Documente Academic

Documente Profesional

Documente Cultură

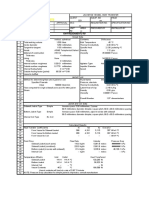

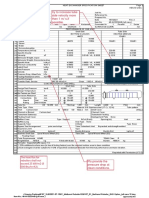

EXCHANGER SPECIFICATION SHEET Hoja Especificaciones

Încărcat de

Daniel Salas0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări2 paginiThis document is a specification sheet for an exchanger that will transfer heat between water from the Nonguén estuary and service water at a university in Chile. The exchanger will have 231 tubes made of carbon steel with an outer diameter of 19.05mm. Water from the estuary at 10°C will exit at 22°C after transferring heat to the service water, which will enter at 55°C and exit at 20.15°C. Additional details are provided on flow rates, materials, pressures, and dimensions of components.

Descriere originală:

Titlu original

EXCHANGER SPECIFICATION SHEET hoja especificaciones

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document is a specification sheet for an exchanger that will transfer heat between water from the Nonguén estuary and service water at a university in Chile. The exchanger will have 231 tubes made of carbon steel with an outer diameter of 19.05mm. Water from the estuary at 10°C will exit at 22°C after transferring heat to the service water, which will enter at 55°C and exit at 20.15°C. Additional details are provided on flow rates, materials, pressures, and dimensions of components.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări2 paginiEXCHANGER SPECIFICATION SHEET Hoja Especificaciones

Încărcat de

Daniel SalasThis document is a specification sheet for an exchanger that will transfer heat between water from the Nonguén estuary and service water at a university in Chile. The exchanger will have 231 tubes made of carbon steel with an outer diameter of 19.05mm. Water from the estuary at 10°C will exit at 22°C after transferring heat to the service water, which will enter at 55°C and exit at 20.15°C. Additional details are provided on flow rates, materials, pressures, and dimensions of components.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

EXCHANGER SPECIFICATION SHEET

CLIENT DRA. Paola Bustos CLIENTS’S REF NO. JOB NO.

PLANT LOCATION Universidad del BioBio DOCUMENT NO.

SERVICE diseño de intercambiadores de calor ITEM NO.

SIZE TYPE NO. OF UNITS

SHELLS PER UNIT CONNECTED IN SERIES PARALLEL

SURFACE PER UNIT SURFACE PER SHELL

PERFORMANCE OF ONE UNIT

SHELL SIDE TUBE SIDE

FLUID CIRCULATED Agua de estero Nonguén Agua de servicio

TOTAL FLUID ENTERING Kg/hr 104400 36000

VAPOR Kg/hr 0 0

LIQUID Kg/hr 104400 36000

STEAM Kg/hr 0 0

NON-CONDENSABLES Kg/hr 0 0

FLUID VAPORIZED OR COND. Kg/hr 0 0

STEAM CONDENSED Kg/hr 0 0

GRAVITY Kg/m3 998,88 992,96

VISCOSITY Cp 1,307 0,9576 0,504 0,998

MOLECULAR WEIGHT VAPORS - - - -

THERMAL CONDUCTIVITY W/mK 0,5908 0,62716

SPECIFIC HEAT kJ/kg°C 4,194 4,1812 4,183 4,18194

TEMPERATURE IN °C 10 55

TEMPERATURE OUT °C 22 20,15

OPERATING PRESSURE Kg/cm2(g)

NUMBER PASSES PER SHELL

VELOCITY m/sec 1,75 1,006

PRESSURE DROP Kg/cm2 ALLOW CALC ALLOW CALC

FOULING RESISTANCE m2°C/W 0,0002 0,00025

HEAT EXCHANGED kW MTD(CORRECTED) °C

TRANSFER RATE – SERVICE kW/m2°C

CONSTRUCTION-EACH SHELL

DESIGN PRESSURE Kg/cm2(g)

TEST PRESSURE Kg/cm2(g)

DESIGN TEMPERATURE °C TUBESHEET

TUBES NO. 231 O.D. 19,05mm BWG 8 LENGTH 488000mm PITCH 23,8mm

SHELL ID

SHELL COVER FLOATING HEAD COVER

CHANNEL CHANNEL COVER

TUBESHEET-STATIONARY Acero al carbono FLOATING

BAFFLES/TUBE SUPPORTS PITCH %CUT Flow UO

LONG. BAFFLE 124mm TYPE OF SEAL DEFLECTOR STRIPS REQUIRED

IMPING.BAFFLE FLOATING HD. SUPPORT

TYPE OF JOINT TUBE TUBE ATTACHMENT

GASKETS-SHELL TO COVER SHELL TO T.S. T.S. TO CHANNEL

FLOATING HEAD CHANNEL TO COVER

CONNECTIONS-SHELL IN INTERCONN. SHELL OUT

CHANNEL IN INTERCONN. CHANNEL OUT

CORROSION ALLOWANCE SHELL SIDE TUBE SIDE

CODE REQUIREMENTS

REMARKS

S-ar putea să vă placă și

- Weaver Heat Transfer Technologies DATA SHEET 1Document1 paginăWeaver Heat Transfer Technologies DATA SHEET 1Bhavin PatelÎncă nu există evaluări

- Heat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriDocument1 paginăHeat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriEduardoÎncă nu există evaluări

- Htri PDFDocument1 paginăHtri PDFLuigy L-aÎncă nu există evaluări

- Process Data: Shell Side Tube SideDocument1 paginăProcess Data: Shell Side Tube SideATUL SONAWANEÎncă nu există evaluări

- Benzene - Preheater Data SheetDocument1 paginăBenzene - Preheater Data Sheetsushant_jhawerÎncă nu există evaluări

- Example 1Document1 paginăExample 1M. Nasikhun WahidinÎncă nu există evaluări

- Shell Side Tube Side Process DataDocument1 paginăShell Side Tube Side Process DataATUL SONAWANEÎncă nu există evaluări

- Heat Exchanger Specification Sheet SI UnitsDocument1 paginăHeat Exchanger Specification Sheet SI UnitsdhaÎncă nu există evaluări

- Thermal Design of Tank Suction HeaterDocument13 paginiThermal Design of Tank Suction HeaterarcelitasÎncă nu există evaluări

- F:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriDocument1 paginăF:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriainunÎncă nu există evaluări

- 101-E-01 (Glycerol Unit) Rating Data SheetDocument1 pagină101-E-01 (Glycerol Unit) Rating Data SheetMekar MeinaÎncă nu există evaluări

- fouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594Document27 paginifouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594김종민Încă nu există evaluări

- TD HE S&T v2020.00Document29 paginiTD HE S&T v2020.00Claudia BonocoreÎncă nu există evaluări

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 paginiTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelÎncă nu există evaluări

- Steam HXDocument1 paginăSteam HXrajachemÎncă nu există evaluări

- Inter Cambiado RDocument2 paginiInter Cambiado RmilenarixÎncă nu există evaluări

- PDS Ga-401Document1 paginăPDS Ga-401wahyuÎncă nu există evaluări

- Cea - 102Document2 paginiCea - 102rezaÎncă nu există evaluări

- Heat Exchanger Specification Sheet SI UnitsDocument1 paginăHeat Exchanger Specification Sheet SI UnitsIdil Fitri100% (1)

- Dowtherm Vent CondenserDocument1 paginăDowtherm Vent Condensersushant_jhawerÎncă nu există evaluări

- CONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Document2 paginiCONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Goran PanticÎncă nu există evaluări

- Ceiling Cassette Chilled Water Fan Coil Unit - Koppel PDFDocument2 paginiCeiling Cassette Chilled Water Fan Coil Unit - Koppel PDFatramanathanÎncă nu există evaluări

- HE Rating Data Sheet v6Document1 paginăHE Rating Data Sheet v6dhaÎncă nu există evaluări

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 paginiData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaÎncă nu există evaluări

- Kern Method Design of HXDocument1 paginăKern Method Design of HXNitin KurupÎncă nu există evaluări

- 106-E-01 (Netralizing Unit) - TEMA SheeDocument1 pagină106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaÎncă nu există evaluări

- Gas Chiller DatasheetDocument2 paginiGas Chiller DatasheetidilfitriÎncă nu există evaluări

- Gas Chiller Datasheet PDFDocument2 paginiGas Chiller Datasheet PDFidilfitriÎncă nu există evaluări

- 0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXDocument1 pagină0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXPhượng NguyễnÎncă nu există evaluări

- RCD1250N200 R407CDocument1 paginăRCD1250N200 R407CtalalÎncă nu există evaluări

- 30 TR IG Tube PDFDocument1 pagină30 TR IG Tube PDFshree awateÎncă nu există evaluări

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 paginiJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Heat Exchanger RatingDocument10 paginiHeat Exchanger RatingAnand BhiseÎncă nu există evaluări

- CCTV - CVHG780-CN123 - Product ReportDocument2 paginiCCTV - CVHG780-CN123 - Product ReportTân NguyễnÎncă nu există evaluări

- Aspen Exchanger Design and Rating Plate V9Document4 paginiAspen Exchanger Design and Rating Plate V9samara navasÎncă nu există evaluări

- Heat Exchanger Specification SheetDocument4 paginiHeat Exchanger Specification SheetAnita PanthiÎncă nu există evaluări

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 paginiAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyÎncă nu există evaluări

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 paginiSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRIÎncă nu există evaluări

- Heat Exchanger RatingDocument5 paginiHeat Exchanger RatingPebriyantoÎncă nu există evaluări

- CH-RA3 Page 2Document1 paginăCH-RA3 Page 2Sonya LoveraÎncă nu există evaluări

- Heat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriDocument1 paginăHeat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriNatarajan RavisankarÎncă nu există evaluări

- F:/anni/contoh Htri/latihan 1.htriDocument1 paginăF:/anni/contoh Htri/latihan 1.htriAnni RahmatÎncă nu există evaluări

- TEMA Spec SheetDocument1 paginăTEMA Spec SheetvikzefgÎncă nu există evaluări

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 paginăHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgÎncă nu există evaluări

- Quo12039 Wbh-BoguraDocument1 paginăQuo12039 Wbh-BoguraMD. MAHMUDUL HASAN 39-044Încă nu există evaluări

- Quotation Proposal For Cotton Club LTD 20-12-18Document5 paginiQuotation Proposal For Cotton Club LTD 20-12-18fakir mohammadÎncă nu există evaluări

- Quo12039 Wbh-IshwardiDocument1 paginăQuo12039 Wbh-IshwardiMD. MAHMUDUL HASAN 39-044Încă nu există evaluări

- Shell&TubeResults 215E009Document5 paginiShell&TubeResults 215E009ganis supriadiÎncă nu există evaluări

- Precision Datasheet - 250 KWDocument1 paginăPrecision Datasheet - 250 KWAnarghya NageshÎncă nu există evaluări

- Shell & Tube Heat Exchanger Rating (Bell Delaware Method) : Chemical Engineer's GuideDocument10 paginiShell & Tube Heat Exchanger Rating (Bell Delaware Method) : Chemical Engineer's GuideAnand BhiseÎncă nu există evaluări

- Thermic Fluid Heater Data Sheet - Rev 0Document10 paginiThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiÎncă nu există evaluări

- SelectRT Coils 2023-03-30Document2 paginiSelectRT Coils 2023-03-30Aheron HizmoÎncă nu există evaluări

- Ceiling & Floor Type Air Conditioner: Service ManualDocument43 paginiCeiling & Floor Type Air Conditioner: Service ManualCesar Calderon GrÎncă nu există evaluări

- Heat Exchanger Calculation SheetDocument6 paginiHeat Exchanger Calculation SheetPrakashÎncă nu există evaluări

- MarineDocument2 paginiMarineMichael NettoÎncă nu există evaluări

- CH-RA3 Page 1Document1 paginăCH-RA3 Page 1Sonya LoveraÎncă nu există evaluări

- Gas-Gas Exchanger DatasheetDocument3 paginiGas-Gas Exchanger DatasheetidilfitriÎncă nu există evaluări

- Well Control Data Sheet: Well: All Values in Have To Be EnteredDocument11 paginiWell Control Data Sheet: Well: All Values in Have To Be Enteredmiguel rojasÎncă nu există evaluări

- Half Pipe Coil AgitatedDocument1 paginăHalf Pipe Coil AgitatedNITINÎncă nu există evaluări

- Handbook of Heating, Ventilating and Air ConditioningDe la EverandHandbook of Heating, Ventilating and Air ConditioningEvaluare: 4 din 5 stele4/5 (6)

- WABCODocument2 paginiWABCOMihai PopaÎncă nu există evaluări

- Fluid Mechanics Jkchrome ComDocument107 paginiFluid Mechanics Jkchrome Comuvraj1234567891Încă nu există evaluări

- HPD Diagram Milroyal B C and D PDFDocument92 paginiHPD Diagram Milroyal B C and D PDForlando perezÎncă nu există evaluări

- Tables of R22 Ammonia R134aDocument17 paginiTables of R22 Ammonia R134aStar GlacierÎncă nu există evaluări

- Apakah Bedanya Double Block and Bleed Dan Double Isolation and BleedDocument1 paginăApakah Bedanya Double Block and Bleed Dan Double Isolation and Bleedwendypost73Încă nu există evaluări

- When The Joukowsky Equation Does Not Predict Maximum Water Hammer PressuresDocument11 paginiWhen The Joukowsky Equation Does Not Predict Maximum Water Hammer PressuresFrancisco OppsÎncă nu există evaluări

- Commissioning GuideDocument2 paginiCommissioning GuideOreolÎncă nu există evaluări

- 7G Particles: Solids, Liquids and GasesDocument3 pagini7G Particles: Solids, Liquids and GasesBen PassmoreÎncă nu există evaluări

- Saturation Evaluation With Rstpro Tool Finds Bypassed Oil and Gas ZonesDocument2 paginiSaturation Evaluation With Rstpro Tool Finds Bypassed Oil and Gas Zoneshamed1725Încă nu există evaluări

- Bombas y Modos de FallaDocument20 paginiBombas y Modos de FallaedwinsazzzÎncă nu există evaluări

- Process Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFDocument69 paginiProcess Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFNgàyMưaÎncă nu există evaluări

- Pressure Reducing and Desuperheating Valves - BrochureDocument8 paginiPressure Reducing and Desuperheating Valves - BrochureSaurav KumarÎncă nu există evaluări

- Air-Cooler Chiller (Heat Pump) (001-073)Document73 paginiAir-Cooler Chiller (Heat Pump) (001-073)cacaÎncă nu există evaluări

- CBSE Class 11 Physics Chapter 13 - Kinetic Theory Important Questions 2023-24Document46 paginiCBSE Class 11 Physics Chapter 13 - Kinetic Theory Important Questions 2023-24Buddhadev BeraÎncă nu există evaluări

- Assignment 3 PDFDocument3 paginiAssignment 3 PDFk l mandalÎncă nu există evaluări

- Confined Space VentilationDocument31 paginiConfined Space VentilationSusan WillisÎncă nu există evaluări

- Catalog 12 Section 1 Flow CoefficientsDocument220 paginiCatalog 12 Section 1 Flow CoefficientsJesus BolivarÎncă nu există evaluări

- AlkaneDocument2 paginiAlkaneJaymee DelfinadoÎncă nu există evaluări

- Indoor Water Cooled Condensing Units 1/2 Through 40 HP: RW SeriesDocument8 paginiIndoor Water Cooled Condensing Units 1/2 Through 40 HP: RW SeriesDaniel CastroÎncă nu există evaluări

- Sprinkler CalculationDocument13 paginiSprinkler CalculationHuynh Ngoc Nghia100% (4)

- Spring Return Dosing Pump A - Piston Type: The Right Dosing ChoiceDocument12 paginiSpring Return Dosing Pump A - Piston Type: The Right Dosing Choicescaletta lvÎncă nu există evaluări

- 7压缩机喘振Document57 pagini7压缩机喘振Leilei WangÎncă nu există evaluări

- Du PontDocument5 paginiDu PontAdhil RissallahÎncă nu există evaluări

- FluidsDocument10 paginiFluidslara alghamdiÎncă nu există evaluări

- General Catalog For Compressed Air, Gas and Vacuum SolutionsDocument220 paginiGeneral Catalog For Compressed Air, Gas and Vacuum Solutionsgomera100% (1)

- CHPTERTHREEFluidStaticandItsApplicationsDr Salahn FarhanDocument21 paginiCHPTERTHREEFluidStaticandItsApplicationsDr Salahn FarhanAnonymous ldkl4EXqefÎncă nu există evaluări

- Aci 376 - 52673Document11 paginiAci 376 - 52673visvisvisvisÎncă nu există evaluări

- Chapter 2 HydrostaticsDocument54 paginiChapter 2 HydrostaticsPiyush ShahaneÎncă nu există evaluări

- Submersible Pump Pre Commissioning ITPDocument12 paginiSubmersible Pump Pre Commissioning ITPTrungVuDinh100% (1)

- Multiphase Well Testing SolutionsDocument22 paginiMultiphase Well Testing SolutionsSlim.BÎncă nu există evaluări