Documente Academic

Documente Profesional

Documente Cultură

Materials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining Instruments

Încărcat de

seeralan balakrishnanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Materials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining Instruments

Încărcat de

seeralan balakrishnanDrepturi de autor:

Formate disponibile

Materials System Specification

34-SAMSS-010 03 October 2019

Quality Requirements for Pressure Retaining Instruments

Document Responsibility: Instrumentation Standards Committee

Contents

Summary of Changes................................................. 2

1 Scope..................................................................... 3

2 Conflicts and Deviations ....................................... 3

3 References ............................................................ 3

4 Purchase Order Information ................................. 4

5 General Requirements ......................................... 5

6 Specific Requirements by Product Type ............. 6

7 Inspection and Testing Requirements ................. 7

8 Other Miscellaneous Requirements..................... 8

Document History ..................................................... 10

Previous Issue: 15 September 2016 Next Revision: 03 October 2024

Contact: SAHANFA Page 1 of 10

©Saudi Aramco 2019. All rights reserved.

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

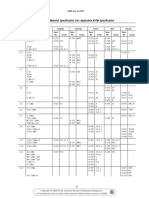

Summary of Changes

Change Type

Paragraph (modification, Technical Change

addition, deletion)

1 References addition Adding ISO 15614 to reference list

2 5.3 deletion Deleting product quality plan

3 7.3 addition Adding ASME B31.3 for MT

Saudi Aramco: Company General Use Page 2 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

1 Scope

This specification, together with the applicable instrument specification sheet and

inspection form, defines the minimum inspection and testing requirements for pressure

retaining instruments used for process measurement.

Requirements of this document are in addition to the existing requirements, if any, that

are stated in individual equipment SAMSS.

Pressure retaining instruments include, but are not limited to, cone meters, flow nozzles,

level gauges, magnetic flowmeters, orifice assemblies, thermowells, turbine flowmeters,

ultrasonic flowmeters, Venturi tubes, and vortex flowmeters.

Specifically excluded from the scope are: valves, transmitters, manifolds, and analyzer

systems.

2 Conflicts and Deviations

Any conflicts between this document and other applicable Mandatory Saudi Aramco

Engineering Requirements (MSAERs) shall be addressed to the EK&RD Coordinator.

Any deviation from the requirements herein shall follow internal company procedure

SAEP-302.

3 References

Material or equipment supplied in accordance with this specification shall comply with

the latest edition of the references listed below, unless otherwise noted.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302 Waiver of a Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Engineering Standard

SAES-A-206 Positive Material Identification

Saudi Aramco Inspection Requirements

Form 175-341700 Pressure Retaining Instruments

Saudi Aramco Form and Data Sheet

NMR-7907 Non-material Requirements for Instrumentation (General)

3.2 Industry Codes and Standards

American Society of Mechanical Engineers

ASME B16.5 Pipe Flanges and Flanged Fittings

Saudi Aramco: Company General Use Page 3 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

ASME B16.36 Orifice Flanges

ASME B16.47 Large Diameter Steel Flanges

ASME B31.3 Chemical Plant and Petroleum Refinery Piping

ASME SEC VIII Rules for Construction of Pressure Vessels

ASME SEC IX Qualification Standard for Welding and Brazing

Procedures, Welders, Brazers, and Welding and Brazing

Operators

ASME PTC 19.3 Thermowells

American Society for Testing and Materials

ASTM A956 Standard Test Method for Leeb Hardness Testing of Steel

Products

ASTM E10 Test Method for Brinnell Hardness of Metallic Materials

ASTM E18 Test Methods for Rockwell Hardness of Metallic

Materials

ASTM E165 Standard Test Method for Liquid Penetrant Examination

ASTM A488 Standard Practice for Steel Castings, Welding,

Qualifications of Procedures and Personnel

European Norm

EN 10204 Inspection Documents, Metal Products, Steel, Nonferrous

Metals, Material Testing

International Organization for Standardization / National Association of

Corrosion Engineers

NACE MR0175/ISO 15156 Petroleum and Natural Gas Industries-Materials for use in

H2S-Containing Environments in Oil and Gas Production

ISO 15614 Specification and Qualification of Welding Procedures for

Metallic Materials – Welding Procedure Test

NACE TM0284 Standard Test Method - Evaluation of Pipeline and

Pressure Vessel Steels for Resistance to Hydrogen-

Induced Cracking

4 Purchase Order Information

The following information shall be included in the Purchase Order:

a) Size and connection type of the pressure retaining instrument

b) Material and grade of the pressure retaining instrument

c) End details and material specification of matching pipe or nozzle

d) Maximum working pressure and temperature

e) Sour or other corrosive service, if applicable

Saudi Aramco: Company General Use Page 4 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

f) Additional material and testing requirements; if applicable

5 General Requirements

5.1 General

Pressure retaining instruments shall be tested, examined, and qualified as specified in

this SAMSS in addition to the established manufacturer tests and applicable Industry

Standard requirements. Nothing in this Specification shall be construed as waiving any

mandatory requirement of the manufacturer or the applicable Industry Standard.

Design and pressure rating of pressure retaining instruments shall be established as per

the requirements of ASME B31.3 Section 304.

All material for use in sour services shall be resistant to sulfide stress cracking (SSC) in

accordance with NACE MR0175/ISO 15156. Devices exposed to an environment with

> 50 ppmw total sulfide content in the aqueous phase require the use of HIC resistant

material. HIC test shall be carried out and reported in accordance with NACE TM0284

as applicable.

5.2 Material Source and Traceability

Raw materials (plates, bars, forgings pipes and components, etc.) to be used for the

manufacturing of pressure retaining components shall be sourced from known and

authorized suppliers. This means suppliers that are audited and approved by the

manufacturer and included in his sub-supplier list.

All materials used for construction of the pressure retaining parts shall be

in accordance with EN 10204, 3.1 Mill Certificate as minimum.

Welding consumable shall be with EN 10204, 2.2 Certificate as minimum.

At the time of quotation, the device manufacturer shall include a statement for country

of origin, if other than the point of shipment. Traceability of finished materials shall

extend back to the original steel making facility.

5.3 Welding Activities

All welding activities shall be carried out by qualified personnel and on the basis of

welding procedures, and shall be continuously monitored and checked to ensure

compliance.

Welding procedures and welders shall be qualified in accordance with the provisions of

ASME SEC IX of the Boiler and Pressure Vessel Code, or ISO 15614.

Welding procedures, qualifications of welders and welding operators at the foundry and

manufacturer shall also meet the requirements of ASTM A488 and other ASME codes

if applicable. Equivalent ISO standards are acceptable.

All welds must meet the minimum quality requirements of ASME B31.3 or equivalent

ISO standard.

Dissimilar metal welds between ferritic steel and either austenitic stainless steel, duplex

stainless steel, or nickel-based alloys as well as use of stainless steel or nickel-based

Saudi Aramco: Company General Use Page 5 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

filler metals on ferritic steel are not permitted for pressure containing welds in sour

service.

Carbon-equivalent (CE) of the steel used shall be verified to ensure that weldability

issues associated with carbon steel are avoided.

Brackets and other attached parts welded on the mechanical equipment, if any, shall

have full length welds. Intermittent welding is prohibited. Attached parts material shall

be selected to prevent galvanic corrosion.

All parts, welds and heat-affected zones of welds, exposed to wet sour service, shall

meet the hardness and heat treatment requirements as specified in

NACE MR0175/ISO 15156. This includes materials under overlays, plating or

coatings.

All welding procedures and welding performance qualification records shall be made

available to Buyer's Inspector for review.

5.4 Flange Ends

All flange installations shall be designed in accordance with ASME B16.5, B16.36, or

B16.47. The following design codes are referenced for new flanges:

ASME B16.5: Class 150 thru 2500, ½” through 24”

ASME B16.36: Orifice Flanges

ASME B16.47 Series A: Large Diameter Flanges Class 150 thru 900

Flanges API spec. 6A (as applicable)

6 Specific Requirements by Product Type

The following requirements are in addition to the General Inspection and Testing

requirements detailed in Section 7 of this document.

6.1 Orifice Flanges and Plates

6.1.1 Casting Orifice flanges are not recommended.

6.1.2 Orifice plates shall be delivered with the appropriate flange facing finish to close

with required gasket.

6.1.3 Material and hardness of Ring Type Joint (RTJ) orifice plate holder shall be

checked to ensure no leakage exists.

6.1.4 Orifice flanges and plates material and dimensions shall be verified by the

inspected.

6.2 Venturi Tubes, Meter Runs and Flow Nozzles

6.2.1 Tube thickness at any point shall be equal or larger than pipe thickness.

Saudi Aramco: Company General Use Page 6 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

6.2.2 Hydrostatic test and radiographic test of welded areas shall be done per Section

7 of this document.

6.3 Level Gauges

6.3.1 To avoid leakages of level gauges, it is recommended that the level gauge body

be machined to house a gasket between body and glass.

6.3.2 Unions between level gauges body and level gauges valves shall be avoided.

6.3.3 The complete level gauge assembly shall be hydrostatically tested with all studs

and nuts torqued to the appropriate values recommended by the manufacturer.

6.4 Thermowells

6.4.1 Thermowells shall be machined from bar stock material.

6.4.2 All thermowells shall be hydro tested.

6.4.3 Ultrasonic test of full penetration welds between flange and well shall be

conducted for flanged thermowells on high pressure services (ANSI 900# rating

and above) or in processes handling hydrogen, corrosive or dangerous fluids.

6.4.4 Additional welded areas, if any, shall be subjected to radiographic tests, e.g.,

multipoint thermowell end.

6.4.5 Wake frequency/Stress calculation shall be performed on all intruding elements

such as pitot tube, thermowell, etc. In addition, these calculations shall be

attached to the respective Instrument Specification Sheet (ISS).

6.4.6 Thermowells not complying with 6.4.5, such as helical type, shall be avoided.

7 Inspection and Testing Requirements

7.1 General

The pressure retaining devices are subject to inspection by the Saudi Aramco Inspection

Representative per Saudi Aramco Inspection Requirements Form 175-341700 attached

to the Purchase Order.

7.2 Visual Examination and Dimensional Check

General appearance, workmanship and fit-up shall be acceptable in accordance with

ASME B31.3. Weld surfaces shall show a smooth contour. Dimensions of the device

shall be checked against applicable standards and approved Vendor's Drawings.

7.3 Dye Penetrant or Magnetic Particle Testing

All welds shall be tested using one of the following methods:

Dye penetrant (color contrast penetrant) in accordance with ASTM E165.

Acceptance criteria shall be per “Boiler & Pressure Vessel Code,”

ASME SEC VIII D1, Appendix 8.

Saudi Aramco: Company General Use Page 7 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

Magnetic particle tested in accordance with ASME B31.3 or ASME SEC VIII

D1, Appendix 6.

7.4 Radiography

Fabricated Welds shall be 100% (or as decided by Inspection Office) radiographed and

evaluated in accordance with the applicable ANSI/ASME standard with a minimum

casting quality factor of 0.95 or with equivalent ISO standard.

7.5 Hydrotest

Hydrotest shall be performed on all bodies in accordance with

ANSI/ASME B31.3.

Chloride content of hydrotest water shall not exceed 50 ppm and the device should be

dried and cleaned after hydrotest.

7.6 Positive Material Identification (PMI)

PMI shall be conducted randomly on finished tubes or nozzles on each lot before

dispatch. A minimum of 10% of tubes in each heat must be tested. Internal

manufacturer procedure can be followed for conducting PMI.

Acceptance criteria shall be as detailed in SAES-A-206.

PMI shall include the weld for items welded with addition of filler metal.

7.7 Hardness Tests

Hardness tests, when required by specified service and/or material specification, shall

be conducted by the Vendor on all wetted parts in accordance with

ASTM E10, ASTM E18 or ASTM A956 Leeb hardness test.

8 Other Miscellaneous Requirements

8.1 Nonmaterial Requirements

The supplier shall provide nonmaterial items as shown on Form NMR-7907.

8.2 Identification

The following information, as applicable, shall be stamped/embossed on a stainless

steel tag permanently attached to the device body:

Manufacturer

Part/Model No.

Serial No. (if applicable)

Instrument Tag No.

Nominal Size

ANSI Class (Flange Rating)

Saudi Aramco: Company General Use Page 8 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

Material of Construction

Functional data as applicable, e.g., Capacity Data, K-Factor, etc.

8.3 Preparation for Shipping

Devices shall be properly packed for shipment to avoid moisture ingress and physical

damage. Methods to avoid moisture during shipment include use of desiccant, airtight

shrink-wrapping or equivalent

Saudi Aramco: Company General Use Page 9 of 10

Saudi Aramco: Company General Use

Document Responsibility: Instrumentation Standards Committee 34-SAMSS-010

Issue Date: 03 October 2019

Next Planned Update: 03 October 2024 Quality Requirements for Pressure Retaining Instruments

Document History

03 October 2019 Adding ISO 15614 to reference list, Deleting product quality plan, Adding

ASME B31.3 for MT.

1 January 2018 Editorial revision to rewrite paragraph 6.4.6.

15 September 2016 Aligned this SAMSS with SAES-J-100 on thermowell wake frequency

calculations and Hydrogen Induced Cracking (HIC) testing for sour

application. This revision proposes enhancements that are summarized

below:

1) Added requirement for wake frequency calculations as per ASME PTC

19.3 for thermowells. This aligns with other Saudi Aramco and

industry standards.

2) Inline devices exposed to an environment with 50 ppmw total sulfide

content in the aqueous phase require the use of HIC resistant

material. HIC test shall be carried out and reported in accordance with

NACE TM0284 as applicable.

3) Carbon-equivalent (CE) of the steel used shall be verified to ensure

that weldability issues associated with carbon steel are avoided.

4) Use of any special design thermowell, such as helical strake type

requires prior written approval of the General Supervisor, Process

Automation Systems Division, Process & Control Systems

Department.

24 April 2012 New

Saudi Aramco: Company General Use Page 10 of 10

Saudi Aramco: Company General Use

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Asme Ix "Welding Qualification": 1 Online TrainingDocument8 paginiAsme Ix "Welding Qualification": 1 Online TrainingIqfal ZulhendriÎncă nu există evaluări

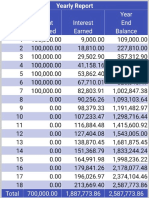

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Asme Section 1 Ped GuideDocument89 paginiAsme Section 1 Ped Guide조의식67% (3)

- Asme B31.5-2019Document16 paginiAsme B31.5-2019Jonathan Espinoza Mejia30% (10)

- ASME Section IX - UpdatedDocument260 paginiASME Section IX - UpdatedIrfan Mehmood96% (26)

- RF Planning BibleDocument128 paginiRF Planning BibleDipanka Borah100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Spec ReferenceDocument40 paginiSpec ReferencesohaibÎncă nu există evaluări

- Pharmaceutical Calculation - PDF 2Document31 paginiPharmaceutical Calculation - PDF 2Cheeyongg Lookonthebrightside100% (4)

- SOW EPCC Effluent Treatment Plant Service Water Header ModificationDocument27 paginiSOW EPCC Effluent Treatment Plant Service Water Header Modificationirfan rayyanÎncă nu există evaluări

- Asme B16.24 PDFDocument25 paginiAsme B16.24 PDFRuben Dario Mamani ArellanoÎncă nu există evaluări

- A17-1S Edtn 2005 PDFDocument134 paginiA17-1S Edtn 2005 PDFphilanderjoeÎncă nu există evaluări

- Asme Ptc-6a-2000 PDFDocument186 paginiAsme Ptc-6a-2000 PDFandhucaosÎncă nu există evaluări

- Asme B1.20.7 PDFDocument24 paginiAsme B1.20.7 PDFHaries Bugarin GarciaÎncă nu există evaluări

- Resume of A Project CoordinatorDocument3 paginiResume of A Project CoordinatorASHIL PRABHAKARÎncă nu există evaluări

- ASME B31.3 CLOSED BOOK PRACTICE QUESTIONSDocument12 paginiASME B31.3 CLOSED BOOK PRACTICE QUESTIONSemaanazeem91% (11)

- 18 Questions and Answers in Planning & SchedulingDocument8 pagini18 Questions and Answers in Planning & SchedulingBeni Best100% (3)

- MR For Production SkidDocument39 paginiMR For Production SkidSandeepNBabuÎncă nu există evaluări

- High Purity Process Piping - Harmonization of ASME Codes and StandardsDocument8 paginiHigh Purity Process Piping - Harmonization of ASME Codes and StandardsLiu Yangtze100% (1)

- Saep 363 PDFDocument10 paginiSaep 363 PDFRami ElloumiÎncă nu există evaluări

- LH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageDocument277 paginiLH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageSumantrra Chattopadhyay100% (2)

- Steam Turbines: ASME PTC 6-2004Document6 paginiSteam Turbines: ASME PTC 6-2004Dena Adi KurniaÎncă nu există evaluări

- Refrigeration & Air Conditioning: Emerson Flow Controls Expansion ValvesDocument1 paginăRefrigeration & Air Conditioning: Emerson Flow Controls Expansion Valvesseeralan balakrishnanÎncă nu există evaluări

- CCW - PVC Steel Wire Hose CatalogueDocument1 paginăCCW - PVC Steel Wire Hose Catalogueseeralan balakrishnanÎncă nu există evaluări

- P5 product data sheet specsDocument4 paginiP5 product data sheet specsseeralan balakrishnanÎncă nu există evaluări

- General Combined Brochure RevisedDocument406 paginiGeneral Combined Brochure Revisedseeralan balakrishnanÎncă nu există evaluări

- SPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPDocument4 paginiSPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPseeralan balakrishnanÎncă nu există evaluări

- Smart Scholar CalculationDocument5 paginiSmart Scholar Calculationseeralan balakrishnanÎncă nu există evaluări

- Itrade Networks Company ProfileDocument8 paginiItrade Networks Company Profileseeralan balakrishnanÎncă nu există evaluări

- Pyrometer Tp7: The Universal Infrared Thermometer For Many Fields of ApplicationDocument6 paginiPyrometer Tp7: The Universal Infrared Thermometer For Many Fields of Applicationseeralan balakrishnanÎncă nu există evaluări

- Singlevoteprice21 1576480252Document1 paginăSinglevoteprice21 1576480252seeralan balakrishnanÎncă nu există evaluări

- Shunt Open - Release 24V DC E1/6-T8Document2 paginiShunt Open - Release 24V DC E1/6-T8seeralan balakrishnanÎncă nu există evaluări

- Tuv Application Form Saudi Arabia Saso ProgramDocument3 paginiTuv Application Form Saudi Arabia Saso Programseeralan balakrishnanÎncă nu există evaluări

- Onion AgmarkDocument33 paginiOnion Agmarkseeralan balakrishnanÎncă nu există evaluări

- Sewage TreatmentDocument1 paginăSewage Treatmentseeralan balakrishnanÎncă nu există evaluări

- Professional infrared thermometer for -50°C to 1000°CDocument6 paginiProfessional infrared thermometer for -50°C to 1000°Cseeralan balakrishnanÎncă nu există evaluări

- Hikvision Port Forwarding For CCTVDocument35 paginiHikvision Port Forwarding For CCTVbuzzkillaÎncă nu există evaluări

- Model Number DetailsDocument1 paginăModel Number Detailsseeralan balakrishnanÎncă nu există evaluări

- B 815791 FCDocument3 paginiB 815791 FCseeralan balakrishnanÎncă nu există evaluări

- Compressor Specifications - © Bristol Compressors International, IncDocument1 paginăCompressor Specifications - © Bristol Compressors International, Incseeralan balakrishnanÎncă nu există evaluări

- Rail BeamsDocument1 paginăRail Beamsseeralan balakrishnanÎncă nu există evaluări

- Las Tek FillerDocument2 paginiLas Tek Fillerseeralan balakrishnanÎncă nu există evaluări

- Lectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 GalDocument2 paginiLectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 Galseeralan balakrishnanÎncă nu există evaluări

- Nokia E71 Vs Samsung B7330 OmDocument2 paginiNokia E71 Vs Samsung B7330 Omseeralan balakrishnanÎncă nu există evaluări

- Nikola Tesla - Wikipedia, The Free EncyclopediaDocument15 paginiNikola Tesla - Wikipedia, The Free Encyclopediaseeralan balakrishnanÎncă nu există evaluări

- SambarDocument1 paginăSambarseeralan balakrishnanÎncă nu există evaluări

- Interpretations: ASME Boiler and Pressure Vessel Code Section Viii-2Document8 paginiInterpretations: ASME Boiler and Pressure Vessel Code Section Viii-2Dio MiÎncă nu există evaluări

- Power Piping: ASME B31.1-2012Document1 paginăPower Piping: ASME B31.1-2012Jonathan GagliardiÎncă nu există evaluări

- Modernization of Pressure Vessel Design Codes ASMEDocument5 paginiModernization of Pressure Vessel Design Codes ASMEHai SayangÎncă nu există evaluări

- Asme 1998Document267 paginiAsme 1998Jéssica Bonow HinterholzÎncă nu există evaluări

- Mahesh G Salagar ExpDocument4 paginiMahesh G Salagar Expsin67438Încă nu există evaluări

- ASME B16.34-2009 Valves-Flanged-Threaded-Welding End - ExtractDocument72 paginiASME B16.34-2009 Valves-Flanged-Threaded-Welding End - ExtractMahmoud Al HomranÎncă nu există evaluări

- Previews AWWA D100 11 PreDocument6 paginiPreviews AWWA D100 11 PreJuliana FortunatoÎncă nu există evaluări

- Asme b16.20Document65 paginiAsme b16.20MARCIOÎncă nu există evaluări

- Pages From MMR-SP-60-001-A4 - Rev3 - Instrument General Specification-SignedDocument6 paginiPages From MMR-SP-60-001-A4 - Rev3 - Instrument General Specification-SignedKykyRizkyÎncă nu există evaluări

- Elevated Flare Tips: ScopeDocument8 paginiElevated Flare Tips: ScopeAna Bella RosarioÎncă nu există evaluări

- Graded Exercise - 20 % Submission Date: 28 June 2021Document9 paginiGraded Exercise - 20 % Submission Date: 28 June 2021kampretÎncă nu există evaluări

- Amims K 3105 - 2Document14 paginiAmims K 3105 - 2wangkai01.sneiÎncă nu există evaluări

- INSPECT Features and Benefits - CodewareDocument5 paginiINSPECT Features and Benefits - CodewareLibardo Bahamón LiscanoÎncă nu există evaluări