Documente Academic

Documente Profesional

Documente Cultură

Normal Modes - Rigid Element Analysis With RBE2 and CONM2

Încărcat de

karthekeyanmenonTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Normal Modes - Rigid Element Analysis With RBE2 and CONM2

Încărcat de

karthekeyanmenonDrepturi de autor:

Formate disponibile

WORKSHOP 17

Normal Modes - Rigid Element

Analysis with RBE2 and CONM2

Y

Y

ZZ

Z X

Objectives:

■ Create a geometric representation of a tube.

■ Use the geometry model to define an analysis model

comprised of plate elements.

■ Idealize a rigid end using RBE2 elements.

■ Define a concentrated mass, to represent the weight of the

rigid enclosure (CONM2).

■ Run an MSC.Nastran normal modes analysis.

■ Visualize analysis results.

MSC.Nastran 120 Exercise Workbook 17-1

17-2 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Model Description:

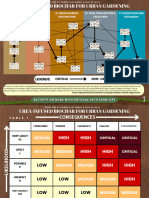

Figure 17.1 is a finite element model of a hollow tube. The end of the

tube is rigidly connected to a large structure.

Instead of adding to the model size by modeling the entire structure, use

a RBE2 and CONM2 to account for the rest of the structure attached to

the cylinder. Table 17.1 contains information for the finite element

model: the cylinder dimensions, material properties, and cylinder

thickness.

Figure 17.1 - Finite Element Model of a Hollow Tube

19

25 13

20

26 31

14 7

21

27 32

15 43 8

1

22 123456(CID=1)

28 33 44 49 123456(CID=1)

16 9 2 61 123456(CID=1)

55

23

29 34 45 50 123456(CID=1)

17 10 62 123456(CID=1)

3 56

24

30 35 46 51

18 11 63 123456(CID=1)

4 123456(CID=1)

57

36 52

47 12 64 123456(CID=1)

5 123456(CID=1)

999 58 123456(CID=1)

48 53 65

6

59

54 66

60

Table 17.1 - Model Properties

Radius: 15 in

Thickness: 0.125 in

Length: 90 in

Elastic Modulus: 10E+06 lb/in2

Density: 0.101 lbs/in3

Poisson Ratio: 0.3

MSC.Nastran 120 Exercise Workbook 17-3

Suggested Exercise Steps:

■ Generate a finite element representation of the cylinder structure

(i.e., The nodes (GRID) and element connectivities (CQUAD4)

should be defined manually).

■ Define material (MAT1) and element (PSHELL) properties.

■ Create grid point 999 at the center of the rigid end. This point is

to serve as the load application point, as well as the connection

point for the rigid element.

■ Idealize the rigid end with rigid elements (RBE2).

■ Apply the fixed boundary constraints (SPC1).

■ Apply a concentrated mass at the center of the top enclosure,

Grid 999 (CONM2).

■ Prepare the model for normal modes analysis (SOL 103).

■ Generate an input file and submit it to the MSC.Nastran solver

for normal modes analysis.

■ Review the results.

17-4 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Exercise Procedure:

1. Create a new database called workshop17.db.

File/New...

New Database Name: workshop17

OK

In the New Model Preference form set the following:

Tolerance: ◆ Default

Analysis code: MSC.Nastran

OK

NOTE: Whenever possible, toggle off the ❑ Auto Execute option by left clicking

the check box.

2. Create a cylindrical coordinate frame.

◆ Geometry

Action: Create

Object: Coord

Method: 3 Point

Type: Cylindrical

Apply

3. Define a curve.

Action: Create

Object: Curve

Method: XYZ

Vector Coordinates List: <0, 0, 90>

Origin Coordinates List: [15, 0, 0]

Apply

MSC.Nastran 120 Exercise Workbook 17-5

Change the view to an isometric view by using the Iso 1 View icon on the

toolbar.

Iso 1 View

4. Construct a surface to model the cylinder by revolving the curve.

Action: Create

Object: Surface

Method: Revolve

Axis: Coord 0.3

Total Angle: 180

Curve List: Curve 1

Apply

4a. Repeat this step a second time to complete the cylinder. This time select the curve

opposite Curve 1 which is Surface 1.2. (see Figure 17.3)

Action: Create

Object: Surface

Method: Revolve

Axis: Coord 0.3

Total Angle: 180

Curve List: Surface 1.2

Apply

17-6 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Figure 17.3

Surface 1.2

Surface 1.3

Curve 1

Y

Z X Surface 2.3

5. Create a mesh using the surfaces. Use Mesh Seeds to define the mesh density.

◆ Finite Elements

Action: Create

Object: Mesh Seed

Type: Uniform

◆ Number of Elements

Number: 5

Curve List: Curve 1, Surface 1.3, 2.3

(See Fig. 22.3)

Apply

5a. After defining the mesh seeds, mesh the surface.

◆ Finite Elements

Action: Create

Object: Mesh

Type: Surface

Node Coordinate Frames...

MSC.Nastran 120 Exercise Workbook 17-7

Analysis Coordinate Frame: Coord 1

Refer. Coordinate Frame: Coord 1

OK

Surface List: Surface 1, 2

Apply

5b. Equivalence the model to connect the mesh.

Action: Equivalence

Object: All

Method: Tolerance Cube

Apply

6. Define material properties for the plate.

◆ Materials

Action: Create

Object: Isotropic

Method: Manual Input

Material Name: mat_1

Input Properties...

Elastic Modulus: 10.0E6

Poisson Ratio: 0.3

Density: 0.101

OK

Apply

7. Define element properties.

◆ Properties

Action: Create

Dimension: 2D

17-8 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Type: Shell

Property Set Name: wall

Input Properties...

Material Name: m:mat_1

Thickness: 0.125

OK

Select Members: Surface 1, 2

Add

Apply

Define loads and boundary conditions to the model.

8. Constrain the right edge in all six degrees of freedom. To make the

entity selection easier change the view to a Right View by selecting

the Right Side View icon.

Right Side View

Figure 17.4

Nodes 6:36:6 48:66:6 999 Nodes 1:31:6, 43:61:6

◆ Loads/BCs

MSC.Nastran 120 Exercise Workbook 17-9

Action: Create

Object: Displacement

Type: Nodal

New Set Name: fixed

Input Data...

Translations <T1 T2 T3> <0, 0, 0>

Rotations <R1 R2 R3> <0, 0, 0>

Analysis Coordinate Frame: Coord 1

OK

Select Application Region...

Geometry Filter: ◆ FEM

Curve List: Node 1:31:6, 43:61:6

(See Fig. 22.4)

Add

OK

Apply

9. Define a node for the concentrated mass.

◆ Finite Elements

Action: Create

Object: Node

Method: Edit

Node ID List: 999

Analysis Coordinate Frame: Coord 1

Refer. Coordinate Frame: Coord 1

❑ Associate with Geometry

Node Location List: [0, 0, 90]

Apply

17-10 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

10. Create the rigid element.

◆ Finite Elements

Action: Create

Object: MPC

Type: RBE2

Define Terms...

◆ Create Dependent

Node List: Node 6:36:6, 48:66:6

Type the nodes into the list directly or select the nodes from the

viewport by changing back to an isometric view and selecting the

nodes on the left edge of the model.

Select DOFs by holding the Shift key down while clicking with the

left mouse button.

DOFs: UX

UY

UZ

Apply

◆ Create Independent

Node List: Node 999

Apply

Cancel

Apply

Change the view to an isometric view by using the Iso 1 View icon

on the toolbar.

Iso 1 View

MSC.Nastran 120 Exercise Workbook 17-11

Figure 17.5

123456(CID=1)

123456(CID=1)

123456(CID=1)

T

123456(CID=1)

123456(CID=1)

1

Z R

123456(CID=1)

123456(CID=1)

123456(CID=1)

123456(CID=1)

123456(CID=1)

X

Z

11. Define a point element on Node 999 for the concentrated mass.

◆ Finite Elements

Action: Create

Object: Element

Method: Edit

Shape: Point

Topology: Point

Node 1: Node 999

Apply

12. Define a concentrated mass.

◆ Properties

Action: Create

Dimension: 0D

Type: Mass

Property Set Name: concentrated_mass

Options(s): Lumped

17-12 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Input Properties...

Mass: 500

OK

Select Members: Element 51

hint: Use the Point Element filter on the Entity Selection menu.

Point Element

Add

Apply

13. Generate an input file for analysis.

◆ Analysis

Action: Analyze

Object: Entire Model

Method: Analysis Deck

Jobname: workshop17

Solution Type...

Solution Type: ◆ NORMAL MODES

Solution Parameters...

❒ Automatic Constraints

(Deselect Automatic Constraints.)

Mass Calculation: Coupled

Wt. -Mass Conversion = .00259

OK

OK

Apply

MSC.Nastran 120 Exercise Workbook 17-13

An MSC.Nastran input file called workshop17.bdf will be

generated. This process of translating the model into an input file is

called the Forward Translation. The Forward Translation is

complete when the Heartbeat turns green.

17-14 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Generating an Input File for MSC.Nastran Users:

MSC.Nastran users can generate an input file using the data from

Table 22.1. The result should be similar to the output below.

14. MSC.Nastran input file: workshop17.dat

ID SEMINAR,workshop 17

SOL 103

TIME 600

CEND

SEALL = ALL

SUPER = ALL

TITLE = Normal Modes w/ RBE2

ECHO = NONE

MAXLINES = 999999999

SUBCASE 1

METHOD = 1

SPC = 2

BEGIN BULK

PARAM AUTOSPC NO

PARAM COUPMASS 1

PARAM WTMASS .00259

PARAM,NOCOMPS,-1

EIGRL 1 10 0

PSHELL 1 1 .125 1 1

CQUAD4 1 1 1 2 8 7

= *1 = *1 *1 *1 *1

=3

CQUAD4 6 1 7 8 14 13

= *1 = *1 *1 *1 *1

=3

CQUAD4 11 1 13 14 20 19

= *1 = *1 *1 *1 *1

=3

CQUAD4 16 1 19 20 26 25

= *1 = *1 *1 *1 *1

=3

CQUAD4 21 1 25 26 32 31

= *1 = *1 *1 *1 *1

=3

CQUAD4 26 1 31 32 44 43

= *1 = *1 *1 *1 *1

=3

CQUAD4 31 1 43 44 50 49

= *1 = *1 *1 *1 *1

=3

CQUAD4 36 1 49 50 56 55

= *1 = *1 *1 *1 *1

=3

CQUAD4 41 1 55 56 62 61

= *1 = *1 *1 *1 *1

=3

CQUAD4 46 1 61 62 2 1

= *1 = *1 *1 *1 *1

MSC.Nastran 120 Exercise Workbook 17-15

=3

CONM2 51 999 500.

MAT1 1 1.+7 .3 .101

RBE2 52 999 123 6 12 18 24 30 + A

+ A 36 48 54 60 66

GRID 1 1 15. 0. 0. 1

= *1 = = = *18 =

=4

GRID 7 1 15. 36. 0. 1

= *1 = = = *18 =

=4

GRID 13 1 15. 72. 0. 1

= *1 = = = *18 =

=4

GRID 19 1 15. 108. 0. 1

= *1 = = = *18 =

=4

GRID 25 1 15. 144. 0. 1

= *1 = = = *18 =

=4

GRID 31 1 15. 180. 0. 1

= *1 = = = *18 =

=4

GRID 43 1 15. 216. 0. 1

= *1 = = = *18 =

=4

GRID 49 1 15. 252. 0. 1

= *1 = = = *18 =

=4

GRID 55 1 15. 288. 0. 1

= *1 = = = *18 =

=4

GRID 61 1 15. 324. 0. 1

= *1 = = = *18 =

=4

GRID 999 1 0. 0. 90. 1

SPCADD 2 1

SPC1 1 123456 1 7 13 19 25 31 + B

+ B 43 49 55 61

CORD2C 1 0. 0. 0. 0. 0. 1. + C

+ C 1. 0. 0.

ENDDATA

17-16 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17 Rigid Element Analysis with RBE2

Submitting the Input File for Analysis:

15. Submit the input file to MSC.Nastran for analysis.

15a. To submit the MSC.Patran .bdf file for analysis, find an

available UNIX shell window. At the command prompt

enter: nastran workshop17.bdf scr=yes. Monitor the

run using the UNIX ps command.

15b. To submit the MSC.Nastran .dat file for analysis, find an

available UNIX shell window. At the command prompt

enter: nastran workshop17.dat scr=yes. Monitor the

run using the UNIX ps command.

16. When the run is completed, edit the workshop17.f06 file and

search for the word FATAL. If no matches exist, search for the

word WARNING. Determine whether existing WARNING

messages indicate modeling errors.

17. While still editing workshop17.f06, search for the word:

E I G E N (spaces are necessary)

What are the first five modes?

Mode 1 = _________ Hz

Mode 2 = _________ Hz

Mode 3 = _________ Hz

Mode 4 = _________ Hz

Mode 5 = _________ Hz

MSC.Nastran 120 Exercise Workbook 17-17

Comparison of Results:

18. Compare the results obtained in the .f06 file with the

results on the following page:

17-18 MSC.Nastran 120 Exercise Workbook

WORKSHOP 17

R E A L E I G E N V A L U E S

MODE EXTRACTION EIGENVALUE RADIANS CYCLES GENERALIZED GENERALIZED

NO. ORDER MASS STIFFNESS

1 1 3.128183E+04 1.768667E+02 2.814921E+01 1.000000E+00 3.128183E+04

2 2 3.128183E+04 1.768667E+02 2.814921E+01 1.000000E+00 3.128183E+04

3 3 9.379013E+05 9.684531E+02 1.541341E+02 1.000000E+00 9.379013E+05

Rigid Element Analysis with RBE2

4 4 1.225376E+06 1.106967E+03 1.761793E+02 1.000000E+00 1.225376E+06

5 5 1.225376E+06 1.106967E+03 1.761793E+02 1.000000E+00 1.225376E+06

6 6 1.273205E+06 1.128364E+03 1.795847E+02 1.000000E+00 1.273205E+06

7 7 1.273205E+06 1.128364E+03 1.795847E+02 1.000000E+00 1.273205E+06

8 8 1.749829E+06 1.322811E+03 2.105319E+02 1.000000E+00 1.749829E+06

9 9 2.463450E+06 1.569538E+03 2.497998E+02 1.000000E+00 2.463450E+06

10 10 2.463450E+06 1.569538E+03 2.497998E+02 1.000000E+00 2.463450E+06

R E A L E I G E N V A L U E S

MODE EXTRACTION EIGENVALUE RADIANS CYCLES GENERALIZED GENERALIZED

NO. ORDER MASS STIFFNESS

MSC.Nastran 120 Exercise Workbook

1 1 3.128183E+04 1.768667E+02 2.814921E+01 1.000000E+00 3.128183E+04

2 2 3.128183E+04 1.768667E+02 2.814921E+01 1.000000E+00 3.128183E+04

3 3 9.379013E+05 9.684531E+02 1.541341E+02 1.000000E+00 9.379013E+05

4 4 1.225376E+06 1.106967E+03 1.761793E+02 1.000000E+00 1.225376E+06

5 5 1.225376E+06 1.106967E+03 1.761793E+02 1.000000E+00 1.225376E+06

6 6 1.273205E+06 1.128364E+03 1.795847E+02 1.000000E+00 1.273205E+06

7 7 1.273205E+06 1.128364E+03 1.795847E+02 1.000000E+00 1.273205E+06

8 8 1.749829E+06 1.322811E+03 2.105319E+02 1.000000E+00 1.749829E+06

9 9 2.463450E+06 1.569538E+03 2.497998E+02 1.000000E+00 2.463450E+06

10 10 2.463450E+06 1.569538E+03 2.497998E+02 1.000000E+00 2.463450E+06

17-19

19. MSC.Nastran Users have finished this exercise.

MSC.Patran Users should proceed to the next step.

20. Proceed with the Reverse Translation process, that is attaching the

workshop.xdb results file into MSC.Patran. To do this, return to the

Analysis form and proceed as follows:

◆ Analysis

Action: Attach XDB

Object: Result Entities

Method Local

Select Results File...

Select Results File: workshop17.xdb

OK

Apply

21. When the translation is complete bring up the Results form.

◆ Results

Action: Create

Object: Deformation

Select Result Case(s): Default, Mode 8:Freq.=210.53

Select Deformation Result: Eigenvectors, Translational

Show As: Resultant

Quit MSC.Patran after completing this exercise.

17-20 MSC.Nastran 120 Exercise Workbook

17-21 MSC.Nastran 120 Exercise Workbook

Mode 1 = 28.149 Hz

Mode 2 = 28.149Hz

Mode 3 = 154.13 Hz

Mode 4 = 176.18 Hz

Mode 5 = 176.18 Hz

Rigid Element Analysis with RBE2 WORKSHOP 17

17-22 MSC.Nastran 120 Exercise Workbook

S-ar putea să vă placă și

- Linear Static - Rigid Element Analysis With RBE2 and CONM2Document16 paginiLinear Static - Rigid Element Analysis With RBE2 and CONM2karthekeyanmenonÎncă nu există evaluări

- Clustering L7Document7 paginiClustering L7u- m-Încă nu există evaluări

- Cirrus: Illustrated Parts Catalog Models Sr22 and Sr22TDocument2 paginiCirrus: Illustrated Parts Catalog Models Sr22 and Sr22Thector joel lizarragaÎncă nu există evaluări

- Exercise 2 - MinitabDocument7 paginiExercise 2 - MinitabLawrence BelloÎncă nu există evaluări

- Math Basic TrainingDocument50 paginiMath Basic TrainingGinoDayo16Încă nu există evaluări

- KmeansDocument6 paginiKmeansRaghavendra SwamyÎncă nu există evaluări

- Problem 1 024Document3 paginiProblem 1 024imadusÎncă nu există evaluări

- An Evaluation of The GCI For Unstructured GridsDocument33 paginiAn Evaluation of The GCI For Unstructured GridsSachin RoutÎncă nu există evaluări

- C-Mos Serial I/O: DD DDDocument2 paginiC-Mos Serial I/O: DD DDelieÎncă nu există evaluări

- For Categorical FDDocument3 paginiFor Categorical FDVerolaÎncă nu există evaluări

- Strukturna Analiza: - Stepen PokretljivostiDocument13 paginiStrukturna Analiza: - Stepen PokretljivostiArmin KovačevićÎncă nu există evaluări

- Insert Wanted Parameter Settings and Press Enter Ssdesdl - 92 Qdesdl 30 Lcompdl 6 Qcompdl 70Document12 paginiInsert Wanted Parameter Settings and Press Enter Ssdesdl - 92 Qdesdl 30 Lcompdl 6 Qcompdl 70Anonymous DUua3A5Încă nu există evaluări

- Sinclair Enterprise Physics Engineering ElectronicsDocument160 paginiSinclair Enterprise Physics Engineering ElectronicsOsegasin Grupo AlertaÎncă nu există evaluări

- CDX 802Document19 paginiCDX 802Mario LopezÎncă nu există evaluări

- C-Mos FDC (Floppy Disk Controller)Document3 paginiC-Mos FDC (Floppy Disk Controller)Bos QuÎncă nu există evaluări

- Which Is The Missing Section?: 62 Test and Assess Your Brain QuotientDocument10 paginiWhich Is The Missing Section?: 62 Test and Assess Your Brain QuotientRd manÎncă nu există evaluări

- Sri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantDocument15 paginiSri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantZaid khanÎncă nu există evaluări

- Sri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantDocument15 paginiSri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantZaid khanÎncă nu există evaluări

- SystemC Based JPEGDocument17 paginiSystemC Based JPEG08-Phạm Gia HuyÎncă nu există evaluări

- StatsDocument17 paginiStatsAryan BudhirajaÎncă nu există evaluări

- T2 ถูกแล้วDocument3 paginiT2 ถูกแล้วAtragalusÎncă nu există evaluări

- Class 12 Maths Project HelpfulDocument23 paginiClass 12 Maths Project HelpfulParam Waje100% (1)

- Stat 4Document5 paginiStat 4francis pacaigueÎncă nu există evaluări

- RealizabilityDocument2 paginiRealizabilityanjÎncă nu există evaluări

- Analytical Relation Between Quark Confinement and Chiral Sym-Metry Breaking in Odd-Number Lattice QCDDocument8 paginiAnalytical Relation Between Quark Confinement and Chiral Sym-Metry Breaking in Odd-Number Lattice QCDcrocoaliÎncă nu există evaluări

- Deluxe Tunnels & Trolls Cheat SheetDocument2 paginiDeluxe Tunnels & Trolls Cheat Sheettruffle1bootsÎncă nu există evaluări

- Module-2 System of Linear Equations and Eigen Value Problems Important Numerical Methods in Module-IDocument24 paginiModule-2 System of Linear Equations and Eigen Value Problems Important Numerical Methods in Module-IJawa freakÎncă nu există evaluări

- Module-2 System of Linear Equations and Eigen Value Problems Important Numerical Methods in Module-IDocument24 paginiModule-2 System of Linear Equations and Eigen Value Problems Important Numerical Methods in Module-Ivenkat sathwik kethepalliÎncă nu există evaluări

- Parvez 4 PDFDocument24 paginiParvez 4 PDFJawa freakÎncă nu există evaluări

- HW 2Document2 paginiHW 2kalaputraÎncă nu există evaluări

- Note #10 Correlation and RegressionDocument7 paginiNote #10 Correlation and Regressiontwanda bryanÎncă nu există evaluări

- SketcherDocument83 paginiSketcherNicholas StrangeÎncă nu există evaluări

- Sae MethodologyDocument35 paginiSae MethodologyessentialstatÎncă nu există evaluări

- Network Models: Group 4 (BSA - 1A)Document36 paginiNetwork Models: Group 4 (BSA - 1A)Raicen Gonzales MirandaÎncă nu există evaluări

- Hce Performance Model: SolabsDocument20 paginiHce Performance Model: SolabsYeshwanth KohliÎncă nu există evaluări

- Wu Icip08Document4 paginiWu Icip08Navneet ChoudharyÎncă nu există evaluări

- CNN Architectures 01Document66 paginiCNN Architectures 01Abdul hadiÎncă nu există evaluări

- Truss ExampleDocument8 paginiTruss Exampledixn__Încă nu există evaluări

- Problem Formation & CalculationDocument13 paginiProblem Formation & CalculationVyshnavi MankalaÎncă nu există evaluări

- HP Heater 2 NewDocument69 paginiHP Heater 2 NewKuppan SrinivasanÎncă nu există evaluări

- Block Stock of HARCODocument76 paginiBlock Stock of HARCOPriyance NababanÎncă nu există evaluări

- An Introduction To JPEG Compression Using Matlab: Arno Swart 28th October 2003Document5 paginiAn Introduction To JPEG Compression Using Matlab: Arno Swart 28th October 2003infiniti47Încă nu există evaluări

- Stat LabDocument4 paginiStat Labcansu parlakÎncă nu există evaluări

- Solving Large Systems: 6.1 Elimination With ReorderingDocument10 paginiSolving Large Systems: 6.1 Elimination With ReorderingEfstathios SiampisÎncă nu există evaluări

- Face RecognitionDocument20 paginiFace RecognitionMubeen TajÎncă nu există evaluări

- An Introduction To JPEG Compression Using Matlab: Arno Swart 30 October, 2003Document6 paginiAn Introduction To JPEG Compression Using Matlab: Arno Swart 30 October, 2003ankancemk0422Încă nu există evaluări

- Schematic Diagrams: 11-1 PWB-MAIN (Power)Document12 paginiSchematic Diagrams: 11-1 PWB-MAIN (Power)JasiekÎncă nu există evaluări

- Grade Thresholds - November 2017: Cambridge International AS & A Level History (9389)Document2 paginiGrade Thresholds - November 2017: Cambridge International AS & A Level History (9389)musa arif gillÎncă nu există evaluări

- Cambridge International As A Level History 9389Document2 paginiCambridge International As A Level History 9389musa arif gillÎncă nu există evaluări

- Systems Analysis and Control: Matthew M. PeetDocument26 paginiSystems Analysis and Control: Matthew M. PeetNour DmourÎncă nu există evaluări

- Clannad - Onaji Takami HeDocument3 paginiClannad - Onaji Takami HeikusadanÎncă nu există evaluări

- 08-01-2022 SR - super60-II Jee-Main PTM-12 Key & Sol'sDocument24 pagini08-01-2022 SR - super60-II Jee-Main PTM-12 Key & Sol'smanideepÎncă nu există evaluări

- Block Stock of SerangDocument72 paginiBlock Stock of SerangPriyance NababanÎncă nu există evaluări

- LegendsDocument4 paginiLegendsKeirvin Cloi RamosÎncă nu există evaluări

- K-Means Clustering: AlgorithmDocument6 paginiK-Means Clustering: AlgorithmmaiedÎncă nu există evaluări

- Dynamic Programming and Partial Differential EquationsDe la EverandDynamic Programming and Partial Differential EquationsÎncă nu există evaluări

- An Introduction to Programming with SpecificationsDe la EverandAn Introduction to Programming with SpecificationsEvaluare: 3 din 5 stele3/5 (1)

- Building Ideas: An Architectural Guide to the University of ChicagoDe la EverandBuilding Ideas: An Architectural Guide to the University of ChicagoEvaluare: 4.5 din 5 stele4.5/5 (2)

- Gray Cast Iron: The Tensile Cyclic Stress Strain CurveDocument2 paginiGray Cast Iron: The Tensile Cyclic Stress Strain CurvekarthekeyanmenonÎncă nu există evaluări

- Integration of MSC/PATRAN With Sandia National Laboratory's EXODUS II Database SystemDocument19 paginiIntegration of MSC/PATRAN With Sandia National Laboratory's EXODUS II Database SystemkarthekeyanmenonÎncă nu există evaluări

- Divergence PDFDocument7 paginiDivergence PDFkarthekeyanmenonÎncă nu există evaluări

- Workshop 16 Stiffened Plate: WS16-1 NAS120, Workshop 16, May 2006 © 2005 MSC - Software CorporationDocument36 paginiWorkshop 16 Stiffened Plate: WS16-1 NAS120, Workshop 16, May 2006 © 2005 MSC - Software CorporationkarthekeyanmenonÎncă nu există evaluări

- Aeroservoelastic Modeling, Analysis, and Design Techniques PDFDocument12 paginiAeroservoelastic Modeling, Analysis, and Design Techniques PDFkarthekeyanmenonÎncă nu există evaluări

- Verification of A Stiffened Plate ModelDocument8 paginiVerification of A Stiffened Plate ModelkarthekeyanmenonÎncă nu există evaluări

- Prof HVLDocument51 paginiProf HVLkarthekeyanmenonÎncă nu există evaluări

- Meshing and Property Assignment: Workshop 3Document12 paginiMeshing and Property Assignment: Workshop 3karthekeyanmenonÎncă nu există evaluări

- Normal Modes Analysis of A Simply-Supported Stiffened PlateDocument6 paginiNormal Modes Analysis of A Simply-Supported Stiffened PlatekarthekeyanmenonÎncă nu există evaluări

- Day 1: 22 July 2011 Finite Element Methods by S. Rajagopal ScientistDocument38 paginiDay 1: 22 July 2011 Finite Element Methods by S. Rajagopal ScientistkarthekeyanmenonÎncă nu există evaluări

- Mr. KameshDocument49 paginiMr. KameshkarthekeyanmenonÎncă nu există evaluări

- MAVEN PFDPU Evaluaton Rev 3Document46 paginiMAVEN PFDPU Evaluaton Rev 3karthekeyanmenonÎncă nu există evaluări

- Center of Pressure PDFDocument2 paginiCenter of Pressure PDFkarthekeyanmenonÎncă nu există evaluări

- 4 Lecture Mr. Nitin S. GokhaleDocument21 pagini4 Lecture Mr. Nitin S. GokhalekarthekeyanmenonÎncă nu există evaluări

- Practical Applications of Aeroelastic Analysis For Aircaft Design and CertificationDocument16 paginiPractical Applications of Aeroelastic Analysis For Aircaft Design and CertificationkarthekeyanmenonÎncă nu există evaluări

- Aerodynamic Influence Coefficients MethodsDocument106 paginiAerodynamic Influence Coefficients Methodskarthekeyanmenon100% (1)

- B.Sc. Part - I PHYSICS-Paper - I Mechanics and Properties of MatterDocument10 paginiB.Sc. Part - I PHYSICS-Paper - I Mechanics and Properties of MatterUpperwala RaiÎncă nu există evaluări

- Part - A Section - I: CLASS X (2020-21) Mathematics Standard (041) Sample Paper-01Document12 paginiPart - A Section - I: CLASS X (2020-21) Mathematics Standard (041) Sample Paper-01Suyash PandeyÎncă nu există evaluări

- Emags 3Document3 paginiEmags 3sygwapoooÎncă nu există evaluări

- Asme y 14.5.1M-1994 (En) - 2004Document92 paginiAsme y 14.5.1M-1994 (En) - 2004Robert Marsella100% (4)

- Maths PDFDocument60 paginiMaths PDFLoh Chee WeiÎncă nu există evaluări

- (11-16) 3B-Ch.7-Areas - Volumes (III) - MCDocument7 pagini(11-16) 3B-Ch.7-Areas - Volumes (III) - MCsophia yeungÎncă nu există evaluări

- Eg Unit 4 QPDocument3 paginiEg Unit 4 QPMICHEL RAJ MechÎncă nu există evaluări

- Assign 02 - CH 22-p. 01 - PHYS 102Document32 paginiAssign 02 - CH 22-p. 01 - PHYS 102Ihab RagabÎncă nu există evaluări

- Class 10th SA-1 MaterialDocument22 paginiClass 10th SA-1 MaterialMd MuzammilÎncă nu există evaluări

- RoundnessDocument23 paginiRoundnessKumar ChowdaryÎncă nu există evaluări

- Sine Bar'Document6 paginiSine Bar'Jonathan PereiraÎncă nu există evaluări

- Sheet 4Document2 paginiSheet 4Mo 16Încă nu există evaluări

- WRC 297 Vs WRC 107Document2 paginiWRC 297 Vs WRC 107Rakesh100% (2)

- 3 Problem Solving With Flac: Section 3.1 Sections 3.2 3.9Document108 pagini3 Problem Solving With Flac: Section 3.1 Sections 3.2 3.9seif17Încă nu există evaluări

- Pressure Vessel DesignDocument21 paginiPressure Vessel DesignAbdullah AlgwhriÎncă nu există evaluări

- Projection of SolidDocument41 paginiProjection of SolidSabareesan SubramanianÎncă nu există evaluări

- 2023 MK Sample QuestionsDocument12 pagini2023 MK Sample QuestionsRubab ZahraÎncă nu există evaluări

- Geomagic Q12 GuideDocument30 paginiGeomagic Q12 Guidecmm5477Încă nu există evaluări

- Math IGCSE-MensurationDocument13 paginiMath IGCSE-MensurationKrish ShahÎncă nu există evaluări

- (W-19) Dynamics of MachinesDocument4 pagini(W-19) Dynamics of MachinesNabeel KhanÎncă nu există evaluări

- Journal of Food Engineering: Si Zhu, Bing Li, Guibing ChenDocument10 paginiJournal of Food Engineering: Si Zhu, Bing Li, Guibing ChenYaniÎncă nu există evaluări

- 2006 Hs ContestDocument7 pagini2006 Hs ContestJohn TafuiÎncă nu există evaluări

- CJ2 PDFDocument113 paginiCJ2 PDFZeljko Vojnic TunicÎncă nu există evaluări

- Math 6Document9 paginiMath 6Jhem VillanuevaÎncă nu există evaluări

- Heat Transfer: Al-Furat Al-Awsat Technical UniversityDocument23 paginiHeat Transfer: Al-Furat Al-Awsat Technical UniversityabasÎncă nu există evaluări

- 10 Maths Set CDocument12 pagini10 Maths Set Canirudhminecraft1Încă nu există evaluări

- Buckling of Imperfect Elliptical Cylindrical Shells UnderDocument6 paginiBuckling of Imperfect Elliptical Cylindrical Shells UnderAdel MuslehÎncă nu există evaluări

- United States Patent (19) : Primary Examiner-Samuel ScottDocument7 paginiUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssÎncă nu există evaluări

- Jacstone 100 - MathDocument11 paginiJacstone 100 - MathArgelyn Joy CreerÎncă nu există evaluări

- Summative Test No. 1Document6 paginiSummative Test No. 1Shaine Dzyll KuizonÎncă nu există evaluări