin Zsebik, PHD, CemAnggoro AntonoÎncă nu există evaluări

- Iso 50001Document26 paginiIso 50001Anand Pande100% (4)

- Energy Management System (Enms) : Chart Nexus/International PlazaDocument8 paginiEnergy Management System (Enms) : Chart Nexus/International PlazaSuri YodÎncă nu există evaluări

- Dekracert Whitepaper Revision50001 Letter en v1 PDFDocument3 paginiDekracert Whitepaper Revision50001 Letter en v1 PDFENTERTAINMENTÎncă nu există evaluări

- KPI Approach For EG v1.0Document5 paginiKPI Approach For EG v1.0Ashish GuptaÎncă nu există evaluări

- Maturity Matrix EnMS 150828Document9 paginiMaturity Matrix EnMS 150828Fizz FirdausÎncă nu există evaluări

- COP and ISO 50001Document4 paginiCOP and ISO 50001subham guptaÎncă nu există evaluări

- NPD Maintenance Baseline StudyDocument83 paginiNPD Maintenance Baseline StudyAndres Felipe Garcia Reina100% (1)

- Controlling 4ECEDocument23 paginiControlling 4ECEKeilla Romabiles LeopandoÎncă nu există evaluări

- Awareness QHSE 9K 14K 45K - EN - PNEPDocument89 paginiAwareness QHSE 9K 14K 45K - EN - PNEPQAMS Dept100% (1)

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)De la EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Evaluare: 4 din 5 stele4/5 (1)

- 2018 March Madness PlaybookDocument43 pagini2018 March Madness PlaybookJCAÎncă nu există evaluări

- After Time Out Quick HittersDocument29 paginiAfter Time Out Quick Hittersblackmor100% (1)

- Nba 2018Document37 paginiNba 2018Gerardo AguirreÎncă nu există evaluări

- 2016 Ncaa Tournament PlaybookDocument135 pagini2016 Ncaa Tournament PlaybookDanilo PoncianoÎncă nu există evaluări

- Ncaa Tournamente Sweet 16Document47 paginiNcaa Tournamente Sweet 16JCAÎncă nu există evaluări

- 16 Euroleague Final Four Plays PDFDocument18 pagini16 Euroleague Final Four Plays PDFMaurizio Pietrelli100% (1)

- Fiba World Cup 2019Document46 paginiFiba World Cup 2019JCAÎncă nu există evaluări

- ANSI-IEEE Device Numbers PDFDocument12 paginiANSI-IEEE Device Numbers PDFMario SamudioÎncă nu există evaluări

- IEEE Standards Info Page PDFDocument1 paginăIEEE Standards Info Page PDFRyan Bacarro BagayanÎncă nu există evaluări

- Foreword: Mr. H. Jin Sim, Chair IEEE/PES Transformers CommitteeDocument1 paginăForeword: Mr. H. Jin Sim, Chair IEEE/PES Transformers CommitteeJCAÎncă nu există evaluări

- Table of Contents of IEEE StandardDocument5 paginiTable of Contents of IEEE StandardShahlan AnuarÎncă nu există evaluări

- Power Distribution & Regulating Transformers: IEEE Standards CollectionDocument1 paginăPower Distribution & Regulating Transformers: IEEE Standards CollectionBruno MilanÎncă nu există evaluări

- Mepc 314Document3 paginiMepc 314JCAÎncă nu există evaluări

- Building Muscle Mass - More Weight or More RepsDocument1 paginăBuilding Muscle Mass - More Weight or More RepsJCAÎncă nu există evaluări

- M5 Port-Ship Interface IMO TTT Course Presentation Final1 PDFDocument58 paginiM5 Port-Ship Interface IMO TTT Course Presentation Final1 PDFJCAÎncă nu există evaluări

- M6 Energy Management Plan and System FinalDocument62 paginiM6 Energy Management Plan and System FinalJCAÎncă nu există evaluări

- Energy EfficiencyDocument76 paginiEnergy Efficiencydan_artimof100% (1)

- Msin 1923 Anx 1Document5 paginiMsin 1923 Anx 1JCAÎncă nu există evaluări

- M5 Port-Ship Interface IMO TTT Course Presentation Final1 PDFDocument58 paginiM5 Port-Ship Interface IMO TTT Course Presentation Final1 PDFJCAÎncă nu există evaluări

- M5 Ship-Port Interface FinalDocument59 paginiM5 Ship-Port Interface FinalJCA0% (1)

- PEDAGOGICS-Energy Efficient Operation-110513 PDFDocument51 paginiPEDAGOGICS-Energy Efficient Operation-110513 PDFOdumoduChigozieUzomaÎncă nu există evaluări

- M2 EE Regulations and Guidelines FinalDocument45 paginiM2 EE Regulations and Guidelines FinalJCAÎncă nu există evaluări

- IMO Course From Management To Operation PDFDocument74 paginiIMO Course From Management To Operation PDFSlim100% (1)

- M1 TTT Course Posters Final1 PDFDocument1 paginăM1 TTT Course Posters Final1 PDFJCAÎncă nu există evaluări

- M4 TTT Course Posters Final1 PDFDocument1 paginăM4 TTT Course Posters Final1 PDFJCAÎncă nu există evaluări

- M3 TTT Course Posters Final1 PDFDocument1 paginăM3 TTT Course Posters Final1 PDFJCAÎncă nu există evaluări

- M5 TTT Course Posters Final1Document1 paginăM5 TTT Course Posters Final1JCAÎncă nu există evaluări

- TTT Trainers Manual Final2 PDFDocument35 paginiTTT Trainers Manual Final2 PDFOdumoduChigozieUzomaÎncă nu există evaluări

- Pre-Training Assignment Three FinalDocument3 paginiPre-Training Assignment Three FinalJCAÎncă nu există evaluări

- Fraud Prevention & DetectionDocument15 paginiFraud Prevention & DetectionswathivishnuÎncă nu există evaluări

- Master Glossary V4: Acronym (If Applicable)Document5 paginiMaster Glossary V4: Acronym (If Applicable)Mesut ÖztürkÎncă nu există evaluări

- Case Study #1: Accounting Software and Operational Systems Control: An Opportunity For FraudDocument11 paginiCase Study #1: Accounting Software and Operational Systems Control: An Opportunity For FraudDonna MarieÎncă nu există evaluări

- Mel 2Document8 paginiMel 2bnolascoÎncă nu există evaluări

- Chapter 7 - Solution ManualDocument22 paginiChapter 7 - Solution Manualjuan100% (3)

- Warranty Manaul PDFDocument88 paginiWarranty Manaul PDFjfcr1234Încă nu există evaluări

- Typical Project Quality Plan & ITP CPCDocument14 paginiTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Dse ReportDocument64 paginiDse ReportHanzuruni RashidiÎncă nu există evaluări

- Notes FSUU AccountingDocument18 paginiNotes FSUU AccountingRobert CastilloÎncă nu există evaluări

- QM With SAPDocument64 paginiQM With SAPdoriangray661Încă nu există evaluări

- Certification Bodies and Auditors Requirements Version 2.1Document12 paginiCertification Bodies and Auditors Requirements Version 2.1PT KPMÎncă nu există evaluări

- R CICOT 01 Audit and Halal Certification EngDocument25 paginiR CICOT 01 Audit and Halal Certification EngMunazza Ali KhanÎncă nu există evaluări

- Unit 5: Quality Sysyems Organizing and ImplementationDocument23 paginiUnit 5: Quality Sysyems Organizing and ImplementationVinitgaÎncă nu există evaluări

- Audit Universe and Risk Assessment ToolDocument10 paginiAudit Universe and Risk Assessment ToolAsis KoiralaÎncă nu există evaluări

- LeanIX Poster Business Capability Map Pharma ENDocument1 paginăLeanIX Poster Business Capability Map Pharma ENMarco Vinicio LenciÎncă nu există evaluări

- KM Auditing: Gautam PendharkarDocument18 paginiKM Auditing: Gautam PendharkarSuyash JainÎncă nu există evaluări

- Brochure Certification Final VersionDocument2 paginiBrochure Certification Final Versionudiptya_papai2007Încă nu există evaluări

- SMPFC Final Prospectus 8 Feb 20111Document263 paginiSMPFC Final Prospectus 8 Feb 20111mon samboÎncă nu există evaluări

- US Internal Audit Policy FormatDocument5 paginiUS Internal Audit Policy Formatshubhs vijayÎncă nu există evaluări

- PROF-Assessing Risk PG PDFDocument17 paginiPROF-Assessing Risk PG PDFsofyan timotyÎncă nu există evaluări

- Operations Management PRELIM MODULE 2Document4 paginiOperations Management PRELIM MODULE 2Ignacio De LunaÎncă nu există evaluări

- FU Wang FoodDocument91 paginiFU Wang FoodBiswas LitonÎncă nu există evaluări

- 7 5 2 Methode EvaluationDocument168 pagini7 5 2 Methode Evaluationeconlady0% (1)

- Good Manufacturing Practice AuditDocument90 paginiGood Manufacturing Practice AuditAzizol WahabÎncă nu există evaluări

- Audit of Current LiabilitiesDocument4 paginiAudit of Current LiabilitiesMark Anthony TibuleÎncă nu există evaluări

- Securities and Exchange CommissionDocument28 paginiSecurities and Exchange CommissionGen GaveriaÎncă nu există evaluări

- First Year First Semester Course Code Subject Title Units Lec Lab TotalDocument8 paginiFirst Year First Semester Course Code Subject Title Units Lec Lab TotalRosemarie VillanuevaÎncă nu există evaluări

- Contingency Rspo Audit Procedure For PC and Ish Standard - v2 - November2021Document28 paginiContingency Rspo Audit Procedure For PC and Ish Standard - v2 - November2021sandra purbaÎncă nu există evaluări

- Financial Statement Audit ProcessDocument3 paginiFinancial Statement Audit ProcesssajiahÎncă nu există evaluări

- AF101 Introduction To Accounting & Financial Management Part IDocument11 paginiAF101 Introduction To Accounting & Financial Management Part IRoiti TarauÎncă nu există evaluări