Documente Academic

Documente Profesional

Documente Cultură

Test Plan 8443B250D

Încărcat de

ЕвгенийDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Test Plan 8443B250D

Încărcat de

ЕвгенийDrepturi de autor:

Formate disponibile

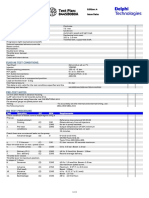

8443B250D

Peugeot XD 3T TEST PLAN Issue No: 2

03/07/89

PUMP SPECIFICATION (Tool 7244-382) SIN RD/PUMPS 71

Rotation: Clockwise Stop test machine & wait 10 sec min. Cambox press. 0.1 bar max.

Plunger Diameter: 7.5 mm 4. Advance Gauge (S) 0 0 mm ( 0°) Boost 0 bar.

Roller to roller: 50.60 mm SIN RD/TOOLS 18 (Tool 7244-590)

Advance Type: Automatic speed and light load. 5. XS fuel valve (S) 125 Increases by 3 to 12 litre/hr.

Governor type: Mechanical mini-maxi. Backleak change Boost 0 bar. Throttle closed.

Gov. Link Length: 16.5 ± 0.2 mm (Initial set) SIN D109

Throttle lever link hole: - LLA lever towards HP outlets.

Gov.arm hole No.: - Set LLA valve lever at 90° to pump axis.

Drive type: Externally splined hub - unsupported shaft. 6. Throttle test (C) 400 1 cm3 maximum, Throttle closed.

Light load advance by external adjustment. Boost 0 bar.

Boost control. 7. T. P Vacuum (C) 100 0.5 bar vacuum. 60 seconds maximum.

Stop solenoid 12 V. Boost 0 bar. Tool 7244-382.

Double lever idling. 8. Transfer press. (C) 70 0.35 bar minimum. Boost 0 bar.

Automatic advance override (Tool 7244-382) SIN RD/PUMPS 71

9. Advance (S) 1500 3.6 mm ( 4.75°) Boost 0.8 bar.

ISO TEST CONDITIONS. (Full load) SIN RD/TOOLS 18. (Tool 7244-590)

This data is only valid for the test conditions specified and the 10. Transfer press. (C) 1500 5.2 to 6.3 bar, Boost 0.8 bar.

following test benches: HA3000/HA2500/HA1150/HA1100MkII/HA875 (Tool 7244-382) SIN RD/PUMPS 71

HA700/HA400/AVM/PGM 11. Boost control (S) 750 43 to 45 mm3/st. Boost 0 bar.

Test Fluid: ISO 4113 at 40 ± 2 °C. 12. Anti-stall (S) 450 1.9 to 2.4 cm3, Tool 1804-481.

Nozzles: ISO 4010. Boost 0 bar.

Nozzle opening pressure: 125 +3 -0 bar. SIN RD/PUMPS A81 & TOOLS A14.

H.P. pipes: 6 x 2 x 600 mm (ISO 4093.1) 13. Idling screw (S) 400 1.9 to 2.4 cm3, Boost 0 bar.

H.P. Outlet Connections: Original (M12 x 1.5) Remove 3mm dia. rod.

Test machine drive: ADC103 14. LLA Linkage (S) 500 Delivery 26 to 34 mm3/st.

Test machine drive in supported position. Boost 0.8 bar. Tool 1804-612.

Inlet feed pressure: 0.1 bar Throttle 15 ± 2 mm off min. stop

Advance 0 to 0.5 mm ( 0 to 0.7°)

PRE-TEST NOTES Tool 7244-590

3.5 mm shim fitted in advance housing. Lock LLA linkage in this position.

Retain idling lever using 3mm dia. rod, SIN RD/TOOLS A13 15. LLA Advance (C) 500 2 to 2.9 mm ( 2.7 to 3.9°)

LLA valve lever to be at 90° to pump axis. Boost 0.8 bar.

See SIN RD/PUMPS 67 (If Pump Housing or Advance parts replaced) Throttle as test(14) - 1 mm.

Fit advance gauge to speed piston end. Tool 7244-590

Timing: -To accurately set the internal and external timing, use 16. Advance (C) 1000 1.5 to 2.4 mm ( 2 to 3.2°)

the following tools: 1804-003/1804-615 (Full load) Boost 0.8 bar.

SIN RD/TOOLS 18 (Tool 7244-590)

ISO TEST PROCEDURE 17. LLA Advance (C) 1500 6.3 to 7.8 mm ( 8.4 to 10.4°)

Boost 0.8 bar.

Test Operation S/C RPM Requirements

Throttle closed. Tool 7244-590.

1. Priming (C) 100 Obtain delivery from all injectors.

Stop test machine - remove tool 7244-382

-1000 No air in pump backleak.

Fit stop solenoid.

2. Transfer press. (S) 1000 4.4 ± 0.2 bar, Boost 0.8 bar.

18. Stop solenoid (C) 400 0.4 cm3 max., De-energize solenoid.

(Initial set.) (Tool 7244-382),SIN RD/PUMPS 71

Boost 0 bar.

3. Transfer press. (C) 500 3.4 to 4.5 bar, Boost 0 bar.

Delphi Diesel Systems 2000 Page 1 -->

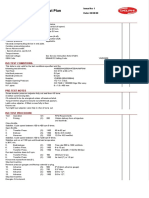

8443B250D

Peugeot XD 3T TEST PLAN Issue No: 2

03/07/89

Stop test machine & wait 10 sec. min. Cambox press. 0.1 bar max. injection or at TDC.

Energise solenoid shut-off with 12 V.

Screw in excess fuel valve adjustment screw. REFER TO STATEMENT AT END OF EXPLANATORY NOTES REGARDING MAXIMUM

19. XS fuel valve (S) 125 Increases by 3 to 12litre/hr. FUEL AND SPEED SETTING AND VARIATIONS IN ENGINE PERFORMANCE.

Backleak change Boost 0 bar. Throttle closed.

3mm dia. rod removed. SIN D109

Stop test machine & wait 10 sec min. Cambox press. 0.1 bar max.

20. Excess delivery (C) 100 8.4 cm3 minimum, Advance 0 mm,

Boost 0bar(7244-590)SIN RD/TOOLS 18

21. LLA Advance (C) 270 1.9 to 2.6 mm ( 2.5 to 3.4°)

Boost 0 bar.

Throttle closed. Tool 7244-590.

22. Cambox pressure (C) 270 0.65 to 0.85 bar. Boost 0 bar

Throttle closed. Tool 1804-447B.

23. Max. delivery (S) 1875 60.5 ± 0.5 mm3/st.

Boost 0.8bar,Max. spread 4mm3/st.

Tools 1804-423 & 1804-448

24. Cambox pressure (C) 1875 0.65 to 0.85 bar. Boost 0.8 bar

Throttle closed. Tool 1804-447B.

25. Gov. delivery (C) 2000 Record average delivery,Boost 0.8bar

26. Gov. operation (S) 2300 25.5 to 28.5 mm3/st, Boost 0.8 bar.

27. Gov. cut-off (C) 2800 Maximum 2 cm3, Line max. 2.4 cm3.

Boost 0.8 bar.

28. Advance (C) 2800 5.4 to 6.6 mm ( 7.2 to 8.8°)

(Full load) Boost 0.8 bar.

SIN RD/TOOLS 18 (Tool 7244-590)

29. Gov. delivery (C) 2000 Minimum as test(25), Boost 0.8 bar.

30. Delivery(F.L.) (C) 1000 10.8 to 11.6 cm3. Boost 0.8 bar.

31. Backleakage (C) 1000 30 to 50 cm3 per 100 shots.

0.30 to 0.50 litre per minute.

Boost 0.8 bar.

32. Boost control (S) 750 44 ± 0.5 mm3/st. Boost 0 bar.

33. Delivery(F.L.) (C) 1875 11.8 to 12.4 cm3. Boost 0.7 bar.

34. Delivery(F.L.) (C) 500 8.9 cm3 maximum, Boost 0 bar.

35. Advance- (C) 500 3.2 to 4.3 mm ( 4.2 to 5.7°)

Override Override in maximum position.

Tool 7244-590

36. Internal timing S/C HP outlet'X ', Press 80 bar

-Micrometric Torque 0.16daN.m

Tools 1804-003 & 1804-615

SIN RD/PUMPS 102,TOOLS 5 on 4 outlets

37. External timing S/C Stamp timing value on the timing disc

Refer to product application sheet.

Tool 1804-615.

Shows if timing is at beginning of

Delphi Diesel Systems 2000 Page 2

S-ar putea să vă placă și

- DPC 8443b184bDocument2 paginiDPC 8443b184bBaytolgaÎncă nu există evaluări

- 8444B622B Tabela PDFDocument2 pagini8444B622B Tabela PDFJaqueline S. S. MaicáÎncă nu există evaluări

- TestplanDocument3 paginiTestplanGiorgio Di CesareÎncă nu există evaluări

- 8921A091WDocument2 pagini8921A091WLTurboÎncă nu există evaluări

- Richard VargasDocument1 paginăRichard VargasRicardo NarvaezÎncă nu există evaluări

- 9320a075g Test DataDocument4 pagini9320a075g Test DataPedro AbellanÎncă nu există evaluări

- 8443A260EDocument2 pagini8443A260EMiguel ChaconÎncă nu există evaluări

- Test Plan for Perkins T4.401 LP18 Pump 8923A050Document2 paginiTest Plan for Perkins T4.401 LP18 Pump 8923A050veshatÎncă nu există evaluări

- 8961A020WDocument2 pagini8961A020WLTurboÎncă nu există evaluări

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 paginiTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215Încă nu există evaluări

- Dorman 3DA Pump Specification and Test PlanDocument1 paginăDorman 3DA Pump Specification and Test PlanFx_205Încă nu există evaluări

- Optimize pump specification test plan titleDocument4 paginiOptimize pump specification test plan titleLIONN SOFTWARESÎncă nu există evaluări

- 8444B360ADocument2 pagini8444B360ABaytolgaÎncă nu există evaluări

- Test Plan Delphi TechnologiesDocument2 paginiTest Plan Delphi TechnologiesFRANCISCOÎncă nu există evaluări

- Test Plan: 3443890: Pump SpecificationDocument2 paginiTest Plan: 3443890: Pump SpecificationLTurboÎncă nu există evaluări

- 9320A093GDocument4 pagini9320A093GKevin TtitoÎncă nu există evaluări

- Test Plan: 9320A530: Pump SpecificationDocument4 paginiTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovÎncă nu există evaluări

- 9320A185H TestplanDocument4 pagini9320A185H TestplanBaytolga canÎncă nu există evaluări

- 9323A271G Catalog DATADocument4 pagini9323A271G Catalog DATALIONN SOFTWARESÎncă nu există evaluări

- 9323a251g PTDocument3 pagini9323a251g PTClarice Alves de FreitasÎncă nu există evaluări

- Ford HSDI pump specification and ISO test procedureDocument2 paginiFord HSDI pump specification and ISO test proceduretaniaÎncă nu există evaluări

- Test Plan: Pump SpecificationDocument3 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- 9320a225g Plano LHDocument3 pagini9320a225g Plano LHForteLubÎncă nu există evaluări

- Test Plan: 9521A030: Pump SpecificationDocument3 paginiTest Plan: 9521A030: Pump Specificationjohnny sabinÎncă nu există evaluări

- 3042f843 Plano de TesteDocument1 pagină3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Aifo 8031.1.05 1500 rpm pump test planDocument2 paginiAifo 8031.1.05 1500 rpm pump test planJose Alexandre SunhegaÎncă nu există evaluări

- Testplan 3239590Document2 paginiTestplan 3239590Fx_2050% (1)

- Pump SpecificationDocument2 paginiPump Specificationedgar ricoÎncă nu există evaluări

- 9521A030H DATA CatalogDocument3 pagini9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- TEST PLAN FOR PERKINS VISTA 1104C-44TAG PUMPDocument2 paginiTEST PLAN FOR PERKINS VISTA 1104C-44TAG PUMPClarice Alves de FreitasÎncă nu există evaluări

- Test Plan for Perkins Vista A 80 KVA @ 15 KVA GeneratorDocument2 paginiTest Plan for Perkins Vista A 80 KVA @ 15 KVA Generatormarco rod100% (1)

- Test Plan 3340f370gDocument1 paginăTest Plan 3340f370gLIONN SOFTWARESÎncă nu există evaluări

- Test Plan: Pump SpecificationDocument4 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- Test Plan: 9320A210: Pump SpecificationDocument7 paginiTest Plan: 9320A210: Pump SpecificationBaytolgaÎncă nu există evaluări

- 8920A360 - New Holland 7740 TractorDocument13 pagini8920A360 - New Holland 7740 TractorBaytolgaÎncă nu există evaluări

- 8924A141WDocument2 pagini8924A141WLTurboÎncă nu există evaluări

- 3340F401G Plano de Teste DelphiDocument2 pagini3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Test Plan: Pump SpecificationDocument2 paginiTest Plan: Pump Specificationmecanik.veracruzÎncă nu există evaluări

- 3230F250 DATA CatalogDocument1 pagină3230F250 DATA CatalogLIONN TESTE2021Încă nu există evaluări

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 paginiTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 8520A020A TestplanDocument2 pagini8520A020A TestplanBaytolga canÎncă nu există evaluări

- INJECTION PUMP CALIBRATION DATADocument3 paginiINJECTION PUMP CALIBRATION DATAElson DorigonÎncă nu există evaluări

- Test Plan: Pump SpecificationDocument2 paginiTest Plan: Pump SpecificationClarice Alves de FreitasÎncă nu există evaluări

- 8520A060A TestplanDocument2 pagini8520A060A TestplanBaytolga can100% (1)

- RDDA Es Metric A4Document1 paginăRDDA Es Metric A4Daniel GómezÎncă nu există evaluări

- TEST PLAN: PUMP SPECIFICATION 3343010Document1 paginăTEST PLAN: PUMP SPECIFICATION 3343010Fx_205Încă nu există evaluări

- 3233F390 TabelaDocument1 pagină3233F390 TabelaOFFICE DANACÎncă nu există evaluări

- 3230f582T PTDocument2 pagini3230f582T PTHeitor Gael Alves de FreitasÎncă nu există evaluări

- 3340F322 Lionn Auto SoftwaresDocument2 pagini3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONÎncă nu există evaluări

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 paginăModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTEÎncă nu există evaluări

- Testplan 3242920Document1 paginăTestplan 3242920Fx_205Încă nu există evaluări

- 8550A223ADocument2 pagini8550A223ALTurboÎncă nu există evaluări

- EU/5/2360 Test PlanDocument2 paginiEU/5/2360 Test PlanOseasJuniorÎncă nu există evaluări

- RDHA Full en Metric LetterasdDocument2 paginiRDHA Full en Metric LetterasdessamÎncă nu există evaluări

- JCB DELPHI PUMP-9520A500-509S03 - Iss 03Document7 paginiJCB DELPHI PUMP-9520A500-509S03 - Iss 03Ravikant Saini100% (2)

- RTM125-18Z5 5+ATC+User+ManualDocument13 paginiRTM125-18Z5 5+ATC+User+Manualnorbert.rendesÎncă nu există evaluări

- RDJA Full en Metric LetterDocument2 paginiRDJA Full en Metric LetteressamÎncă nu există evaluări

- RTM120X103-30-24-4.5 Air Cooled Spindle User Manual.docDocument14 paginiRTM120X103-30-24-4.5 Air Cooled Spindle User Manual.docBalkanboyÎncă nu există evaluări

- DINDIGULDocument10 paginiDINDIGULAnonymous BqLSSexOÎncă nu există evaluări

- Skin Yale University Protein: Where Does Collagen Come From?Document2 paginiSkin Yale University Protein: Where Does Collagen Come From?Ellaine Pearl AlmillaÎncă nu există evaluări

- Organisation Study of KAMCODocument62 paginiOrganisation Study of KAMCORobin Thomas100% (11)

- AVK Butterfly Valves Centric 75 - TADocument1 paginăAVK Butterfly Valves Centric 75 - TANam Nguyễn ĐứcÎncă nu există evaluări

- Summer Internship ReportDocument135 paginiSummer Internship Reportsonal chandra0% (1)

- Architectural PlateDocument3 paginiArchitectural PlateRiza CorpuzÎncă nu există evaluări

- My PDSDocument16 paginiMy PDSRosielyn Fano CatubigÎncă nu există evaluări

- Midgard - Player's Guide To The Seven Cities PDFDocument32 paginiMidgard - Player's Guide To The Seven Cities PDFColin Khoo100% (8)

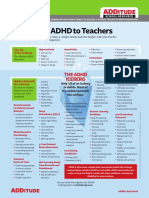

- Explaining ADHD To TeachersDocument1 paginăExplaining ADHD To TeachersChris100% (2)

- Speech Writing MarkedDocument3 paginiSpeech Writing MarkedAshley KyawÎncă nu există evaluări

- Marrickville DCP 2011 - 2.3 Site and Context AnalysisDocument9 paginiMarrickville DCP 2011 - 2.3 Site and Context AnalysiskiranjiÎncă nu există evaluări

- Supreme Court declares Pork Barrel System unconstitutionalDocument3 paginiSupreme Court declares Pork Barrel System unconstitutionalDom Robinson BaggayanÎncă nu există evaluări

- Opportunity, Not Threat: Crypto AssetsDocument9 paginiOpportunity, Not Threat: Crypto AssetsTrophy NcÎncă nu există evaluări

- Database Interview QuestionsDocument2 paginiDatabase Interview QuestionsshivaÎncă nu există evaluări

- Tanroads KilimanjaroDocument10 paginiTanroads KilimanjaroElisha WankogereÎncă nu există evaluări

- List of Parts For Diy Dremel CNC by Nikodem Bartnik: Part Name Quantity BanggoodDocument6 paginiList of Parts For Diy Dremel CNC by Nikodem Bartnik: Part Name Quantity Banggoodyogesh parmarÎncă nu există evaluări

- Developments in ESP: A Multi-Disciplinary ApproachDocument12 paginiDevelopments in ESP: A Multi-Disciplinary ApproachDragana Lorelai JankovicÎncă nu există evaluări

- NBPME Part II 2008 Practice Tests 1-3Document49 paginiNBPME Part II 2008 Practice Tests 1-3Vinay Matai50% (2)

- GASB 34 Governmental Funds vs Government-Wide StatementsDocument22 paginiGASB 34 Governmental Funds vs Government-Wide StatementsLisa Cooley100% (1)

- Topic 4: Mental AccountingDocument13 paginiTopic 4: Mental AccountingHimanshi AryaÎncă nu există evaluări

- Oyo Rooms-Case StudyDocument13 paginiOyo Rooms-Case StudySHAMIK SHETTY50% (4)

- Housekeeping NC II ModuleDocument77 paginiHousekeeping NC II ModuleJoanne TolopiaÎncă nu există evaluări

- Equity Valuation Concepts and Basic Tools (CFA) CH 10Document28 paginiEquity Valuation Concepts and Basic Tools (CFA) CH 10nadeem.aftab1177Încă nu există evaluări

- Italy VISA Annex 9 Application Form Gennaio 2016 FinaleDocument11 paginiItaly VISA Annex 9 Application Form Gennaio 2016 Finalesumit.raj.iiit5613Încă nu există evaluări

- Arpia Lovely Rose Quiz - Chapter 6 - Joint Arrangements - 2020 EditionDocument4 paginiArpia Lovely Rose Quiz - Chapter 6 - Joint Arrangements - 2020 EditionLovely ArpiaÎncă nu există evaluări

- IndiGo flight booking from Ahmedabad to DurgaPurDocument2 paginiIndiGo flight booking from Ahmedabad to DurgaPurVikram RajpurohitÎncă nu există evaluări

- NAZRUL - CV ChuadangaDocument2 paginiNAZRUL - CV ChuadangaNadira PervinÎncă nu există evaluări

- TITLE 28 United States Code Sec. 3002Document77 paginiTITLE 28 United States Code Sec. 3002Vincent J. Cataldi91% (11)

- (Template) Grade 6 Science InvestigationDocument6 pagini(Template) Grade 6 Science InvestigationYounis AhmedÎncă nu există evaluări

- An Analysis of Students Pronounciation Errors Made by Ninth Grade of Junior High School 1 TengaranDocument22 paginiAn Analysis of Students Pronounciation Errors Made by Ninth Grade of Junior High School 1 TengaranOcta WibawaÎncă nu există evaluări