Documente Academic

Documente Profesional

Documente Cultură

Untitled PDF

Încărcat de

KevinDataHilaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Untitled PDF

Încărcat de

KevinDataHilaDrepturi de autor:

Formate disponibile

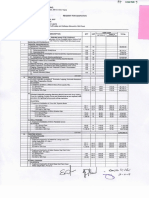

TABLE 1 TABLE 2 EST.

SHEET EQPT

LABOR PRODUCTION TABLE

MANHOURS PER QUANTITY (M.H./UNIT)

ITEM NO. WORK DESCRIPTION M.H./ UNIT LOW AVERAGE HIGH

A. FORM WORKS INSTALLATION

WALL ON THE GROUND SQ.M. 4 2 1.6

WALL ABOVER GROUND SQ.M. 4.7 2.35 1.88

BEAMS SQ.M. 6.16 3.08 2.46

COLUMN SQ.M. 4.7 2.35 1.88

SUSPENDED SLAB

0 TO 18' SQ.M. 3.34 1.67 1.34

18' TO 36' UP SQ.M. 6.66 3.33 2.66

ELEVATED AND SHORED SLAB FORMING

FORMING ONLY SQ.M. 17.2 9 6.88

FORMING AND SHORING SQ.M. 22 11 8.8

WOOD WALL AND PARTITION SQ.M. 1 0.6 0.4

B. FORMWORKS FABRICATION SQ.M. 2.15 1.08 0.86

C. STRIPPING OF FORMS

WALL ON GROUND SQ.M. 0.5 0.25 0.2

WALL ABOVE 10' SQ.M. 2.58 1.29 1.03

BEAMS SQ.M. 2.06 1.03 0.82

COLUMNS SQ.M. 1.7 0.85 0.68

SUSPENDED SLAB SQ.M.

0 TO 18' SQ.M. 1.67 0.83 0.67

18' TO 36' UP SQ.M. 2.16 1.08 0.86

ELEVATED AND SHORED SLAB FORMING SQ.M.

STRIP OF FORMS SQ.M. 7 3.5 2.8

FLOOR SLAB AT GRADE STRIP OF FORMS SQ.M. 5.6 2.8 2.24

D INSTALLION OF CARPENTRY WORKS

PLYWOOD PARTITION PC 2 1 0.8

T & G FLOORING AND SHORING B.F. 0.29 0.14 0.11

CEILING FRAME B.F. 0.3 0.36 0.29

SIDING FRAME B.F. 0.53 0.27 0.21

FLOORING FRAME B.F. 1.94 0.97 0.77

WOODEN POSS ERECTION B.F. 0.85 0.43 0.34

TRUSS FABRICATION B.F. 0.7 0.35 0.28

TRUSS INSTALLATION B.F. 1.6 0.8 0.64

GIRTS INSTALLTION B.F. 0.43 0.21 0.17

PLATES INSTALLATION B.F. 0.27 0.13 0.11

PURLINS INSTALLATION B.F. 0.53 0.27 0.1

FASCIA BOARD INSTALLATION B.F. 0.91 0.46 0.36

1/4" or 3/4" thk PLYWOOD

CUTTING BY MANUAL PC 2 1 0.8

ASSEMBLY S.F. 0.83 0.42 0.33

CEILNG:

FRAME INSTALLATION SQ.M. 2.66 1.33 1.06

PLYWOOD INSTALLLATION SQ.M. 2 1 0.9

CABINET BOARDING B.F. 0.26 0.13 0.1

CABINET FRAMING B.F. 0.36 0.18 0.14

WOOD WALL PARTITION SQ.M. 1 0.5 0.4

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 1 of 7

WOOD WALL PARTITION SQ.M. 1 0.5 0.4

PANEL WALL SQ.M. 14 7 5.6

FORMING WEIGHT ANCHOR BOLT SQ.M. 9 4.5 3.6

WET FORMING SQ.M. 7 3.5 2.8

E. DOORS AND WINDOWS

W-PANEL INSTALLATION PC. 0.8 0.4 0.32

STEEL WINDOWS INSTALLATION PC. 4 2 1.6

LOUVER WINDOWS INSTALLATION:

FIXED ASBESTOS SQ.M. 9.26 4.63 3.7

FIXED METAL LOUVERS SQ.M. 6.24 3.12 2.5

FIXED GI SHEETS SQ.M. 9.26 4.63 3.7

FIXED GLASS SQ.M. 6.34 3.12 2.5

FIXED WOODEN SQ.M. 6.76 3.38 2.7

ALUMINUM FRAME WINDOWS EACH 20 10 8

SLIDING GLASS DOOR EACH 24 12 9.6

HOLLOW METAL DOOR EACH 20 10 8

ROLLING DOORS EACH 50 25 20

FIXED WINDOW S.F. 0.63 0.31 0.25

DOOR LOCKSET SET 3.2 1.6 1.28

DOOR JAMB FABRICATION B.F. 0.44 0.22 0.18

DOOR JAMB INSTALLATION B.F. 0.66 0.33 0.26

CYCLONE WIRE INSTALLATION SQ.M. 6.24 3.12 2.5

F. TRADE MASONRY WORKS

GROUTING and TOL PLASTERING SQ.M. 3.34 1.67 1.34

PEBBLE FINISHED SQ.M. 2.86 1.43 1.34

MABLE INSTALLATION SQ.M. 4 2 1.6

1/4" x 2' x 8" RED BRICKS SQ.M. 10 5 4

GLAZED TILES SQ.M. 21.06 10.53 8.42

UNGLAZED TILES SQ.M. 8.7 4.35 3.48

GLAZED TILE WALL SQ.M. 6 3 2.4

CONC. BLOCK INT. WALL SQ.M. 9 4.5 3.6

CONC. BLOCK EXT. WALL SQ.M. 8 4 3.2

BRICKWORK SQ.M. 1 0.5 0.4

PLASTER WALL AND CEILING SQ.M. 6 3 3.4

HOLLOW TILE WALL SQ.M. 4 2 1.6

ACOUSTICAL TILE WALL SQ.M. 2.4 1.2 0.96

VINYL FLOOR TILE SQ.M. 3.6 1.8 1.44

UNGLAZED OR MOSAIC FLOOR TILE SQ.M. 17 9.5 6.8

LAYING OF CHB & ADOBE SQ.M. 2.28 1.14 0.91

CEMENT FINISH SQ.M. 1.43 0.72 0.57

CONC. HOLLOW BLOCK LAYING:

6" CHB SQ.M. 3.2 1.6 1.28

4" CHB SQ.M. 2.66 1.33 1.06

8" CHB SQ.M. 4 2 1.6

VIT. TILES FLOOR SQ.M. 10.66 5.33 4.26

VIT. TILES WALL SQ.M. 11.94 5.97 4.78

G. TINSMITHING WORK

CORR GI SHEETS:

LIFTING SQ.M. 2.16 1.08 0.86

INSTALLATION SQ.M. 6.12 3.06 2.45

INSTALLATION OF ASBESTOS ROOFING SHT. 2 1 0.8

INSTALLATION OF ALUMINUM GI SHEET SHT. 1.6 9.8 0.64

COPPER CLADDING ROOF DECK L.M. 1.01 0.51 0.4

FAB, GI GUTTER SHT. 6.94 3.47 2.78

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 2 of 7

FAB, GI GUTTER SHT. 6.94 3.47 2.78

GI SHEET ROOFING SHT. 1.64 0.82 0.66

FAB OF GI GUTTER L.M. 1.05 0.53 0.42

FAB. GI DOWNSPOUT L.M. 1.94 0.97 1.78

GUTTER CUT & SHAPE L.M. 0.32 0.16 0.13

INST. OF GUTTER L.M. 1.78 9 0.71

DOWNSPOUT CUT AND SHAPE L.M. 0.59 0.3 0.24

DOWNSPOUT INSTALLATION L.M. 0.27 0.13 0.11

CORR. GI ROOFING SQ.M. 3.6 1.8 1.44

CORR ALUMINUM ROOFING SQ.M. 3.6 1.8 1.44

BUILT UP ROOFING 4 PLY SQ.M. 17 8.5 6.8

PROTECTED METAL SQ.M. 4 2 1.6

CORR. ASBESTOS INST., LIFTING & HAULING SQ.M. 3.4 1.7 1.36

LEADERS & GUTTERS SQ.M. 1.2 0.6 0.48

H CONCRETE AND REBAR WORKS

PLACING CONCRETE:

SLAB ON FILL CU.M. 10 5 4

SLIP FORM CU.M. 50 25 20

FLR FINISH UNHARDENED SQ.M. 2 1 0.8

CONC. FINISH HARDENED SQ.M. 2.86 1.43 1.14

REBAR WORKS:

GROUND FLR. INSTALLATION KGS 0.14 0.07 0.06

UPPER FLR. INSTALLATION KGS 0.16 0.08 0.06

FABRICATION KGS 0.2 0.1 0.08

MIXING MANUAL CU.M. 32 16 12.8

MIXING MACHINE CU.M. 3.6 1.8 1.44

MORE THAN 1.80 CU.M. POUR:

CHUTE FROM TRUCK CU.M. 14 7 5.6

CRANE AND BUCKET CU.M. 28 14 11.2

WHEELING CU.M. 54 27 21.6

FINISHING SQ.M. 5.6 2.8 2.24

CONCRETE POUR ON ELEVATED AND SHORED

SLAB FORMING CHUTE & BUCKET CU.M. 42 21 16.8

PLACEMENT OF REBARS ON FOOTING KGS 1.06 0.53 0.42

FIELD FABRICATION OF REBARS KGS 0.66 0.33 0.26

I. EARTH WORKS

MACHINE EXCAVATION:

SAND CU.M. 1.2 0.6 0.48

SAND AND MARL CU.M. 1.6 0.8 0.64

MARL CU.M. 2.2 1.1 0.88

GRANULAR BACKFILL CU.M. 2.4 1.2 0.96

GRANULAR SOIL BACKFILL CU.M. 3 1.5 1.2

MANUAL FOUNDATION EXCAVATION & BACKFILL:

SAND CU.M. 8 4 3.2

EXCAVATION OF SAND &MARL CU.M. 13 6.5 5.2

EXCAVATION OF MARL CU.M. 21 10.5 8.4

BACKFILL OF SAND CU.M. 11 5.5 4.4

BACKFILL OF SAND &MARL CU.M. 16 8 6.4

BACKFILL OF MARL CU.M. 24 12 9.6

FLOOR SLAB & GRADE:

GRADING MANUAL SQ.M. 2.6 1.3 1.04

EXCAVATION AND BACKFILL CU.M. 36 18 14.4

FINE GRADING & FINISHING

GRADING MANUAL SQ.M. 0.9 0.45 0.36

FINISHING SOIL SURFACE SQ.M. 1.1 0.55 0.44

DIKES CU.M. 2.4 1.2 0.96

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 3 of 7

DIKES CU.M. 2.4 1.2 0.96

J ROAD WORKS

BASE COURSE SQ.M. 0.24 0.12 0.1

CURBS & GUTTER CU.M. 3.6 1.8 1.44

4" THK ROAD SQ.M. 2.6 1.3 1.04

6" THK ROAD SQ.M. 2.8 1.4 1.12

8" THK ROAD SQ.M. 3 1.5 1.2

TROWEL FINISH SQ.M. 0.64 0.32 0.26

SPECIAL TOPPING SQ.M. 2.4 1.2 0.96

4" STONE OR SHELL ROAD SQ.M. 0.64 0.32 0.26

6" STONE OR SHELL ROAD SQ.M. 0.84 0.42 0.34

8" STONE OR SHELL ROAD SQ.M. 1.04 0.52 0.42

ACID PROOFING CU.M. 1.2 0.6 0.48

ASPHALT PAVING:

FINE GRADING & FINISHING SQ.M. 0.84 0.42 0.34

PLACE BASE COURSE SQ.M. 0.4 0.2 0.16

ASPHALT SQ.M. 0.4 0.2 0.16

ACID BLOCK OR PAVING BLOCK:

FIND GRADING SQ.M. 0.84 0.42 0.34

INSTALL BRICK SQ.M. 8.4 4.2 3.36

CRUSH STONE OR SHELL SURFACING

FINE GRADING SQ.M. 0.64 0.32 0.26

PLACE SPREAD AND COMPACT STONE TO 4" SQ.M. 0.84 0.42 0.34

OVER 9" THK SQ.M. 1.04 0.52 0.42

TANK CUSHION

SAND CUSHION CU.M. 1.4 0.7 0.56

APHALT RETAINER RING SQ.M. 0.4 0.2 0.16

NON GRANULAR BACKFILL CU.M. 4 2 1.6

EXCAVATION MANUAL:

COMMON EARTH CU.M. 16 8 6.4

LOAN OF SAND CU.M. 2.62 1.31 1.05

CLAY OR HEAVY SOIL ROCK CU.M. 3.28 1.64 1.31

ROCK CU.M. 5.26 2.63 2.1

MECHANICAL EXCAVATION

COMMON EARTH CU.M. 13.34 6.67 5.34

ROCK W/ JACKHAMMER CU.M. 33.34 16.67 13.34

BACKFILLING

COMMON MANUAL CU.M. 1.64 0.82 0.66

GRAVEL FILL MANUAL CU.M. 10 5 4

TRENCHING AND BACKFILLING OF UNDERGROUND

PIPING USING EXCAVATION MATERIALS MANUAL

FROM 0 TO 2 MTRS. DEPTH L.M. 2.5 1.25 1

2 TO 3 L.M. 3.34 1.67 2.34

3 TO 4 L.M. 5 2.5 2

4 TO 5 L.M. 6.66 3.33 2.66

PLACING BINDER GRAVEL CU.M. 0.21 0.11 0.08

ESCOMBRO BACKFILLING CU.M. 0.42 0.21 0.17

SPREADING, TAMPING AND GRADING SQ.M. 0.96 0.48 0.38

MECHANICAL COMPACTION, PLATE COMPACTION CU.M. 0.11 0.06 0.04

MANUAL CLEARING AND GRUBBING

CLEARING UNDERGROWTH AND TREES 12" SQ.M. 0.1 0.05 0.04

CLEARING UNDERGROWTH AND SHRUBS SQ.M. 0.06 0.03 0.02

DISPOSAL OF SOIL CU.M. 3.38 1.69 1.35

MAULING OF SOIL CU.M. 2 1 0.8

GRAVEL FILL CU.M. 4.14 2.07 1.66

EXCAVATION CRANE AND CLAMPSHELL

. WITH 8-MEN AND 2 CARPENTERS CU.M. 2.14 1.07 0.86

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 4 of 7

. WITH 8-MEN AND 2 CARPENTERS CU.M. 2.14 1.07 0.86

K. TRADE: UNDERGROUND PIPING AND PLUMBING WORKS

1 LAYING ASBESTOS PIPES:

1//2Ø L.M. 1.32 0.66 0.53

3/4" Ø L.M. 1.32 0.66 0.53

1 1/4" L.M. 1.48 0.74 0.59

1 1/2 TO 2" Ø L.M. 1.64 0.82 0.66

2 1/2" Ø L.M. 1.97 0.98 0.7

3" Ø L.M. 2.16 1.08 0.86

3 1/2" Ø L.M. 2.3 1.15 0.92

4" Ø L.M. 2.64 1.32 1.06

2 CAST IRON PIPE

2" Ø L.M. 4.38 2.19 1.75

4" Ø L.M. 6.58 3.29 2.63

6" Ø L.M. 9.84 4.92 3.94

8" Ø L.M. 13.14 6.57 5.26

10" Ø L.M. 19.7 9.85 7.98

12" Ø L.M. 20.62 10.31 8.25

14" Ø L.M. 24.1 12.05 9.64

16" Ø L.M. 27.38 13.69 10.95

18" Ø L.M. 30.68 15.34 12.27

20" Ø L.M. 32.86 16.43 13.14

24" Ø L.M. 36.14 18.07 14.46

30" Ø L.M. 41.08 20.54 16.43

3 LAYING PVC PIPE

1/2 TO 3/4" Ø L.M. 0.38 0.19 0.15

1 TO 1 1/4" Ø L.M. 1.48 0.74 0.59

1 1/2 TO 2" Ø L.M. 1.64 0.82 0.66

2 1/2" Ø L.M. 1.96 0.98 0.78

3" Ø L.M. 2.16 1.08 0.86

4" Ø L.M. 2.62 1.31 1.05

5" Ø L.M. 3.28 1.64 1.31

6" Ø L.M. 4.92 2.46 1.97

4 LAYING RCP 8 MEN (1 TEAM)

24"Ø L.M. 9 4 3.2

36"Ø L.M. 12.8 6.4 5.12

48"Ø L.M. 21.34 10.67 8.54

6-18"Ø L.M. 2.66 1.33 1.06

LAVATORY EACH 16 8 6.4

WATER CLOSET EACH 24 12 9.6

URINAL UTILITY STALL EACH 48 24 19.2

URINAL PEDESTRAL TYPE EACH 32 16 12.8

SHOWER AND INSTALL EACH 20 10 8

5 MAN GROUP SHOWER EACH 72 36 28.8

BAH TUBS EACH 48 24 19.2

SLOPE SINK EACH 28 14 11.2

HOT WATER HEATER EACH 28 14 11.2

16 PERSON WASH SINK EACH 52 26 20.8

DRINKING FOUNTAIN EACH 26 13 10.4

EYE WASH EACH 16 9 6.4

MISC. FIXTURES EACH 4 2 1.6

PARTITIONS EACH 16 8 6.4

LAYING OF 24"Ø RCP PIPE 8 4 3.2

LAYING OF 36"Ø RCP PIPE 12.8 6.4 5.12

LAYING OF 48"Ø RCP PIPE 21.32 10.66 8.53

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 5 of 7

L. TRADE INSULATION

EQUIPMENT INSTALLATION

VESSEL, EXCHANGE & TANKS

FIELD FABRICATION INSULATION S.M. 5 2.5 2

FIELD FABRICATION SHEET METAL COVER S.M. 24 12 9.6

APPLY INSULATION S.M. 10 5 4

APPLY SHEET METAL COVER S.M. 10 5 4

PUMPS, COMPRESSORS & TURBINES

FABRICATE S.M. 34 17 13.6

APPLY S.M. 60 30 24

PIPINGS AND COMPONENT INSULATION

FIELD FABRICATE FLG. 8 4 3.2

FIELD FABRICATESHEET METAL COVER S.M. 1.6 0.8 0.64

APPLY INSULATION L.M. 5.4 2.7 2.16

APPLY SHEET METAL COVER OR METAL COVER EACH 3 1.5 1.2

FABRICATE INSTRUMENT COVER EACH 16 8 6.4

INSTALL INSTRUMENT COVER EACH 12 6 4.8

INSULATE PIPE HANGERS EACH 8 4 3.2

FOR STREAM TRACED LINES L.M. 7.4 3.7 2.96

REMOVAL OF OLD OR EXISTING INSTALLATION L.M. 3 1.5 1.2

M. TRADE:FIRE PROOFING

INSTALL STUDS EACH 1 0.5 0.4

INSTALL MESH S.M. 2.4 1.2 0.96

POURED

FORMING S.M. 28 14 11.2

STRIP FORMS S.M. 12 6 4.8

POUR CONCRETE S.M. 140 70 56

CURING/PATCHING S.M. 1.2 0.6 0.48

FINISHING S.M. 1.4 0.7 0.56

TROWEL, PLASTERED S.M. 5.4 2.7 2.16

PNEUMATIC APPLICATION

GUNITE S.M. 2.4 1.2 0.96

APPLY FINEBRICK OR BLOCK PC. 1.6 0.8 0.64

REMOVAL OF EXISTING OR OLD FIREPROOFING S.M. 5 2.5 2

APPLY FIREPROOFING PAINT S.M. 6 3 2.4

FIRE PROTERCTION:

FIRE PROTECTION EQUIPMENT INSTALLATION:

MONITOR EACH 10 5 4

HOSE REELS AND CARTS EACH 30 15 12

FIRE EXTINGUISHERS EACH 10 5 4

PERSONAL EQUIPMENT:

EYE WASH EACH 20 10 8

SAFETY SHOWERS EACH 20 10 8

BREATHING APPARATUS EACH 10 5 4

SPRINKLER SYSTEM

SPRAY NOZZLES EACH 2 1 80

WATER CANNONS EACH 10 5 4

N. TRADE:PERMANENT FENCING

INSTALL FENCE L.M. 2.4 1.2 0.96

INSTALL GATES L.M. 6 3 2.4

TO RAIL L.M. 0.6 0.3 0.24

BARBE WIRE, 3 STRANDS L.M. 0.6 0.3 0.24

O. TRADE:PAINTING WORKS

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 6 of 7

O. TRADE:PAINTING WORKS

NEW STRUCTURAL STEEL TON 20 1 9

OLD STRUCTURAL STEEL S.M. 1.1 0.55 44

NEW FLAT FLAT PLATES S.M. 0.64 0.32 26

SURFACE PREPARATION:

IN TERMS OF WEIGHT TON 16 8 6.4

IN TERMS OF AREA S.M. 0.86 30 0.34

SAND PREPARATION TON 60 24

P. TRADE:HEATING VENTILATING AND CONDITIONING

HEAVY PIPING L.M. 7 3.5 2.8

DUCT WORK INSTALL S.M. 12 6 4.8

DUCT WORK FAB. S.M. 36 18 14.4

PACKAGE UNIT AIR CONDITIONER EACH 48 24 19.2

UNIT HEATER EACH 24 12 9.6

FINNED CONVERTER EACH 10 5 4

EXHAUST FAN PROPELLER EACH 16 8 6.4

GRAVITY ROOF PAINT L.M. 14 7.3 5.84

POWER ROOF VENT EACH 48 24 19.2

ROUND ROOF VENT EACH 16 8 6.4

PLUMBING PIPING L.M. 7 3.5 2.8

Q. MISCELLANEOUS

WATER STOP INSTALLATION L.M. 1.34 0.67 0.54

CAULKING SLAB JOINT L.M. 0.4 0.2 0.16

ASPHALTING S.M. 1.6 0.8 0.64

GROUTNG AND TOOL PLASTERING S.M. 3.34 1.67 0.84

WATER PROOFING RUBBERIZED S.M. 1.1 0.55 0.28

COPPER CLADDING ROOF DECK L.M. 1 0.5 0.25

WATER PROOFING FLINKOTE S.M. 0.54 0.27 0.14

DEMOLITION OF ADOBE WALL CU.M. 3.2 1.6 0.8

PAINTING S.M. 0.68 0.34 0.17

COPPER WATER STOP CUT AND SHAPE L.M. 11 6 0.03

COPPER WATER STOP CUT AND INSTALLATION L.M. 22 11 0.06

SETTING ANCHOR BOLT KG 97 49 0.24

SETTING ANCHOR BOXES CU.M. 3.64 1.82 0.91

https://lookaside.fbsbx.com/file/151591149-Productivity-Rate…smql7Hb0SbN55Jyivac4ivUX3h8XJJgCxqbv_0Qb4bNVuEKokvP 18/08/2019, 10U07 AM

Page 7 of 7

S-ar putea să vă placă și

- Fire Code of The Philippines 2008Document475 paginiFire Code of The Philippines 2008RISERPHIL89% (28)

- Fire Code of The Philippines 2008Document475 paginiFire Code of The Philippines 2008RISERPHIL89% (28)

- Opening: Sub. Total 1 2Document13 paginiOpening: Sub. Total 1 2MarielSevillaÎncă nu există evaluări

- Earthquake Lateral ForcesDocument10 paginiEarthquake Lateral ForcesOnurUmanÎncă nu există evaluări

- Boq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountDocument6 paginiBoq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountEng Hinji RudgeÎncă nu există evaluări

- BC C Punmia BeamDocument14 paginiBC C Punmia BeamvikrantgoudaÎncă nu există evaluări

- Tumaga Bridge Estimate - RevisedDocument25 paginiTumaga Bridge Estimate - RevisedBert EngÎncă nu există evaluări

- Bill of Material For FoundationDocument8 paginiBill of Material For FoundationnsureshbabuÎncă nu există evaluări

- 3-STOREY HOUSE ESTIMATEDocument4 pagini3-STOREY HOUSE ESTIMATEJhoe SamÎncă nu există evaluări

- Productivity Rate Labor EqptDocument31 paginiProductivity Rate Labor Eqptnemat1233Încă nu există evaluări

- Design of Footing 1Document10 paginiDesign of Footing 1Val MendozaÎncă nu există evaluări

- BOQ - Civil, Structural and ArchitecturalDocument46 paginiBOQ - Civil, Structural and ArchitecturalVincent SaysonÎncă nu există evaluări

- Protecting The Pianist's Hand: The Carrezando Touch and MoreDocument6 paginiProtecting The Pianist's Hand: The Carrezando Touch and MoreAdrianÎncă nu există evaluări

- LABOR PRODUCTION TABLE FOR CONSTRUCTION PROJECTSDocument7 paginiLABOR PRODUCTION TABLE FOR CONSTRUCTION PROJECTSKevinDataHilaÎncă nu există evaluări

- LABOR PRODUCTION TABLE FOR CONSTRUCTION PROJECTSDocument7 paginiLABOR PRODUCTION TABLE FOR CONSTRUCTION PROJECTSKevinDataHilaÎncă nu există evaluări

- SABP Q 008 Concrete Masonry WallsDocument22 paginiSABP Q 008 Concrete Masonry Wallsaseptman1Încă nu există evaluări

- Circular Slab Estimation of SteelDocument3 paginiCircular Slab Estimation of SteelGaddam Padmaja ReddyÎncă nu există evaluări

- Bracing ConnectionsDocument3 paginiBracing ConnectionspradeeshÎncă nu există evaluări

- Filipino Catholic Wedding Ceremony LiturgyDocument8 paginiFilipino Catholic Wedding Ceremony LiturgyHoney Joy ChuaÎncă nu există evaluări

- Komatsu HD785-7 Shop Manual PDFDocument1.491 paginiKomatsu HD785-7 Shop Manual PDFIB EldinÎncă nu există evaluări

- Rebar Take Off (Skyway)Document2 paginiRebar Take Off (Skyway)Allan SorianoÎncă nu există evaluări

- Ledger - Problems and SolutionsDocument1 paginăLedger - Problems and SolutionsDjamal SalimÎncă nu există evaluări

- Sao-Atan House - Fencing EstimateDocument89 paginiSao-Atan House - Fencing EstimateJun Michael Artates VelascoÎncă nu există evaluări

- Structural Analysis For Two Story Residential BuildingDocument4 paginiStructural Analysis For Two Story Residential BuildingMathan LuceroÎncă nu există evaluări

- Tutorial 7 - Connections - Part ADocument28 paginiTutorial 7 - Connections - Part ACyrus HongÎncă nu există evaluări

- Productivity Rate Labor EqptDocument31 paginiProductivity Rate Labor EqptAllan CubacubÎncă nu există evaluări

- Cost EstimateDocument3 paginiCost EstimateHazel GuevarraÎncă nu există evaluări

- Labor Production Table PDFDocument6 paginiLabor Production Table PDFFroilan EspinosaÎncă nu există evaluări

- InsulationDocument13 paginiInsulationBaDa Lee100% (1)

- 1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFDocument141 pagini1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFKevinDataHilaÎncă nu există evaluări

- Unitized Curtain Wall SystemDocument38 paginiUnitized Curtain Wall Systems.senthil nathan100% (1)

- Effortless by Greg McKeownDocument6 paginiEffortless by Greg McKeownNaison StanleyÎncă nu există evaluări

- D5092 - Design and Installation of Ground Water Monitoring Wells in AquifersDocument14 paginiD5092 - Design and Installation of Ground Water Monitoring Wells in Aquifersmaxuelbestete100% (1)

- Eaab BomceDocument22 paginiEaab BomceBert EngÎncă nu există evaluări

- Project Name: Description: Concrete: SLAB 1Document10 paginiProject Name: Description: Concrete: SLAB 1DCM.MacalbeÎncă nu există evaluări

- Pedro Flores El Chapo TrialDocument19 paginiPedro Flores El Chapo TrialChivis MartinezÎncă nu există evaluări

- VFTO DocumentationDocument119 paginiVFTO DocumentationSheri Abhishek ReddyÎncă nu există evaluări

- Boq For RCC BuildingDocument35 paginiBoq For RCC Buildingjatin kalraÎncă nu există evaluări

- Guidelines For Dowel Alignment in Concrete Pavements: Appendix A Review of Literature and Other Relevant InformationDocument41 paginiGuidelines For Dowel Alignment in Concrete Pavements: Appendix A Review of Literature and Other Relevant InformationEunice Joy Tabucanon Villegas100% (1)

- Sample House Construction Cost Estimate PhilippinesDocument7 paginiSample House Construction Cost Estimate PhilippinesJebong A. MarquezÎncă nu există evaluări

- Purlin and Roof DesignDocument4 paginiPurlin and Roof DesignKhairul JaggerÎncă nu există evaluări

- 1 To 2: A To: Proposed Hostel CompexDocument4 pagini1 To 2: A To: Proposed Hostel Compexanon_577049076Încă nu există evaluări

- Project Title: Location: Owner: Bill of Quantities: General RequirementsDocument4 paginiProject Title: Location: Owner: Bill of Quantities: General RequirementsTano ChavezÎncă nu există evaluări

- Loads On Industrial BuildingsDocument29 paginiLoads On Industrial Buildingsmcg_3m100% (1)

- Analysis of Reinforced Concrete BeamsDocument1 paginăAnalysis of Reinforced Concrete BeamsAly Arquillano JrÎncă nu există evaluări

- BOM-Est-Masonry-WoodTruss-Roofing-Carpentry-Tile-Plumbing-ElectricalDocument2 paginiBOM-Est-Masonry-WoodTruss-Roofing-Carpentry-Tile-Plumbing-Electricalho designÎncă nu există evaluări

- Columnsteel 1Document1 paginăColumnsteel 1Gelbert SilotÎncă nu există evaluări

- Using Long Span Color RoofDocument3 paginiUsing Long Span Color RoofMaria Rose Giltendez - BartianaÎncă nu există evaluări

- Column design details for rectangular columnDocument27 paginiColumn design details for rectangular columnnsureshbabu0% (1)

- RCD-DeSIGN Engr. Mark ChristianDocument9 paginiRCD-DeSIGN Engr. Mark ChristianTaki TachibanaÎncă nu există evaluări

- DepEd PSIP-2 Building SpecificationsDocument6 paginiDepEd PSIP-2 Building Specificationston carolinoÎncă nu există evaluări

- Concrete Slabs On GradeDocument4 paginiConcrete Slabs On Grademr.KramÎncă nu există evaluări

- Pueblo Verde Expansion Column Cutting ListDocument20 paginiPueblo Verde Expansion Column Cutting ListAilyn O. DungogÎncă nu există evaluări

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 paginiSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 paginiIIT Hyderabad Faculty Housing Design CalculationssmijusÎncă nu există evaluări

- Estimate FormatDocument97 paginiEstimate FormatSilver James AustriaÎncă nu există evaluări

- Concrete Estimate by Jack FajardoDocument67 paginiConcrete Estimate by Jack FajardojAck oяenseÎncă nu există evaluări

- 14.0 Slab ExtractorDocument13 pagini14.0 Slab ExtractorklynchelleÎncă nu există evaluări

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 paginiModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioÎncă nu există evaluări

- Cutting List Pnr1Document1 paginăCutting List Pnr1Jason Teves DomasigÎncă nu există evaluări

- Here are the answers to the jumbled letters exercise:1. PLUMB BOB2. MEASURING WHEEL 3. CLINICIAN4. LEVELING STAFF5. THEODOLITE6. TRANSITDocument13 paginiHere are the answers to the jumbled letters exercise:1. PLUMB BOB2. MEASURING WHEEL 3. CLINICIAN4. LEVELING STAFF5. THEODOLITE6. TRANSITLloyd Bryan Deric100% (1)

- Roof load capacity and design load calculationsDocument2 paginiRoof load capacity and design load calculationstyannottiÎncă nu există evaluări

- Bar EstimateDocument10 paginiBar EstimateKarl MonfortÎncă nu există evaluări

- Bill of Materials: I Concrete WorksDocument4 paginiBill of Materials: I Concrete WorksKimberly Binay-anÎncă nu există evaluări

- Typical Detail of Slab: Schedule of RCC Slabs (Level: First Floor Slab)Document1 paginăTypical Detail of Slab: Schedule of RCC Slabs (Level: First Floor Slab)Manju BirjeÎncă nu există evaluări

- How To Make A PERT-CPM Chart and SWOT AnalysisDocument8 paginiHow To Make A PERT-CPM Chart and SWOT Analysis'Ronnel Cris ⎝⏠⏝⏠⎠ Consul'0% (1)

- Truss Design - Faculty Wing - EN1993Document13 paginiTruss Design - Faculty Wing - EN1993JonathanÎncă nu există evaluări

- Rebar Cutting ListDocument12 paginiRebar Cutting ListJett Mark ContrerasÎncă nu există evaluări

- Design Criteria Stru.Document9 paginiDesign Criteria Stru.Ar John Bernard AbadÎncă nu există evaluări

- WSD Beam DesignDocument11 paginiWSD Beam DesignThea Audrey SF DeritÎncă nu există evaluări

- 151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MDocument9 pagini151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MZelalem MengistuÎncă nu există evaluări

- Labor Production Table: A. Form Works InstallationDocument7 paginiLabor Production Table: A. Form Works InstallationMac KYÎncă nu există evaluări

- Deck Design 17.12.2020Document7 paginiDeck Design 17.12.2020Ankush SharmaÎncă nu există evaluări

- ATO FANTU BUILDING HAWASSA B+G+6+T+SHEFETA Bar OrderDocument69 paginiATO FANTU BUILDING HAWASSA B+G+6+T+SHEFETA Bar OrderJaspergroup 15Încă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019 PDFDocument47 paginiHP3 - Operations Meeting Report JULY 2019 PDFKevinDataHilaÎncă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019Document47 paginiHP3 - Operations Meeting Report JULY 2019KevinDataHilaÎncă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019Document47 paginiHP3 - Operations Meeting Report JULY 2019KevinDataHilaÎncă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019Document47 paginiHP3 - Operations Meeting Report JULY 2019KevinDataHilaÎncă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019 PDFDocument47 paginiHP3 - Operations Meeting Report JULY 2019 PDFKevinDataHilaÎncă nu există evaluări

- HP3 - Operations Meeting Report JULY 2019Document47 paginiHP3 - Operations Meeting Report JULY 2019KevinDataHilaÎncă nu există evaluări

- Rebar, Masonry, Painting & Tile EstimatesDocument2 paginiRebar, Masonry, Painting & Tile EstimatesKevinDataHilaÎncă nu există evaluări

- PDF CHARGING FOR CIVIL ENGINEERING SERVICES Michelle Minoza - AcademiaeduDocument6 paginiPDF CHARGING FOR CIVIL ENGINEERING SERVICES Michelle Minoza - AcademiaeduKevinDataHilaÎncă nu există evaluări

- Builderware Price List 5Document38 paginiBuilderware Price List 5Jongson Dantes RodriguezÎncă nu există evaluări

- Building OfficialsRequirements For Building PermitsBuilding PermitsPhilippineDocument5 paginiBuilding OfficialsRequirements For Building PermitsBuilding PermitsPhilippineKevinDataHilaÎncă nu există evaluări

- Purchase OrderDocument4 paginiPurchase OrderKevinDataHilaÎncă nu există evaluări

- R.A. No. 544 - An Act To Regulate The Practice of Civil Engineering in The Philippines - The Corpus JurisDocument1 paginăR.A. No. 544 - An Act To Regulate The Practice of Civil Engineering in The Philippines - The Corpus JurisKevinDataHilaÎncă nu există evaluări

- Global-Estateresorts,Lnc.: Da丁E;W闘Nesday,November22,2017 Proj∈Ct Hp3&4・Holiandpa「K3&4Document2 paginiGlobal-Estateresorts,Lnc.: Da丁E;W闘Nesday,November22,2017 Proj∈Ct Hp3&4・Holiandpa「K3&4KevinDataHilaÎncă nu există evaluări

- Contractor's Contract (Breakdown)Document5 paginiContractor's Contract (Breakdown)KevinDataHilaÎncă nu există evaluări

- Purchase Order (Sample)Document2 paginiPurchase Order (Sample)KevinDataHilaÎncă nu există evaluări

- 2020 02 04 - HP34 - ST - Ramp and Stair Details PDFDocument1 pagină2020 02 04 - HP34 - ST - Ramp and Stair Details PDFKevinDataHilaÎncă nu există evaluări

- Sample of Purchase OrderDocument4 paginiSample of Purchase OrderKevinDataHilaÎncă nu există evaluări

- 2-Storey With 3 Bedroom Floor PlanDocument1 pagină2-Storey With 3 Bedroom Floor PlanKevinDataHilaÎncă nu există evaluări

- Adventures of Huckleberry Finn by Shared Via My Books AppDocument1 paginăAdventures of Huckleberry Finn by Shared Via My Books AppKevinDataHilaÎncă nu există evaluări

- Sample of Purchase OrderDocument4 paginiSample of Purchase OrderKevinDataHilaÎncă nu există evaluări

- Globaし-Estateresorts,Inc.: 2,Supp Hsta Ationlof50MmshadowgaDocument2 paginiGlobaし-Estateresorts,Inc.: 2,Supp Hsta Ationlof50MmshadowgaKevinDataHilaÎncă nu există evaluări

- Pamantasan NG Lungsod NG Maynila - Freshmen AdmissionDocument6 paginiPamantasan NG Lungsod NG Maynila - Freshmen AdmissionPoppy HowellÎncă nu există evaluări

- EC604(A) Microcontrollers and Embedded Systems Unit 2 SummaryDocument38 paginiEC604(A) Microcontrollers and Embedded Systems Unit 2 SummaryAbhay AmbuleÎncă nu există evaluări

- History of Technical Writing HardDocument4 paginiHistory of Technical Writing HardAllyMae LopezÎncă nu există evaluări

- AA Practice Problems on Amino Acids and Peptides (less than 40 charsDocument20 paginiAA Practice Problems on Amino Acids and Peptides (less than 40 charsNurlaeli NaelulmunaMajdiyahÎncă nu există evaluări

- HB Im70 QRDocument1 paginăHB Im70 QROsamaÎncă nu există evaluări

- Tie Technology DK SKDocument32 paginiTie Technology DK SKVladimir PleșcaÎncă nu există evaluări

- Earth's StructureDocument10 paginiEarth's StructureMaitum Gemark BalazonÎncă nu există evaluări

- Symbolic Calculus Sage ReferenceDocument25 paginiSymbolic Calculus Sage ReferenceLn Amitav BiswasÎncă nu există evaluări

- Introduction To Computing Week 2Document23 paginiIntroduction To Computing Week 2Jerick FernandezÎncă nu există evaluări

- QUARMEN Prerequisites - SEM1Document12 paginiQUARMEN Prerequisites - SEM1Valérie NguyenÎncă nu există evaluări

- Troubleshoot WLAN IssuesDocument4 paginiTroubleshoot WLAN IssuesIvan Herrera CoronaÎncă nu există evaluări

- Virtual Art PaperDocument5 paginiVirtual Art Paperbrandy oldfieldÎncă nu există evaluări

- Plumbing Layout and SpecificationsDocument1 paginăPlumbing Layout and SpecificationsLiza P. PaculanangÎncă nu există evaluări

- Topic 2Document6 paginiTopic 2Vince Diza SaguidÎncă nu există evaluări

- RTL8185 Windows7 FixDocument2 paginiRTL8185 Windows7 FixJamesHackÎncă nu există evaluări

- Sexual ExtacyDocument18 paginiSexual ExtacyChal JhonnyÎncă nu există evaluări

- 1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterDocument10 pagini1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterJhancarlos Carrasco MÎncă nu există evaluări

- QF-16 Security ProceduresDocument55 paginiQF-16 Security Proceduresmaruka33Încă nu există evaluări

- Blasting 001 Abb WarehouseDocument2 paginiBlasting 001 Abb WarehouseferielvpkÎncă nu există evaluări

- Burning Arduino Bootloader With AVR USBASP PDFDocument6 paginiBurning Arduino Bootloader With AVR USBASP PDFxem3Încă nu există evaluări