Documente Academic

Documente Profesional

Documente Cultură

Technical Data Sheet C2..QPT-..: Type Overview

Încărcat de

JTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Data Sheet C2..QPT-..: Type Overview

Încărcat de

JDrepturi de autor:

Formate disponibile

Technical data sheet C2..QPT-..

PI Zone Valve, 2-way, Internal thread

• For closed cold and warm water

systems

• For modulating control of air-

handling and heating systems on the

water side

• Snap-assembly of the actuator

• Version with measuring ports (P/T

ports)

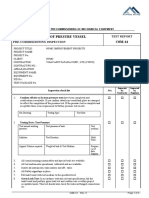

Type overview

Type DN Rp Vnom PN Sv min.

[ ] [“] [ l/h] [ ] [ ]

C215QPT-B 15 1/2 210 25 100

C215QPT-D 15 1/2 420 25 100

C220QPT-F 20 3/4 980 25 100

C225QPT-G 25 1 2100 25 100

Technical data

Functional data Media Cold and warm water, water with glycol up to

max. 50% vol.

Medium temperature 2...90°C

Pressure value 16...350 kPa

Permissible pressure ps 1600 kPa

Closing pressure ∆ps 700 kPa

Flow characteristic equal percentage (VDI/VDE 2178), optimised in

the opening range

Pressure stability With a pressure value of 16...350 kPa: ±10%

Leakage rate Leakage rate A, tight (EN 12266-1)

Flow setting see Installation instructions

Pipe connector Internal thread according to ISO 7-1

Angle of rotation 90°

Angle of rotation note Operating range 15...90°

Installation position Upright to horizontal (in relation to the stem)

Maintenance Maintenance-free

Materials Housing Brass body

Closing element Stainless steel

Stem Stainless steel

Stem seal O-ring EPDM

Ball seat PTFE, O-ring EPDM

Diaphragm EPDM

Terms Abbreviations Vnom = nominal flow with valve completely

opened

Vmax = maximum flow set by the angle of

rotation limitation on the actuator

Safety notes

• The valve has been designed for use in stationary heating, ventilation and air-

! conditioning systems and must not be used outside the specified field of application,

especially in aircraft or in any other airborne means of transport.

• Only authorised specialists may carry out installation. All applicable legal or

institutional installation regulations must be complied during installation.

• The valve does not contain any parts that can be replaced or repaired by the user.

• The valve may not be disposed of as household refuse. All locally valid regulations

and requirements must be observed.

• When determining the flow rate characteristic of controlled devices, the recognised

directives must be observed.

www.belimo.com C2..QPT-.. • en-gb • 2017-09-22 • subject to changes 1

PI Zone Valve, 2-way, Internal thread

C2..QPT-..

Product features

Mode of operation The ball valve is adjusted by a rotary actuator. The actuator is controlled by a

commercially available modulating or 3-point control system and moves the ball of the

valve – the throttling device – to the position dictated by the positioning signal. Open

the characterised control valve counterclockwise and close it clockwise.

Flow characteristic Equal percentage flow control is ensured by the special design of the ball.

Constant flow volume With a differential pressure of 16…350 kPa, a constant flow volume is achieved thanks

to the integrated pressure regulationg valve. Independent of the differential pressure

through the valve, a valve authority of 1 is achieved. Even with pressure variatons and

in the partial load range, the flow rate remains constant with each respective opening

position (angle of rotation) and ensures a steady control.

P- P+

M

P3 P1

Pressure at valve inlet P1

Pressure at valve outlet P3

Measuring point at measuring port (Inlet - red

marking) P+

Measuring point at measuring port (Outlet - blue

marking) P-

Flow limitation Instead of the electric actuator, the PIQCV-valve can also be operated with a flow

limiter (see accessories).

The flow limiter ensures that the heat exchanger is continuously supplied with a

manually fixed amount of water.

Measurement ports (P/T ports) The C2..QPT-.. type valves have two measurement ports. The total drop in pressure

across the valve can be determined using the measurement points at the valve inlet

(P1) and outlet (P3).

The measurement ports can be used to easily establish whether the effective

differential pressure across the valve is within the effective pressure range of 16…350

kPa. If it is, the valve operates independently of pressure and the correct flow rate is

automatically ensured by the valve according to the setting table.

The differential pressure measurement can also be used to optimise the pump

setting. This involves reducing the delivery height of the pump until only the minimum

differential pressure required (16 kPa) is still present across the valve at the point of

lowest pressure (the furthest away from the pump in hydraulic terms).

Accessories

Description Type

Mechanical accessories Pipe connector to ball valve DN 15 Rp 1/2” ZR2315

Pipe connector to ball valve DN 20 Rp 3/4” ZR2320

Pipe connector to ball valve DN 25 Rp 1” ZR2325

Spindle extension CQ, for cooling applications only ZCQ-E

Flow limiter PIQCV ZCQ-FL

2 C2..QPT-.. • en-gb • 2017-09-22 • subject to changes www.belimo.com

PI Zone Valve, 2-way, Internal thread

C2..QPT-..

Installation notes

Recommended installation positions The ball valve can be installed upright to horizontal. The ball valve may not be installed

in a hanging position, i.e. with the stem pointing downwards.

90° 90°

Mounting position in the return Installation in the return is recommended.

Water quality requirements The water quality requirements specified in VDI 2035 must be adhered to.

Belimo valves are regulating devices. For the valves to function correctly in the long

term, they must be kept free from particle debris (e.g. welding beads during installation

work). The installation of suitable strainer is recommended.

Maintenance Ball valves and rotary actuators are maintenance-free.

Before any service work on the final controlling device is carried out, it is essential to

isolate the rotary actuator from the power supply (by unplugging the electrical cable

if necessary). Any pumps in the part of the piping system concerned must also be

switched off and the appropriate slide valves closed (allow all components to cool

down first if necessary and allways reduce the system pressure to ambient pressure

level).

The system must not be returned to service until the ball valve and the rotary actuator

have been correctly reassembled in accordance with the instructions and the pipeline

has been refilled by professionally trained personnel.

Flow direction The direction of flow, specified by an arrow on the housing, is to be complied with,

since otherwise the ball valve could become damaged. Please ensure that the ball is in

the correct position (marking on the spindle).

100% 0%

www.belimo.com C2..QPT-.. • en-gb • 2017-09-22 • subject to changes 3

PI Zone Valve, 2-way, Internal thread

C2..QPT-..

Installation notes

Dimensions / Weight

Flow setting The angle of rotation of the actuator can be changed by clip in 2.5° increments. This is

used to set the max-value (maximum flow rate of the valve).

Remove end stop clip and place at desired position.

After every change of the flow setting by means of end stop clip, an adaptation must

be triggered on the modulating actuators.

3

4

2

5

1

6

N

1 2 3 3+ 4- 4 4+ 5- 5 5+ 6- 6 6+ N- N

Pos

max (l/h) 20 30 40 45 50 60 70 80 90 105 120 135 150 165 180 210

C215QP(T)-B

max (l/s) 0.006 0.008 0.011 0.013 0.014 0.017 0.019 0.022 0.025 0.029 0.033 0.038 0.042 0.046 0.050 0.058

max (l/h) 50 70 100 110 130 150 170 190 210 240 270 300 330 360 400 420

C215QP(T)-D

max (l/s) 0.014 0.019 0.028 0.031 0.036 0.042 0.047 0.053 0.058 0.067 0.075 0.083 0.092 0.100 0.111 0.117

max (l/h) 90 130 190 220 250 290 340 390 440 500 570 630 700 760 820 980

C220QP(T)-F

max (l/s) 0.025 0.036 0.053 0.061 0.069 0.081 0.094 0.108 0.122 0.139 0.158 0.175 0.194 0.211 0.228 0.272

max (l/h) 260 410 600 670 750 840 920 1010 1110 1210 1310 1420 1530 1640 1750 2100

C225QPT-G

max (l/s) 0.072 0.114 0.167 0.186 0.208 0.233 0.256 0.281 0.308 0.336 0.364 0.394 0.425 0.456 0.486 0.583

4 C2..QPT-.. • en-gb • 2017-09-22 • subject to changes www.belimo.com

PI Zone Valve, 2-way, Internal thread

C2..QPT-..

Dimensions / Weight

Dimensional drawings

min. Y B2

min. X1 (X2)

max. H1 (H2)

H3

H

L2 L1 Rp

L B1

H1/X1: without spindle extension CQ

H2/X2: with spindle extension CQ (ZCQ-E)

L2: Maximum screwing depth.

Type DN Rp L L1 L2 B1 B2 H H1 H2 H3 Y

[ ] [“] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm]

C215QPT-B 15 1/2 96 34 13 52 61 26 80 112 44 40

C215QPT-D 15 1/2 96 34 13 52 61 26 80 112 44 40

C220QPT-F 20 3/4 106 39 14 63 72 31 85 117 49 45

C225QPT-G 25 1 118 42 16.8 77 80 40 87 119 55 52

Type Y X1 X2 Weight

[ mm] [ mm] [ mm] [ kg]

C215QPT-B 40 125 155 0.8

C215QPT-D 40 125 155 0.8

C220QPT-F 45 130 165 1.2

C225QPT-G 52 137 175 1.7

Further documentation

• Overview Valve-actuator combinations

• Data sheets for actuators CQ..

• Installation instruction for zone valves and actuators

• General notes for project planning

www.belimo.com C2..QPT-.. • en-gb • 2017-09-22 • subject to changes 5

S-ar putea să vă placă și

- 3-Way Valve DN 20 PDFDocument4 pagini3-Way Valve DN 20 PDFEng MidoÎncă nu există evaluări

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- C2..QFL-.. R2..FL-.. Datasheet En-GbDocument4 paginiC2..QFL-.. R2..FL-.. Datasheet En-GbROGER CHÎncă nu există evaluări

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 paginiSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizÎncă nu există evaluări

- 2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Document4 pagini2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Francisco Mones RuizÎncă nu există evaluări

- 3/2-Way Solenoid Valve, Direct-Acting: Type 744Document4 pagini3/2-Way Solenoid Valve, Direct-Acting: Type 744Francisco Mones RuizÎncă nu există evaluări

- Technical Data Sheet C2..QFL-.. / R2..FL-..: Type OverviewDocument4 paginiTechnical Data Sheet C2..QFL-.. / R2..FL-..: Type Overviewcarlos perdomoÎncă nu există evaluări

- DK CP enDocument20 paginiDK CP enbrilian pungkyÎncă nu există evaluări

- EXT-TI-SBV2 Datasheet en PDFDocument3 paginiEXT-TI-SBV2 Datasheet en PDFjimmiilongÎncă nu există evaluări

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pagini3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizÎncă nu există evaluări

- Solenoid Valve - Pneumatic: Direct Acting, Pressure Relieved NamurDocument4 paginiSolenoid Valve - Pneumatic: Direct Acting, Pressure Relieved NamurFrancisco Mones RuizÎncă nu există evaluări

- Technical Data Sheet H4..B: Type OverviewDocument5 paginiTechnical Data Sheet H4..B: Type OverviewClimaco EdwinÎncă nu există evaluări

- Technical Data Sheet R3..-S..: Type OverviewDocument3 paginiTechnical Data Sheet R3..-S..: Type OverviewMohammed AttounÎncă nu există evaluări

- Gate Valve Die-Forged: Pressure Seal BonnetDocument8 paginiGate Valve Die-Forged: Pressure Seal Bonnetedark2009Încă nu există evaluări

- Belimo H6250SP-VDocument3 paginiBelimo H6250SP-VTiến Lý NhậtÎncă nu există evaluări

- V5329A TWDocument4 paginiV5329A TWS M NaveedÎncă nu există evaluări

- 2/2-Way Solenoid Valve, Direct-Acting: Type 741Document4 pagini2/2-Way Solenoid Valve, Direct-Acting: Type 741Francisco Mones RuizÎncă nu există evaluări

- Solenoid Valve For Aggressive Fluids, With Coupled Valve OperationDocument4 paginiSolenoid Valve For Aggressive Fluids, With Coupled Valve OperationFrancisco Mones RuizÎncă nu există evaluări

- KAT-A 5512 EKN-HYsec Edition1 en 07-11Document4 paginiKAT-A 5512 EKN-HYsec Edition1 en 07-11Sonny LuuÎncă nu există evaluări

- Vag Pico Pilot Operated Control Valve Level Control Valve: PN 10/16 - DN 50... 300Document2 paginiVag Pico Pilot Operated Control Valve Level Control Valve: PN 10/16 - DN 50... 300SathishkumarÎncă nu există evaluări

- Pressure Reducing Valve Pilot Operated VP-DRP10: Subplate To ISO 5781Document2 paginiPressure Reducing Valve Pilot Operated VP-DRP10: Subplate To ISO 5781Felipe Pisklevits LaubeÎncă nu există evaluări

- Belimo R3..-S.. Datasheet En-GbDocument3 paginiBelimo R3..-S.. Datasheet En-GbLaurentiu LapusescuÎncă nu există evaluări

- Flanged Linear Valve Pn6/16: FeaturesDocument4 paginiFlanged Linear Valve Pn6/16: FeaturesCrisTimÎncă nu există evaluări

- Valvula Honeywel V5329a1Document4 paginiValvula Honeywel V5329a1DAVIDÎncă nu există evaluări

- DKM CP DN25-65 En1Document24 paginiDKM CP DN25-65 En1brilian pungkyÎncă nu există evaluări

- BRC Geral SD 0100-2E02Document3 paginiBRC Geral SD 0100-2E02eduardogss100% (1)

- Burkert Type 2052 Pneumatic Rotary Drive 1Document5 paginiBurkert Type 2052 Pneumatic Rotary Drive 1Tech and Cool GadgetsÎncă nu există evaluări

- WSP22 3 - 400 P 120801 enDocument4 paginiWSP22 3 - 400 P 120801 enDavid AltarribaÎncă nu există evaluări

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Document4 pagini2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Sohail AhmedÎncă nu există evaluări

- BYPASSDocument2 paginiBYPASSSting DâuÎncă nu există evaluări

- G77x - 77xK Valve - CatalogueDocument8 paginiG77x - 77xK Valve - CatalogueEzgi PelitÎncă nu există evaluări

- RS 210 RS 210: Sectional Directional Control Valve Control ValveDocument20 paginiRS 210 RS 210: Sectional Directional Control Valve Control ValveAnemÎncă nu există evaluări

- Boreas Varioplus DVDocument3 paginiBoreas Varioplus DVCsaba SándorÎncă nu există evaluări

- 2/2-Way Solenoid Valve: Type 253Document4 pagini2/2-Way Solenoid Valve: Type 253Francisco Mones RuizÎncă nu există evaluări

- TechDS DV1800AP-DV28500WPDocument4 paginiTechDS DV1800AP-DV28500WPHendri KurniawanÎncă nu există evaluări

- 2/2-Way Diaphragm Valve, Air Piloted: Type 174Document4 pagini2/2-Way Diaphragm Valve, Air Piloted: Type 174Francisco Mones RuizÎncă nu există evaluări

- 4-3 Directional Spool Valve 4WE6EDocument2 pagini4-3 Directional Spool Valve 4WE6ERaphael SasdelliÎncă nu există evaluări

- DanfossDocument10 paginiDanfossconstantin balanÎncă nu există evaluări

- Proportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 BarDocument4 paginiProportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 Barbiomed2083Încă nu există evaluări

- Burkert Solenoid Valve Type 5420Document4 paginiBurkert Solenoid Valve Type 5420Faulhaber AdrianÎncă nu există evaluări

- GCV & SRV ServovalveDocument11 paginiGCV & SRV ServovalvechdiÎncă nu există evaluări

- IMI Bopp-Reuther Product SIRA AW LRESDocument4 paginiIMI Bopp-Reuther Product SIRA AW LRESPratik SinghÎncă nu există evaluări

- Ktm512 en MainDocument12 paginiKtm512 en MainFilip SerafimovÎncă nu există evaluări

- NTBNG0704ENDocument3 paginiNTBNG0704ENgvp9000Încă nu există evaluări

- 4-2 Directional Spool Valve 4WE6DDocument2 pagini4-2 Directional Spool Valve 4WE6DRaphael SasdelliÎncă nu există evaluări

- A6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enDocument16 paginiA6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enhugoÎncă nu există evaluări

- 2/2-Way Solenoid Valve Servo Operated For High PressureDocument3 pagini2/2-Way Solenoid Valve Servo Operated For High PressuremhaioocÎncă nu există evaluări

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 paginiInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- TD190164 Ball Valves SEDDocument12 paginiTD190164 Ball Valves SEDPablo Andres CartesÎncă nu există evaluări

- 3 Way Sauter ValveDocument8 pagini3 Way Sauter ValverkssÎncă nu există evaluări

- Ficha Técnica d200Document2 paginiFicha Técnica d200ventas3Încă nu există evaluări

- SF20-22 Poppet, 2-Way, N.C., High Pressure: Solenoid ValvesDocument2 paginiSF20-22 Poppet, 2-Way, N.C., High Pressure: Solenoid ValvesMarcos RodrigoÎncă nu există evaluări

- CO2 Fire Suppression SystemsDocument18 paginiCO2 Fire Suppression Systemsmarpaung saberindoÎncă nu există evaluări

- Piston Pump PVDocument16 paginiPiston Pump PVtreinamentoÎncă nu există evaluări

- Main Pump PDFDocument36 paginiMain Pump PDFElia MekdadÎncă nu există evaluări

- VC Serie Honeywell Home - Datablad-EN-1Document8 paginiVC Serie Honeywell Home - Datablad-EN-1Sehar KhanÎncă nu există evaluări

- 01 15 FCU-Kit Brotec EN Rev01Document14 pagini01 15 FCU-Kit Brotec EN Rev01Lucian BaraganÎncă nu există evaluări

- 3/2-Way Direct Mounting Pilot ValveDocument3 pagini3/2-Way Direct Mounting Pilot ValveTan Chee KwangÎncă nu există evaluări

- Gas Pressure Switch (Variable) : (SGPS 3V) (SGPS 10V) (SGPS 50V) (SGPS 150V) (SGPS 500V)Document21 paginiGas Pressure Switch (Variable) : (SGPS 3V) (SGPS 10V) (SGPS 50V) (SGPS 150V) (SGPS 500V)Alex DanielÎncă nu există evaluări

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 paginiTechnical Data Sheet 01DT-1L..: Type OverviewJÎncă nu există evaluări

- Technical Data Sheet LF24-SRDocument3 paginiTechnical Data Sheet LF24-SRJÎncă nu există evaluări

- Technical Data Sheet 22UTH-510..: Type OverviewDocument5 paginiTechnical Data Sheet 22UTH-510..: Type OverviewJÎncă nu există evaluări

- 08 Suply Fan Zone 2Document2 pagini08 Suply Fan Zone 2JÎncă nu există evaluări

- Technical Data Sheet 22D..C..-11: Type OverviewDocument5 paginiTechnical Data Sheet 22D..C..-11: Type OverviewJÎncă nu există evaluări

- 10 Bphe CHWDocument3 pagini10 Bphe CHWJÎncă nu există evaluări

- Qty. Description CRN 32-1-1 A-F-A-V-HQQV: Company Name: Grundfos Created By: Phone: DateDocument6 paginiQty. Description CRN 32-1-1 A-F-A-V-HQQV: Company Name: Grundfos Created By: Phone: DateJÎncă nu există evaluări

- Qty. Description Cri 5-2 A-Fgj-A-E-Hqqe: Company Name: Created By: Phone: DateDocument6 paginiQty. Description Cri 5-2 A-Fgj-A-E-Hqqe: Company Name: Created By: Phone: DateJÎncă nu există evaluări

- 07 Supply Fan Zone 1Document2 pagini07 Supply Fan Zone 1JÎncă nu există evaluări

- Technical Data - Fan Model HUD354: Location: Designation: Performance - Required ActualDocument2 paginiTechnical Data - Fan Model HUD354: Location: Designation: Performance - Required ActualJÎncă nu există evaluări

- Technical Data - Fan Model HUD354: Location: Designation: Performance - Required ActualDocument2 paginiTechnical Data - Fan Model HUD354: Location: Designation: Performance - Required ActualJÎncă nu există evaluări

- Natural Convection Heat Transfer Coefficient Correlations (U.S. Units) 1. With An Isothermal Vertical PlaneDocument4 paginiNatural Convection Heat Transfer Coefficient Correlations (U.S. Units) 1. With An Isothermal Vertical PlaneMahmoud Ahmed AlyÎncă nu există evaluări

- Instruments Index RO Plant YTMDocument8 paginiInstruments Index RO Plant YTMSswahyudiÎncă nu există evaluări

- Refrigerating Plant Test and Performance Sample ProblemsDocument2 paginiRefrigerating Plant Test and Performance Sample ProblemsMerie Ann DudangÎncă nu există evaluări

- Boiling and CondensationDocument22 paginiBoiling and CondensationKelmy Thomas MariaÎncă nu există evaluări

- Experiment: Single Stage & Multi Stage Centrifugal Pumps: ENT 462 Turbomachinery Laboratory ModuleDocument4 paginiExperiment: Single Stage & Multi Stage Centrifugal Pumps: ENT 462 Turbomachinery Laboratory ModuleVincent Paul SantosÎncă nu există evaluări

- Hydraulics Pneumatics NumericalDocument2 paginiHydraulics Pneumatics Numericalmahesh kumbhareÎncă nu există evaluări

- Bangladesh Gas & Coal Reserve & Production May 2023Document45 paginiBangladesh Gas & Coal Reserve & Production May 2023Pranoy BaruaÎncă nu există evaluări

- Tenatative List of Rexroth Make Hydraulic Items To Be Procured (As Provided by Various Shops)Document62 paginiTenatative List of Rexroth Make Hydraulic Items To Be Procured (As Provided by Various Shops)vsvinaykumarÎncă nu există evaluări

- Vertical Spiral Rib Tubeless Steam BoilersDocument6 paginiVertical Spiral Rib Tubeless Steam BoilersbenÎncă nu există evaluări

- Engine Fuel SystemDocument14 paginiEngine Fuel Systemusmankhanakbar100% (2)

- Albao Laboratory 3Document35 paginiAlbao Laboratory 3Shaun Patrick AlbaoÎncă nu există evaluări

- MEC 4105 Test Marking GuideDocument4 paginiMEC 4105 Test Marking GuideBirimumaso DavidÎncă nu există evaluări

- Testcycle 1 For Nozzle 1 PDFDocument28 paginiTestcycle 1 For Nozzle 1 PDFAnonymous bJZz94Încă nu există evaluări

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 paginiC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongÎncă nu există evaluări

- Charle's LawDocument23 paginiCharle's Lawmark gonzalesÎncă nu există evaluări

- Rerynolds NumberDocument8 paginiRerynolds NumberMonglen Z. CasiñoÎncă nu există evaluări

- 19 AlvheimDocument3 pagini19 AlvheimLem Fei-BronjulÎncă nu există evaluări

- Ensc26 Lecture02 PressureDocument44 paginiEnsc26 Lecture02 PressureCassandra AyadÎncă nu există evaluări

- Fike Ig-55 B9134 Proinert2Document6 paginiFike Ig-55 B9134 Proinert2Arthur DeiparineÎncă nu există evaluări

- 312D Hyd PDFDocument2 pagini312D Hyd PDFMbahdiro Kolenx100% (3)

- Turbo Machinery Class NotesDocument28 paginiTurbo Machinery Class NotesGagan Saini50% (2)

- Che111p Quiz 2ot - 3Q1516Document1 paginăChe111p Quiz 2ot - 3Q1516Rejed VillanuevaÎncă nu există evaluări

- Fans and BlowersDocument8 paginiFans and BlowersJerick Angeles Fajardo100% (1)

- Volumetric Pumps and Compressors PDFDocument36 paginiVolumetric Pumps and Compressors PDFAhmed shawkyÎncă nu există evaluări

- Discharge CoefficientDocument11 paginiDischarge Coefficientsisai12u2420% (2)

- VLE ReportDocument4 paginiVLE ReportAmeerul AhwazÎncă nu există evaluări

- Eone Generator Gas Dryer (GGD Ii) Justification and Specification InfoDocument6 paginiEone Generator Gas Dryer (GGD Ii) Justification and Specification InfoAmal ChinthakaÎncă nu există evaluări

- SC-manual-R8 (EN+SMOKE) - 2013.06.14Document30 paginiSC-manual-R8 (EN+SMOKE) - 2013.06.14TharinSiriwardanaÎncă nu există evaluări

- Steam Bench: ObjectiveDocument6 paginiSteam Bench: Objectiveحسين عمريÎncă nu există evaluări

- Appendices D: Problems: EtohDocument4 paginiAppendices D: Problems: EtohJensen Myles CollasÎncă nu există evaluări