Documente Academic

Documente Profesional

Documente Cultură

3-Reactor, ESTA 7 PDF

Încărcat de

Martono Abu Hanif0 evaluări0% au considerat acest document util (0 voturi)

79 vizualizări1 paginăTitlu original

3-Reactor,ESTA 7.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

79 vizualizări1 pagină3-Reactor, ESTA 7 PDF

Încărcat de

Martono Abu HanifDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

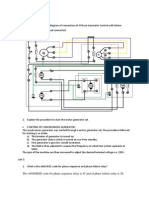

ESTA 7% Detuned reactor - for use in PF Correction capacitor bank

Why use a harmonic filter reactor in a power factor correction capacitor bank?

1. Capacitor are required to improve power factor, and possible system interaction may occur with the

installation of a plain capacitor bank.

2. Permissible distortion limits of the local utility or IEEE-519 are

exceeded, and filters are required to reduced them.

3. A combination of 1 & 2 above, whereby capacitor are required

to improve power factor and with the addition of the capacitors,

permissible distortion limits are exceeded.

Benefit of using ESTA De-tuned reactor .

1. Pro-long the life of power factor capacitor by reducing

overheating, or fuse failure.

2. Prevent nuisance input fuse blowing or circuit breaker tripping.

3. Reduce over heating of transformer.

4. Reduce the harmonic current in the electrical supply system.

5. Addressing the harmonic problems created by non-linear load such as AFD's, AC-DC converter, DC

drives, welding m/c etc.

** The use of specific filtering factor requires careful system analysis. As a general rule, filtering factor

p=7% is used where imported harmonics from the power source is the main concern.

Specification of ESTA De-tuned reactor p=7% .

1. The reactor is manufactured to withstand 125% capacitor current (I1) at its rated operating voltage.

2. Harmonic current handling capacity (for p=7% de-tuned reactor):

I1 = 1.06 Ic ( fundamental current )

I3 = 0.04 x I1 ( 3rd harmonic. )

I5 = 0.31 x I1 ( 5th harmonic. )

I7 = 0.13 x I1 ( 7th harmonic. )

I th =1.25x I1

3. Inductance tolerance is manufactured to be less than ± 3%, for admissible capacitor tolerance of ± 5%.

4. Reactor Linearity Reactors still have 100% of their nominal inductance at 150% of their rated current.

This assures maximum filtering of distortion even in the presence of severe harmonics and best

absorption of surges.

5. Saturation of iron core: The reactor will not saturated (a drop of

10% of the inductance value) at 175% of rated current.

6. Design: comply to IEC 289.

7. Insulation class - Class H 180ºC. Vacumm pressure inpregnated

varnishing.

8. Operating temperature: 135ºC temperature rise at max. ambient

temperature of 40°C. Thermostat 145°C (NC) is fitted to the coil

windings for over temperature protection.

9. Testing: Insulation strength tested at 3.0kV.

10.Noise level: below 55db. - reactor will not hum at no harmonics condition.

*** Other specification available upon request.

S-ar putea să vă placă și

- Detuned, Series Filter Reactor For Power Factor Corection CapacitorDocument5 paginiDetuned, Series Filter Reactor For Power Factor Corection CapacitorNghia NguyenÎncă nu există evaluări

- Capacitor Bank PDFDocument2 paginiCapacitor Bank PDFsapnaadiyodiÎncă nu există evaluări

- Chapter 7Document62 paginiChapter 7alhajriaxÎncă nu există evaluări

- Diff ProtnDocument3 paginiDiff ProtnAtulya Kumar NaikÎncă nu există evaluări

- Lec7 Generator ProtectionDocument53 paginiLec7 Generator ProtectionEVTÎncă nu există evaluări

- Research On Reactive Power Compensation Mode and Harmonic Wave Control Technique For Submerged Arc FurnaceDocument4 paginiResearch On Reactive Power Compensation Mode and Harmonic Wave Control Technique For Submerged Arc FurnaceSEP-PublisherÎncă nu există evaluări

- EC-8453 Linear Integrated Circuits QA BankDocument7 paginiEC-8453 Linear Integrated Circuits QA Banksanthosh sekarÎncă nu există evaluări

- Static Excitation SystemDocument44 paginiStatic Excitation Systemgigelu79Încă nu există evaluări

- Over Current Protection AnnexDocument20 paginiOver Current Protection Annexryumadmax100% (1)

- AN-182 Improving Power Supply Reliability With IC Power RegulatorsDocument5 paginiAN-182 Improving Power Supply Reliability With IC Power Regulatorshooman9999Încă nu există evaluări

- 7PG1903 B3 Catalogue Sheet PDFDocument5 pagini7PG1903 B3 Catalogue Sheet PDFAhmed HussainÎncă nu există evaluări

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument28 paginiPower Systems Protection Course: Al-Balqa Applied UniversityPIOS CHICKENÎncă nu există evaluări

- Designing Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558Document15 paginiDesigning Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558PredragPeđaMarkovićÎncă nu există evaluări

- IEEE Standards Interpretations For IEEE STD 18™-2002 IEEE Standard For Shunt Power CapacitorsDocument3 paginiIEEE Standards Interpretations For IEEE STD 18™-2002 IEEE Standard For Shunt Power CapacitorsAndres Alva JustoÎncă nu există evaluări

- English Service Manual RAINBOW200HFDocument52 paginiEnglish Service Manual RAINBOW200HFJaroslaw BrzozowskiÎncă nu există evaluări

- Application Note Protection ClassDocument5 paginiApplication Note Protection ClassshuwingÎncă nu există evaluări

- The ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58Document9 paginiThe ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58ax33m144Încă nu există evaluări

- Ee6303 - Linear Integrated Circuits and ApplicationsDocument19 paginiEe6303 - Linear Integrated Circuits and ApplicationsBALAKRISHNANÎncă nu există evaluări

- Protection Principles and ComponentsDocument57 paginiProtection Principles and Componentsyibelta abebeÎncă nu există evaluări

- 5B3 Fact Sheet (New)Document4 pagini5B3 Fact Sheet (New)Nikunj DaveÎncă nu există evaluări

- Automatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksDocument13 paginiAutomatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksBrajan's B.Încă nu există evaluări

- Question Bank, 2 Marks With AnswersDocument30 paginiQuestion Bank, 2 Marks With AnswersbinukirubaÎncă nu există evaluări

- Rotating diode exciter design for nuclear plantsDocument9 paginiRotating diode exciter design for nuclear plantsR0B0T2013Încă nu există evaluări

- Industrial Power System Protection Series - Differential ProtectionDocument9 paginiIndustrial Power System Protection Series - Differential Protectionlakthant7967Încă nu există evaluări

- PCB Layout GuidelinesDocument3 paginiPCB Layout GuidelinesChindris IoanÎncă nu există evaluări

- 06-Rotating Machinery ProtectionDocument20 pagini06-Rotating Machinery Protectionfdsfs2131Încă nu există evaluări

- Generator Protection XZCDocument25 paginiGenerator Protection XZCblaagica100% (1)

- Ee6303 - Linear Integrated Circuits and Applications Unit-I Circuit Configuration For Linear IcsDocument18 paginiEe6303 - Linear Integrated Circuits and Applications Unit-I Circuit Configuration For Linear IcsNarasimha KumarÎncă nu există evaluări

- Single Phasing EffectsDocument41 paginiSingle Phasing EffectsdiljithÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionÎncă nu există evaluări

- Reverse Power Protection of Alternator PDFDocument29 paginiReverse Power Protection of Alternator PDFjupiterox75% (4)

- Generator ProtectionDocument62 paginiGenerator ProtectionCorey PorterÎncă nu există evaluări

- Differential RelayDocument24 paginiDifferential RelayMortuzaÎncă nu există evaluări

- RFL 9550 Line TrapDocument12 paginiRFL 9550 Line TrapSINU0607IITEEEÎncă nu există evaluări

- Generator ,-3Document16 paginiGenerator ,-3IbrahimÎncă nu există evaluări

- Harmonic Filter Design Case StudyDocument26 paginiHarmonic Filter Design Case StudyAlfredo Lopez CordovaÎncă nu există evaluări

- Lic QB With AnswerDocument29 paginiLic QB With AnswerNoddy SenÎncă nu există evaluări

- Chapter-4 Power System Apparatus ProtectionDocument33 paginiChapter-4 Power System Apparatus ProtectionKeneni AlemayehuÎncă nu există evaluări

- 2 Marks Ldica NotesDocument8 pagini2 Marks Ldica NotesRAJOLI GIRISAI MADHAV100% (2)

- Mit 161Document24 paginiMit 161Santosh Gairhe100% (1)

- Easun Reyrolle Limited: Application and Commissioning Manual Mit161 RelayDocument24 paginiEasun Reyrolle Limited: Application and Commissioning Manual Mit161 RelaySumonto MajiÎncă nu există evaluări

- Generator Earthing and Stator Earth Fault ProtectionDocument9 paginiGenerator Earthing and Stator Earth Fault ProtectionYousif_AbdalhalimÎncă nu există evaluări

- Manual 2Document0 paginiManual 2Rafat ThongÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- 12 Steps For Designing Toroidal TransformersDocument9 pagini12 Steps For Designing Toroidal TransformersFernando SotoÎncă nu există evaluări

- Low Impedance Restricted Earth Fault ProtectionDocument4 paginiLow Impedance Restricted Earth Fault ProtectionGary_Tan_Kai_S_9974Încă nu există evaluări

- Power Supply DesignDocument8 paginiPower Supply DesigndarknessmonÎncă nu există evaluări

- Cautions For Using Aluminum Electrolytic CapacitorsDocument4 paginiCautions For Using Aluminum Electrolytic CapacitorsFrank GonzalezÎncă nu există evaluări

- Generator Earthing and Stator Earth Fault ProtectionDocument17 paginiGenerator Earthing and Stator Earth Fault ProtectionjosehenriquezsotoÎncă nu există evaluări

- LINEAR INTEGRATED CIRCUITS AND APPLICATIONS (2 Marks)Document16 paginiLINEAR INTEGRATED CIRCUITS AND APPLICATIONS (2 Marks)Gokul G-Factor Kumar100% (5)

- Design and Research of 110kv Intelligent SubstatioDocument10 paginiDesign and Research of 110kv Intelligent SubstatioJihad Hossain AkibÎncă nu există evaluări

- 700KVA-50KV Test Device ManualDocument22 pagini700KVA-50KV Test Device ManualFrank LinÎncă nu există evaluări

- Assignment - ENT777 - 2022Document5 paginiAssignment - ENT777 - 2022teektak1Încă nu există evaluări

- Linear IC ApplicationsDocument8 paginiLinear IC ApplicationsSwarna SugandhÎncă nu există evaluări

- Differential ProtectionDocument8 paginiDifferential Protectionchandra_shekhar2221941Încă nu există evaluări

- E01 GeneratorDocument28 paginiE01 GeneratorvenkateshbitraÎncă nu există evaluări

- Sizing Grounding Transformers and ResistorsDocument12 paginiSizing Grounding Transformers and ResistorsRajendra Prasad ShuklaÎncă nu există evaluări

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe la EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- IEEE STD 519 1992vs2014Document50 paginiIEEE STD 519 1992vs2014DaniNurFaruqÎncă nu există evaluări

- The Ranges: ABB Catalogue - 2/1Document3 paginiThe Ranges: ABB Catalogue - 2/1Martono Abu HanifÎncă nu există evaluări

- IMC-III Eng ManualDocument19 paginiIMC-III Eng ManualMartono Abu HanifÎncă nu există evaluări

- IEEE 519 harmonic limits guideDocument3 paginiIEEE 519 harmonic limits guideMartono Abu HanifÎncă nu există evaluări

- FR F800 Mitsubishi Inverter PDFDocument28 paginiFR F800 Mitsubishi Inverter PDFMartono Abu HanifÎncă nu există evaluări

- 2CDS241001R0064 Miniature Circuit Breaker sh200l 1p C 6 Ampere PDFDocument4 pagini2CDS241001R0064 Miniature Circuit Breaker sh200l 1p C 6 Ampere PDFMartono Abu HanifÎncă nu există evaluări

- ES Instruction PDFDocument5 paginiES Instruction PDFMartono Abu HanifÎncă nu există evaluări

- Use 7% detuned reactor for power factor correctionDocument1 paginăUse 7% detuned reactor for power factor correctionMartono Abu HanifÎncă nu există evaluări

- Hi Power 24kV MCSG Manual - EN PDFDocument74 paginiHi Power 24kV MCSG Manual - EN PDFMartono Abu HanifÎncă nu există evaluări

- ACB Maintenance ProcedureDocument1 paginăACB Maintenance ProcedureMartono Abu HanifÎncă nu există evaluări

- 2CDS241001R0064 Miniature Circuit Breaker sh200l 1p C 6 Ampere PDFDocument4 pagini2CDS241001R0064 Miniature Circuit Breaker sh200l 1p C 6 Ampere PDFMartono Abu HanifÎncă nu există evaluări

- ES Instruction PDFDocument5 paginiES Instruction PDFMartono Abu HanifÎncă nu există evaluări

- MCSG TA Biz Proposal PDFDocument24 paginiMCSG TA Biz Proposal PDFMartono Abu HanifÎncă nu există evaluări

- EmsDocument1 paginăEmsMartono Abu HanifÎncă nu există evaluări

- Setup and configure Siemens 7SJ602 multifunction relayDocument300 paginiSetup and configure Siemens 7SJ602 multifunction relayNí HảoÎncă nu există evaluări

- 3-8 Operation and Maintenance of Protective Relays and Associated Circuits (September 2006)Document88 pagini3-8 Operation and Maintenance of Protective Relays and Associated Circuits (September 2006)Yogesh BadheÎncă nu există evaluări

- The Ranges: ABB Catalogue - 2/1Document3 paginiThe Ranges: ABB Catalogue - 2/1Martono Abu HanifÎncă nu există evaluări

- Sliding Table Eng 20140102Document1 paginăSliding Table Eng 20140102Martono Abu HanifÎncă nu există evaluări

- ANSI Codes PDFDocument3 paginiANSI Codes PDFelectrical_1012000100% (2)

- ANSI Device NumbersDocument7 paginiANSI Device Numbersrajpre1213Încă nu există evaluări

- C4P ICPERE2016 Extended PDFDocument1 paginăC4P ICPERE2016 Extended PDFMartono Abu HanifÎncă nu există evaluări

- Principles of Differential RelayingDocument115 paginiPrinciples of Differential RelayingelitesankarÎncă nu există evaluări

- Table Cascading MCCB-MCCBDocument13 paginiTable Cascading MCCB-MCCBMartono Abu HanifÎncă nu există evaluări

- C4P ICPERE2016 ExtendedDocument1 paginăC4P ICPERE2016 ExtendedMartono Abu HanifÎncă nu există evaluări

- Stdxi Voc Ema em 1 PDFDocument263 paginiStdxi Voc Ema em 1 PDFDino AlajbegovicÎncă nu există evaluări

- 87vex Umeng0000Document64 pagini87vex Umeng0000cristachedinuÎncă nu există evaluări

- Ascii Code Control CharacterDocument2 paginiAscii Code Control CharacterMartono Abu HanifÎncă nu există evaluări

- IEC 60815-1, Aisladores HV, Definiciones PDFDocument30 paginiIEC 60815-1, Aisladores HV, Definiciones PDFarturoncÎncă nu există evaluări

- Bonding and GroundingDocument183 paginiBonding and Groundingbanjan0230Încă nu există evaluări

- PNOZ X2.1: Safety RelaysDocument18 paginiPNOZ X2.1: Safety RelaysgustavoÎncă nu există evaluări

- 271 Chroma 66205Document170 pagini271 Chroma 66205Oscar MendozaÎncă nu există evaluări

- Substation Commissioning 2Document4 paginiSubstation Commissioning 2Helmy RosadiÎncă nu există evaluări

- XC Hardware ManualDocument138 paginiXC Hardware ManualSeferino CampazÎncă nu există evaluări

- Jntuhb - Tech 3-1 - r16Document18 paginiJntuhb - Tech 3-1 - r16lakshmilavanyaÎncă nu există evaluări

- IGCSE Physics Formula SheetDocument5 paginiIGCSE Physics Formula SheetBrandly NyamapnziÎncă nu există evaluări

- Hvdc-Light Technology: Presented byDocument15 paginiHvdc-Light Technology: Presented bypodila lavanya lavanyaÎncă nu există evaluări

- PCD3.M9: User ManualDocument30 paginiPCD3.M9: User Manualalex140979Încă nu există evaluări

- Specification for Disk Varistor ReleaseDocument4 paginiSpecification for Disk Varistor ReleaseGonzalo RojasÎncă nu există evaluări

- T495D336K025ATE090Document1 paginăT495D336K025ATE090snow69yÎncă nu există evaluări

- Proflame™ Integrated Flame Scanner: Model Zpf-120Document2 paginiProflame™ Integrated Flame Scanner: Model Zpf-120angel anastacioÎncă nu există evaluări

- Modeling and Simulation of Distribution Network with Solar Inverter InterconnectionDocument8 paginiModeling and Simulation of Distribution Network with Solar Inverter InterconnectionAli HadiÎncă nu există evaluări

- Kailh CPG1511F01S172Document14 paginiKailh CPG1511F01S172xujiaqi730Încă nu există evaluări

- Rain Water Detector Project - FinalDocument14 paginiRain Water Detector Project - FinalKapil Rathod100% (1)

- SOUND IMPACT Lights and Sounds (Revised Contract For Wedding at Lakeshore, 102514)Document6 paginiSOUND IMPACT Lights and Sounds (Revised Contract For Wedding at Lakeshore, 102514)Lowela Aileen Limbaring100% (5)

- Advances in Earthing Methods and TechnologiesDocument20 paginiAdvances in Earthing Methods and TechnologiesR. K. ViralÎncă nu există evaluări

- Operation Manual: Smart-UPS On-Line SRT Uninterruptible Power SupplyDocument37 paginiOperation Manual: Smart-UPS On-Line SRT Uninterruptible Power SupplyKudzaishe MutambaneshiriÎncă nu există evaluări

- CR800 Series Controller INSTRUCTION MANUAL Controller Setup, Basic Operation, and Maintenance Bfp-A3476dDocument90 paginiCR800 Series Controller INSTRUCTION MANUAL Controller Setup, Basic Operation, and Maintenance Bfp-A3476dLuật NguyễnÎncă nu există evaluări

- New Pricelist for Energy ProductsDocument20 paginiNew Pricelist for Energy Productsjcolmosmora5212Încă nu există evaluări

- Vacon Nxs Robust Drive For Heavy UseDocument11 paginiVacon Nxs Robust Drive For Heavy UseLuis PinedaÎncă nu există evaluări

- SDMyers Test Packages BrochureDocument4 paginiSDMyers Test Packages BrochureYesid FigueroaÎncă nu există evaluări

- Power System Commissioning and Maintenance PracticeDocument38 paginiPower System Commissioning and Maintenance PracticeMohamed MohsenÎncă nu există evaluări

- Service Manual: VOLKSWAGEN Automobile Genuine AM/FM Radio Cassette/ CD StereoDocument24 paginiService Manual: VOLKSWAGEN Automobile Genuine AM/FM Radio Cassette/ CD StereoGB EletronicaÎncă nu există evaluări

- FSL206MRDocument16 paginiFSL206MRnightreader99Încă nu există evaluări

- Electric Vehicle Conductive Charging System: Indian StandardDocument54 paginiElectric Vehicle Conductive Charging System: Indian StandardSharath Kumar100% (1)

- AOYG 18 LAC2 - Outdoor PCB DiagramsDocument4 paginiAOYG 18 LAC2 - Outdoor PCB DiagramsJack BilyÎncă nu există evaluări

- Communication Frequencies and Signal PropagationDocument11 paginiCommunication Frequencies and Signal PropagationAkash SharmaÎncă nu există evaluări

- Basic Electronics HandoutDocument34 paginiBasic Electronics Handoutamanuelfitsum589Încă nu există evaluări

- Steval lll012v1Document5 paginiSteval lll012v1Angelė LÎncă nu există evaluări

- Kistler Accelerometer K-Beam 8212BDocument3 paginiKistler Accelerometer K-Beam 8212BherbertmgÎncă nu există evaluări