Documente Academic

Documente Profesional

Documente Cultură

Resistance To Airflow of Grains, Seeds, Other Agricultural Products, and Perforated Metal Sheets

Încărcat de

Daniela DiazDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Resistance To Airflow of Grains, Seeds, Other Agricultural Products, and Perforated Metal Sheets

Încărcat de

Daniela DiazDrepturi de autor:

Formate disponibile

ASAE D272.

3 MAR96

Resistance to Airflow of Grains, Seeds, Other Agricultural

Products, and Perforated Metal Sheets

Approved by the ASAE Committee on Technical Data; adopted by ASAE 1 Purpose and scope

1948; revised 1954, 1962; reconfirmed by the ASAE Electric Power and

1.1 These data can be used to estimate the resistance to airflow of beds

Processing Division Technical Committee December 1968, December

of grain, seeds, and other agricultural products, and of perforated metal

1973, December 1978, December 1979; revised December 1980;

sheets. An estimate of this airflow resistance is the basis for the design

reconfirmed December 1985; revised by the Grain and Feed Processing

of systems to dry or aerate agricultural products.

and Storage Committee; approved by the Food and Process Engineering

Institute Standards Committee March 1987; reconfirmed December 1.2 Data are included for common grains, seeds, other agricultural

1991; reaffirmed December 1992, December 1993, December 1994, products, and for perforated metal sheets, over the airflow range

December 1995; revised March 1996. common for aeration and drying systems.

2 Empirical curves

NOTE – This chart gives values for a loose fill (not packed) of clean, relatively dry grain. For a loose fill of clean grain having high moisture content (In equilibrium with

relative humidities exceeding 85%), use only-80% of the indicated pressure drop for a given rate of air flow.

Packing of the grain in a bin may cause 50% higher resistance to air flow than the values shown. White rice is a variety of popcorn.

The pressure drop for airflow through bulk grain in the horizontal direction has been measured for wheat and barley (Kumar and Muir, 1986); canola (Jayas et al., 1987);

corn (Kay et al., 1989); alfalfa pellets (Sokhansanj et al., 1990); flaxseed (Jayas et al., 1991); and bird’s foot trefoil, canary seed, fababeans, lentils, meadow fescue, oats,

timothy, and tara peas (Alagusundaram et al., 1992). The pressure drop in the horizontal direction may be 60% to 70% of the pressure drop for airflow in the vertical

direction. For some seeds, however, the difference between the pressure drops for the horizontal and vertical airflows may be nonexistent.

Figure 1 – Resistance to airflow of grains and seeds (SI Units) (Shedd’s data)

544 ASAE STANDARDS 1999

NOTE – This chart gives values for a loose fill (not packed) of clean, relatively dry grain. For a loose fill of clean grain having high moisture content (in equilibrium with

relative humidities exceeding 85%), use only 80% of the indicated pressure drop for a given rule of air flow. Packing of the grain in a bin may cause 50% higher resistance

to air flow than the values shown.

When foreign material is mixed with grain no specific correction can be recommended. However, it should be noted that resistance to air flow is increased if the foreign

material is finer than the grain, and resistance to air flow is decreased if the foreign material is coarser than the grain.

The pressure drop for airflow through bulk grain in the horizontal direction has been measured for wheat and barley (Kumar and Muir, 1986); canola (Jayas et al., 1987);

corn (Key et al., 1989); alfalfa pellets (Sokhansanj et al., 1990); flaxseed (Jayas et al., 1991); and bird’s foot trefoil, canary seed, fababeans, lentils, meadow fescue, oats,

timothy, and tara peas (Alagusundaram et al., 1992). The pressure drop in the horizontal direction may be 60% to 70% of the pressure drop for airflow in the vertical

direction. For some seeds, however, the difference between the pressure drops for the horizontal and vertical airflows may be nonexistent.

Figure 2 – Resistance to airflow of grains and seeds (Inch-pound units) (Shedd’s data)

ASAE STANDARDS 1999 545

Figure 3 – Resistance to airflow for other agricultural products (SI units)

Figure 4 – Resistance to airflow of other agricultural products (Inch-pound units)

546 ASAE STANDARDS 1999

Figure 5 – Resistance to airflow of shelled corn and wheat at low airflows (SI units)

Figure 6 – Resistance to airflow of shelled corn and wheat at low airflows (Inch-pound units)

ASAE STANDARDS 1999 547

where:

D P 5 pressure drop, Pa or inches of water;

L 5 bed depth, m or ft;

Q 5 airflow, m3/s·m2 or cfm/ft2;

fm = decimal fraction of fines, by weight.

NOTE – Range of applicability: 0.076 to 0.20 m3/s ·m2 (15 to

40 CFM/FT2) and 0 < fm < 0.2. Broken grain and other matter

which passed through a 4.76-mm (12/64-in.) round-hole sieve are

defined as fines. (Hague)

5 Effect of bulk density on resistance to airflow of

shelled corn

5.1 An increase in bulk density causes an increase in the airflow

resistance per unit bed depth of the corn. The pressure drop per unit bed

depth can be predicted as a function of airflow rate and corn bulk density

by use of this empirical equation:

DP S D

rb 2

rk

Q

rk S D

rb 2

Q

S D S D

5 X 11 X 2 1X3

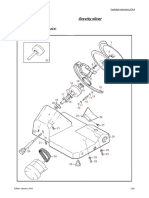

Figure 7 – Resistance to airflow of perforated metal sheets L rb 3 rb 3

when supporting grain (Henderson) 12 12

rk rk

3 Airflow resistance equation

where:

DP aQ 2

5

L loge ~ 11 bQ !

where:

DP 5 pressure drop, Pa or inches of water;

DP 5 pressure drop, Pa or inches or water; L 5 bed depth, m or ft;

L 5 bed depth, m or ft; pb 5 corn bulk density, kg/m3 or lb/ft3;

a 5 constant for particular grain (see table 1); pk 5 corn kernel density, kg/m3 or lb/ft3;

Q 5 airflow, m3/s·m2 or cfm/ft2; Q 5 airflow, m3/s·m2 or cfm/ft2;

b 5 constant for particular grain (see table 1). X1 ,X2 ,X3 5 constants (see table 2 or table 3).

4 Effect of fines on resistance to airflow of shelled

corn

4.1 An effect of adding fines to shelled corn is an increase in the airflow

resistance of the corn. The pressure drop per unit bed depth can be

corrected to account for fines using this equation:

SI units: S D

DP

L

5

corrected

S D

DP

L

~ 11 ~14.5566226.418Q !~ fm!!

clean

Customary units: S D

DP

L

5

corrected

S D

DP

L

~ 11 ~ 14.5566

clean

20.1342Q !~ fm!!

548 ASAE STANDARDS 1999

Table 1 – Values for constants in airflow resistance equation

Value of a Value of b Range of Q

Material (Pa·s2/m3) (m2·s/m3) (m3/m2s) Reference

Alfalfa 6.40 3 104 3.99 0.0056–0.152 Shedd (1953)

Alfalfa cubes 1.27 3 103 22.99 0.13–3.15 Sokhansanj et al. (1993)

Alfalfa pellets 1.80 3 104 68.72 0.0053–0.63 Sokhansanj et al. (1993)

Barley 2.14 3 104 13.2 0.0056–0.203 Shedd

Brome grass 1.35 3 104 8.88 0.0056–0.152 Shedd

Canola, Tobin 5.22 3 104 7.27 0.0243–0.2633 Jayas and Sokhansanj (1989)

Canola, Westar 4.55 3 104 9.72 0.0243–0.2633 Jayas and Sokhansanj (1989)

Clover, alsike 6.11 3 104 2.24 0.0056–0.101 Shedd

Clover, crimson 5.32 3 104 5.12 0.0056–0.203 Shedd

Clover, red 6.24 3 104 3.55 0.0056–0.152 Shedd

Corn, ear (lot 1) 1.04 3 104 325. 0.051–0.353 Shedd

Corn, shelled 2.07 3 104 30.4 0.0056–0.304 Shedd

Corn, shelled (low airflow) 9.77 3 103 8.55 0.00025–0.0203 Sheldon et al. (1960)

Fescue 3.15 3 104 6.70 0.0056–0.203 Shedd

Flax 8.63 3 104 8.29 0.0056–0.152 Shedd

Lentils, Laird 5.43 3 104 36.79 0.0028–0.5926 Sokhansanj et al. (1990)

Lespedeza, Kobe 1.95 3 104 6.30 0.0056–0.203 Shedd

Lespedeza, Sericea 6.40 3 104 3.99 0.0056–0.152 Shedd

Lupine, blue 1.07 3 104 21.1 0.0056–0.152 Shedd

Milkweed pods 2.11 3 103 4.65 0.06–0.4 Jones and Von Bargen (1992)

Oats 2.41 3 104 13.9 0.0056–0.203 Shedd

Peanuts 3.80 3 103 111. 0.030–0.304 Steele

Peppers, bell 5.44 3 102 868. 0.030–1.00 Gaffney and Baird (1975)

Popcorn, white 2.19 3 104 11.8 0.0056–0.203 Shedd

Popcorn, yellow 1.78 3 104 17.6 0.0056–0.203 Shedd

Potatoes 2.18 3 103 824. 0.030–0.300 Staley and Watson (1967)

Rescue 8.11 3 103 11.7 0.0056–0.203 Shedd

Rice, rough 2.57 3 104 13.2 0.0056–0.152 Shedd

Rice, long brown 2.05 3 104 7.74 0.0055–0.164 Calderwood (1973)

Rice, long milled 2.18 3 104 8.34 0.0055–0.164 Calderwood

Rice, medium brown 3.49 3 104 10.9 0.0055–0.164 Calderwood

Rice, medium milled 2.90 3 104 10.6 0.0055–0.164 Calderwood

Sorghum 2.12 3 104 8.06 0.0056–0.203 Shedd

Soybeans 1.02 3 104 16.0 0.0056–0.304 Shedd

Sunflower, confectionery 1.10 3 104 18.1 0.055–0.178 Schuler (1974)

Sunflower, oil 2.49 3 104 23.7 0.025–0.570 Nguyen (1981)

Sweet potatoes 3.40 3 103 6.103108 0.050–0.499 Abrams and Fich (1982)

Wheat 2.70 3 104 8.77 0.0056–0.203 Shedd

Wheat (low airflow) 8.41 3 103 2.72 0.00025–0.0203 Sheldon et al.

NOTE – The parameters given were determined by a least square fit of the data in Figures 1 to 6. To obtain the corresponding values of (a) in inch-pound units (in

H2O min2/ft3) divide the above a-values by 31635726. To obtain corresponding values of (b) in inch-pound units (ft2/cfm) divide the above b-values by 196.85. Parameters

for the Lot 2 Ear Corn data are not given since the above equation will not fit the data.

Although the parameters listed in this table were developed from data at moderate airflows, extrapolations of the curves for shelled corn, wheat, and sorgbum agree well

with available data (Stark and James) at airflows up to 1.0 m3/s · m2.

Table 3 – Values for constants (inch-pound units) for equation in clause 5.1

Airflow range,

Table 2 – Value for constants (SI units) for equation in clause 5.1 cfm/ft3 X1 X2 X3

Airflow range, m3/s·m2 X1 X2 X3 5.3 < Q < 26.3 20.0012 5.5331024 1.62 3 1025

26.3 , Q < 52.5 20.013 6.9431024 1.39 3 1025

0.027 < Q < 0.13 20.998 88.8 511 52.5 , Q < 117 20.094 10.2 31024 1.23 3 1025

0.13 < Q < 0.27 210.9 111 439

0.27 < Q < 0.60 276.5 163 389 NOTE – Range of applicability: 732 to 799 kg/m3 (45.7 to 49.9 lb/ft3) (corn

bulk density) 0.027 to 0.60 m3 /s · m2 (5.3 to 117 cfm/ft2) (Bern and Charity).

ASAE STANDARDS 1999 549

Annex A Jones, D. and K. L. Von Bargen. 1992. Some physical properties of

(informative) milkweed pods. Transactions of the ASAE 35(1):243–246.

Bibliography Kay, R. L., C. J. Bern and C. R. Hurburgh, Jr. 1989. Horizontal and

vertical airflow resistance of shelled corn at various bulk densities. Trans-

actions of the ASAE 32(2):733–736.

Abrams, C. F. and J. D. Fish, Jr. 1982. Air flow resistance characteristics

of bulk piled sweet potatoes. Transactions of the ASAE 25(4):1103– Kumar, A. and W. E. Muir. 1986. Airflow resistance of wheat and barley

1106. affected by airflow direction, filling method and dockage. Transactions of

the ASAE 29(5):1423–1426.

Alagusundaram, K., D. S. Jayas, F. Chotard and N. D. G. White. 1992.

Airflow pressure drop relationships of some specialty seeds. Sciences Nguyen, V. T. 1981. Airflow resistance of sunflower seed. Unpublished

des Aliments 12(1):101–116. term project for AE568 at Iowa State University, Ames, IA. Under the

direction of Carl I. Bern.

Bern, C. J. and L. F. Charity. 1975. Airflow resistance characteristics of

corn as influenced by bulk density. ASAE Paper No. 75-3510. ASAE, St. Schuler, R. T. 1974. Drying-related properties of sunflower seeds. ASAE

Joseph, MI 49085. Paper No. 74-3534. ASAE. St. Joseph. MI 49085.

Calderwood, D. L. 1973. Resistance to airflow of rough, brown and milled Shedd, C. K. 1953. Resistance of grains and seeds to air flow. Agricul-

rice. Transactions of the ASAE 16(3):525–527, 532. tural Engineering 34(9):616–619.

Gaffney, J. J. and C. D. Baird. 1975. Forced air cooling of bell peppers Sheldon, W. H., C. W. Hall, and J. K. Wang. 1960. Resistance of shelled

in bulk. ASAE Paper No. 75-6525. ASAE, St. Joseph, MI 49085. corn and wheat to low airflows. Transactions of the ASAE 3(2):92–94.

Hague, E., G. H. Foster, D. S. Chung, and F. S. Lai, 1978. Static Siebenmorgen, T. J. and V. K. Jindal, 1987. Airflow resistance of rough

pressure across a corn bed mixed with fines. Transactions of the ASAE rice as affected by moisture content, fines concentration and bulk

21(5):997–1000. density. Transactions of the ASAE 30(4):1138–1143.

Henderson, S. M. 1943. Resistance of shelled corn and bin walls to Sokhansanj, S., A. A. Falacinski, F. W. Sosulski, D. S. Jayas and J.

airflow. Agricultural Engineering 24(11):367–369. Tang. 1990. Resistance of bulk lentils to airflow. Transactions of the

ASAE 33(4):1281–1285.

Hukil, W. V. and N. C. Ives. 1955. Radial air flow resistance of grain.

Agricultural Engineering 36(5):332–335. Sokhansanj, S., W. Li and O. O. Fasina. 1993. Resistance of alfalfa

cubes, pellets and compressed herbage to airflow. Can. Agric. Eng.

Jayas, D. S., S. Sokhansanj, E. B. Moysey and E. M. Barber. 1987. The 35(3):207–213.

effect of airflow direction on the resistance of canola (rapeseed) to

airflow. Can. Agric. Eng. 29(2):189–192. Staley, L. M. and E. L. Watson. 1961. Some design aspects of refriger-

ated potato storages. Can. Agric. Eng. 3(1):20–22.

Jayas, D. S. and S. Sokhansanj. 1989. Design data on resistance of

airflow through canola (rapeseed). Transactions of the ASAE 32(1):295– Stark, B. and K. James. 1982. Airflow characteristics of grains and

296. seeds. National Conference Publication N:82/8. 242–243. The Institution

of Engineers, Australia.

Jayas, D. S. and W. E. Muir. 1991. Airflow-pressure drop data for model-

ling fluid flow in anisotropic bulks. Transactions of the ASAE 34(1):251– Steele, J. L. 1974. Resistance of peanuts to airflow. Transactions of the

254. ASAE 17(3):573–577.

Jayas, D. S., K. Alagusundaram and D. A. Irvine. 1991. Resistance to

airflow through bulk flax seed as affected by the moisture content, direc-

tion of airflow and foreign material. Can. Agric. Eng. 33(2):279–285.

550 ASAE STANDARDS 1999

S-ar putea să vă placă și

- Resistencia Al Desgaste Abrasivo Según Norma Astm 105Document9 paginiResistencia Al Desgaste Abrasivo Según Norma Astm 105Robin J. Pico MontesÎncă nu există evaluări

- Jitorres SIEMENS.2012.MOTORs PDFDocument230 paginiJitorres SIEMENS.2012.MOTORs PDFJhonatan VargasÎncă nu există evaluări

- Tabla de Severidad Unidades SullairDocument1 paginăTabla de Severidad Unidades Sullairlambjabibi100% (1)

- 07-01 MafDocument5 pagini07-01 MafJuan Roberto López BetanzosÎncă nu există evaluări

- Tutorial 10 Vibration PDFDocument2 paginiTutorial 10 Vibration PDFBharat SaiÎncă nu există evaluări

- Peimar en Sg340pDocument2 paginiPeimar en Sg340pRonnie Mere JuárezÎncă nu există evaluări

- 27595149Document5 pagini27595149Anshul AgarwalÎncă nu există evaluări

- F116 + Rev 1.2 2003-07-15 Underwing Refueling NozzleDocument30 paginiF116 + Rev 1.2 2003-07-15 Underwing Refueling NozzleJim HollingerÎncă nu există evaluări

- A Method of Calculating The Heat Dissipation From Radiators To Cool Vehicle EnginesDocument9 paginiA Method of Calculating The Heat Dissipation From Radiators To Cool Vehicle EnginespeterÎncă nu există evaluări

- Determining Air Change in A Single Zone by Means of A Tracer Gas DilutionDocument18 paginiDetermining Air Change in A Single Zone by Means of A Tracer Gas DilutionGarima GuptaÎncă nu există evaluări

- Fisher - Actuators PDFDocument16 paginiFisher - Actuators PDFsambhajiÎncă nu există evaluări

- HX HN Compressors Brochure 2015 0318 LRDocument20 paginiHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaÎncă nu există evaluări

- Catalogue Air Handling Unit DDW Without Frame PDFDocument27 paginiCatalogue Air Handling Unit DDW Without Frame PDFFirman AnriÎncă nu există evaluări

- Catalogo Stock VogtVogtDocument10 paginiCatalogo Stock VogtVogtmmaldonado10Încă nu există evaluări

- Manual GreenseekerDocument56 paginiManual GreenseekerMailson Oliveira100% (1)

- Biocleaner - Manual de Operacion y MantenimientoDocument9 paginiBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioÎncă nu există evaluări

- Dokumen - Tips - Threlkeld 5 Answers PDFDocument11 paginiDokumen - Tips - Threlkeld 5 Answers PDFSheensky V. SalasaÎncă nu există evaluări

- SibenergomashDocument47 paginiSibenergomashheroj83Încă nu există evaluări

- 2nd ReviewDocument29 pagini2nd ReviewretechÎncă nu există evaluări

- Module 25 Solution Distortion Energy TheoryDocument4 paginiModule 25 Solution Distortion Energy TheoryWolf LordÎncă nu există evaluări

- 15me53 Important Questions Paper-3Document3 pagini15me53 Important Questions Paper-3Karthi SiddhÎncă nu există evaluări

- Pump FirePumps-BDocument12 paginiPump FirePumps-BCARLOS RIAÑOÎncă nu există evaluări

- 2003 Freightliner FL70: 4x4 Cab & ChassisDocument1 pagină2003 Freightliner FL70: 4x4 Cab & ChassisNorlan Jarquin FloresÎncă nu există evaluări

- IM200-20 (LC Mag Insertion) PDFDocument8 paginiIM200-20 (LC Mag Insertion) PDFLazzarus Az GunawanÎncă nu există evaluări

- P1219Document2 paginiP1219ridzimÎncă nu există evaluări

- 2ROwners PDFDocument59 pagini2ROwners PDFRicardo FernandezÎncă nu există evaluări

- ESDAW 9CH热水机 PDFDocument18 paginiESDAW 9CH热水机 PDFanghelahernanÎncă nu există evaluări

- 200912515224111903Document5 pagini200912515224111903GBHJRÎncă nu există evaluări

- Examples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyDocument4 paginiExamples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyHarish Mohankrishnan NairÎncă nu există evaluări

- Assembly-Install STD Control Dryer PDFDocument106 paginiAssembly-Install STD Control Dryer PDFdonyaÎncă nu există evaluări

- Design of Sugar Mill Gears by P.w.jonesDocument5 paginiDesign of Sugar Mill Gears by P.w.jonesanwarmughal0% (1)

- Manual Algor TuberiasDocument0 paginiManual Algor TuberiascaletonesÎncă nu există evaluări

- SNR Genelkatalog PDFDocument231 paginiSNR Genelkatalog PDFa04205Încă nu există evaluări

- LWN Operating Manual of FanDocument20 paginiLWN Operating Manual of FanYogesh Badhe100% (1)

- Strength of Materials - Task 1. Chapter 1.Document3 paginiStrength of Materials - Task 1. Chapter 1.Eduard Avila Meriño100% (1)

- Sinter-1 UserGuideDocument36 paginiSinter-1 UserGuideElvin MuseyibovÎncă nu există evaluări

- Doku - Pub Process Heat Transfer Kern Solution Manual PDF 2Document4 paginiDoku - Pub Process Heat Transfer Kern Solution Manual PDF 2Fikri fadli ramadaniÎncă nu există evaluări

- Ficha TecnicaDocument27 paginiFicha TecnicaRaul Karniel Cruz LópezÎncă nu există evaluări

- A Handbook For Cane Sugar Manufacturers and Their Chemists 1000763605 PDFDocument615 paginiA Handbook For Cane Sugar Manufacturers and Their Chemists 1000763605 PDFVerin VericuetoÎncă nu există evaluări

- Elementos FinitosDocument72 paginiElementos FinitosPedro Leos100% (1)

- DAYTON Brand Drop-In: Manufactured by EMERSON For Over 30 YearsDocument20 paginiDAYTON Brand Drop-In: Manufactured by EMERSON For Over 30 Yearsjohn GonzalezÎncă nu există evaluări

- Busch Instruction Manual RA 0400 0630 C Usen 0872929551Document32 paginiBusch Instruction Manual RA 0400 0630 C Usen 0872929551priyaprasad367792Încă nu există evaluări

- ACPSB 380P Rooftop PackageDocument28 paginiACPSB 380P Rooftop Package6PakÎncă nu există evaluări

- Auxiliar: Jhonny David Iquise Ope MEC 2334 "A" Ing. Mec - Elm - MCTDocument5 paginiAuxiliar: Jhonny David Iquise Ope MEC 2334 "A" Ing. Mec - Elm - MCTCristoffer Castelo ArgüellasÎncă nu există evaluări

- Lab Report Template BEE2123Document4 paginiLab Report Template BEE2123alsthenieaÎncă nu există evaluări

- wbt-4 2 4Document99 paginiwbt-4 2 4orelei121Încă nu există evaluări

- Loss Coefficients KLDocument2 paginiLoss Coefficients KLNicolHernandezNarvaezÎncă nu există evaluări

- Especificaciones Técnicas Agitador FlyghtDocument8 paginiEspecificaciones Técnicas Agitador FlyghtedwinsazzzÎncă nu există evaluări

- Tutorial: GEARS II: Spur Gears - Force AnalysisDocument14 paginiTutorial: GEARS II: Spur Gears - Force AnalysisNdivhuwo NdivhuwoÎncă nu există evaluări

- Ficha Tecnica Motor NeumaticoDocument7 paginiFicha Tecnica Motor NeumaticoDestaco IngenieroÎncă nu există evaluări

- Evisa E300 RDocument4 paginiEvisa E300 RFlores Juan Carlos100% (1)

- Tipos Acero Estructural ASTMDocument3 paginiTipos Acero Estructural ASTMJorge Emilio Gonzalez MataÎncă nu există evaluări

- Aerodynamics Assignment On Air-FoilsDocument14 paginiAerodynamics Assignment On Air-Foilsashish choudharyÎncă nu există evaluări

- FLAT Heat PipeDocument102 paginiFLAT Heat Pipeafic219473Încă nu există evaluări

- Pumping MachinesDocument2 paginiPumping MachinesKerwinPerezÎncă nu există evaluări

- Euler Equation v1.2Document19 paginiEuler Equation v1.2DUVAN FELIPE MUNOZ GARCIAÎncă nu există evaluări

- MANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016Document10 paginiMANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016ivan reyes TorresÎncă nu există evaluări

- Pump Learning PDFDocument21 paginiPump Learning PDFfahimehÎncă nu există evaluări

- Armbrust Et Al 1997. Relating Plant Canopy Characteristics To Soil Transport Capacity by WindDocument6 paginiArmbrust Et Al 1997. Relating Plant Canopy Characteristics To Soil Transport Capacity by Windemmanuel seguraÎncă nu există evaluări

- Characterization of Evaporation and Drift Losses With Centre PivotsDocument6 paginiCharacterization of Evaporation and Drift Losses With Centre PivotsAymen Al Al-BaajÎncă nu există evaluări

- Effet Soja IJIAS-15-117-13Document7 paginiEffet Soja IJIAS-15-117-13kowiou ABOUDOUÎncă nu există evaluări

- SAKS Project Brochure English1Document2 paginiSAKS Project Brochure English1ntv2000Încă nu există evaluări

- 2004 Kumar and Tiwari Black GramDocument3 pagini2004 Kumar and Tiwari Black Gramsapana choudharyÎncă nu există evaluări

- Crop ProductionDocument28 paginiCrop ProductionAbdul qadeerÎncă nu există evaluări

- J. Solum Vol. VII No. 1 Januari 2010: 37-48 ISSN: 1829-7994Document13 paginiJ. Solum Vol. VII No. 1 Januari 2010: 37-48 ISSN: 1829-7994Afrilia MuslimÎncă nu există evaluări

- Experential Learning Project On LPP ModelDocument7 paginiExperential Learning Project On LPP ModelabhiÎncă nu există evaluări

- Unesco - Eolss Sample Chapters: Growth and Production of Oat and RyeDocument9 paginiUnesco - Eolss Sample Chapters: Growth and Production of Oat and RyeShiva KhanalÎncă nu există evaluări

- Region II CORN All Program PDFDocument1.523 paginiRegion II CORN All Program PDFVirgo CayabaÎncă nu există evaluări

- Inmateh I - 2011Document91 paginiInmateh I - 2011Ionut Velescu100% (1)

- Crop RotationDocument8 paginiCrop RotationYash VardhanÎncă nu există evaluări

- Bio FertilizersDocument7 paginiBio Fertilizersrockingtwo07Încă nu există evaluări

- Philippines-Factsheet Kangkong Field English PDFDocument3 paginiPhilippines-Factsheet Kangkong Field English PDFeychezdy07Încă nu există evaluări

- Agrodok-17-Cultivation of Tomato PDFDocument93 paginiAgrodok-17-Cultivation of Tomato PDFrpine3580% (5)

- Analysis of Liquid Manures and Their Use - ND Kumar - UAS Bangalore - OFAI SAC - 2009Document39 paginiAnalysis of Liquid Manures and Their Use - ND Kumar - UAS Bangalore - OFAI SAC - 2009H.n. AswathanarayanaÎncă nu există evaluări

- 6.principles and Methods of Weed ControlDocument66 pagini6.principles and Methods of Weed ControlSHABNAM KUMARIÎncă nu există evaluări

- IFFCO MissionDocument48 paginiIFFCO MissionMamta GuptaÎncă nu există evaluări

- Daily Quality Analysis Report: Wheat DaliaDocument2 paginiDaily Quality Analysis Report: Wheat Daliaamit sharmaÎncă nu există evaluări

- Transmara East District ProfileDocument4 paginiTransmara East District ProfileegertonÎncă nu există evaluări

- The Early Days of The Natal Sugar IndustryDocument7 paginiThe Early Days of The Natal Sugar Industryrforteza100% (1)

- DLP-agriculture Grade 11Document3 paginiDLP-agriculture Grade 11Eden Shen Sumilay100% (6)

- 2010 PARAGUAY ww2 CH 19Document34 pagini2010 PARAGUAY ww2 CH 19manÎncă nu există evaluări

- Eastern Visayas Short Story Totoy Indic: The Vegetable Farmer Who Ripples His SuccessDocument2 paginiEastern Visayas Short Story Totoy Indic: The Vegetable Farmer Who Ripples His SuccessAyeah Metran EscoberÎncă nu există evaluări

- Pulses ReportDocument51 paginiPulses Reportheinhtet aungÎncă nu există evaluări

- Mango Planting ManualDocument12 paginiMango Planting ManualBryan ScofieldÎncă nu există evaluări

- Resource Conservation Techniques in Rice Wheat Cropping SystemDocument47 paginiResource Conservation Techniques in Rice Wheat Cropping SystemChristopher Potts100% (4)

- UG Courses Wef (2007-08)Document13 paginiUG Courses Wef (2007-08)Ganpat Lal SharmaÎncă nu există evaluări

- Laser Land Leveling in India - A Success - M.L. Jat & HS SidhuDocument30 paginiLaser Land Leveling in India - A Success - M.L. Jat & HS SidhuCSISA ProjectÎncă nu există evaluări

- Lesson 1.1.1Document57 paginiLesson 1.1.1christopher palacioÎncă nu există evaluări

- 10 1 1 685 5006 PDFDocument6 pagini10 1 1 685 5006 PDFEmilyn Rose Manalo EscosuraÎncă nu există evaluări

- Plantation CropsDocument216 paginiPlantation CropsAkanksha AttriÎncă nu există evaluări