Documente Academic

Documente Profesional

Documente Cultură

Liebherr Hydraulic Cylinders 380 Bar Series Production Range Product Brochure Es Web

Încărcat de

Jesus D. Gutierrez G.Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Liebherr Hydraulic Cylinders 380 Bar Series Production Range Product Brochure Es Web

Încărcat de

Jesus D. Gutierrez G.Drepturi de autor:

Formate disponibile

Hydraulic Cylinders by Liebherr

380 bar Series-Production Range

380 bar Series-Production Range

2 Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range

Flexible, with High Load Also interesting?

Capacity and fast Availability 260 bar series-production range

With the 260 bar series Liebherr offers its customers a range

The Liebherr 380 bar series-production range gives cus of hydraulic cylinders optimised to what is essential, which

tomers a broad choice of flexible cylinder variants which can still also be used in demanding conditions – both in the

have been proven under the toughest operating conditions. mobile and stationary area. There is a broad range of mount-

The use of standardised components means that new hy- ing types as well as two alternative oil connections and piston

draulic cylinders and spare parts are quickly available despite rod coatings available. In order to be able to realise the most

the high degree of flexibility. The 380 bar series includes 40 economical solution for the respective target application, no

basic variants for nominal diameter combinations of piston extended functions such as sensor technology or cushioning

and piston rod. Besides stroke, numerous options can be options are intended for this series.

configured for each of these basic variants. Corresponding

3D models can be supplied for each variant. Through an im- Series-production range according to ISO 6022

proved pressure reduction system friction is decreased. The series developed specially for industry applications is

This ensures a longer service life for the cylinder. designed and manufactured according to the applicable

standards of ISO 6022. The products are used in various sta-

Area of application tionary applications such as steelworks, for example. There

The hydraulic cylinders of the 380 bar series-production is a wide selection of mounting types available. Furthermore,

range are employed in mobile applications. For example, they the hydraulic cylinders can be equipped with a large portfolio

are used wherever durable and robust products are needed of configurable additional optional equipment (e.g. position

for highly dynamic applications. Such applications include transducer, end of stroke cushioning, proximity switch or

construction machinery, e. g. as boom cylinder, stick cylinder pressure sensor) as required.

or bucket cylinder for wheeled and crawler excavators.

Product range – overview

Type Differential hydraulic cylinder

Operating pressure max. 380 bar

Stroke Up to 2,300 mm, larger lengths on request

Installation length Up to 3,100 mm

Piston diameter 100 – 220 mm

Piston rod diameter 65 – 150 mm

Pin diameter 70 – 130 mm

Piston head width 90 – 150 mm

End of stroke cushioning End of stroke cushioning on piston and / or rod side

Media port SAE 3 / 4" – 1 1 / 2"

Operating fluid Hydraulic fluids as per ISO 4406: 20 / 18 / 15

Coating Chrome, nickel-chrome, special solutions for specific applications

Anti-corrosion Standard paint finish, maritime paint finish

Operating temperature -30 °C to +95 °C

Piston speed Up to 1 m / s

Usage Dynamic, static

Maintenance Spare parts and sealing packages available worldwide through the Liebherr network

Applications Mobile machinery e.g. construction machines, industrial applications

Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range 3

Technical Design

Hydraulic cylinder configuration

The hydraulic cylinders are computed and designed using

state-of-the-art technology. Here, for example, the finite

element method is used to help configure designs. The

380 bar series is designed for highly dynamic mobile ap-

plications. Extreme external forces of the kind encoun-

tered in construction machinery were assumed for the

configuration of the hydraulic cylinders. Here, Liebherr

sets a reliable standard with respect to durability and

resilience in heavy operations.

Sensor technology

In order to realise many different regulation tasks, the linear

movements and the response of the hydraulic cylinders have

to be exactly recorded, monitored and controlled. For this

reason, Liebherr offers the own developed LiView® position

transducer. This is the first length measuring system for cy

linders, which is designed completely for highly dynamic ap-

plications. It is easy to integrate in the hydraulic cylinders of

this series and can also be retrofitted.

Piston rod coating

High quality chrome and nickel-chrome coatings are used as

standard. Depending on the application, either a coating with

normal resilience (AASS acetic acid salt spray testing as per

DIN EN ISO 9227 with 96 hrs.) is used or one with increased

resilience (AASS with 240 hrs.). A sea water coating (AASS

with 500 hrs.) is also available. Assessment basis for all coat-

ings is rating 10 as per DIN EN ISO 10289.

Rating 10

AASS – 96 h

AASS – 240 h

AASS – 500 h

4 Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range

End of stroke cushioning

Controlled and gentle approach to the end positions is also

important with highly dynamic movements. Here, Liebherr

offers the option of an optimised cushioning system, which

has proven its worth in practice on many occasions. The

customer is able to choose between cushioning on piston

and /or rod-side. Alternatively, the hydraulic cylinder can also

be configured so that the cushioning can be retrofitted if

necessary. The system ensures a smooth and stutter-free

acting of the hydraulic cylinder.

Seals

Seals are extremely important for the reliability of hydraulic

cylinders. Only if they are suitably chosen to the specific

application will they be long-lasting and leak-free. Liebherr

uses a compact arrangement of seals and an innovative

sealing system in this series to satisfy the most exacting of

standards. A tandem sealing system consisting of a primary

and a secondary seal is used for the rod seal. This relieves

intermediate pressure and reduces the stick-slip effect.

Bearing positions

To guarantee optimal operation of the hydraulic cylinders,

Liebherr has designed the bearing positions for maximum

loads in both static and dynamic applications. The 380 bar

series-production range employs bearing bushes with op-

timised lubrication surfaces to guarantee good emergency

running characteristics. Each bearing position is equipped

with a thread M10x1 for lubrication.

Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range 5

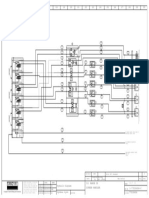

Sizes and Dimensions

L3 L4+Stroke

D4 D5

3 0° 45°

R1

0 M1

0 x1

H1

M1

H2

0x

1

D3

D

d

D2

R1

1

L1+Stroke

Basic dimensions Oil connection at piston rod end Oil connection at base

D d D2 D3 max, L1 Hub min, Hub max,* L3 D4** H1 L4 D5** H2

100 D1065 175 126 480 310 2,300 207 3/4" 88 213 D11

3/4" 73

100 70 175 126 480 310 2,300 207 3/4" 88 213 3/4" 73

105 70 175 132 480 310 2,300 203 3/4" 88 217 3/4" 73

105 75 175 132 480 310 2,300 203 3/4" 88 217 3/4" 73

110 70 175 138 480 310 2,300 199 3/4" 88 221 3/4" 73

110 75 175 138 480 310 2,300 199 3/4" 88 221 3/4" 73

L11

L11

L12

L12

115 75 180 144 520 315 2,300 231 3/4" 92 221 3/4" 81

115 80 180 144 520 315 2,300 231 3/4" 92 221 3/4" 81

120 80 190 150 520 315 2,300 234 3/4" 95 218 3/4" 81

120 85 190 150 520 315 2,300 234 3/4" 95 218 3/4" 81

125 80 L2 190 L5 157 520 315 2,300 231 3/4" 95 221 L13 3/4" 85

125 85 190 157 520 315 2,300 231 3/4" 95 221 3/4" 85

130 85 211 162 560 340 2,300 247 1" 106 237 1" 90

130 90 211 162 560 340 2,300 247 1" 106 237 1" 90

135 85 211 168 560 340 2,300 243 1" 106 241 1" 90

135 95 211 168 560 340 2,300 243 1" 106 241 1" 90

140 90 223 174 600 340 2,300 268 1" 112 252 1" 95

140 100 223 174 600 340 2,300 268 1" 112 252 1" 95

145 95 223 180 600 340 2,300 261 1" 112 259 1" 95

145 100 223 180 600 340 2,300 261 1" 112 259 1" 95

150 95 234 186 610 340 2,300 262 1" 118 263 1" 102

150 105 234 186 610 340 2,300 262 1" 118 263 1" 102

155 100 234 194 620 340 2,300 268 1 1/4" 118 267 1 1/4" 102

155 110 234 194 620 340 2,300 268 1 1/4" 118 267 1 1/4" 102

160 105 249 198 620 340 2,300 264 1 1/4" 125 271 1 1/4" 102

160 110 249 198 620 340 2,300 264 1 1/4" 126 271 1 1/4" 102

165 105 249 204 620 340 2,300 261 1 1/4" 126 274 1 1/4" 103

165 115 249 204 620 340 2,300 261 1 1/4" 126 274 1 1/4" 103

170 110 264 210 710 350 2,300 320 1 1/4" 133 290 1 1/4" 118

170 120 264 210 710 350 2,300 320 1 1/4" 133 290 1 1/4" 118

180 115 264 219 730 350 2,300 321 1 1/2" 133 304 1 1/2" 135

180 125 264 223 730 350 2,300 321 1 1/2" 133 304 1 1/2" 135

190 125 307 235 750 350 2,300 334 1 1/2" 154 311 1 1/2" 135

190 140 307 236 720 350 2,300 304 1 1/2" 154 311 1 1/2" 135

200 125 307 248 770 350 2,300 331 1 1/2" 154 329 1 1/2" 142

200 140 307 248 750 350 2,300 311 1 1/2" 154 329 1 1/2" 142

210 140 325 262 760 360 2,300 314 1 1/2" 163 336 1 1/2" 142

210 150 325 262 780 360 2,300 334 1 1/2" 163 336 1 1/2" 142

220 140 325 274 765 360 2,300 312 1 1/2" 163 343 1 1/2" 142

220 150 325 274 785 360 2,300 332 1 1/2" 163 343 1 1/2" 142

* Reduction of maximum stroke can be necessary depending on the load and the result of the buckling calculation.

** SAE-connection according to ISO 6162 6000 PSI-line.

6 Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range

0 M1

0 x1

H1

M1

H2

0x

1

D3

D

d

D2

R1

1

L1+Stroke

D10 D11

L11

L11

L12

L12

L2 L5 L13

Specific dimensions regarding mounting type Other details Volume flow at 0,1 m/s

D10 D11 Compr, Tension Piston area Annular Area VExtend VRetract

L11 L12 L2 L5 L13 R10 R11

(H9) (H9) [kN] [kN] [mm²] area [mm²] ratio [l/min] [l/min]

90 70 70 70 122 30 87 72 72 298 172 7,854 4,536 1.7 47 27

90 70 70 70 122 30 87 72 72 298 152 7,854 4,006 2.0 47 24

90 70 70 70 118 30 87 72 72 329 183 8,659 4,811 1.8 52 29

90 70 70 70 118 30 87 72 72 329 161 8,659 4,241 2.0 52 25

90 70 70 70 114 30 87 72 72 361 215 9,503 5,655 1.7 57 34

90 70 70 70 114 30 87 72 72 361 193 9,503 5,085 1.9 57 31

90 70 80 80 136 34 89 85 80 395 227 10,387 5,969 1.7 62 36

90 70 80 80 136 34 89 85 80 395 204 10,387 5,360 1.9 62 32

90 70 80 80 137 39 89 85 80 430 239 11,310 6,283 1.8 68 38

90 70 80 80 137 39 89 85 80 430 214 11,310 5,635 2.0 68 34

90 70 80 80 134 39 85 85 78 466 275 12,272 7,245 1.7 74 43

90 70 80 80 134 39 85 85 78 466 251 12,272 6,597 1.9 74 40

90 70 90 90 150 35 101 97 86 504 289 13,273 7,599 1.7 80 46

90 70 90 90 150 35 101 97 86 504 263 13,273 6,912 1.9 80 41

90 70 90 90 146 35 101 97 86 544 328 14,314 8,639 1.7 86 52

90 70 90 90 146 35 101 97 86 544 275 14,314 7,226 2.0 86 43

100 80 90 90 146 40 111 92 90 585 343 15,394 9,032 1.7 92 54

100 80 90 90 146 40 111 92 90 585 287 15,394 7,540 2.0 92 45

100 80 90 90 139 40 111 92 90 627 358 16,513 9,425 1.8 99 57

100 80 90 90 139 40 111 92 90 627 329 16,513 8,659 1.9 99 52

110 90 100 100 140 40 121 97 97 672 402 17,671 10,583 1.7 106 63

110 90 100 100 140 40 121 97 97 672 342 17,671 9,012 2.0 106 54

110 90 100 100 146 40 121 97 97 717 419 18,869 11,015 1.7 113 66

110 90 100 100 146 40 121 97 97 717 356 18,869 9,366 2.0 113 56

110 90 100 100 142 46 121 97 97 764 435 20,106 11,447 1.8 121 69

110 90 100 100 142 46 121 97 97 764 403 20,106 10,603 1.9 121 64

110 90 100 100 139 45 121 97 97 813 483 21,382 12,723 1.7 128 76

110 90 100 100 139 45 121 97 97 813 418 21,382 10,996 1.9 128 66

130 105 120 120 195 46 128 120 125 863 501 22,698 13,195 1.7 136 79

130 105 120 120 195 46 128 120 125 863 433 22,698 11,388 2.0 136 68

130 105 120 120 196 46 126 120 125 967 572 25,447 15,060 1.7 153 90

130 105 120 120 196 46 126 120 125 967 501 25,447 13,175 1.9 153 79

130 105 120 120 194 51 126 120 125 1,077 611 28,353 16,081 1.8 170 96

130 105 120 120 164 51 126 118 125 1,077 492 28,353 12,959 2.2 170 78

150 124 130 130 191 51 159 136 135 1,194 727 31,416 19,144 1.6 188 115

150 124 130 130 171 51 159 136 135 1,194 609 31,416 16,022 2.0 188 96

150 124 130 130 174 51 159 136 135 1,316 731 34,636 19,242 1.8 208 115

150 124 130 130 194 51 159 136 135 1,316 645 34,636 16,965 2.0 208 102

150 124 130 130 172 51 159 136 135 1,445 860 38,013 22,619 1.7 228 136

150 124 130 130 192 51 159 136 135 1,445 773 38,013 20,342 1.9 228 122

Note: If not otherwise indicated, all information are provided in millimetres.

Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range 7

Cylinder Selection

The table on the left gives an overview of the 380 bar Starting with the necessary tensile and compression

series-production range. Each combination of piston forces, the required combination of piston and piston

and piston rod diameter defines a basic variant. rod diameter can be determined. The surface ratio,

cylinder force and volume flow can be taken from the

table for any given piston/piston rod combination.

Calculation of Buckling and Volume Flow

Buckling calculation Force and volume flow calculations

Buckling describes the change in shape that can be These calculations provide information about the rela-

caused by a certain load. To ensure the safe design tionship between cylinder geometry, volume flow and

of hydraulic cylinders, they are examined for buckling stroke speed. The different sizes are essentially de-

resistance. The prevailing compression force (FC) must pending on each other. Please note that the volume flow

be less than or equal to the buckling force (FB) of the calculations below do not take into account all efficiency

hydraulic cylinder. This buckling calculation is an ap- levels.

proximate calculation. This can be verified by Liebherr

when a cylinder is inquired about.

Calculation of buckling force π2 × E × l D2 × π

FK = [kN] Piston surface area AK = [mm2]

as per Euler sK × L2 × 1,000 400

π

Ring surface area AR = (D2 - d2) × [mm2]

Only the second Euler case is considered for this series: 4

p × AK

Compressive force FD = [kN]

10,000

FK

p × AR

Tensile force FZ = [kN]

10,000

V l

Volume flow Q= 0.06 × A × v = _ × 60 ___

t min

A × h

Volume flow V = [l]

106

A × h × 60

Stroke time t = [s]

Q × 106

Case 2 h Q _m_

Stroke speed v = =

IK = L t × 1,000 0.06 × A s

D = Piston diameter [mm] l = Geometrical moment of inertia in mm4, FD FZ

for circular cross-section = d × π = 0.0491 × d4

4

d = Piston rod diameter [mm]

64

p = Operating pressure [bar]

E = Elasticity module in N 2 = 210,000 for steel

h = Stroke [mm] mm

L = Installation length [mm]

sK = Buckling safety factor (3 to 6)

Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range 8

General Information

The maximum operating pressures must be less than or Generelly the selected seals of the hydraulic cylinders

equal to the rated pressure of 380 bar. With increased are suitable for the operation with mineral oils. The usa

loads such as pressure peaks or a high running frequen- bility of the requested oil need to be verified by Liebherr

cy, the hydraulic cylinder design needs to be checked. in detail.

For the installation, commissioning, safe use, as well as All graphic representations serve as an example and do

the maintenance of the hydraulic cylinders in the 380 not necessarily correspond to the configured product.

bar series-production range, the relevant instruction

and maintenance manual in its most up-to-date version

must be observed.

9 Hydraulic Cylinders by Liebherr, 380 bar Series-Production Range

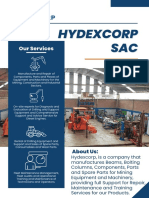

Liebherr Components

Gas engines Diesel engines Fuel injection systems Axial piston hydraulics Hydraulic cylinders

Slewing bearings Gearboxes and winches Electric machines Remanufacturing

Human-machine interfaces Control electronics and Power electronics Control cabinets Software

and gateways sensor technology

From A to Z – the components division of the Liebherr Group Components AG and the regional sales and distribution

offers a broad range of solutions in the area of mechanical, branches.

hydraulic, electric and electronic drive system and control

technology. The efficient components and systems are pro- Liebherr is your partner for joint success: from the product

duced at a total of ten production sites around the world to idea to development, manufacture and commissioning right

the highest standards of quality. Central contact persons for through to customer service solutions like remanufacturing.

all product lines are available to our customers at Liebherr-

Printed in Germany by Schirmer BK HyZ-SPR380-PB-03.19-0.1-en

components.liebherr.com

Subject to technical modifications.

Liebherr-Components AG Liebherr USA, CO.

Post box 222, CH-5415 Nussbaumen / AG 1465 Woodland Drive, Saline, MI 48176, USA

+41 56 296 43 00 +1 734 944 63 34

components@liebherr.com components.usa@liebherr.com

S-ar putea să vă placă și

- IC Project Report Dashboard 10673 0Document6 paginiIC Project Report Dashboard 10673 0Anonymous Sls6WCF100% (2)

- Fire InvestigationDocument126 paginiFire InvestigationAbcede IloiloÎncă nu există evaluări

- Fundamentals of Bearings and SealsDocument26 paginiFundamentals of Bearings and SealscarlHoughÎncă nu există evaluări

- 1323Document75 pagini1323Werner SchulzÎncă nu există evaluări

- 5370Document300 pagini5370Arnaldo BenitezÎncă nu există evaluări

- 3 Statement Model: Strictly ConfidentialDocument13 pagini3 Statement Model: Strictly ConfidentialLalit mohan PradhanÎncă nu există evaluări

- Liebherr Hobbing Machines lc200 500Document8 paginiLiebherr Hobbing Machines lc200 500Jesus D. Gutierrez G.Încă nu există evaluări

- Gleitlager enDocument32 paginiGleitlager enMarcelo Topon100% (1)

- At Ti Automatic Transmission Fluids: Mti TBB Martin TabbeyDocument40 paginiAt Ti Automatic Transmission Fluids: Mti TBB Martin TabbeygaryvarnerÎncă nu există evaluări

- USAIRTOWER AirtowerSeries 07-2019!46!37027Document8 paginiUSAIRTOWER AirtowerSeries 07-2019!46!37027vkees1987Încă nu există evaluări

- Concrete Mix DesignDocument11 paginiConcrete Mix DesignV Vinoth Edac100% (1)

- Rmhofffman Vigo Grease Reo Data 2015Document1 paginăRmhofffman Vigo Grease Reo Data 2015Noche de EstrellasÎncă nu există evaluări

- Haitian Series: Haitian Partner: Haitian International Holdings LimitedDocument6 paginiHaitian Series: Haitian Partner: Haitian International Holdings LimitedsandulupeniÎncă nu există evaluări

- Catalogue V20 PDFDocument404 paginiCatalogue V20 PDFUstad Remy0% (1)

- Re17002 CDM1Document12 paginiRe17002 CDM1Kaushik GhoshÎncă nu există evaluări

- Why SKF? Single Row Cylindrical Roller Bearings: Common ApplicationsDocument2 paginiWhy SKF? Single Row Cylindrical Roller Bearings: Common ApplicationsDebabrata PaulÎncă nu există evaluări

- Types of Hydraulic FluidsDocument5 paginiTypes of Hydraulic FluidsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjÎncă nu există evaluări

- Mil PRF 87100a PDFDocument12 paginiMil PRF 87100a PDFNadia SalemÎncă nu există evaluări

- CM2309 en SKF Machine Analyst-TrendOilDocument4 paginiCM2309 en SKF Machine Analyst-TrendOilcarlosÎncă nu există evaluări

- Haitian Jupiter SeriesDocument4 paginiHaitian Jupiter SeriesRenardÎncă nu există evaluări

- Hydraulic FluidDocument6 paginiHydraulic FluidDesiree Cena CapunoÎncă nu există evaluări

- 3M Selection GuideDocument4 pagini3M Selection Guideechobravo1Încă nu există evaluări

- Haitian Series: Haitian International Holdings LimitedDocument6 paginiHaitian Series: Haitian International Holdings LimitedDenisa PopÎncă nu există evaluări

- Rexroth Drive R911322210 08Document334 paginiRexroth Drive R911322210 08Priyank JainÎncă nu există evaluări

- Exactra 2014 PDFDocument52 paginiExactra 2014 PDFUsuarioTurbio0% (1)

- MA 3 Plus 700 3500Document4 paginiMA 3 Plus 700 3500ismail.guendouz19881988100% (1)

- 6698 en Hub UnitsDocument13 pagini6698 en Hub UnitsAlvaro MunozÎncă nu există evaluări

- Erc Series Brochure PDFDocument4 paginiErc Series Brochure PDFmouh omariÎncă nu există evaluări

- Mobile Cylinder Div.: Dump Product & Quick Reference GuideDocument56 paginiMobile Cylinder Div.: Dump Product & Quick Reference GuideMario JayaÎncă nu există evaluări

- Haitian Mars H Series SpecificationsDocument6 paginiHaitian Mars H Series SpecificationsHau TranÎncă nu există evaluări

- RotarySeals EPS5350 Usa PDFDocument434 paginiRotarySeals EPS5350 Usa PDFJose Paulo Dal PontÎncă nu există evaluări

- Unit 2 MCB Key PDFDocument19 paginiUnit 2 MCB Key PDFDafne Fertig88% (32)

- Mothballing Requires More Than Idle ThoughtDocument4 paginiMothballing Requires More Than Idle Thoughtfawmer61Încă nu există evaluări

- Seria MX PrezDocument57 paginiSeria MX PrezPablo Alejandro Barra Castro100% (1)

- Tech Haitian Mars 2 en PDFDocument4 paginiTech Haitian Mars 2 en PDFHau TranÎncă nu există evaluări

- Hydroline R5a5 - 2Document34 paginiHydroline R5a5 - 2HYDRAULICGURUÎncă nu există evaluări

- 6.13 - E7011-3-11-16 - Handbook Filtration - HYDAC International PDFDocument22 pagini6.13 - E7011-3-11-16 - Handbook Filtration - HYDAC International PDFMaximiliano DreyerÎncă nu există evaluări

- 951 130 407 enDocument26 pagini951 130 407 enli geneÎncă nu există evaluări

- NS Specs 2-15-16 High ResDocument2 paginiNS Specs 2-15-16 High ResMarti PrakosoÎncă nu există evaluări

- Rolamentos e Retentores - Falk-Type-YB,-YBTDocument5 paginiRolamentos e Retentores - Falk-Type-YB,-YBTVendedorÎncă nu există evaluări

- HT DOC MA2 Image GB EU V14Document9 paginiHT DOC MA2 Image GB EU V14Hau TranÎncă nu există evaluări

- Micro Crack AdvantagesDocument2 paginiMicro Crack AdvantageshycromeÎncă nu există evaluări

- Lubricant Properties CalculatorDocument10 paginiLubricant Properties CalculatorAlberico Muratori0% (1)

- Seal Friction Parker SealsDocument6 paginiSeal Friction Parker SealsChristian MavarezÎncă nu există evaluări

- Design of Hyd. CylindersDocument10 paginiDesign of Hyd. CylindersVinod YbÎncă nu există evaluări

- ARO Piston Pump ApplicationsDocument57 paginiARO Piston Pump ApplicationskenriÎncă nu există evaluări

- EN3553 Hydrospeicher-Nachschaltung KatalogversionDocument8 paginiEN3553 Hydrospeicher-Nachschaltung KatalogversionsivakumarÎncă nu există evaluări

- Design Guide - O-Ring, Quad-Ring, TrelleborgDocument32 paginiDesign Guide - O-Ring, Quad-Ring, TrelleborgDerekÎncă nu există evaluări

- Flender Gearbox Lubricant 7300 (En)Document28 paginiFlender Gearbox Lubricant 7300 (En)samer salamehÎncă nu există evaluări

- 08 PU-lubrication Pinion For Gearings PDFDocument4 pagini08 PU-lubrication Pinion For Gearings PDFSugiharto RichardÎncă nu există evaluări

- Vertical Allrounders: For Inserts: Problem-Free, Ergonomic EncapsulationDocument20 paginiVertical Allrounders: For Inserts: Problem-Free, Ergonomic EncapsulationmadalinÎncă nu există evaluări

- En GRAVICOLOR 60 100Document4 paginiEn GRAVICOLOR 60 100tryÎncă nu există evaluări

- Single Line Progressive SystemsDocument70 paginiSingle Line Progressive SystemsOverhaul QAÎncă nu există evaluări

- Kubota Super UDT2 Fluid PI SheetDocument2 paginiKubota Super UDT2 Fluid PI Sheetcamilo ZambranoÎncă nu există evaluări

- Haitian Jupiter SeriesDocument6 paginiHaitian Jupiter SeriesClaudio Rafael Deola SadaÎncă nu există evaluări

- Flextec 500P PDFDocument12 paginiFlextec 500P PDFjuanchepeinÎncă nu există evaluări

- Foodec 800Document4 paginiFoodec 800vinayak gaikwadÎncă nu există evaluări

- Bechem AL20Document1 paginăBechem AL20Anil NegiÎncă nu există evaluări

- RS Clare Oil & Gas BrochureDocument12 paginiRS Clare Oil & Gas BrochureVALENTIN PATRASÎncă nu există evaluări

- OEM Approval GuideDocument8 paginiOEM Approval GuideEsteban Fernando Meza IbacetaÎncă nu există evaluări

- E04 Using Kalsi Seals in Washpipe AssembliesDocument17 paginiE04 Using Kalsi Seals in Washpipe AssembliesSuresh Kumar MittapalliÎncă nu există evaluări

- Ecco Finishing-Airless Oprema Za Farbanje VP Bez Vazduha-EDocument18 paginiEcco Finishing-Airless Oprema Za Farbanje VP Bez Vazduha-EPithakaras CasparÎncă nu există evaluări

- Mav 2005 InstalationDocument1 paginăMav 2005 InstalationCamilo Andrés Nope FajardoÎncă nu există evaluări

- Tamaños AcoplesDocument2 paginiTamaños AcoplesJohnny Diaz VargasÎncă nu există evaluări

- Liebherr Hydraulic Cylinders Series Prduction RangeDocument10 paginiLiebherr Hydraulic Cylinders Series Prduction RangeCharlie QiÎncă nu există evaluări

- Valve Automation BrochureDocument8 paginiValve Automation BrochuresalemÎncă nu există evaluări

- KKI Series 1200 and 7200Document18 paginiKKI Series 1200 and 7200Tabiquera Guadalupe Victoria Texcoco De Mora100% (1)

- DNM S SeriesDocument20 paginiDNM S SeriesJesus D. Gutierrez G.Încă nu există evaluări

- SandvikDocument1 paginăSandvikJesus D. Gutierrez G.Încă nu există evaluări

- A Different Financial EducationDocument110 paginiA Different Financial EducationJesus D. Gutierrez G.Încă nu există evaluări

- Doosan VMC BVM 5700Document16 paginiDoosan VMC BVM 5700Jesus D. Gutierrez G.Încă nu există evaluări

- IndexDocument4 paginiIndexJesus D. Gutierrez G.Încă nu există evaluări

- MSDS Alloys Delivered From UDDEHOLM-2Document8 paginiMSDS Alloys Delivered From UDDEHOLM-2Jesus D. Gutierrez G.Încă nu există evaluări

- Alumec 89 Eng - P - 1910 E7Document12 paginiAlumec 89 Eng - P - 1910 E7Jesus D. Gutierrez G.Încă nu există evaluări

- DIN ISO 513 Comparison Chart Grades For MillingDocument1 paginăDIN ISO 513 Comparison Chart Grades For MillingJesus D. Gutierrez G.Încă nu există evaluări

- Company Profile FlyerDocument2 paginiCompany Profile FlyerJesus D. Gutierrez G.Încă nu există evaluări

- Foodpro Epdm Materials enDocument8 paginiFoodpro Epdm Materials enJesus D. Gutierrez G.Încă nu există evaluări

- Advanced Composite Solutions enDocument2 paginiAdvanced Composite Solutions enJesus D. Gutierrez G.Încă nu există evaluări

- Instruction Sheet Sequence Valves MVP-5, WVP-5, MVPM-5: 1.0 Important Receiving Instructions EIS 57.111-2 Rev. A 10/00Document4 paginiInstruction Sheet Sequence Valves MVP-5, WVP-5, MVPM-5: 1.0 Important Receiving Instructions EIS 57.111-2 Rev. A 10/00Jesus D. Gutierrez G.Încă nu există evaluări

- Pages From Printout - PDF Gobernador 1,1 Hidromac.Document55 paginiPages From Printout - PDF Gobernador 1,1 Hidromac.Jesus D. Gutierrez G.100% (1)

- OT SC Mod N/P N/P Troquela DODocument4 paginiOT SC Mod N/P N/P Troquela DOJesus D. Gutierrez G.Încă nu există evaluări

- Par - 40833 - en - 05 Parametros de Aplicacion HvofDocument22 paginiPar - 40833 - en - 05 Parametros de Aplicacion HvofJesus D. Gutierrez G.Încă nu există evaluări

- Anti Bond MetcoDocument4 paginiAnti Bond MetcoJesus D. Gutierrez G.Încă nu există evaluări

- 14" Surfacing Cutterhead: Options F90Y ManualDocument3 pagini14" Surfacing Cutterhead: Options F90Y ManualJesus D. Gutierrez G.Încă nu există evaluări

- Rottler Manufacturing Company: Performance Racing & Engine Rebuilding Machinery & EquipmentDocument2 paginiRottler Manufacturing Company: Performance Racing & Engine Rebuilding Machinery & EquipmentJesus D. Gutierrez G.Încă nu există evaluări

- Centro Mecanizado de 5 Ejes HAAS PDFDocument4 paginiCentro Mecanizado de 5 Ejes HAAS PDFJesus D. Gutierrez G.Încă nu există evaluări

- Status Pro 2Document2 paginiStatus Pro 2Jesus D. Gutierrez G.Încă nu există evaluări

- DSMTS-0052.7 NiCr Wires PDFDocument4 paginiDSMTS-0052.7 NiCr Wires PDFJesus D. Gutierrez G.Încă nu există evaluări

- DSMTS-0063.1 FeMo Wire PDFDocument2 paginiDSMTS-0063.1 FeMo Wire PDFJesus D. Gutierrez G.Încă nu există evaluări

- Centro de Torneado HAAS PDFDocument4 paginiCentro de Torneado HAAS PDFJesus D. Gutierrez G.Încă nu există evaluări

- 2019 - S80 - Rectificadora de Camaras RottlerDocument5 pagini2019 - S80 - Rectificadora de Camaras RottlerJesus D. Gutierrez G.Încă nu există evaluări

- DSMTS-0032.5 FeCr StainlessSteel WireDocument4 paginiDSMTS-0032.5 FeCr StainlessSteel WireJesus D. Gutierrez G.Încă nu există evaluări

- Material Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersDocument4 paginiMaterial Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersJesus D. Gutierrez G.Încă nu există evaluări

- Chapter 8Document7 paginiChapter 8Maiane JunqueiraÎncă nu există evaluări

- Coding 3 D ShapesDocument10 paginiCoding 3 D ShapesgmconÎncă nu există evaluări

- Theories and Methods of Two Way Slab Design-5-8-2017Document3 paginiTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320Încă nu există evaluări

- Review For Final ExamDocument29 paginiReview For Final ExamhaddanÎncă nu există evaluări

- 5.4.1 EM Patch Release NotesDocument11 pagini5.4.1 EM Patch Release Notessuraj saketÎncă nu există evaluări

- Mac Keyboard ShortcutsDocument16 paginiMac Keyboard ShortcutsSaira FazalÎncă nu există evaluări

- Seborg Chapter 1Document3 paginiSeborg Chapter 1maykesguerraÎncă nu există evaluări

- Pre-Assessment Form Problem Solving Techniques (2 Day Course)Document1 paginăPre-Assessment Form Problem Solving Techniques (2 Day Course)sumit1975Încă nu există evaluări

- LS Retail Data Director User GuideDocument28 paginiLS Retail Data Director User GuideJad EL HittiÎncă nu există evaluări

- Computer Networks: Introduction (Chapter 1)Document92 paginiComputer Networks: Introduction (Chapter 1)Speed PianoÎncă nu există evaluări

- X++ Control StatementsDocument42 paginiX++ Control StatementsHarish MehraÎncă nu există evaluări

- 1SC0 2PF Exam-Paper 20180616Document20 pagini1SC0 2PF Exam-Paper 20180616Thasanya AlgamaÎncă nu există evaluări

- Thermodynamics NotesDocument2 paginiThermodynamics Notesjpu_48Încă nu există evaluări

- HSSC G PhysicsDocument78 paginiHSSC G Physicshasnain ghazalaÎncă nu există evaluări

- Python Fundamentals SheetDocument29 paginiPython Fundamentals Sheetwp1barabaÎncă nu există evaluări

- Battery SubsystemDocument7 paginiBattery SubsystemahmaborashedÎncă nu există evaluări

- Operating and Maintenance Manual 322375H01 Rev CDocument82 paginiOperating and Maintenance Manual 322375H01 Rev CGustavo BarbosaÎncă nu există evaluări

- X2IPI ManualDocument51 paginiX2IPI ManualFadiliAhmedÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1Document17 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1BukÎncă nu există evaluări

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteDocument4 paginiStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniÎncă nu există evaluări

- HR Wallingford-009 - Wave - GaugeDocument2 paginiHR Wallingford-009 - Wave - GaugeSutanto HadiÎncă nu există evaluări

- 1 Egg & Egg Cookery LectureDocument15 pagini1 Egg & Egg Cookery LectureErin DelavinÎncă nu există evaluări

- Ece R13Document36 paginiEce R13DilipReddiarÎncă nu există evaluări

- Periodic Table of ElementsDocument60 paginiPeriodic Table of ElementsruchitlpatelÎncă nu există evaluări