Documente Academic

Documente Profesional

Documente Cultură

Gen+cp 13-32 PDF

Încărcat de

Brayan RosalesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gen+cp 13-32 PDF

Încărcat de

Brayan RosalesDrepturi de autor:

Formate disponibile

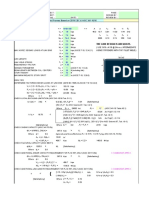

Electrical Production line 12/24h 460/60HZ

wiring diagram

Ref Created: Last modified

== ++ Page: No

LHO 02-06-2016 20-03-2020 = GEN + CP 13 / 32 008-1076

¤H-K1.7 LOCAL: ¤H-K1.9 LOCAL:

=STOCK+PULP/6.0 =STOCK+PMPFL/4.6

=STOCK+PMPFL/3.0 U

-X1:1;2;3 =STOCK+PMPFL/5.2 1

=STOCK+PMPFL/14.0 7:I.Ch0 =STOCK+PULP/6.1 Transmisor de nivel TK regaderas ANLG-COM

=STOCK+PMPFL/14.2 =STOCK+PMPFL/14.3

-X1:4 2

=STOCK+PMPFL/15.0 ANLG-COM U =STOCK+PULP/6.1 =STOCK+PMPFL/16.6 9:O.Ch0 =STOCK+PMPFL/14.3 Válvula proporcional agua a cuba

=MM+MM/8.1 -X1:5;6;7 =STOCK+PMPFL/17.6 3

7:I.Ch1 =X3.4 LIBRE ANLG-COM =STOCK+PMPFL/16.7

=MM+MM/10.0 -X1:8 =VACWT+PMPFL/1.6 9:O.Ch1 4

ANLG-COM =STOCK+PMPFL/3.1 =STOCK+PMPFL/16.7 Speed reference, stock feeding pump for MM

=DRYING+AH/12.0 U

-X1:9;10;11 =MM+MM/8.4 5

/5.6 7:I.Ch2 =STOCK+PMPFL/14.1 Nivel caja de cabeza pasta =MM+MM/14.7 ANLG-COM =STOCK+PMPFL/17.7

-X1:12 6

8 * ANALOG IN ANLG-COM =STOCK+PMPFL/14.1 /5.7 9:O.Ch2 =STOCK+PMPFL/14.5 Válvula proporcional pasta a cuba

U

-X1:13;14;15 7

7:I.Ch3 =STOCK+PMPFL/15.1 Consistency in stock 8 * ANALOG OUT ANLG-COM =VACWT+PMPFL/1.7

-X1:16 8

ANLG-COM /5.6 9:O.Ch3 =VACWT+PMPFL/1.6 Speed reference, white water pump at vacuum tank

1 1 -X1:17 1 9

2 2 NC 2 ANLG-COM =STOCK+PMPFL/5.3

3 3 -X1:18 3 10

4 4 NC 4 9:O.Ch4 =X3.19 LIBRE

U

-X2:1;2;3 11

5 5 7:I.Ch4 =MM+MM/10.1 Level transmitter in machine chest 5 ANLG-COM =STOCK+PMPFL/4.6

6 6 -X2:4 6 12

7 7 ANLG-COM =MM+MM/10.1 7 9:O.Ch5 =X3.20 LIBRE

U

8 8 -X2:5;6;7 8 13

7:I.Ch5 =DRYING+AH/12.1 Temperature in inlet to dryer ANLG-COM =MM+MM/8.4

9 9 -X2:8 9 14

10 10 ANLG-COM =DRYING+AH/12.1 10 9:O.Ch6 =MM+MM/8.4 Speed reference for moulding machine main drive

11 11 -X2:9;10;11 11 15

12 12 7:I.Ch6 =LIBRE 12 ANLG-COM =MM+MM/14.7

-X2:12 16

13 13 ANLG-COM 13 9:O.Ch7 =MM+MM/14.7 Die cleaner brush speed reference

14 14 U

-X2:13;14;15 14

15 15 7:I.Ch7 =MM+MM/8.2 Main drive, motor load, 0-100% 15

16 16 -X2:16 16 17

ANLG-COM /5.6 DC_NEUT /5.7

17 17 -X2:17 17 18

18 18 NC 18 +24VDC /5.7

-X2:18

NC

X1 X2

¤H-K1.8 LOCAL: ¤H-K1.10 LOCAL:

=STOCK+PMPFL/4.0 =DRYING+AH/4.1

=STOCK+PMPFL/5.0 U

-X1:1;2;3 =DRYING+AH/5.1 1

/5.6 8:I.Ch0 =X3.22 LIBRE =DRYING+AH/12.3 ANLG-COM =DRYING+AH/5.2

-X1:4 2

8 * ANALOG IN ANLG-COM =STOCK+PMPFL/4.1 =DRYING+AH/12.8 10:O.Ch0 =DRYING+AH/5.1 Speed reference exhaust air fan

U

-X1:5;6;7 =AT+TD/1.0 3

8:I.Ch1 =X3.18 LIBRE ANLG-COM =DRYING+AH/4.2

-X1:8 =AP2+TD3/1.0 4

ANLG-COM =STOCK+PMPFL/5.1 10:O.Ch1 =DRYING+AH/4.1 Speed reference circulation blower

U

-X1:9;10;11 /5.8 5

8:I.Ch2 =VACWT+VAC/5C Nivel agua caliente ANLG-COM =DRYING+AH/12.4

-X1:12 8 * ANALOG OUT 6

ANLG-COM 10:O.Ch2 =DRYING+AH/12.3 Burner capacity demand

U

-X1:13;14;15 =VACWT+VAC/5C Nivel agua fria 7

8:I.Ch3 ANLG-COM =DRYING+AH/12.9

-X1:16 8

ANLG-COM /5.7 10:O.Ch3 =DRYING+AH/12.8 Heatoil capacity demand

1 1 -X1:17 1 9

2 2 NC 2 ANLG-COM =AT+TD/1.1

3 3 -X1:18 3 10

4 4 NC 4 10:O.Ch4 =AT+TD/1.0 Speed reference for belt at tipping device

U

-X2:1;2;3 11

5 5 8:I.Ch4 =LIBRE 5 ANLG-COM

6 6 -X2:4 6 12 =MODULO UNITRONICS ENTRADA ANÁLOGA AI0

7 7 ANLG-COM 7 10:O.Ch5

U

8 8 -X2:5;6;7 8 13

8:I.Ch5 =VACWT+VAC/6.1 Nivel scrubber ANLG-COM

9 9 -X2:8 9 14

10 10 ANLG-COM 10 10:O.Ch6 =AP2+TD3/1.0 Speed reference for belt at tipping device 3

11 11 -X2:9;10;11 11 15

12 12 8:I.Ch6 =LIBRE 12 ANLG-COM =AP2+TD3/1.1

-X2:12 16

13 13 ANLG-COM 13 10:O.Ch7 =STOCK+PMPFL/15.6 Válvula proporcional dilución TK C

14 14 U

-X2:13;14;15 14

15 15 8:I.Ch7 =LIBRE 15

16 16 -X2:16 16 17

ANLG-COM /5.7 DC_NEUT /5.8

17 17 -X2:17 17 18

18 18 NC 18 +24VDC /5.8

-X2:18

NC

X1 X2

0 1 2 3 4 5 6 7 8 9

PREVIOUS PAGE: 12 NEXT PAGE: 14

Analog PLC modules, overview

COMOLSA COLUMBIA

S-ar putea să vă placă și

- Gen+cp 11-32 PDFDocument1 paginăGen+cp 11-32 PDFBrayan RosalesÎncă nu există evaluări

- Gen+cp 9-32 PDFDocument1 paginăGen+cp 9-32 PDFBrayan RosalesÎncă nu există evaluări

- CMA9000 - RRJ - Operating - Manual - v360 PDFDocument561 paginiCMA9000 - RRJ - Operating - Manual - v360 PDFMuhammad Adnan ArumpadatuÎncă nu există evaluări

- Time Sheet Oktober Suharsono 2021Document1 paginăTime Sheet Oktober Suharsono 2021Arief SilalahiÎncă nu există evaluări

- Dense Phase Ash Handling DBDocument2 paginiDense Phase Ash Handling DBexplorer5034Încă nu există evaluări

- DP15LSDocument11 paginiDP15LSapi-3800166Încă nu există evaluări

- Hendrik Febriyanto & Sylvia Caroline Indonesia Page 2 of 2Document1 paginăHendrik Febriyanto & Sylvia Caroline Indonesia Page 2 of 2nana mayangsariÎncă nu există evaluări

- #Design Equation D (X) /D (W) (-Raprime) / Fao X (0) 0 X (F) 0.70 W (0) 0Document2 pagini#Design Equation D (X) /D (W) (-Raprime) / Fao X (0) 0 X (F) 0.70 W (0) 0AzmiHafifiÎncă nu există evaluări

- CarWash P8 V11Document72 paginiCarWash P8 V11Fábio Seabra100% (1)

- 22KW VFD Panel DrawingDocument10 pagini22KW VFD Panel Drawingmdnadim42Încă nu există evaluări

- Gen+cp 12-32 PDFDocument1 paginăGen+cp 12-32 PDFBrayan RosalesÎncă nu există evaluări

- DNP File TransferDocument1 paginăDNP File TransferRyoma KuugaÎncă nu există evaluări

- The Link Design Is Adequate.: Seismic Design For Eccentrically Braced Frames Based On 2019 CBC & AISC 341-10/16Document7 paginiThe Link Design Is Adequate.: Seismic Design For Eccentrically Braced Frames Based On 2019 CBC & AISC 341-10/16ridho ziskaÎncă nu există evaluări

- Boeing Type Recurrent 1-2020 (Captain - First Officer) Study GuideDocument3 paginiBoeing Type Recurrent 1-2020 (Captain - First Officer) Study Guidealbert manansalaÎncă nu există evaluări

- Dwnload Full Essentials of International Economics 3rd Edition Feenstra Solutions Manual PDFDocument35 paginiDwnload Full Essentials of International Economics 3rd Edition Feenstra Solutions Manual PDFlucyfoster8j95100% (10)

- Laporan Sementara Percobaan 7 "Kontrol Motor DC Menggunakan Arduino Dan Processing"Document5 paginiLaporan Sementara Percobaan 7 "Kontrol Motor DC Menggunakan Arduino Dan Processing"Sadriva ZalukhuÎncă nu există evaluări

- Los Multilane Hcm2010: DR - MahDocument4 paginiLos Multilane Hcm2010: DR - MahAhmed Non MeemÎncă nu există evaluări

- Farex 4.0V - Useful Host Entry For Retail Agent: Retrieve A List of Routings/Stopovers Details For A Fare RecordDocument2 paginiFarex 4.0V - Useful Host Entry For Retail Agent: Retrieve A List of Routings/Stopovers Details For A Fare RecordhamidedrisÎncă nu există evaluări

- Baca Ultrasonic Display AndroidDocument8 paginiBaca Ultrasonic Display AndroidbaniÎncă nu există evaluări

- ECEN415/715:Physical and Economical Operations of Sustainable Energy Systems Spring 2021 Solutions To Homework Assignment #4Document4 paginiECEN415/715:Physical and Economical Operations of Sustainable Energy Systems Spring 2021 Solutions To Homework Assignment #4JakÎncă nu există evaluări

- Cepu Fract. ProjectDocument1 paginăCepu Fract. Projectsari susantiÎncă nu există evaluări

- Runway Capacity Calculation - Palegre AirportDocument23 paginiRunway Capacity Calculation - Palegre Airportamansax77Încă nu există evaluări

- A318/A319/A320/A321: Flight Crew Operating ManualDocument3.334 paginiA318/A319/A320/A321: Flight Crew Operating ManualgagaÎncă nu există evaluări

- Design Triangular Waveform Generator For Frequency of 5KHz and $V - (Opp) $ 6V Using Op-AmpDocument4 paginiDesign Triangular Waveform Generator For Frequency of 5KHz and $V - (Opp) $ 6V Using Op-AmpAchal SinghÎncă nu există evaluări

- Ebf IbcDocument7 paginiEbf IbcBang SutresÎncă nu există evaluări

- 2.draft Survey - NumericalsDocument30 pagini2.draft Survey - Numericalssamar jeet100% (1)

- Essentials of International Economics 3rd Edition Feenstra Solutions ManualDocument35 paginiEssentials of International Economics 3rd Edition Feenstra Solutions Manualreginagwyn0157y100% (21)

- Quick Reference Guide: Release 2.1 - January 2016 - COMPUNEL & Sons B.VDocument19 paginiQuick Reference Guide: Release 2.1 - January 2016 - COMPUNEL & Sons B.VMuhammad AkramÎncă nu există evaluări

- Feenstra Intlecon3e SM ch02 Econ TradeDocument12 paginiFeenstra Intlecon3e SM ch02 Econ TradeKhushi JainÎncă nu există evaluări

- Cmpen 411 Vlsidiitlci It Vlsi Digital Circuits Spring 2011 Lecture 12: Logical EffortDocument33 paginiCmpen 411 Vlsidiitlci It Vlsi Digital Circuits Spring 2011 Lecture 12: Logical EffortToby DatorÎncă nu există evaluări

- M/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClassDocument2 paginiM/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClasshalimÎncă nu există evaluări

- Circuito Lab1Document1 paginăCircuito Lab1emze_franzÎncă nu există evaluări

- Full Download International Trade 3rd Edition Feenstra Solutions ManualDocument35 paginiFull Download International Trade 3rd Edition Feenstra Solutions Manualisaacc4sbbaileyÎncă nu există evaluări

- GE10 Across ROADM 9500 PDFDocument5 paginiGE10 Across ROADM 9500 PDFDerek Peters100% (1)

- Slab On Grade DesignDocument1 paginăSlab On Grade DesignManoj JaiswalÎncă nu există evaluări

- Distribution System and Substation Design: Form 2Document11 paginiDistribution System and Substation Design: Form 2EmmanuelReyesIIIÎncă nu există evaluări

- International Trade 3rd Edition Feenstra Solutions ManualDocument35 paginiInternational Trade 3rd Edition Feenstra Solutions Manualbrandihansenjoqll295% (21)

- 0 - Sprinkler Hydraulic Calculation For Ordinary Hazard-1 For VideoDocument6 pagini0 - Sprinkler Hydraulic Calculation For Ordinary Hazard-1 For Videoariseelectricals18Încă nu există evaluări

- Ta7368p, Ta7368fDocument12 paginiTa7368p, Ta7368fPramote RodbonÎncă nu există evaluări

- Ne Csu Pr0 F 6053 (Appendix)Document55 paginiNe Csu Pr0 F 6053 (Appendix)Ekundayo JohnÎncă nu există evaluări

- R Epi KB: Solution: Part 1: Checking Pile BehaviourDocument3 paginiR Epi KB: Solution: Part 1: Checking Pile BehaviourMalik AbedÎncă nu există evaluări

- Gen+cp 10-32 PDFDocument1 paginăGen+cp 10-32 PDFBrayan RosalesÎncă nu există evaluări

- Samsung Bn94-05570w Echo P Unique Es8000 Main SCHDocument19 paginiSamsung Bn94-05570w Echo P Unique Es8000 Main SCHNachiket Kshirsagar100% (1)

- CDL 319Document666 paginiCDL 319Jan kopáčekÎncă nu există evaluări

- Calculation Sprinkler GPMDocument15 paginiCalculation Sprinkler GPMfireoniceÎncă nu există evaluări

- Kertas UjianDocument153 paginiKertas UjianDesiiNurmalaSariiÎncă nu există evaluări

- LL E D: Landing Performance AssessmentDocument7 paginiLL E D: Landing Performance Assessmentwhitney chanÎncă nu există evaluări

- Case StudyDocument5 paginiCase StudyPamela PomantocÎncă nu există evaluări

- F1. SCT - SN-Steel Formwork Design - ST COLUMN FORMWORKDocument18 paginiF1. SCT - SN-Steel Formwork Design - ST COLUMN FORMWORKshihabÎncă nu există evaluări

- Tid 0000049 01 PDFDocument4 paginiTid 0000049 01 PDFjoaojitoÎncă nu există evaluări

- Material List: 2.1. Table of AbbreviationsDocument24 paginiMaterial List: 2.1. Table of Abbreviationslucio ruiz jrÎncă nu există evaluări

- Torus 1500 Indoor Vertical - Seismic AnchorageDocument2 paginiTorus 1500 Indoor Vertical - Seismic AnchorageLionel LapuzÎncă nu există evaluări

- ReissueDocument9 paginiReissueالموظفونالأحرار100% (1)

- CS EE380 Lec01 DemoDocument13 paginiCS EE380 Lec01 DemoRajneesh YadavÎncă nu există evaluări

- Assessment Report On Tolerances of CIP Girders at Final Construction Stage Under CP01Document5 paginiAssessment Report On Tolerances of CIP Girders at Final Construction Stage Under CP01Tung NguyenÎncă nu există evaluări

- Quick Help 1Document7 paginiQuick Help 1mennasaied25042000Încă nu există evaluări

- CHE 482 Individual Writing Assignment Hamad AlhajriDocument11 paginiCHE 482 Individual Writing Assignment Hamad AlhajriTimelessÎncă nu există evaluări

- RPLL-VHHH CFPDocument30 paginiRPLL-VHHH CFPTony WongÎncă nu există evaluări

- Content List Drawing: R0 R1 R2 No. Remark Revision Title Drawing NoDocument29 paginiContent List Drawing: R0 R1 R2 No. Remark Revision Title Drawing NoLuqman ArifudinÎncă nu există evaluări

- Tesco 750 ESIDocument2 paginiTesco 750 ESIjlmunozvÎncă nu există evaluări

- NammalvarDocument22 paginiNammalvarPranesh Brisingr100% (1)

- SPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0Document25 paginiSPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0contact2vikasÎncă nu există evaluări

- What Is SAP PS (Project Systems) ModuleDocument3 paginiWhat Is SAP PS (Project Systems) ModuleahmerÎncă nu există evaluări

- Audi Navigation System Plus - MMI Operating ManualDocument100 paginiAudi Navigation System Plus - MMI Operating ManualchillipaneerÎncă nu există evaluări

- BSC IT SyllabusDocument32 paginiBSC IT Syllabusஜூலியன் சத்தியதாசன்Încă nu există evaluări

- Chapter 1Document2 paginiChapter 1Reymond Homigop GalarpeÎncă nu există evaluări

- Compose Testing CheatsheetDocument1 paginăCompose Testing CheatsheetEstampados SIn ApellidoÎncă nu există evaluări

- Safe and Gentle Ventilation For Little Patients Easy - Light - SmartDocument4 paginiSafe and Gentle Ventilation For Little Patients Easy - Light - SmartSteven BrownÎncă nu există evaluări

- Deploying MVC5 Based Provider Hosted Apps For On-Premise SharePoint 2013Document22 paginiDeploying MVC5 Based Provider Hosted Apps For On-Premise SharePoint 2013cilango1Încă nu există evaluări

- Chapter 3 - A Top-Level View of Computer Function and InterconnectionDocument8 paginiChapter 3 - A Top-Level View of Computer Function and InterconnectionChu Quang HuyÎncă nu există evaluări

- Lich King Chorus PDFDocument21 paginiLich King Chorus PDFMacgy YeungÎncă nu există evaluări

- FMDQ Codified Rule Book FGN BondsDocument65 paginiFMDQ Codified Rule Book FGN BondsOladipupo Mayowa PaulÎncă nu există evaluări

- Statement of Facts:: State of Adawa Vs Republic of RasasaDocument10 paginiStatement of Facts:: State of Adawa Vs Republic of RasasaChristine Gel MadrilejoÎncă nu există evaluări

- ETA-1 Service PDFDocument44 paginiETA-1 Service PDFgansolÎncă nu există evaluări

- Vehicle Detection and Identification Using YOLO in Image ProcessingDocument6 paginiVehicle Detection and Identification Using YOLO in Image ProcessingIJRASETPublicationsÎncă nu există evaluări

- Title To The ProjectDocument14 paginiTitle To The ProjectJatinChadhaÎncă nu există evaluări

- Process Plant Layout and Piping DesignDocument4 paginiProcess Plant Layout and Piping Designktsnl100% (1)

- Nature Hill Middle School Wants To Raise Money For A NewDocument1 paginăNature Hill Middle School Wants To Raise Money For A NewAmit PandeyÎncă nu există evaluări

- Fpga De0-Nano User Manual PDFDocument155 paginiFpga De0-Nano User Manual PDFCesarÎncă nu există evaluări

- K8+ Single Chip Keyer Manual: 3 To 5 VDCDocument8 paginiK8+ Single Chip Keyer Manual: 3 To 5 VDCtito351Încă nu există evaluări

- Di MCB DB Pricelist01!07!2018Document1 paginăDi MCB DB Pricelist01!07!2018saurabhjerps231221Încă nu există evaluări

- Heirs of Tancoco v. CADocument28 paginiHeirs of Tancoco v. CAChris YapÎncă nu există evaluări

- PETRO TCS Engineering Manual 682Document44 paginiPETRO TCS Engineering Manual 682paulm3565Încă nu există evaluări

- IM0973567 Orlaco EMOS Photonview Configuration EN A01 MailDocument14 paginiIM0973567 Orlaco EMOS Photonview Configuration EN A01 Maildumass27Încă nu există evaluări

- Allergies To Cross-Reactive Plant Proteins: Takeshi YagamiDocument11 paginiAllergies To Cross-Reactive Plant Proteins: Takeshi YagamisoylahijadeunvampiroÎncă nu există evaluări

- Water Quality Management For Production of Freshwater Ornamental SHDocument14 paginiWater Quality Management For Production of Freshwater Ornamental SHVarun KÎncă nu există evaluări

- PCIB Vs ESCOLIN (G.R. No. L-27860 & L-27896)Document61 paginiPCIB Vs ESCOLIN (G.R. No. L-27860 & L-27896)strgrlÎncă nu există evaluări

- The Truth About Customer ExperienceDocument11 paginiThe Truth About Customer Experienceaksr27Încă nu există evaluări

- CS 148 - Introduction To Computer Graphics and ImagingDocument3 paginiCS 148 - Introduction To Computer Graphics and ImagingMurtaza TajÎncă nu există evaluări