Documente Academic

Documente Profesional

Documente Cultură

Sdpeg PDF

Încărcat de

SankaraSatyadev0 evaluări0% au considerat acest document util (0 voturi)

9 vizualizări3 paginiTitlu original

SDPEG.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

9 vizualizări3 paginiSdpeg PDF

Încărcat de

SankaraSatyadevDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

3.3.

Preparation of solid molecular dispersions

Drug-polymer mixtures (5–100% w/w of polymer) were dissolved in

anhydrous

methanol, stirred overnight and cast on Teflon sheets. The solvent

was allowed to evaporate in a partially open desiccator at room

temperature

for 3 days. The samples were then placed under vacuum for 2 days

and the resulting films were gently ground into powder with a

mortar and

pestle for 1 min. The powder obtained was dried under vacuum at

room

temperature for 24 h and at 40 _C for 12 h. The samples were

passed

though a 60 mesh sieve and stored at 0 _C over phosphorous

pentoxide

until used.

3.4. Preparation of physical mixtures

Physical mixtures were prepared by mixing the components using

a spatula

and a glass mortar for 2 min. The samples were then dried at 40

_C

under vacuum for 12 h. Dried physical mixtures were used

immediately in

the experiments.

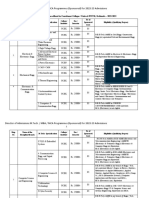

Preparation of physical mixture and solid dispersion

Physical mixtures (PMs) were prepared by manually mixing ABZ powder with other

ingredients according to the ratios in (Table1). The powders were sieved with a 450-

μm sieve and were stored in a screw-cap vial at room temperature until further

analysis. SD of ABZ in PVP K30 alone or in combination with either P 188 or P 407

was prepared in different ratios (Table1) by conventional solvent evaporation

method. Drug and carrier were dissolved in minimum volume of 95% ethanol. The

solvent was then evaporated under stirring at 80°C using hot plate stirrer. The result

residue was then cooled in a refrigerator for 48 h. Dispersion was then pulverized

using mortar and pestle and passed through a 450-μm sieve.

Table 1: Solid ABZ PVP K30 P 188 P 407

dispersions and physical

mixtures Composition

(% w/w) Formula

PM1 50% 50% ― ―

PM2 50% 48% 2% ―

PM3 50% 48% ― 2%

SD1 50% 50% ― ―

SD2 50% 49% 1% ―

glass vials. Then methanol was added on each vial 13. Then each

of every polymer were dissolved in the solvent using a vortex mixer

to make a polymer solution. Drug, polymer and solvent (methanol)

combination was dried by using hair dryer until solid dispersion

was formed and the solvent evaporated completely. Finally, the

formulations were withdrawn from vials, crushed in mortar and

pestle, passed through #60 sieve and the resulted samples were

weighed and then transferred in clean vials with proper labelling

and its double amount of lactose was added on each vials as

adsorbent and mixed well. These formulations were kept also in

desiccator until the dissolution started.

Selection of Solvent for solvent evaporation method

Since the drugs which are usually hydrophobic in nature usually

chosen for solid dispersions and with them hydrophilic polymers

are used to enhance the rate of dissolution. The selection of proper

solvent in solvent evaporation method is very much important

because its removal rate is critical to the quality of dispersion. For

complete removal of solvent lower temperature and reduced

pressure can be used. Solvent evaporation method is considered as

the effective method for SDS but the major disadvantage associate

with the method is that different polymorphic forms of the same

drug may be formed if different solvents are used 17. Sometimes

after selecting a proper solvent it was observed that complete

removal of solvent was very much difficult in some SDS. In some

cases, large volume of organic solvent is required to dissolve both

drug and carriers. So to avoid multiple complications care should

be taken to make proper choice and use of organic solvents during

formulations

Azad et al Journal of Drug Delivery & Therapeutics. 2018;

8(5):475-480

ISSN: 2250-1177 [477] CODEN (USA): JDDTAO

Preparation of solid dispersion

For the preparation of solid dispersions of

Albendazole fusion method was used. Dispersions

systems by the fusion method were prepared by mixing

the required amount of drug and polymer in glass vials.

The mixture was then heated till it was completely melted.

The temperature was maintained to a range of 80°C-

90°C.Continuous stirring during the melting procedure

prevented separation of the constituents. The melt was

then rapidly solidified. The formulations were kept in

desiccators'. The solidified mass was then crushed, size

The drug content of the physical mixture and

The stored mixture (SM) was determined UV

Spectrophotometrically by dissolving the sample in

Glacial acetic acid followed by sufficient dilution

With water to measure the absorbance at 291 nm

(UV-1601 PC, Shimadzu, Japan).

Formulations:

Physical mixture (PM) was prepared by mixing ABZ with urea or

PEG or PXR for 5 min at 1:1, 1:3 and 1:5 weight ratios using glass

mortar and pestle. Melting method (MM), solvent method (SM) and

kneading method (KM) were followed for the preparation of SDs

13-

.

14

The PM was heated by stirring at 190-200° in an oil bath Samples

were withdrawn, filtered through a membrane filter (0.45 μm),

diluted with water and analyzed in a spectrophotometer (UV-

1601PC, Shimadzu) at 291 nm.

The PM was dissolved in a minimal volume of anhydrous of 5°/min

from 35 to 300° under a nitrogen purge of 40 methanol, and the

solvent was removed by slow ml/min. TA 60WS software (version

1.4, Shimadzu, Japan) evaporation under reduced pressure. The

dried co-was used. precipitate was passed through 30 mesh, stored

in a vacuum desiccator (48 h) and passed through 60 mesh In

order to evaluate the presence of residual solvent in before

packaging in an airtight container.

Preparation of solid dispersed

systems

The preparation of solid dispersed systems

between ABZ and NIC was performed by

kneading method as described below.

Accurately weighed quantity (complying with

the weighed ratio corresponding to the coded

solid samples SD1, SD2, SD3, SD4) of NIC

and drug ABZ was placed in a mortar and

triturated in presence of small amount of

ethanol (95%) to obtain dough like mass,

which was kneaded for 45 minutes. The

product was then dried under vacuum to

constant weight. The dried mass was further

pulverized and screened through a 0.25 mm

mesh.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Witchcraft Demonology and Magic PDFDocument162 paginiWitchcraft Demonology and Magic PDFDee100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Gold BookDocument1.670 paginiGold BookManu Rodríguez Romero100% (2)

- KRBFullDocument246 paginiKRBFullPamella SandovalÎncă nu există evaluări

- All About Space ExoplanetsDocument100 paginiAll About Space ExoplanetsVivek AgÎncă nu există evaluări

- Vba Tutorial PDFDocument39 paginiVba Tutorial PDFDan Matinca100% (1)

- Ch02 QuestionsDocument8 paginiCh02 QuestionsAdliÎncă nu există evaluări

- MCHL-002 Separation Methods Lab Credits: 2 ExperimentsDocument1 paginăMCHL-002 Separation Methods Lab Credits: 2 ExperimentsSankaraSatyadevÎncă nu există evaluări

- New Registration For B Pharmacy ChecklistDocument1 paginăNew Registration For B Pharmacy ChecklistVamsi viharÎncă nu există evaluări

- Cxykeq (KH V"Vksrrj&'Kruke&Lrks E : Baglamukhi Ashtottar Shatnam StotramDocument17 paginiCxykeq (KH V"Vksrrj&'Kruke&Lrks E : Baglamukhi Ashtottar Shatnam StotramSankaraSatyadevÎncă nu există evaluări

- Apedcet-2023: Instruction BookletDocument38 paginiApedcet-2023: Instruction BookletSankaraSatyadevÎncă nu există evaluări

- Sumalatha CVDocument7 paginiSumalatha CVSankaraSatyadevÎncă nu există evaluări

- APPGCET-2023 Instruction BookletDocument154 paginiAPPGCET-2023 Instruction BookletSankaraSatyadevÎncă nu există evaluări

- APICET2023 InstructionBookletDocument8 paginiAPICET2023 InstructionBookletSankaraSatyadevÎncă nu există evaluări

- Action Taken Teachers Feedback 2018-29Document2 paginiAction Taken Teachers Feedback 2018-29SankaraSatyadevÎncă nu există evaluări

- MTech MBA MCA 2022 23 Spo Courses EligibilityDocument5 paginiMTech MBA MCA 2022 23 Spo Courses EligibilitySankaraSatyadevÎncă nu există evaluări

- List of Study Centres PGDAST November 2022Document4 paginiList of Study Centres PGDAST November 2022SankaraSatyadevÎncă nu există evaluări

- Programme Guide PGDAST 2022Document52 paginiProgramme Guide PGDAST 2022SankaraSatyadevÎncă nu există evaluări

- Chapter IV (Final) HFDocument12 paginiChapter IV (Final) HFSankaraSatyadevÎncă nu există evaluări

- MCHL-001 Basic Analytical Chemistry Lab Credits: 2 ExperimentsDocument1 paginăMCHL-001 Basic Analytical Chemistry Lab Credits: 2 ExperimentsSankaraSatyadevÎncă nu există evaluări

- M.tech R 19 Syllabus For Audit CourseDocument10 paginiM.tech R 19 Syllabus For Audit CourseSankaraSatyadevÎncă nu există evaluări

- APPGECET-2022 Nano Technology (NT)Document2 paginiAPPGECET-2022 Nano Technology (NT)SankaraSatyadevÎncă nu există evaluări

- Basic Immunological Concepts and Cells of The Immune System: Immunology: Study of How An Organism Responds To PathogensDocument27 paginiBasic Immunological Concepts and Cells of The Immune System: Immunology: Study of How An Organism Responds To PathogensSankaraSatyadevÎncă nu există evaluări

- Ibs Leasin Sinovial EbookDocument11 paginiIbs Leasin Sinovial EbookSankaraSatyadevÎncă nu există evaluări

- Interactions of Metronidazole With Other Medicines: A Brief ReviewDocument7 paginiInteractions of Metronidazole With Other Medicines: A Brief ReviewSankaraSatyadevÎncă nu există evaluări

- Medical Writing Careers Quick Start Guide For PhDsDocument5 paginiMedical Writing Careers Quick Start Guide For PhDsSankaraSatyadevÎncă nu există evaluări

- Ibs Leasin Sinovial EbookDocument11 paginiIbs Leasin Sinovial EbookSankaraSatyadevÎncă nu există evaluări

- Chapter II (Final) HFDocument48 paginiChapter II (Final) HFSankaraSatyadevÎncă nu există evaluări

- Chapter III (Final) HFDocument21 paginiChapter III (Final) HFSankaraSatyadevÎncă nu există evaluări

- JD Invitro Biology Group LeaderDocument2 paginiJD Invitro Biology Group LeaderSankaraSatyadevÎncă nu există evaluări

- Po Hand BookDocument3 paginiPo Hand BookDinesh ManikantaÎncă nu există evaluări

- Chapter Vii Finale XeroxhfDocument3 paginiChapter Vii Finale XeroxhfSankaraSatyadevÎncă nu există evaluări

- CHAPTER VI FINAL xeroxHFDocument31 paginiCHAPTER VI FINAL xeroxHFSankaraSatyadevÎncă nu există evaluări

- CHAPTER8Document21 paginiCHAPTER8SankaraSatyadevÎncă nu există evaluări

- Carbon and Its Compounds: Multiple Choice QuestionsDocument10 paginiCarbon and Its Compounds: Multiple Choice QuestionssenjicsÎncă nu există evaluări

- Atomic ModelsDocument13 paginiAtomic Modelsmax mishraÎncă nu există evaluări

- API 571 2nd 2011 Unlocked - 051Document1 paginăAPI 571 2nd 2011 Unlocked - 051nguyenÎncă nu există evaluări

- Stevens Institute of Technology Fall 2018: CH117 A, B, C, D, E, F, G, H, I, J, K, L, M: General Chemistry Laboratory IDocument7 paginiStevens Institute of Technology Fall 2018: CH117 A, B, C, D, E, F, G, H, I, J, K, L, M: General Chemistry Laboratory IShawnÎncă nu există evaluări

- MCQS ORGANIC ChemistryDocument6 paginiMCQS ORGANIC Chemistrymalikimran28Încă nu există evaluări

- Steam Generation - Distribution 2023Document64 paginiSteam Generation - Distribution 2023Aaqil cassimÎncă nu există evaluări

- Synthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesDocument133 paginiSynthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesBoopathi RajaÎncă nu există evaluări

- 11Document9 pagini11nyogtÎncă nu există evaluări

- AQA Chemistry: 4.3 Measuring Enthalpy Changes Follow Up SheetDocument2 paginiAQA Chemistry: 4.3 Measuring Enthalpy Changes Follow Up SheetDaniel's RevisionÎncă nu există evaluări

- Exceptions To The Octet Rule: Molecules With Electron-Deficient AtomsDocument22 paginiExceptions To The Octet Rule: Molecules With Electron-Deficient AtomsJohn RammÎncă nu există evaluări

- Nickel Alloy (182, 112, 141) Electrodes For Arc WeldingDocument1 paginăNickel Alloy (182, 112, 141) Electrodes For Arc WeldingMus LimÎncă nu există evaluări

- Rasi Navamsa: Ra Ma Ve Mo Ke JuDocument11 paginiRasi Navamsa: Ra Ma Ve Mo Ke JuManickavasagamÎncă nu există evaluări

- Alcalase 2.5 L - PH and TemperatureDocument2 paginiAlcalase 2.5 L - PH and TemperatureAída MorenoÎncă nu există evaluări

- Stem Big Bang Project 9 11Document8 paginiStem Big Bang Project 9 11api-375178817Încă nu există evaluări

- Simulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysDocument7 paginiSimulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysAdhityaEkoBagusÎncă nu există evaluări

- The Apparent Dual Nature of Cathode RaysDocument4 paginiThe Apparent Dual Nature of Cathode RaysFrederick David TombeÎncă nu există evaluări

- Journal of Physics & AstronomyDocument12 paginiJournal of Physics & Astronomysnigdha shromaÎncă nu există evaluări

- ENG208 Lecture 1P1 PDFDocument28 paginiENG208 Lecture 1P1 PDFFantasiaMariamÎncă nu există evaluări

- Grade 3 Energy Summary Grade 3 Learning Standards (From Bced Curriculum)Document4 paginiGrade 3 Energy Summary Grade 3 Learning Standards (From Bced Curriculum)Akbar KurniawanÎncă nu există evaluări

- Cryogenic Centrifugal Pump.Document28 paginiCryogenic Centrifugal Pump.SIDDARAJU NÎncă nu există evaluări

- BoQ-Beam Retrofitting Works LandTDocument2 paginiBoQ-Beam Retrofitting Works LandTAbhijit KarpeÎncă nu există evaluări

- Lesson 1: Basic Terminology and ConceptsDocument160 paginiLesson 1: Basic Terminology and Conceptsdiala alazraiÎncă nu există evaluări

- BSC Grade System Pt. Ravishankar Shukla University PDFDocument66 paginiBSC Grade System Pt. Ravishankar Shukla University PDFparmeshwar singhÎncă nu există evaluări

- BGMEA University of Fashion & Technology (BUFT) Topic:: Reactive DyeDocument19 paginiBGMEA University of Fashion & Technology (BUFT) Topic:: Reactive Dyeদীপ্তি হুমাইরাÎncă nu există evaluări

- The Effect of Monosaccharides Versus Disaccharides On The Rate of CO ProductionDocument4 paginiThe Effect of Monosaccharides Versus Disaccharides On The Rate of CO ProductionRyan LamÎncă nu există evaluări

- General Chemistry I - Tutorial 1Document5 paginiGeneral Chemistry I - Tutorial 1Khuê Nguyễn ThếÎncă nu există evaluări

- Chemical Inventory List: Responsible Person: Update Date: January, 2018 P: Physical, H: Health, E: EnvironmentalDocument1 paginăChemical Inventory List: Responsible Person: Update Date: January, 2018 P: Physical, H: Health, E: Environmentalratu nurhaliza syamÎncă nu există evaluări