Documente Academic

Documente Profesional

Documente Cultură

For New Designs: AOZ1051PI

Încărcat de

GioVoTamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

For New Designs: AOZ1051PI

Încărcat de

GioVoTamDrepturi de autor:

Formate disponibile

AOZ1051PI

EZBuck™ 3 A Synchronous Buck Regulator

Not Recommended For New Designs

General Description Features

The AOZ1051PI is a high efficiency, easy to use, 3 A z 4.5 V to 18 V operating input voltage range

synchronous buck regulator. The AOZ1051PI works from z Synchronous Buck: 70 mΩ internal high-side switch

4.5 V to 18 V input voltage range, and provides up to 3 A and 40 mΩ internal low-side switch (at 12 V)

of continuous output current with an output voltage

ns

z Up to 95 % efficiency

adjustable down to 0.8 V.

z External soft start

ig

The AOZ1051PI comes in an exposed pad SO-8 z Output voltage adjustable to 0.8 V

package and is rated over a -40 °C to +85 °C operating

z 3 A continuous output current

es

ambient temperature range.

z 500 kHz PWM operation

D

z Cycle-by-cycle current limit

Replacement Parts:

z Pre-bias start-up

AOZ6663DI

ew

z Short-circuit protection

AOZ6683CI z Thermal shutdown

N

z Exposed pad SO-8 package

r Applications

Fo

z Point of load DC/DC converters

z LCD TV

d

z Set top boxes

de

z DVD and Blu-ray players/recorders

z Cable modems

en

m

om

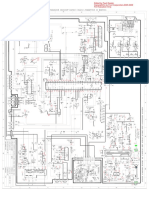

Typical Application

VIN

ec

C1 CSS

10µF

R

VIN SS

L1 4.7µH

ot

EN VOUT

AOZ1051PI LX

N

COMP R1

C2, C3

RC FB 22µF

CC AGND PGND R2

Figure 1. 3.3 V 3 A Synchronous Buck Regulator, Fs = 500 kHz

Rev. 1.0 June 2011 www.aosmd.com Page 1 of 14

AOZ1051PI

Ordering Information

Part Number Ambient Temperature Range Package Environmental

AOZ1051PI -40 °C to +85 °C EPAD SO-8 Green Product

AOS Green Products use reduced levels of Halogens, and are also RoHS compliant.

Please visit www.aosmd.com/web/quality/rohs_compliant.jsp for additional information.

Pin Configuration

ns

PGND 1 8 NC

ig

es

VIN 2 7 SS

PAD

AGND (LX) EN

D

3 6

FB 4 5 COMP

ew

Exposed Pad SO-8

N

(Top View)

r

Fo

Pin Description

d

de

Pin Number Pin Name Pin Function

1 PGND Power ground. PGND needs to be electrically connected to AGND.

en

2 VIN Supply voltage input. When VIN rises above the UVLO threshold and EN is logic high,

the device starts up.

m

3 AGND Analog ground. AGND is the reference point for controller section. AGND needs to be

om

electrically connected to PGND.

4 FB Feedback input. The FB pin is used to set the output voltage via a resistive voltage divider

between the output and AGND.

ec

5 COMP External loop compensation pin. Connect a RC network between COMP and AGND to

compensate the control loop.

R

6 EN Enable pin. Pull EN to logic high to enable the device. Pull EN to logic low to disable the

device. If on/off control in not needed, connect EN to VIN and do not leave it open.

ot

7 SS Soft-start pin. 5 µA current charging current.

8 NC No Connect Pin. Pin 8 is not internally connected. Connect this pin externally to LX and

N

use it for better thermal performance.

Exposed pad LX Switching node. LX is the drain of the internal PFET. LX is used as the thermal pad of the

power stage.

Rev. 1.0 June 2011 www.aosmd.com Page 2 of 14

AOZ1051PI

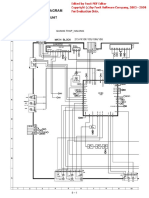

Block Diagram

VIN

EN UVLO 5V LDO Internal OTP

& POR Regulator +5V

Reference ISen

ns

Softstart –

& Bias

Q1

ILimit

ig

SS

SS

5µA

es

+

+ PWM Level

0.8V PWM Shifter

EAmp – Control

D

FB – Comp +

Logic

+ FET LX

Driver

ew

Q2

COMP

N

500kHz

Oscillator r

Fo

d

de

AGND PGND

en

Absolute Maximum Ratings Recommended Operating Conditions

m

Exceeding the Absolute Maximum Ratings may damage the The device is not guaranteed to operate beyond the Maximum

device. Recommended Operating Conditions.

om

Parameter Rating Parameter Rating

Supply Voltage (VIN) 20 V Supply Voltage (VIN) 4.5 V to 18 V

ec

LX to AGND -0.7 V to VIN +0.3 V Output Voltage Range 0.8 V to 0.85 • VIN

LX to AGND (20 ns) -5 V to 22 V Ambient Temperature (TA) -40 °C to +85 °C

R

EN to AGND -0.3 V to VIN +0.3 V Package Thermal Resistance

Exposed Pad SO-8 (ΘJA)(2) 50 °C/W

ot

FB, SS, COMP to AGND -0.3 V to 6.0 V

PGND to AGND -0.3 V to +0.3 V Note:

2. The value of ΘJA is measured with the device mounted on a 1-in2

N

Junction Temperature (TJ) +150 °C

FR-4 board with 2 oz. Copper, in a still air environment with

Storage Temperature (TS) -65 °C to +150 °C TA = 25 °C. The value in any given application depends on the

ESD Rating(1) 2.0 kV user’s specific board design.

Note:

1. Devices are inherently ESD sensitive, handling precautions are

required. Human body model rating: 1.5 kΩ in series with 100 pF.

Rev. 1.0 June 2011 www.aosmd.com Page 3 of 14

AOZ1051PI

Electrical Characteristics

TA = 25 °C, VIN = VEN = 12 V, VOUT = 3.3 V unless otherwise specified(3)

Symbol Parameter Conditions Min. Typ. Max. Units

VIN Supply Voltage 4.5 18 V

VUVLO Input Under-Voltage Lockout VIN Rising 4.1

Threshold V

VIN Falling 3.7

IIN Supply Current (Quiescent) IOUT = 0, VFB = 1.2 V, VEN > 1.2 V 1.6 2.5 mA

IOFF Shutdown Supply Current VEN = 0 V 1 10 µA

VFB Feedback Voltage TA = 25 °C 0.788 0.8 0.812 V

ns

Load Regulation 0.5 %

Line Regulation 1 %

ig

IFB Feedback Voltage Input Current 200 nA

es

VEN EN Input Threshold Off Threshold 0.6

V

On Threshold 2

D

VHYS EN Input Hysteresis 100 mV

ew

EN Leakage Current 1 µA

SS Time CSS = 10 nF 2 ms

MODULATOR

N

fO Frequency 400 500 600 kHz

DMAX Maximum Duty Cycle r 85 %

Fo

TMIN Controllable Minimum On Time 150 ns

Current Sense Transconductance 8 A/ V

d

Error Amplifier Transconductance 200 µA / V

de

PROTECTION

ILIM Current Limit 3.5 4.5 A

en

Over-Temperature Shutdown Limit TJ Rising 150

°C

TJ Falling 100

m

OUTPUT STAGE

om

High-Side Switch On-Resistance VIN = 12 V 70

mΩ

VIN = 5 V 110

Low-Side Switch On-Resistance VIN = 12 V 40

ec

mΩ

VIN = 5 V 50

R

Note:

3. Specification in BOLD indicate an ambient temperature range of -40 °C to +85 °C. These specifications are guaranteed by design.

ot

N

Rev. 1.0 June 2011 www.aosmd.com Page 4 of 14

AOZ1051PI

Typical Performance Characteristics

Circuit of Figure 1. TA = 25 °C, VIN = VEN = 12 V, VOUT = 3.3 V unless otherwise specified.

Light Load Operation Full Load Operation

Vin ripple

0.5V/div

Vin ripple

0.1V/div

Vo ripple

Vo ripple

0.1V/div

0.1V/div

ns

IL

IL

2A/div

2A/div

ig

VLX

VLX

10V/div

es

10V/div

D

2µs/div 2µs/div

ew

Start Up to Full Load Short Circuit Protection

N

Vin LVX

5V/div 10V/div

r

Fo

Vo

Vo

d

2V/div

2V/div

de

IL

en

lin 2A/div

2A/div

m

2ms/div 20ms/div

om

50% to 100% Load Transient Short Circuit Recovery

ec

VLX

R

10V/div

Vo

ot

0.1V/div

Vo

N

2V/div

Io

2A/div IL

2A/div

100µs/div 20ms/div

Rev. 1.0 June 2011 www.aosmd.com Page 5 of 14

AOZ1051PI

Efficiency

Efficiency (VIN = 12V) vs. Load Current

100

95

90

85

Efficiency (%)

ns

80

ig

5V OUTPUT

75 3.3V OUTPUT

es

1.8V OUTPUT

1.2V OUTPUT

70

D

65

ew

60

0.3 0.6 0.9 1.2 1.5 1.8 2.1 2.4 2.7 3.0

N

Load Current (A)

r

Fo

Detailed Description

d

The AOZ1051PI is a current-mode step down regulator Steady-State Operation

de

with an integrated high-side PMOS switch and a low-side Under heavy load steady-state conditions, the converter

NMOS switch. The AOZ1051PI operates from a 4.5 V to operates in fixed frequency and Continuous-Conduction

18 V input voltage range and supplies up to 3 A of load

en

Mode (CCM).

current. Features include enable control, power-on reset,

input under voltage lockout, output over voltage The AOZ1051PI integrates an internal P-MOSFET as the

m

protection, external soft-start and thermal shut down. high-side switch. Inductor current is sensed by amplifying

the voltage drop across the drain to source of the high

om

The AOZ1051PI is available in an exposed pad SO-8 side power MOSFET. Output voltage is divided down by

package. the external voltage divider at the FB pin. The difference

of the FB pin voltage and reference voltage is amplified

ec

Enable and Soft Start

by the internal transconductance error amplifier. The

The AOZ1051PI has an external soft start feature to limit error voltage, which shows on the COMP pin, is

R

in-rush current and ensure the output voltage ramps up compared against the current signal, which is the sum of

smoothly to regulation voltage. The soft start process inductor current signal and ramp compensation signal, at

ot

begins when the input voltage rises to 4.1 V and voltage the PWM comparator input. If the current signal is less

on the EN pin is HIGH. In the soft start process, the than the error voltage, the internal high-side switch is on.

N

FB voltage is ramped to follow the voltage of the soft start The inductor current flows from the input through the

pin until it reaches 0.8 V. The voltage of the soft-start pin inductor to the output. When the current signal exceeds

is charged by an internal 5 µA current. the error voltage, the high-side switch is off. The inductor

current is freewheeling through the internal low-side

The EN pin of the AOZ1051PI is active high. Connect the N-MOSFET switch to output. The internal adaptive FET

EN pin to VIN if the enable function is not used. Pulling driver guarantees no turn on overlap of both the

EN to ground will disable the AOZ1051PI. Do not leave high-side and the low-side switch.

EN open. The voltage on the EN pin must be above 2 V

to enable the AOZ1051PI. When the EN pin voltage falls

below 0.6 V, the AOZ1051PI is disabled.

Rev. 1.0 June 2011 www.aosmd.com Page 6 of 14

AOZ1051PI

Compared with regulators using freewheeling Schottky Since the switch duty cycle can be as high as 100 %, the

diodes, the AOZ1051PI uses a freewheeling NMOSFET maximum output voltage can be set as high as the input

to realize synchronous rectification. This greatly voltage minus the voltage drop on the upper PMOS and

improves the converter efficiency and reduces power the inductor.

loss in the low-side switch.

Protection Features

The AOZ1051PI uses a P-Channel MOSFET as the

high-side switch. This saves the bootstrap capacitor The AOZ1051PI has multiple protection features to

normally seen in a circuit using an NMOS switch. It also prevent system circuit damage under abnormal

allows 100 % turn-on of the high-side switch to achieve conditions.

linear regulation mode of operation. The minimum

Over Current Protection (OCP)

voltage drop from VIN to VO is the load current times DC

ns

resistance of the MOSFET plus DC resistance of the The sensed inductor current signal is also used for over

buck inductor. It can be calculated by equation below: current protection. Since the AOZ1051PI employs peak

ig

current mode control, the COMP pin voltage is

V O_MAX = V IN – I O × R DS ( ON ) proportional to the peak inductor current. The COMP pin

es

voltage is limited to be between 0.4 V and 2.5 V internally.

where; The peak inductor current is automatically limited

D

VO_MAX is the maximum output voltage, cycle-by-cycle.

VIN is the input voltage from 4.5 V to 18 V,

ew

When the output is shorted to ground under fault

IO is the output current from 0 A to 3 A, and

conditions, the inductor current slowly decays during a

RDS(ON) is the on resistance of the internal MOSFET. switching cycle because the output voltage is 0 V.

N

To prevent catastrophic failure, a secondary current limit

Output Voltage Programming

is designed inside the AOZ1051PI. The measured

Output voltage can be set by feeding back the output to r

inductor current is compared against a preset voltage

Fo

the FB pin using a resistor divider network as shown in which represents the current limit, between 3.5 A and 5.0

Figure 1. The resistor divider network includes R1 and A. When the output current is greater than the current

R2. Usually, a design is started by picking a fixed R2 limit, the high side switch will be turned off. The converter

d

value and calculating the required R1 with the equation will initiate a soft start once the over-current condition is

de

below: resolved.

⎛ R ⎞

V O = 0.8 × ⎜ 1 + ------1-⎟ Power-On Reset (POR)

en

⎝ R 2⎠ A power-on reset circuit monitors the input voltage. When

the input voltage exceeds 4.1 V, the converter starts

m

Some standard value of R1 and R2 for the most common operation. When input voltage falls below 3.7 V, the

om

output voltages are listed in Table 1. converter will be shut down.

Table 1. Thermal Protection

ec

An internal temperature sensor monitors the junction

VO (V) R1 (kΩ) R2 (kΩ) temperature. The sensor shuts down the internal control

circuit and high side PMOS if the junction temperature

R

0.8 1.0 Open

exceeds 150 ºC. The regulator will restart automatically

1.2 4.99 10

under the control of the soft-start circuit when the junction

ot

1.5 10 11.5 temperature decreases to 100 ºC.

N

1.8 12.7 10.2

2.5 21.5 10

3.3 31.1 10

5.0 52.3 10

The combination of R1 and R2 should be large enough to

avoid drawing excessive current from the output, which

will cause power loss.

Rev. 1.0 June 2011 www.aosmd.com Page 7 of 14

AOZ1051PI

Application Information For reliable operation and best performance, the input

capacitors must have a current rating higher than

The basic AOZ1051PI application circuit is show in

ICIN_RMS at the worst operating conditions. Ceramic

Figure 1. Component selection is explained below.

capacitors are preferred for input capacitors because of

Input Capacitor their low ESR and high current rating. Depending on the

application circuits, other low ESR tantalum capacitors

The input capacitor must be connected to the VIN pin and

may be used. When selecting ceramic capacitors, X5R or

the PGND pin of AOZ1051PI to maintain steady input

X7R type dielectric ceramic capacitors should be used

voltage and filter out the pulsing input current. The

for their better temperature and voltage characteristics.

voltage rating of input capacitor must be greater than

Note that the ripple current rating from capacitor

maximum input voltage plus ripple voltage.

manufactures are based on a certain operating life time.

ns

The input ripple voltage can be approximated by Further de-rating may need to be considered for long

equation below: term reliability.

ig

IO ⎛ VO ⎞ VO Inductor

ΔV IN = ----------------- × ⎜ 1 – --------

-⎟ × ---------

es

The inductor is used to supply constant current to output

f × C IN ⎝ V IN⎠ V IN when it is driven by a switching voltage. For a given input

and output voltage, inductance and switching frequency

D

Since the input current is discontinuous in a buck together decide the inductor ripple current, which is:

converter, the current stress on the input capacitor is

ew

another concern when selecting the capacitor. For a buck VO ⎛ VO ⎞

circuit, the RMS value of input capacitor current can be ΔI L = ----------- × ⎜ 1 – --------

-⎟

f×L ⎝ V ⎠

calculated by: IN

N

VO ⎛ VO ⎞ The peak inductor current is:

I CIN_RMS = I O × --------

- ⎜ 1 – --------

-⎟ r

V IN ⎝ V IN⎠

Fo

ΔI

I Lpeak = I O + -------L-

if we let m equal the conversion ratio:

2

d

VO

de

High inductance gives low inductor ripple current but

- = m

-------- requires larger size inductor to avoid saturation. Low

V IN

ripple current reduces inductor core losses. It also

en

reduces RMS current through inductor and switches,

The relationship between the input capacitor RMS which results in less conduction loss. Usually, peak to

m

current and voltage conversion ratio is calculated and peak ripple current on the inductor is designed to be

shown in Figure 2 below. It can be seen that when VO is 20 % to 40 % of output current.

om

half of VIN, CIN is under the worst current stress. The

worst current stress on CIN is 0.5 x IO. When selecting the inductor, confirm it is able to handle

the peak current without saturation at the highest

0.5

ec

operating temperature.

0.4

R

The inductor takes the highest current in a buck circuit.

The conduction loss on the inductor needs to be checked

ICIN_RMS(m) 0.3 for thermal and efficiency requirements.

ot

IO

Surface mount inductors in different shape and styles are

N

0.2

available from Coilcraft, Elytone and Murata. Shielded

0.1 inductors are small and radiate less EMI noise. However,

they cost more than unshielded inductors. The choice

0 depends on EMI requirement, price and size.

0 0.5 1

m

Figure 2. ICIN vs. Voltage Conversion Ratio

Rev. 1.0 June 2011 www.aosmd.com Page 8 of 14

AOZ1051PI

Output Capacitor Usually, the ripple current rating of the output capacitor is

The output capacitor is selected based on the DC output a smaller issue because of the low current stress. When

voltage rating, output ripple voltage specification and the buck inductor is selected to be very small and

ripple current rating. inductor ripple current is high, the output capacitor could

be overstressed.

The selected output capacitor must have a higher rated

voltage specification than the maximum desired output Loop Compensation

voltage including ripple. De-rating needs to be The AOZ1051PI employs peak current mode control for

considered for long term reliability. ease of use and fast transient response. Peak current

mode control eliminates the double pole effect of the

Output ripple voltage specification is another important output L&C filter. It also greatly simplifies the

factor for selecting the output capacitor. In a buck

ns

compensation loop design.

converter circuit, output ripple voltage is determined by

inductor value, switching frequency, output capacitor With peak current mode control, the buck power stage

ig

value and ESR. It can be calculated by the equation can be simplified to be a one-pole and one-zero system

es

below: in frequency domain. The pole is dominant pole can be

calculated by:

ΔV O = ΔI L × ⎛ ESR CO + -------------------------⎞

1

⎝ 8 × f × C O⎠

D

1

f P1 = -----------------------------------

2π × C O × R L

ew

where,

CO is output capacitor value, and The zero is a ESR zero due to the output capacitor and

its ESR. It is can be calculated by:

N

ESRCO is the equivalent series resistance of the output

capacitor.

1

f Z1 = ------------------------------------------------

r 2π × C O × ESR CO

Fo

When a low ESR ceramic capacitor is used as the output

capacitor, the impedance of the capacitor at the switching

where;

frequency dominates. Output ripple is mainly caused by

capacitor value and inductor ripple current. The output CO is the output filter capacitor,

d

ripple voltage calculation can be simplified to: RL is load resistor value, and

de

1 ESRCO is the equivalent series resistance of output capacitor.

ΔV O = ΔI L × -------------------------

8×f×C

en

O The compensation design shapes the converter control

loop transfer function for the desired gain and phase.

If the impedance of ESR at switching frequency

m

Several different types of compensation networks can be

dominates, the output ripple voltage is mainly decided by used with the AOZ1051PI. For most cases, a series

om

capacitor ESR and inductor ripple current. The output capacitor and resistor network connected to the

ripple voltage calculation can be further simplified to: COMP pin sets the pole-zero and is adequate for a stable

ΔV O = ΔI L × ESR CO high-bandwidth control loop.

ec

In the AOZ1051PI, FB and COMP are the inverting input

R

For lower output ripple voltage across the entire and the output of the internal error amplifier. A series

operating temperature range, X5R or X7R dielectric type R and C compensation network connected to COMP

ot

of ceramic, or other low ESR tantalum capacitors are provides one pole and one zero. The pole is:

recommended as output capacitors.

G EA

N

In a buck converter, output capacitor current is f P2 = ------------------------------------------

-

2π × C C × G VEA

continuous. The RMS current of output capacitor is

decided by the peak to peak inductor ripple current. It can

where;

be calculated by:

GEA is the error amplifier transconductance, which is 200 x 10-6

ΔI L A/V,

I CO_RMS = ----------

12 GVEA is the error amplifier voltage gain, which is 500 V/V, and

CC is the compensation capacitor in Figure 1.

Rev. 1.0 June 2011 www.aosmd.com Page 9 of 14

AOZ1051PI

The zero given by the external compensation network, Thermal Management and Layout

capacitor CC and resistor RC, is located at: Considerations

1 In the AOZ1051PI buck regulator circuit, high pulsing

f Z2 = ----------------------------------- current flows through two circuit loops. The first loop

2π × C C × R C

starts from the input capacitors, to the VIN pin, to the

LX pad, to the filter inductor, to the output capacitor and

To design the compensation circuit, a target crossover

load, and then returns to the input capacitor through

frequency fC to close the loop must be selected. The

ground. Current flows in the first loop when the high side

system crossover frequency is where the control loop

switch is on. The second loop starts from the inductor,

has unity gain. The crossover is the also called the

to the output capacitors and load, to the low side

converter bandwidth. Generally a higher bandwidth

NMOSFET. Current flows in the second loop when the

ns

means faster response to load transients. However, the

low side NMOSFET is on.

bandwidth should not be too high because of system

stability concern. When designing the compensation

ig

In PCB layout, minimizing the area of the two loops will

loop, converter stability under all line and load condition reduce the noise of the circuit and improves efficiency.

es

must be considered. A ground plane is strongly recommended to connect the

input capacitor, the output capacitor, and the PGND pin

Usually, it is recommended to set the bandwidth to be

D

of the AOZ1051PI.

equal or less than 1/10 of the switching frequency.

ew

In the AOZ1051PI buck regulator circuit, the major power

The strategy for choosing RC and CC is to set the cross

dissipating components are the AOZ1051PI and the

over frequency with RC and set the compensator zero

output inductor. The total power dissipation of converter

with CC. Using selected crossover frequency, fC, to

N

circuit can be measured by input power minus output

calculate RC:

power:

VO 2π × C C r

P total_loss = V IN × I IN – V O × I O

Fo

R C = f C × ---------- × -----------------------------

-

V G ×G

FB EA CS

The power dissipation of the inductor can be

d

where; approximately calculated by the output current and DCR

de

fC is the desired crossover frequency. For best performance, value of the inductor:

fC is set to be about 1/10 of the switching frequency;

P inductor_loss = IO2 × R inductor × 1.1

en

VFB is 0.8V,

GEA is the error amplifier transconductance, which is The actual junction temperature can be calculated by the

200 x 10-6 A/V, and

m

power dissipation in the AOZ1051PI and the thermal

GCS is the current sense circuit transconductance, which is impedance from junction to ambient:

om

8 A/V

T junction = ( P total_loss – P inductor_loss ) × Θ JA

The compensation capacitor CC and resistor RC together

ec

make a zero. This zero is put somewhere close to the The maximum junction temperature of the AOZ1051PI is

dominate pole fp1 but lower than 1/5 of the selected 150 ºC, which limits the maximum load current capability.

crossover frequency. CC can is selected by:

R

The thermal performance of the AOZ1051PI is strongly

1.5 affected by the PCB layout. Care should be taken during

ot

C C = -----------------------------------

2π × R C × f P1 the design process to ensure that the IC will operate

under the recommended environmental conditions.

N

The above equation can be simplified to:

CO × RL

C C = ---------------------

RC

An easy-to-use application software which helps to

design and simulate the compensation loop can be found

at www.aosmd.com.

Rev. 1.0 June 2011 www.aosmd.com Page 10 of 14

AOZ1051PI

Layout Considerations

The AOZ1051PI is an exposed pad SO-8 package.

Several layout tips are listed for the best electric and

thermal performance.

1. The exposed pad (LX) is connected to the internal

PFET and NFET drains. Connected a large copper

plane to the LX pin to help thermal dissipation.

2. Do not use a thermal relief connection to the VIN pin

or the PGND pin. Pour a maximized copper area to

the PGND pin and the VIN pin to help thermal

ns

dissipation.

3. The input capacitor should be connected as close as

ig

possible to the VIN pin and the PGND pin.

es

4. A ground plane is preferred. If a ground plane is not

used, separate PGND from AGND and only connect

D

them at one point to avoid the PGND pin noise

coupling to the AGND pin.

ew

5. Make the current trace from the LX pad to L to Co to

the PGND as short as possible.

N

6. Pour copper plane on all unused board area and

connect it to stable DC nodes, like VIN, GND or

VOUT. r

Fo

7. Keep sensitive signal trace away from the LX pad.

d

de

en

m

om

ec

R

ot

N

Rev. 1.0 June 2011 www.aosmd.com Page 11 of 14

AOZ1051PI

Package Dimensions, SO-8 EP1

Gauge plane

D0 0.2500

C

L1

E2 E3 E1 E

ns

ig

es

D

D1 L1'

Note 5

D

θ

ew

7 (4x)

N

A2 A

r

Fo

B e

A1

Dimensions in millimeters Dimensions in inches

d

Symbols Min. Nom. Max. Symbols Min. Nom. Max.

de

RECOMMENDED LAND PATTERN A 1.40 1.55 1.70 A 0.055 0.061 0.067

A1 0.00 0.05 0.10 A1 0.000 0.002 0.004

en

3.70

A2 1.40 1.50 1.60 A2 0.055 0.059 0.063

B 0.31 0.406 0.51 B 0.012 0.016 0.020

m

C 0.17 — 0.25 C 0.007 — 0.010

2.20 D 4.80 4.96 5.00 D 0.189 0.195 0.197

om

D0 3.20 3.40 3.60 D0 0.126 0.134 0.142

5.74 D1 3.10 3.30 3.50 D1 0.122 0.130 0.138

E 5.80 6.00 6.20 E 0.228 0.236 0.244

ec

2.71

e — 1.27 — e — 0.050 —

2.87 E1 3.80 3.90 4.00 E1 0.150 0.153 0.157

R

E2 2.21 2.41 2.61 E2 0.087 0.095 0.103

E3 0.40 REF E3 0.016 REF

ot

L 0.40 0.95 1.27 L 0.016 0.037 0.050

N

0.80 y — — 0.10 y — — 0.004

1.27 θ 0° 3° 8° θ 0° 3° 8°

0.635

UNIT: mm | L1–L1' | — 0.04 0.12 | L1–L1' | — 0.002 0.005

L1 1.04 REF L1 0.041 REF

Notes:

1. Package body sizes exclude mold flash and gate burrs.

2. Dimension L is measured in gauge plane.

3. Tolerance 0.10mm unless otherwise specified.

4. Controlling dimension is millimeter, converted inch dimensions are not necessarily exact.

5. Die pad exposure size is according to lead frame design.

6. Followed from JEDEC MS-012

Rev. 1.0 June 2011 www.aosmd.com Page 12 of 14

AOZ1051PI

Tape and Reel Dimensions, SO-8 EP1

Carrier Tape P1

D1

P2

T

E1

E2 E

ns

B0

ig

K0 D0

A0 P0 Feeding Direction

es

UNIT: mm

Package A0 B0 K0 D0 D1 E E1 E2 P0 P1 P2 T

D

SO-8 6.40 5.20 2.10 1.60 1.50 12.00 1.75 5.50 8.00 4.00 2.00 0.25

(12mm) ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10

ew

N

Reel

W1

r

Fo

S

G

d

de

N

M K

V

en

R

m

H

om

W

UNIT: mm

Tape Size Reel Size M N W W1 H K S G R V

ec

12mm ø330 ø330.00 ø97.00 13.00 17.40 ø13.00 10.60 2.00 — — —

±0.50 ±0.10 ±0.30 ±1.00 +0.50/-0.20 ±0.50

R

ot

Leader/Trailer and Orientation

N

Trailer Tape Components Tape Leader Tape

300mm min. or Orientation in Pocket 500mm min. or

75 empty pockets 125 empty pockets

Rev. 1.0 June 2011 www.aosmd.com Page 13 of 14

AOZ1051PI

Part Marking

Z1051PI

Part Number Code

FAYWLT

ns

ig

Fab & Assembly Location Assembly Lot Code

es

Year & Week Code

D

ew

r N

Fo

d

de

en

m

om

ec

This data sheet contains preliminary data; supplementary data may be published at a later date.

Alpha & Omega Semiconductor reserves the right to make changes at any time without notice.

R

LIFE SUPPORT POLICY

ot

ALPHA & OMEGA SEMICONDUCTOR PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL

COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS.

N

As used herein:

1. Life support devices or systems are devices or 2. A critical component in any component of a life

systems which, (a) are intended for surgical implant into support, device, or system whose failure to perform can

the body or (b) support or sustain life, and (c) whose be reasonably expected to cause the failure of the life

failure to perform when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can be effectiveness.

reasonably expected to result in a significant injury of

the user.

Rev. 1.0 June 2011 www.aosmd.com Page 14 of 14

S-ar putea să vă placă și

- For New Designs: AOZ1051PIDocument14 paginiFor New Designs: AOZ1051PISelmar CavalcantiÎncă nu există evaluări

- For New Designs: AOZ1033AIDocument15 paginiFor New Designs: AOZ1033AIPaulo Roberto s freireÎncă nu există evaluări

- AOZ1038DIDocument15 paginiAOZ1038DIjiledarÎncă nu există evaluări

- Z1031ADocument15 paginiZ1031ALORIUNEAÎncă nu există evaluări

- Ezbuck™ 3A Synchronous Buck Regulator: General Description FeaturesDocument15 paginiEzbuck™ 3A Synchronous Buck Regulator: General Description FeaturesJulio BarrosÎncă nu există evaluări

- RT8289 DatasheetDocument13 paginiRT8289 DatasheetAbdulraouf DefnanyÎncă nu există evaluări

- AOZ3018PIDocument14 paginiAOZ3018PIpravin jadavÎncă nu există evaluări

- RT8290: 3A, 23V, 340kHz Synchronous Step-Down ConverterDocument12 paginiRT8290: 3A, 23V, 340kHz Synchronous Step-Down ConverterMarcius RodriguesÎncă nu există evaluări

- 5A, 36V, 500Khz Step-Down Converter: General Description FeaturesDocument14 pagini5A, 36V, 500Khz Step-Down Converter: General Description FeaturesHitesh GambhavaÎncă nu există evaluări

- General Description Features: Ezbuck™ 1.5A Non-Synchronous Buck RegulatorDocument15 paginiGeneral Description Features: Ezbuck™ 1.5A Non-Synchronous Buck RegulatorLuis AntunesÎncă nu există evaluări

- Aoz1017ai DC DCDocument15 paginiAoz1017ai DC DCVukica IvicÎncă nu există evaluări

- AOZ3015PIDocument13 paginiAOZ3015PIBan NeoÎncă nu există evaluări

- AOZ3013PI: General Description FeaturesDocument14 paginiAOZ3013PI: General Description FeaturesJohn KleinÎncă nu există evaluări

- 2A, 23V, 1.2Mhz Synchronous Step-Down Converter: General Description FeaturesDocument14 pagini2A, 23V, 1.2Mhz Synchronous Step-Down Converter: General Description FeaturesHaroldo VieiraÎncă nu există evaluări

- 2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pagini2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGioVoTamÎncă nu există evaluări

- Ame5269 AmeDocument18 paginiAme5269 AmeCharles PÎncă nu există evaluări

- DC To DC Converter rt8272Document14 paginiDC To DC Converter rt8272hadÎncă nu există evaluări

- 3A, 1Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument12 pagini3A, 1Mhz, Synchronous Step-Down Converter: General Description FeatureskiryanoffÎncă nu există evaluări

- LWNMNP : General Description FeaturesDocument16 paginiLWNMNP : General Description FeaturesArturo ArmuellesÎncă nu există evaluări

- DatasheetDocument12 paginiDatasheetWAN MOZESÎncă nu există evaluări

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pagini3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesJuan Carlos SrafanÎncă nu există evaluări

- Aoz1212ai PDFDocument18 paginiAoz1212ai PDF060279Încă nu există evaluări

- AOZ6623DI Regulador de VoltajeDocument15 paginiAOZ6623DI Regulador de VoltajeDaiverJuarezÎncă nu există evaluări

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 paginiRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhÎncă nu există evaluări

- AOZ3015AIDocument14 paginiAOZ3015AIIcomÎncă nu există evaluări

- 3A, 18V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pagini3A, 18V, 340Khz Synchronous Step-Down Converter: General Description FeaturesAgung KaryaÎncă nu există evaluări

- RT8068AZQWDocument13 paginiRT8068AZQWTaller 62Încă nu există evaluări

- 5V/12V Synchronous Buck PWM DC-DC and Linear Power ControllerDocument18 pagini5V/12V Synchronous Buck PWM DC-DC and Linear Power Controllerraed hasaniaÎncă nu există evaluări

- LWNMNM : General Description FeaturesDocument16 paginiLWNMNM : General Description FeaturesSergio BarbozaÎncă nu există evaluări

- 3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument13 pagini3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesKavinda Jayasinghege DonÎncă nu există evaluări

- 5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionDocument17 pagini5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionLuis Dark-passengerÎncă nu există evaluări

- General Description Features: EzbuckDocument9 paginiGeneral Description Features: EzbuckCristina NistorÎncă nu există evaluări

- A5268 3A, 28V, 340Khz Synchronous Rectified Step-Down ConverterDocument16 paginiA5268 3A, 28V, 340Khz Synchronous Rectified Step-Down ConverterAnderson Galarza CalderonÎncă nu există evaluări

- Datasheet - Aoz1280 Simple Buck RegulatorDocument13 paginiDatasheet - Aoz1280 Simple Buck RegulatorCesar ServidoneÎncă nu există evaluări

- DatasheetDocument10 paginiDatasheetmartin andres rodriguez rengifoÎncă nu există evaluări

- 3A, 18V, 700Khz Acot Synchronous Step-Down Converter: Features General DescriptionDocument14 pagini3A, 18V, 700Khz Acot Synchronous Step-Down Converter: Features General DescriptionVasil StoyanovÎncă nu există evaluări

- Tiny Package, High Performance, Constant Current Switching Regulator For White LEDDocument15 paginiTiny Package, High Performance, Constant Current Switching Regulator For White LEDFahed AlmaktariÎncă nu există evaluări

- R1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineDocument33 paginiR1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineajisardadiÎncă nu există evaluări

- AOZ123 DatasheetDocument18 paginiAOZ123 Datasheetmartin sembinelliÎncă nu există evaluări

- 500mA Peak, Thermal Folded Back CMOS LDO RegulatorDocument12 pagini500mA Peak, Thermal Folded Back CMOS LDO RegulatorpeternewsÎncă nu există evaluări

- AOZ2023PIDocument11 paginiAOZ2023PIjuliocunachiÎncă nu există evaluări

- General Description Features: 28V/12A Synchronous Ezbuck RegulatorDocument16 paginiGeneral Description Features: 28V/12A Synchronous Ezbuck RegulatorholinsunÎncă nu există evaluări

- 4A, 21V, 500Khz Synchronous Step-Down Converter: General DescriptionDocument17 pagini4A, 21V, 500Khz Synchronous Step-Down Converter: General DescriptionJose MartinezÎncă nu există evaluări

- Out Products: Monolithic IC MM192x SeriesDocument16 paginiOut Products: Monolithic IC MM192x SeriesIbrain MoranÎncă nu există evaluări

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pagini3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesAbdul MuhidÎncă nu există evaluări

- MITSUBISHI MR-J2 AC Servo Specifications for MAZAK Turret ControlDocument28 paginiMITSUBISHI MR-J2 AC Servo Specifications for MAZAK Turret ControlBrendisÎncă nu există evaluări

- AOZ1282CIDocument13 paginiAOZ1282CIBelalang TempurÎncă nu există evaluări

- DatasheetDocument7 paginiDatasheetDarcio TolottiÎncă nu există evaluări

- Synchronous-Rectified Buck MOSFET Drivers: Features General DescriptionDocument5 paginiSynchronous-Rectified Buck MOSFET Drivers: Features General DescriptionTeles SilvaÎncă nu există evaluări

- LD7550B-PWM 6pinDocument14 paginiLD7550B-PWM 6pinSanjeev GuptaÎncă nu există evaluări

- RT9293Document13 paginiRT9293Bijan AmiriÎncă nu există evaluări

- CR6224Document10 paginiCR6224sergioviriliÎncă nu există evaluări

- 28V/10A Synchronous Buck Regulator with 0.8V OutputDocument15 pagini28V/10A Synchronous Buck Regulator with 0.8V OutputРоман ІкалюкÎncă nu există evaluări

- Data SheetDocument16 paginiData SheetHugo BurgosÎncă nu există evaluări

- RT9025 25GSP RichtekDocument12 paginiRT9025 25GSP RichtekBengkel Kompu7erÎncă nu există evaluări

- RT8015 2A 2MHz Synchronous Step-Down RegulatorDocument15 paginiRT8015 2A 2MHz Synchronous Step-Down RegulatorPedrolaura BethencourtÎncă nu există evaluări

- General Description Features: 28V/6A Synchronous Ezbuck RegulatorDocument15 paginiGeneral Description Features: 28V/6A Synchronous Ezbuck RegulatorholinsunÎncă nu există evaluări

- Adjustable 5A LDO Regulator for High Current ApplicationsDocument9 paginiAdjustable 5A LDO Regulator for High Current ApplicationsJMSÎncă nu există evaluări

- (Codientu - Org) - 29Q317B, CHASSIS CW4Document14 pagini(Codientu - Org) - 29Q317B, CHASSIS CW4GioVoTam100% (1)

- (Codientu - Org) - 29M41-CHASSIS TB97-VN (CRT CHUNGHWA)Document1 pagină(Codientu - Org) - 29M41-CHASSIS TB97-VN (CRT CHUNGHWA)GioVoTamÎncă nu există evaluări

- (Codientu - Org) - 21H181 (LG2)Document1 pagină(Codientu - Org) - 21H181 (LG2)GioVoTamÎncă nu există evaluări

- Samsung Le26s81bx, Le32s81bh, Le37s81bx, Le40s81bx, Le46s81bxDocument35 paginiSamsung Le26s81bx, Le32s81bh, Le37s81bx, Le40s81bx, Le46s81bxDavid TesztÎncă nu există evaluări

- (Codientu - Org) - (Codientu - Org) - JVC AV-21Q219BDocument2 pagini(Codientu - Org) - (Codientu - Org) - JVC AV-21Q219BGioVoTamÎncă nu există evaluări

- (Codientu - Org) 21HT99, TMPA8823Document1 pagină(Codientu - Org) 21HT99, TMPA8823GioVoTam100% (1)

- 7-2 Schematic Diagram: 7-2-1 Main BoardDocument4 pagini7-2 Schematic Diagram: 7-2-1 Main BoardMario Arteaga RojasÎncă nu există evaluări

- (Codientu - Org) - (Codientu - Org) - SHARP 21S-FX10V GA-7S (IXC324WJ)Document9 pagini(Codientu - Org) - (Codientu - Org) - SHARP 21S-FX10V GA-7S (IXC324WJ)GioVoTamÎncă nu există evaluări

- Schematic Diagrams Samsung Electronics TV RepairDocument6 paginiSchematic Diagrams Samsung Electronics TV RepairMendez StuartÎncă nu există evaluări

- (Codientu - Org) - (Codientu - Org) - TCL 21M63SX-M83 - TDA11135 - 24C08 - TDA4864 - CQ0765Document1 pagină(Codientu - Org) - (Codientu - Org) - TCL 21M63SX-M83 - TDA11135 - 24C08 - TDA4864 - CQ0765GioVoTamÎncă nu există evaluări

- Circuit diagram for an electronic deviceDocument1 paginăCircuit diagram for an electronic deviceGioVoTamÎncă nu există evaluări

- (Codientu - Org) (Codientu - Org) KV-SR29M53KDocument116 pagini(Codientu - Org) (Codientu - Org) KV-SR29M53KGioVoTamÎncă nu există evaluări

- RJP30E2DPP-M0: DatasheetDocument7 paginiRJP30E2DPP-M0: DatasheetPablo AllosiaÎncă nu există evaluări

- 1.2Mhz Low-Cost, High-Performance Chargers: General Description FeaturesDocument24 pagini1.2Mhz Low-Cost, High-Performance Chargers: General Description FeaturesGioVoTamÎncă nu există evaluări

- (Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kDocument10 pagini(Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kGioVoTamÎncă nu există evaluări

- DMG4435SSS: P-Channel Enhancement Mode MosfetDocument6 paginiDMG4435SSS: P-Channel Enhancement Mode MosfetGioVoTamÎncă nu există evaluări

- NE14C05 April 2007 circuit diagramDocument1 paginăNE14C05 April 2007 circuit diagramImran FarooqÎncă nu există evaluări

- 4.5V To 18V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™Document31 pagini4.5V To 18V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™GioVoTamÎncă nu există evaluări

- FSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersDocument18 paginiFSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersGioVoTamÎncă nu există evaluări

- 4V Drive NCH+NCH MOS FET: TransistorsDocument6 pagini4V Drive NCH+NCH MOS FET: TransistorsGioVoTamÎncă nu există evaluări

- LGE6841Document1 paginăLGE6841Windy AmestyÎncă nu există evaluări

- Viper22A-E Viper22Adip-E, Viper22As-E: Low Power Off-Line Smps Primary SwitcherDocument21 paginiViper22A-E Viper22Adip-E, Viper22As-E: Low Power Off-Line Smps Primary SwitcherAkash KumarÎncă nu există evaluări

- P1260ATF: N-Channel Enhancement Mode MOSFETDocument5 paginiP1260ATF: N-Channel Enhancement Mode MOSFETGioVoTamÎncă nu există evaluări

- Eds-5562 - 5562a LCD T-Con IcDocument4 paginiEds-5562 - 5562a LCD T-Con Ic918329078279% (19)

- Datasheet RJP30H1 PDFDocument7 paginiDatasheet RJP30H1 PDFMartín SayagoÎncă nu există evaluări

- Bd8174muv eDocument41 paginiBd8174muv eprimero marnez0% (1)

- FQPF10N60CDocument10 paginiFQPF10N60Cmiloud1911Încă nu există evaluări

- Bd9423efv e 1223519 PDFDocument61 paginiBd9423efv e 1223519 PDFVươngÎncă nu există evaluări

- bd48xxx bd49xxx Series r008 Rohm PDFDocument19 paginibd48xxx bd49xxx Series r008 Rohm PDFJose Enrique Aguirre GuerreroÎncă nu există evaluări

- BD 9883Document6 paginiBD 9883luisfeipezzÎncă nu există evaluări

- GENERAL PHYSICS 2 - Q3 - Week 8Document19 paginiGENERAL PHYSICS 2 - Q3 - Week 8ariinnggg onichaÎncă nu există evaluări

- Etabs 9.7.2 Shear Wall Design SWD-ACI-318-08Document89 paginiEtabs 9.7.2 Shear Wall Design SWD-ACI-318-08chauhannishargÎncă nu există evaluări

- Evolution and Analysis of Suspension BridgesDocument69 paginiEvolution and Analysis of Suspension BridgesshubhadipÎncă nu există evaluări

- Midas Tutorial Fea 7Document3 paginiMidas Tutorial Fea 7sasiÎncă nu există evaluări

- Lesson 5 Threshold 3 - New Chemical ElementsDocument4 paginiLesson 5 Threshold 3 - New Chemical ElementsHoney MuliÎncă nu există evaluări

- Addis Ababa projectionsDocument2 paginiAddis Ababa projectionsYohannes Tibebu0% (1)

- Determine Solar Cell Fill Factor from V-I CharacteristicsDocument5 paginiDetermine Solar Cell Fill Factor from V-I CharacteristicsNikhil MaheswariÎncă nu există evaluări

- Christie Cp4330 RGB DatasheetDocument2 paginiChristie Cp4330 RGB DatasheetWahyu HalimÎncă nu există evaluări

- ASME PTC 7.1 Displacement PumpsDocument22 paginiASME PTC 7.1 Displacement PumpsLorenzo Antonio CordovaÎncă nu există evaluări

- A Report On Compliant MechanismsDocument22 paginiA Report On Compliant MechanismsRajesh Shyamrao KajeÎncă nu există evaluări

- Applied Partial Differential Equations With Fourier Series and Boundary Value Problems 5th Edition Richard Haberman Solutions ManualDocument14 paginiApplied Partial Differential Equations With Fourier Series and Boundary Value Problems 5th Edition Richard Haberman Solutions Manualgeldable.abjugate84rbl100% (13)

- Learning to Control an Inverted Pendulum Using Neural NetworksDocument7 paginiLearning to Control an Inverted Pendulum Using Neural NetworksAditya AgarwalÎncă nu există evaluări

- Degenerate Circles: ProblemsDocument4 paginiDegenerate Circles: ProblemsNguyễnMinhNhiênÎncă nu există evaluări

- Study On AC Resistance of Layering Enamelled Stranded ConductorDocument5 paginiStudy On AC Resistance of Layering Enamelled Stranded ConductorKush SharmaÎncă nu există evaluări

- Differential and Integral CalculusDocument10 paginiDifferential and Integral CalculusRizchelle ReyesÎncă nu există evaluări

- Analysis and Optimisation of All Terrain WheelchairDocument10 paginiAnalysis and Optimisation of All Terrain WheelchairAshish NandaÎncă nu există evaluări

- Mechanism and Machine Theory: Chiu-Fan HsiehDocument12 paginiMechanism and Machine Theory: Chiu-Fan HsiehabhairulzÎncă nu există evaluări

- Lecture 27 Thermal Engineering II (08.09.2020)Document81 paginiLecture 27 Thermal Engineering II (08.09.2020)Dr. BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Xiria: UK Version (In Accordance With ENA Specification 41-36Document51 paginiXiria: UK Version (In Accordance With ENA Specification 41-36Alejo MiraÎncă nu există evaluări

- SFRADocument14 paginiSFRARahul DasÎncă nu există evaluări

- Useful Tips For Designing Thermal Insulation SystemsDocument25 paginiUseful Tips For Designing Thermal Insulation SystemsEddie FongÎncă nu există evaluări

- Basic-Electronics (Rectifier) !Document30 paginiBasic-Electronics (Rectifier) !Rahim AnsariÎncă nu există evaluări

- A Comparative Study of Simulated Body Fluids in The Presence of ProteinsDocument9 paginiA Comparative Study of Simulated Body Fluids in The Presence of ProteinsWeitian ZhaoÎncă nu există evaluări

- Demagnetization Fault Diagnosis of PMSM Based On Analytic Inductance CalculationDocument5 paginiDemagnetization Fault Diagnosis of PMSM Based On Analytic Inductance CalculationFaiza OuiddirÎncă nu există evaluări

- Molecular Modelling and Drug DesigningDocument16 paginiMolecular Modelling and Drug DesigningAsh-shirHasanÎncă nu există evaluări

- Shandong Luwei Pharmaceutical Co.,Ltd.: Shuangfeng Industrial Park, Zichuan District, Zibo City, Shandong, ChinaDocument1 paginăShandong Luwei Pharmaceutical Co.,Ltd.: Shuangfeng Industrial Park, Zichuan District, Zibo City, Shandong, ChinaSouheila MniÎncă nu există evaluări

- Series and Parallel Circuits Questions - KS3 EditDocument4 paginiSeries and Parallel Circuits Questions - KS3 EditDominic Wynes-DevlinÎncă nu există evaluări

- Question Phy 101Document19 paginiQuestion Phy 101Mohammed kashimÎncă nu există evaluări

- Performance Evaluation of A Chiller Plant in A Bottling CompanyDocument12 paginiPerformance Evaluation of A Chiller Plant in A Bottling CompanyIJRASETPublicationsÎncă nu există evaluări

- ISA Transactions: Jinzhu Peng, Rickey DubayDocument11 paginiISA Transactions: Jinzhu Peng, Rickey DubayVictor PassosÎncă nu există evaluări