Documente Academic

Documente Profesional

Documente Cultură

Punchrite PressFitLimits PDF

Încărcat de

wulfgang66Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Punchrite PressFitLimits PDF

Încărcat de

wulfgang66Drepturi de autor:

Formate disponibile

Technical Information

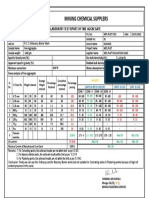

Punchrite® BALL LOCK ACCESSORIES

Recommended Press FitBALL

Limits LOCK ACCESSORIES

SOFT PLATES HARDENED PLATES

PUNCHES

Nominal Press Fit Dia. Retainer Hole Retainer Hole

Interference Interference

Dia. Limits Limits Limits

PILOTS

D HIGH LOW HIGH LOW MIN. MAX. HIGH LOW MIN. MAX.

DIES 1/4 – 1/2 +.0005 +.0002 +.0000 -.0005 .0002 .0010 +.0000 -.0002 .0002 .0007

GUIDES 5/8 – 1 +.0005 +.0002 +.0000 -.0014 .0002 .0019 +.0000 -.0005 .0002 .0010

1-1/4 – 1-1/2 +.0005 +.0002 +.0000 -.0020 .0002 .0025 +.0000 -.0008 .0002 .0013

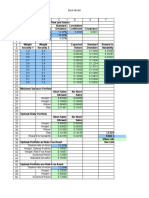

Punch to Die Clearances

A B C D E

CUTTING EDGES: Burr: Tensile and Burr: Tensile and Burr: Tensile Burr: Tensile Burr: Tensile and

.002 TO .006 CORNER Compressive Compressive Extrusion

BREAKDOWN Moderate Large

Minimum Minimum Roll-Over Roll-Over Very Large

BURR AND BURNISHED Roll-Over Roll-Over Roll-Over

LENGTHS INCREASE AS

CUTTING EDGES BREAK

DOWN

DURATION OF RUN:

LONGER RUNS AS

CLEARANCES INCREASE

EJECTOR PUNCHES REQUIRED

MATERIAL TOTAL CLEARANCE IN PERCENT OF MATERIAL THICKNESS

ALUMINUM – HARD 1 - 2% 10 - 12% 18 - 20% 25 - 28% 40% Max.

– SOFT 1 - 2% 4 - 8% 12 - 16% 16 - 20% 34% Max.

BRASS – 1/2 HARD 1 - 2% 6 - 10% 12 - 16% 18 - 22% 48% Max.

– ANNEALED 1 - 3% 4 - 6% 12 - 16% 16 - 20% 42% Max.

BRONZE, PHOSPHOR 3 - 5% 7 - 10% 20 - 24% 25 - 27% 50% Max.

COPPER – 1/2 HARD 2 - 4% 6 - 10% 12 - 16% 18 - 22% 50% Max.

– ANNEALED 1 - 2% 4 - 8% 10-14% 16 - 18% 50% Max.

LEAD 3 - 5% 8 - 12% 13 - 15% 16 - 20% 44% Max.

MAGNESIUM 1 - 2% 3 - 5% 7 - 9% 10 - 14% 32% Max.

STAINLESS STEEL 2 - 4% 6 - 10% 18 - 22% 25 - 27% 46% Max.

STEEL – CRS (1020) 2 - 4% 10 - 14% 16 - 20% 23 - 25% 42% Max.

– HIGH CARBON 5 - 10% 22 - 26% 28 - 32% 34 - 38% 50% Max.

DS514-1 02/07

The Anchor Danly Company © 2007 Punchrite 1

S-ar putea să vă placă și

- Ducting (Section IV) : Part No. Description Page NoDocument6 paginiDucting (Section IV) : Part No. Description Page NoVilius BukysÎncă nu există evaluări

- SL (02.05.23) PipeDocument1 paginăSL (02.05.23) Pipefaizk54Încă nu există evaluări

- Dowex HCR SS LDocument2 paginiDowex HCR SS LOmar SaeedÎncă nu există evaluări

- Spec Sheet - SD200NDocument16 paginiSpec Sheet - SD200NGchica MejiaÎncă nu există evaluări

- Uk 506 - Fita GuiaDocument5 paginiUk 506 - Fita GuiaAlessandro OliveiraÎncă nu există evaluări

- Comparasion Characteristic Raw MaterialDocument1 paginăComparasion Characteristic Raw MaterialLaili AzkiyahÎncă nu există evaluări

- Ganesha Ecosphere - Pet Recycle ProductsDocument17 paginiGanesha Ecosphere - Pet Recycle ProductsSanjay Kumar ShahiÎncă nu există evaluări

- HD Hose, Compact, Abrasion Resistant PropertiesDocument1 paginăHD Hose, Compact, Abrasion Resistant PropertiesAlexandrÎncă nu există evaluări

- Dowex HCR-S/S: A High Capacity Cation Exchange Resin For Domestic ApplicationsDocument2 paginiDowex HCR-S/S: A High Capacity Cation Exchange Resin For Domestic ApplicationsJesus AngaritaÎncă nu există evaluări

- Rod Seal: DesignDocument7 paginiRod Seal: Designgamal abousamraÎncă nu există evaluări

- Technical Data - Epoxy Dotted PaperDocument1 paginăTechnical Data - Epoxy Dotted PaperMly Saad BoudiafÎncă nu există evaluări

- Spec Sheet SD300Document10 paginiSpec Sheet SD300Yohanes ArgamÎncă nu există evaluări

- Dowex Monosphere 650CDocument2 paginiDowex Monosphere 650CBrianÎncă nu există evaluări

- Thebault Dop01 Teboply Ext GBDocument2 paginiThebault Dop01 Teboply Ext GBDumitrache IulianÎncă nu există evaluări

- Epilux 219: Product DescriptionDocument2 paginiEpilux 219: Product DescriptionMoin AltafÎncă nu există evaluări

- TDS Unilink Tx-65a-Bk-01Document2 paginiTDS Unilink Tx-65a-Bk-01madalinÎncă nu există evaluări

- F10ab - Pvcexcon 2LR8 DB20 U0v05 Fa AbDocument1 paginăF10ab - Pvcexcon 2LR8 DB20 U0v05 Fa AbCustomer ServiceÎncă nu există evaluări

- Model: Doosan Infracore Co., LTDDocument9 paginiModel: Doosan Infracore Co., LTDAndrea T FilottoÎncă nu există evaluări

- Spec Sheet SD200Document8 paginiSpec Sheet SD200Yohanes ArgamÎncă nu există evaluări

- DenalDocument1 paginăDenalNORDBÎncă nu există evaluări

- Pds Epilux 218 VocDocument2 paginiPds Epilux 218 VocmuthukumarÎncă nu există evaluări

- Performacen Dl250aDocument22 paginiPerformacen Dl250aRoger FederÎncă nu există evaluări

- Description: Polytetrafluoroethylene (Teflon, PTFE)Document6 paginiDescription: Polytetrafluoroethylene (Teflon, PTFE)Yaho HosÎncă nu există evaluări

- Geartek Catalog (Completo)Document102 paginiGeartek Catalog (Completo)Mauricio Ariel H. Orellana100% (1)

- Geartek CatalogDocument106 paginiGeartek CatalogJohnSengsuÎncă nu există evaluări

- Model: Doosan Infracore Co., LTDDocument17 paginiModel: Doosan Infracore Co., LTDysik1102Încă nu există evaluări

- Polyester Fabric: T 5 AertesDocument1 paginăPolyester Fabric: T 5 AertesKristianto CahyonoÎncă nu există evaluări

- Vee Pack Sets: Technical DetailsDocument2 paginiVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)Încă nu există evaluări

- F10BL - Pvcexcon 2LR8 DB20 U0v05 FaDocument1 paginăF10BL - Pvcexcon 2LR8 DB20 U0v05 FaCustomer ServiceÎncă nu există evaluări

- Cmt-1075-Smt Datasheet - Piezo Buzzer Transducer - Cui IncDocument3 paginiCmt-1075-Smt Datasheet - Piezo Buzzer Transducer - Cui IncLUDWINGÎncă nu există evaluări

- Kämmer Actuators Series 4: Pneumatic and ElectropneumaticDocument8 paginiKämmer Actuators Series 4: Pneumatic and Electropneumaticesteban casanovaÎncă nu există evaluări

- Epimastic 7200 SRDocument2 paginiEpimastic 7200 SRqc_531040655Încă nu există evaluări

- Hi-Lo Diş FormuDocument1 paginăHi-Lo Diş FormuGökhan AnliÎncă nu există evaluări

- Application Manual Chapter 1 - Moulding SandDocument98 paginiApplication Manual Chapter 1 - Moulding SandVishal MaliÎncă nu există evaluări

- Polyethylene Gel-Spinning: Dinesh AheerDocument64 paginiPolyethylene Gel-Spinning: Dinesh AheerDinesh YadavÎncă nu există evaluări

- F10ab-Pvcexcon 2LR8 DB20 U0v05 Fa AbDocument1 paginăF10ab-Pvcexcon 2LR8 DB20 U0v05 Fa AbCustomer ServiceÎncă nu există evaluări

- Braided Hose, Two-Layer, EN853 2SN PropertiesDocument1 paginăBraided Hose, Two-Layer, EN853 2SN PropertiesDaniel WitzkeÎncă nu există evaluări

- THICKNESS - 1.2 CM: Designer CollectionDocument16 paginiTHICKNESS - 1.2 CM: Designer Collectionprvns0074377Încă nu există evaluări

- Product List Under SWR Fittings Standard IS 14735: 1999: MinimumDocument2 paginiProduct List Under SWR Fittings Standard IS 14735: 1999: MinimumPrakash KumarÎncă nu există evaluări

- F10 - Pvcexcon 2LR8 W20 U0v05 FaDocument1 paginăF10 - Pvcexcon 2LR8 W20 U0v05 FaCustomer ServiceÎncă nu există evaluări

- TruFloTK SeriesDocument3 paginiTruFloTK Seriesaxelarias960Încă nu există evaluări

- Technical Data Sheet Sack Kraft: Subtance Tappi Item Unit 70 75 80Document2 paginiTechnical Data Sheet Sack Kraft: Subtance Tappi Item Unit 70 75 80Pamangus TappulakÎncă nu există evaluări

- "Specific" Use and Maintenance Manual: (Translation of The Original Manual)Document16 pagini"Specific" Use and Maintenance Manual: (Translation of The Original Manual)Tina ManousiÎncă nu există evaluări

- Corod SWR High Strength 29feb12Document3 paginiCorod SWR High Strength 29feb12Ronald LlerenaÎncă nu există evaluări

- Sieve Analysis For Fine Aggregate - Kico ProjectDocument1 paginăSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanÎncă nu există evaluări

- 1SC 100R2AT Spec PageDocument1 pagină1SC 100R2AT Spec PageWolker MqzÎncă nu există evaluări

- Epimastic 7200: Product DescriptionDocument2 paginiEpimastic 7200: Product DescriptionSu KaÎncă nu există evaluări

- Matco's Presentation 2Document34 paginiMatco's Presentation 2Mohamad Nasuthion MakkasauÎncă nu există evaluări

- Johnson Endura EDC 40x40cm 12mm Rajkot Nov 21Document16 paginiJohnson Endura EDC 40x40cm 12mm Rajkot Nov 21SANRACHANA officeÎncă nu există evaluări

- Constantes de HilosDocument5 paginiConstantes de HilosRicardoMuzanteParedesÎncă nu există evaluări

- General Information: 9.6 PP 100 / 20 PP 1.2Document3 paginiGeneral Information: 9.6 PP 100 / 20 PP 1.2vijayÎncă nu există evaluări

- XM Filter ElementDocument2 paginiXM Filter ElementhafsakrknÎncă nu există evaluări

- Properties of Plastics: R&D SACL Jul-20Document7 paginiProperties of Plastics: R&D SACL Jul-20VIJAYÎncă nu există evaluări

- Reloop SMDocument23 paginiReloop SMrviacavaÎncă nu există evaluări

- Rock Mastic 477D: Epoxy - Based PaintDocument3 paginiRock Mastic 477D: Epoxy - Based PaintHASÎncă nu există evaluări

- Macdrill TSSDocument2 paginiMacdrill TSSRaed fouadÎncă nu există evaluări

- Serie Ir-V StucchiDocument4 paginiSerie Ir-V StucchiHIDRAFLUIDÎncă nu există evaluări

- SD300H Spec Sheet - 2015.03.09Document19 paginiSD300H Spec Sheet - 2015.03.09Luis Fernando Leal100% (2)

- Arbit: Tested According ISO 1402Document1 paginăArbit: Tested According ISO 1402Agus Be PeÎncă nu există evaluări

- Alloy 6022 Sheet: Higher Strength With Improved FormabilityDocument6 paginiAlloy 6022 Sheet: Higher Strength With Improved Formabilitywulfgang66Încă nu există evaluări

- With Balinit and Balitherm, Efficiency and Productivity Are in Top FormDocument6 paginiWith Balinit and Balitherm, Efficiency and Productivity Are in Top Formwulfgang66Încă nu există evaluări

- Guidelines For Making PFMEA - A PDFDocument10 paginiGuidelines For Making PFMEA - A PDFKalimuthu PsÎncă nu există evaluări

- Benteler Logistics ManualDocument100 paginiBenteler Logistics Manualwulfgang66Încă nu există evaluări

- Hot Stamping 642-8Document2 paginiHot Stamping 642-8wulfgang66Încă nu există evaluări

- W WW WW W..S SP Pe Ec Ciia Allm Me Etta Alls S..C Co Om M: Pull/Pull Tests With 5 Ksi (34 Mpa) Base StressDocument8 paginiW WW WW W..S SP Pe Ec Ciia Allm Me Etta Alls S..C Co Om M: Pull/Pull Tests With 5 Ksi (34 Mpa) Base Stresswulfgang66Încă nu există evaluări

- Hydraulic Press DesignDocument20 paginiHydraulic Press DesignEyup Yuksel60% (5)

- OGIHARA CFixture Standards-5 11 2012 PDFDocument83 paginiOGIHARA CFixture Standards-5 11 2012 PDFwulfgang66Încă nu există evaluări

- Circle Grid Marking and Measurement and FLD PDFDocument10 paginiCircle Grid Marking and Measurement and FLD PDFwulfgang66Încă nu există evaluări

- IMVP Modular - PaperDocument60 paginiIMVP Modular - Paperwulfgang66Încă nu există evaluări

- Dayton Rogers Design Handbook E-Edition PDFDocument42 paginiDayton Rogers Design Handbook E-Edition PDFwulfgang66Încă nu există evaluări

- Manufacturing Management (1988) PDFDocument563 paginiManufacturing Management (1988) PDFwulfgang66Încă nu există evaluări

- Daimler Supplier Quality Manual SQM, Mar 2017Document17 paginiDaimler Supplier Quality Manual SQM, Mar 2017wulfgang66Încă nu există evaluări

- WORLDAUTOSTEEL 00 - AHSSGuidelines - V6 - 20170430 - Part2Document120 paginiWORLDAUTOSTEEL 00 - AHSSGuidelines - V6 - 20170430 - Part2wulfgang66Încă nu există evaluări

- MPERSDocument1 paginăMPERSKen ChiaÎncă nu există evaluări

- Mobrey CLT PDFDocument18 paginiMobrey CLT PDFAnonymous Oydnu9Încă nu există evaluări

- Measurement of Bioreactor K ADocument18 paginiMeasurement of Bioreactor K AAtif MehfoozÎncă nu există evaluări

- Shizhong Liang, Xueming Liu, Feng Chen, Zijian Chan, (2004) .Document4 paginiShizhong Liang, Xueming Liu, Feng Chen, Zijian Chan, (2004) .Kiệt LêÎncă nu există evaluări

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDocument2 paginiComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINAÎncă nu există evaluări

- Bitumen BasicsDocument25 paginiBitumen BasicsMILON KUMAR HOREÎncă nu există evaluări

- Ventura 4 DLX ManualDocument36 paginiVentura 4 DLX ManualRoland ErdőhegyiÎncă nu există evaluări

- Chapter 7 Unemployment, Inflation, and Long-Run GrowthDocument21 paginiChapter 7 Unemployment, Inflation, and Long-Run GrowthNataly FarahÎncă nu există evaluări

- Library PDFDocument74 paginiLibrary PDFfumiÎncă nu există evaluări

- NURTURE Module-V 11 1 en PDFDocument4 paginiNURTURE Module-V 11 1 en PDFJorge SingÎncă nu există evaluări

- Course Guide Pe1 PDFDocument4 paginiCourse Guide Pe1 PDFrahskkÎncă nu există evaluări

- Radproduction Chapter 2-9Document276 paginiRadproduction Chapter 2-9Christian DioÎncă nu există evaluări

- Index Medicus PDFDocument284 paginiIndex Medicus PDFVania Sitorus100% (1)

- Biology - Cell City AnswersDocument5 paginiBiology - Cell City AnswersDaisy be100% (1)

- OM Hospital NEFTDocument1 paginăOM Hospital NEFTMahendra DahiyaÎncă nu există evaluări

- MCQ Homework: PeriodonticsDocument4 paginiMCQ Homework: Periodonticsفراس الموسويÎncă nu există evaluări

- The Impact Behaviour of Composite MaterialsDocument6 paginiThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- BUERGER's Inavasc IV Bandung 8 Nov 2013Document37 paginiBUERGER's Inavasc IV Bandung 8 Nov 2013Deviruchi GamingÎncă nu există evaluări

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Document4 pagini(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungÎncă nu există evaluări

- Unit-7 (EVS)Document32 paginiUnit-7 (EVS)g6614134Încă nu există evaluări

- Careerride Com Electrical Engineering Interview Questions AsDocument21 paginiCareerride Com Electrical Engineering Interview Questions AsAbhayRajSinghÎncă nu există evaluări

- Tri-Partite Agreement AssociationDocument9 paginiTri-Partite Agreement AssociationThiyagarjanÎncă nu există evaluări

- BKM 10e Ch07 Two Security ModelDocument2 paginiBKM 10e Ch07 Two Security ModelJoe IammarinoÎncă nu există evaluări

- Schindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsDocument20 paginiSchindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsHakim BgÎncă nu există evaluări

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDocument5 paginiFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiÎncă nu există evaluări

- Nodular Goiter Concept MapDocument5 paginiNodular Goiter Concept MapAllene PaderangaÎncă nu există evaluări

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 paginiAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoÎncă nu există evaluări

- Fundamental Molecular Biology: GenomesDocument45 paginiFundamental Molecular Biology: GenomesMoonHoLeeÎncă nu există evaluări

- 13105389Document22 pagini13105389Larry RicoÎncă nu există evaluări

- Safety Tips in Playing ArnisDocument2 paginiSafety Tips in Playing ArnisDensyo De MensyoÎncă nu există evaluări