Documente Academic

Documente Profesional

Documente Cultură

L & T Construction - PT & D Ic: Safe Operating Procedure

Încărcat de

arvindsarkarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

L & T Construction - PT & D Ic: Safe Operating Procedure

Încărcat de

arvindsarkarDrepturi de autor:

Formate disponibile

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 1 of 20

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 2 of 20

REVISION CONTROL SHEET

Rev. No Date Details of Revision Purpose of Revision Approved By

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 3 of 20

Table of Contents

REVISION CONTROL SHEET .................................................................................................... 2

1.0 PURPOSE ..................................................................................................................... 4

2.0 SCOPE ......................................................................................................................... 4

3.0 REFERENCES ................................................................................................................ 4

4.0 ABBREVIATIONS .......................................................................................................... 4

5.0 DEFINITIONS ............................................................................................................... 5

6.0 RESPONSIBILITY .......................................................................................................... 6

7.0 PPE TO BE USED .......................................................................................................... 6

8.0 PLANT, MACHINERY, TOOLS & TACKLES USED .............................................................. 7

9.0 FLOW CHART - SEQUENCE OF OPERATION ................................................................... 9

10.0 PROCEDURE .............................................................................................................. 10

11.0 RELATED DOCUMENTS & CHECKLIST .......................................................................... 20

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 4 of 20

1.0 Purpose

To describe the procedure for safe execution of Panel Erection activity at Electrical Substation

projects.

2.0 Scope

This SOP is applicable to all L&T Employees, Sub contractors and their employees. It shall be

applicable to activities pertaining to Panel Erection at site for various projects of EHV SS & E & I,

in all its domestic operation.

3.0 References

EHS manual

IMS Manual

The Electricity Act 2003 and The Electricity Rule 2005

Manufacturer’s instruction, manuals and drawings to erection of equipment.

Site specific EHS Plan.

4.0 Abbreviations

SOP – Safe operating procedure

EHS - Environment, Health and Safety

PPE - Personal Protective Equipment

PTW - Permit to Work

PM - Project Manager

SI /SE - Section Incharge / Site Engineer

EHSO - Environment Health and Safety officer

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 5 of 20

5.0 Definitions

Responsible Person A person who has sufficient knowledge and training with one year

experience in execution, shall be able to recognize obvious defects and

is responsible to the Section Incharge / Site Engineer the 'in Service'

inspection and maintenance of equipment.

Competent Person Someone who has sufficient training and experience or knowledge and

other qualities that allow them to assist you properly. The level of

competence required will depend on the complexity of the situation and

the particular assignment.( minimum two years of experience in the

respective area of work)

Lifting Gear / Lifting Any item used to connect a load to a lifting machine or appliance, but

Tackle which is not in itself capable of providing any movement to lift or lower the

load. Lifting Gear is in some circumstance known as Lifting tackle

Lifting Appliance Any machine which is able to raise, lower or suspend a load but

excluding machines incorporating a guided load (i.e., lifts) and continuous

mechanical handling devices (i.e., conveyors).

Automatic Safe Load A device fitted to a Crane, or incorporated in its design, that automatically

/ Indicator gives visual indication to the operator when the load being lifted or

carried by the crane approaches the Safe Working load, and that also

gives a continuous audible warning to the operator and other persons in

the vicinity, when the load being lifted or carried exceeds the Sate

Working Load.

Load Radius A device fitted on a Crane that shows the radius of the hook and the

Indicator corresponding Safe Working Load.

Operating Radius The horizontal distance between the point at which the centre of rotation

of the Crane meets the ground, and the vertical centerline through the

hook.

Capacity Chart (or A notice fitted on a Crane specifying the lifting capacities of the Crane at

Plate) different load-radii and for different operational conditions.

EOT Crane Electric overhead travelling crane, this is used for erection, handling and

moving specified weight of the equipment’s called capacity of the crane

within a specified area.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 6 of 20

6.0 Responsibility

It shall be the responsibility of the line function (Construction Manager / Section In charges/ Site

Engineer /EHS Engineer) to implement this Procedure.

7.0 PPE to be used

Safety Helmet, ISI Certified

Made of HDPE, Nape Type

Suspension with Chin Strap & Sweat Band

Full body harness webbing made of Nylon with front D-

ring / Textile Loop for fall arrestor attachment (Class: L),

with double lanyard & double scaffold hook, Shoulder &

Thigh adjustable, ISI or CE Certified

Safety Shoe

Leather Safety Footwear with Direct Injection Moulded,

Poly urethane (PU) Sole – Single Density, with steel /

fibre toe

REFLECTIVE JACKET

Red – Workmen ; Green - Staff

Background Fabric - 100% Polyester Low Mesh (80

GSM)

Cotton Hand gloves

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 7 of 20

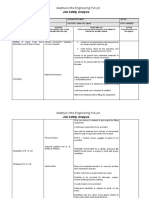

8.0 Plant, Machinery, Tools & Tackles used

Name of the Equipment /

Pictorial View Check Points

Tools & Tackle

Hydra Crane 12 T / 14 T Physical condition

Third party certification

(Escort TRX 1550 14T / Hydraulic jack function

ACE FX 12) Operator fitness

Mobile Crane – 18 T Physical condition

Third party certification

Hydraulic jack function

Operator fitness

Truck - 10 T Physical condition

Third party certification

Hydraulic jack function

Operator fitness

Web Sling – 6T No Damage in the Web belt

& stiches

Third party certification

Colour code tag

D Shackle – 5 T Check for wear and

Straightness

Check that pin is always

seated

Check that shackle is

opening up

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 8 of 20

PP Rope – 25 mm dia Broken ropes

If any kink present

Colour Change

Chain pulley block – 2 T / 5 Chain links

T capacity Hook Latches

Physical condition

Third party certification

Pallet Truck – 1 T capacity Physical condition

Third party certification

Hydraulic jack function

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 9 of 20

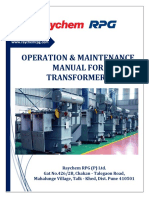

9.0 Flow chart - Sequence of operation

Panel Erection

Man Material Machinery

Check for fitness of the

Identify the Panel Machinery / tools

Select the work Group

Check the Packing Verify the lifting accessories

Screen & Induct

Decide Mode of

Validate the lifting plan

Transport

Load the equipment on Vehicle

Issue PPE Clear the approach

and shift

Plan for transport Unload near the erection point

Task Briefing (Pep Talk)

Arrange Resourse Check the orientaion and erect

Supervise Check tightness of bolt and

Monitor

nuts

Relaese the lifting

Equipment & tackles

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 10 of 20

10.0 Procedure

a) Pre operational Checks

Select the Workers and screen for competency and physical fitness to perform the

activity.

Ensure EHS induction training provided before engaging on work.

PEP talk specific to the erection activity shall be conducted explaining hazards

associated with the job and the safety measures to be adopted including ERP,

First aid.

All workers at site to wear Safety shoe, helmet, hand gloves.

For work at height, full body harness with double lanyard, fall arrester and height

pass are required.

A standard signals to use in passing / communicating / controlling erection

activities.

Fully equipped First Aid box should be made available at each erection location.

Emergency contact details to be displayed in the workplace.

The requirement identified in the Emergency response plan shall be in place

Engage skilled workmen for loading and unloading of panels.

Approach and access to work area to be ensured.

Before erection, check all tools and tackles.

Ensure Permit to Work System where ever applicable is in place before starting the

job

Site / work-front clearances to be obtained.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 11 of 20

Un-authorized person shall not be allowed to the area of erection

Erection work will be carried out under supervision of responsible persons.

Unloading arrangements are to be planned before receipt of panels at erection

site.

Soil condition shall be checked for the load bearing capacity and its level.

Check the equipment fitness of Crane as per ( IM – 15 B Equipment Fitness

Report For Vehicle & Earth Moving Equipment)

Attach the web sling on the hook and pass them under the wooden pallet provided

on the bottom of the Panel.

Packing shall be used for edge protection and slinging.

Lift the transportation unit of the Panel.

Load the panels from storage yard on truck by using crane. Panels shall be placed

on the truck in vertical position. ( Fig : 1)

FIG : 1 PANEL LOADED @ VERTICLE POSITION

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 12 of 20

Panels shall be tied with web slings to prevent the movement of the panels tied

with guy rope from both sides.

Ensure correct panel is being received from the store as per drawing and it is

being taken to its correct destination at the site.

Check the approach from unloading spot to erection spot for any obstruction.

Ensure the area is levelled to avoid toppling of panels.

Ensure identification markings on the panels for their easy traceability in

workplace.

Ensure that the panels are not given any undue jerks.

No person shall stand below crane or even in the boom radius during lifting,

lowering and swinging.

No person / workmen should travel / sitting on heavy equipment while

transportation of materials.

While travelling by trailer no person should sit on trailer except driver.

Ensure that a workmen who is going to work on height is competent, having safe

climbing arrangement (like scaffold, ladder, staircase, etc.), equipped with

required PPEs, having fall arrestor to arrest falling from height.

Scaffold shall be inspected by the competent trained person and scaff tag to be

provided.

Colour coding system is to be in place to ensure only inspected tools are in use.

If welding machine is engaged for welding, equipment earthing also to be ensured.

Direct earting shall be provided from the machine to parent material to be welded.

Cables shall free of any damage.

Before operation, check all tools and tackles to be ensured.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 13 of 20

Lifting tools & tackles are to be stacked in such a manner that they can be taken

out easily.

Audio visual alarm should be in operation while operating the EOT Crane (if the

facility is available).

Emergency switch shall be operating Condition.

Illumination level of 200 lux shall be maintained at erection site.

Opening if any in and around the panel unloading or erection area to be guarded /

covered with rigid material ( 6mm chequred plate / 25mm thick wooden planks)

Before erection complete Panel room levelling shall be taken in 4 or 5 places and

take average of the levels to maintain the same level for all panels.

If any Bus duct are to be connected with panels check the outside transformer

levels, distance from switchgear to facilitate the Bisducts.

Clearance between panel’s rear side, front side, left & right side should be

maintained 1500mm or otherwise specifically mentioned as per O&M manual

issued by the manufacturer.

Provide Rail track with ISMC Chennel to roll out the trolley for shifting of panels.

Crowbars, ISMC channels, Wooden blankets are to be used for tracking the

panels on the floor.

Check Panel board gland plate’s position to facilitate the cable terminations, it

should not come the base channels or floor concrete beams.

Panel erection should be started after completion of the switchgear panel Room

civil work like plastering, window, door installation, internal painting.

Approach for the vehicle movement to the panel room at least plain road should be

there to avoid tilting.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 14 of 20

Leveling of the panels should be made in such a way that bottom of the panel

base frame should match with flooring.

Panel coupling to be done with correct hardware’s to avoid gap between panels.

Main bus bars jointing with spring washers applying petroleum jelly.

Control wiring between the compartments to be done as per the drawing.

Tightness of joints to be done & checked with torque wrench pressure as per

recommendation of the manufacture.

Loose items supplied like relays , meters, draw out type module to be installed on

the cutouts. Fixing of panel with Base frame after final alignment or welding with

base channel as per the specification.

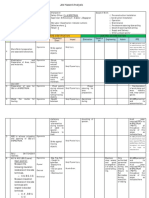

b) Operational Checks

Receipt and storage of panels.

Unload the panels in storage yard at

specified / identified location using 12 T

mobile crane

Panels, and accessories received shall be

checked with the shipping release and

packing list.

Check that the packing of the panels is not

damaged anywhere.

Position the crane hook on top of

Fig: 2

transportation unit.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 15 of 20

Fig : 3 Tag line

Manufacturers’ instruction for

lifting & shifting shall be strictly

followed.( Fig : 2)

Suspend the ropes from the

hook and pass them under the

wooden pallet under the

bottom of the panel to be

transported.

Use tag line Rope minimum of

3meter long to control the oscillation.( Fig: 3)

Store the panels in closed storage

till the site is ready for the erection

of it.

Keep proper tag markings on the

panels for their easy traceability in

stores.( Fig:4)

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 16 of 20

Handling & Shifting Of Panels

Shifting of the panel shall be

done as per manufacturer’s

instruction with truck and

crane.( Fig :5)

Panels shall be placed on the

truck in vertical position as

shown in Fig:1

Panels shall be tied at two

Fig : 5

places to prevent the jerk or

toppling of the panels.

Ensure correct panel is received at

store as per drawing

It is being taken to its right destination

at the site.

Unload the transportation unit of Panel

near to the erection spot.

Verify the route from unloading spot to

erection spot for free access.

Fig: 6

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 17 of 20

Panel shifting inside the building

Pallet truck shall be used for panel

movement inside the building. (Fig:6)

Where the use of pallet truck is not possible,

2 nos of ISMC 100 channels shall be

provided to place the Trolley with 4 wheels

and Panel shall be kept on trolley for

internal movement inside the panel room.(

Fig :7)

Top anchoring arrangement made of 12 mm Fig : 7

steel wire rope shall be provided at top support in order to restrict toppling of

panel.

In case of narrow base, the panel is shall lift the case at either end, to insert pallet

truck but never lift too much.

Workers handling panels should be CAUTIOUS IN ORDER to avoid injuries to toe

& fingers getting caught under roller

Workers should always be behind the panels while pushing. To avoid tilting

sideways tag line ropes can be provided.

Embedded parts (EP’s) provided for panel erection shall be checked for level.

After the panels have reached the erection spot wooden packing shall be

removed from the panel.

Use step ladder for unpacking as shown in the Fig:8

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 18 of 20

Dispose the wood packing

material to its allocated area.

Removal of protruded nails from

the wooden planks is to be

done.

Ensure that the communication

between the signal man are the

concerned fitter gang is correct.

Skilled rigger shall be engaged

to control hoisting & de-hoisting

of crane.

Fig:8

3 Meter of long Tag line should be used from both the ends to minimize oscillation

of equipment.

Chain pulley block should never be used for horizontal / oblique pulling.

Only “tirfor” is to be used for such pulling.

When lifting the panel, area must be protected and no un- authorized person

should be permitted to enter the area.

Do not load beyond the rated capacity of the crane.

While lifting of panel, sharp edge protection such as gunny bags, cotton pads

should be provided.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 19 of 20

Panel Erection

Embedded parts (EP’s) provided for panel erection shall be checked for leveling

After the panels have reached the erection spot wooden packing shall be removed

from the panel.

Place panels with hydra / EOT Crane with their own base frame over EP’s as per

sequence indicated in drawing.

Check the leveling and alignment of panels.

Panels shall be coupled together with given fasteners wherever applicable.

Check for alignment and leveling.

If the gap exists

between base

frame and EP,

then the

procedure for

welding shall be

decided on a

case-to-case

basis.

Lower the crane

hook and de sling

from the panel

Release the crane and continue for next panel erection.

Follow the same sequence for subsequent panel erection.

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

L & T Construction – PT & D IC Location:

Date:

HQ - Chennai

EHV SS & IE - Segment Rev: 00

SAFE OPERATING PROCEDURE Doc No: EHV /SOP /0

Panel Erection Page no: 20 of 20

c) Post operational Checks

All the tools & tackles used for such activity are to be taken back by the group of

workmen after completion of day work.

Opening if any in and around the panel erection area shall be closed.

Work permits shall be returned after completion of the activity.( if obtained)

Remove the unwanted material from workplace.

Dispose the wood to its allocated area. ( Packing material if any)

Supervisor should ensure all workers have left the building before leaving the

workplace himself.

Handed over the lock & Key to the identified security incharge / section incharge.

11.0 Related Documents & Checklist

Erection schedule / Approved Drawing

Safety Induction card to all workmen

EHS Risk Assessment - IM - 08 B Rev 03

Training Records - IM -11-B Rev 03

Pep Talk Report - IM -12 A Rev.03

Equipment Fitness Report

Vehicle & Earth Moving Equipment - IM -15 B Rev.03

Crane Inspection Checklist - IM -09-A7 Rev 03

Erection Safety Checklist - IM -9 A3 Rev 03

General EHS Inspection Checklist - IM -09-A1 Rev 03

Working at Height Checklist – IM -09-A2 Rev 03

Project Emergency response plan

Name & Signature Date Document Control

Prepared by Supersedes:

Reviewed by Date Issued:

Approved by Review date:

S-ar putea să vă placă și

- Job Procedure 05 For CABLE LAYING & TERMINATIONDocument6 paginiJob Procedure 05 For CABLE LAYING & TERMINATIONSoumik KarÎncă nu există evaluări

- Switch Gear Commissioning ChecklistDocument27 paginiSwitch Gear Commissioning ChecklistRAM SHANMUGAMÎncă nu există evaluări

- JSA Transformer InstallationDocument10 paginiJSA Transformer InstallationWeru Morris100% (1)

- TRANSFORMER TESTINGDocument2 paginiTRANSFORMER TESTINGmartins7333% (3)

- JOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONDocument1 paginăJOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONpushpanath reddy100% (1)

- Shut Down Procedure (Tata Steel)Document19 paginiShut Down Procedure (Tata Steel)Prakash Kumar100% (1)

- Method Statement - Cable LayingDocument5 paginiMethod Statement - Cable LayingsoubhagyaÎncă nu există evaluări

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Document3 paginiPower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMAÎncă nu există evaluări

- Cable Tray Erection ProcedureDocument3 paginiCable Tray Erection ProcedureAnmohieyÎncă nu există evaluări

- Installation - A - EarthmatDocument11 paginiInstallation - A - Earthmatpdky yadavÎncă nu există evaluări

- Jsa For Cable Tray ErectionDocument2 paginiJsa For Cable Tray Erectionanko heroÎncă nu există evaluări

- Temporary Electrical Safety ProcedureDocument9 paginiTemporary Electrical Safety ProcedurejaimonjoyÎncă nu există evaluări

- Humed Method Statement For Mono-Poles InstallationDocument3 paginiHumed Method Statement For Mono-Poles InstallationUtibe EkongÎncă nu există evaluări

- Risk Assessment Form: 1 Biophysical HazardsDocument5 paginiRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Method Statement For Cable & TerminationDocument6 paginiMethod Statement For Cable & TerminationRajuÎncă nu există evaluări

- RA Risk Assessment for 33kVA Transformer MaintenanceDocument4 paginiRA Risk Assessment for 33kVA Transformer MaintenancePandu BirumakovelaÎncă nu există evaluări

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 paginăHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaÎncă nu există evaluări

- Bus Duct Unloading, Shifting, Installing MS 01Document25 paginiBus Duct Unloading, Shifting, Installing MS 01Sufiyan KhedekarÎncă nu există evaluări

- Transformer Oil Leak Repair and Top Up ProcedureDocument2 paginiTransformer Oil Leak Repair and Top Up Procedurenicholaslee100% (7)

- VCB PM PDFDocument15 paginiVCB PM PDFAccidental EngineerÎncă nu există evaluări

- Inspection Test Plan (ITP) Procedure-DigabungkanDocument9 paginiInspection Test Plan (ITP) Procedure-Digabungkanpankrasius herbudiÎncă nu există evaluări

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Document2 paginiJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaÎncă nu există evaluări

- 32 - SOP - Stringing of Transmission LineDocument22 pagini32 - SOP - Stringing of Transmission LineAsheptya Kurniawan100% (1)

- LT Panel PDI SOPDocument4 paginiLT Panel PDI SOPShrikanth Sola100% (2)

- Jsa Cable LayingDocument2 paginiJsa Cable LayingAbcd efgh100% (1)

- Method of Statement and JSA For Live Line Crosssing in PXIDocument8 paginiMethod of Statement and JSA For Live Line Crosssing in PXITwin BullsÎncă nu există evaluări

- Standard Procedure for Megger Testing TransformersDocument3 paginiStandard Procedure for Megger Testing TransformersLincoln DsouzaÎncă nu există evaluări

- Annexure 4 - TransformerDocument36 paginiAnnexure 4 - TransformerBala MÎncă nu există evaluări

- Foundation Work Method Statement for 220kV Uganda Transmission ProjectDocument20 paginiFoundation Work Method Statement for 220kV Uganda Transmission ProjectAnonymous CPEha1db7UÎncă nu există evaluări

- JSA Transformer InstallationDocument1 paginăJSA Transformer Installationpushpanath reddyÎncă nu există evaluări

- 47 Cable Glanding and TerminationDocument3 pagini47 Cable Glanding and TerminationvasudevanmÎncă nu există evaluări

- Jsa D. G. INSTALLATIONDocument5 paginiJsa D. G. INSTALLATIONRavi thokalÎncă nu există evaluări

- Method Statement For MV Switchgear (Inspire)Document5 paginiMethod Statement For MV Switchgear (Inspire)Gajendran Sriram50% (2)

- SOP MAINTENANCE FINAL - Part2Document55 paginiSOP MAINTENANCE FINAL - Part2mansoorÎncă nu există evaluări

- Method Statement - 115kV 100 MVA Transformer InstallationDocument75 paginiMethod Statement - 115kV 100 MVA Transformer Installationessam khalilÎncă nu există evaluări

- Earthing Method StatementDocument5 paginiEarthing Method StatementMuhammad Saqib AsifÎncă nu există evaluări

- Job Safety Analysis Power Transformer TestingDocument8 paginiJob Safety Analysis Power Transformer TestingAnilPagoluÎncă nu există evaluări

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 paginiCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarÎncă nu există evaluări

- Field Quality Plan (FQP)Document2 paginiField Quality Plan (FQP)Ranjit Singh100% (3)

- Power-Transformers-Installation-Manual (Torques)Document33 paginiPower-Transformers-Installation-Manual (Torques)Cesar Andrés Prada Vega100% (1)

- HIRA Electrical Works HRC 002Document7 paginiHIRA Electrical Works HRC 002syed khaja misbhuddinÎncă nu există evaluări

- Risk Assessment Switchgear Testing & CommissioningDocument7 paginiRisk Assessment Switchgear Testing & CommissioningguspriyÎncă nu există evaluări

- Final Work Instructions - Electrical ErectionDocument116 paginiFinal Work Instructions - Electrical ErectionBuggy App100% (2)

- Checklist For Erection of Control & Relay Panel-Busbar Protection.Document2 paginiChecklist For Erection of Control & Relay Panel-Busbar Protection.sasikumarÎncă nu există evaluări

- Inspection Checklist For Installation of Earthing System123Document1 paginăInspection Checklist For Installation of Earthing System123Shahir Ibrahimi100% (1)

- Method of Statement For Foundation of P5, P11 69kvDocument8 paginiMethod of Statement For Foundation of P5, P11 69kvTwin Bulls100% (2)

- Method Statement - Panel ErectionDocument2 paginiMethod Statement - Panel ErectionsoubhagyaÎncă nu există evaluări

- METHOD STATEMENT Installation of HV Switch Gear 11kv PanelsDocument2 paginiMETHOD STATEMENT Installation of HV Switch Gear 11kv Panelsanuraj arackalÎncă nu există evaluări

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDocument3 paginiLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINÎncă nu există evaluări

- HT Panel & Transmission Line ChecklistDocument1 paginăHT Panel & Transmission Line Checklisttango member0% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 paginiCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 paginiFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005Încă nu există evaluări

- Etihad Southside Catering Facility Light Fitting Installation Method StatementDocument68 paginiEtihad Southside Catering Facility Light Fitting Installation Method StatementAnandu AshokanÎncă nu există evaluări

- Jha Solar Transformer ProjectDocument6 paginiJha Solar Transformer Projectperquino oasanÎncă nu există evaluări

- Transformer Erection ChecklistDocument2 paginiTransformer Erection Checklistmohan babu100% (2)

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 paginiJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseÎncă nu există evaluări

- ITP-Application of PaintingDocument2 paginiITP-Application of PaintingMuthu Saravanan100% (1)

- 20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3Document21 pagini20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3lintangÎncă nu există evaluări

- Ess-Byn-Hw-Sat-005-Report (R4-S2) - 7 Oct 22Document47 paginiEss-Byn-Hw-Sat-005-Report (R4-S2) - 7 Oct 22Mrbean BeanÎncă nu există evaluări

- Abj 89 103778 Ba 6070 00024 0000 01Document16 paginiAbj 89 103778 Ba 6070 00024 0000 01Nithin GÎncă nu există evaluări

- Acetyline Cylinder PDFDocument2 paginiAcetyline Cylinder PDFniazÎncă nu există evaluări

- Thinner Ms DsDocument6 paginiThinner Ms DsSetiawan HatmajiÎncă nu există evaluări

- New Guidelines CP CDocument9 paginiNew Guidelines CP CAngadÎncă nu există evaluări

- How To Calculate Duty and Surface Area of Heat Ex ChangersDocument7 paginiHow To Calculate Duty and Surface Area of Heat Ex ChangersJohn Obidi100% (2)

- Oxygen Cylinder MSDS General IndustrialDocument4 paginiOxygen Cylinder MSDS General IndustrialarvindsarkarÎncă nu există evaluări

- 1.2 Basics of Energy and Its Various FormsDocument19 pagini1.2 Basics of Energy and Its Various FormsKali DasÎncă nu există evaluări

- Acetyline Cylinder PDFDocument2 paginiAcetyline Cylinder PDFniazÎncă nu există evaluări

- Energy ScenarioDocument37 paginiEnergy ScenarioShashidhar14Încă nu există evaluări

- Adv - HSE OfficerDocument5 paginiAdv - HSE OfficerarvindsarkarÎncă nu există evaluări

- Sample SolutionDocument1 paginăSample SolutionadhavanrkÎncă nu există evaluări

- CSP ReferencesDocument5 paginiCSP ReferencesarvindsarkarÎncă nu există evaluări

- CSP ReferencesDocument5 paginiCSP ReferencesarvindsarkarÎncă nu există evaluări

- GEOCEAN PROTIS ACCOMODATION WORK PIPELAY BARGEDocument19 paginiGEOCEAN PROTIS ACCOMODATION WORK PIPELAY BARGEmaxÎncă nu există evaluări

- Amendments To List of Codes, Recommendations, Guidelines and Other Safety-And Security-Related Non-Mandatory InstrumentsDocument13 paginiAmendments To List of Codes, Recommendations, Guidelines and Other Safety-And Security-Related Non-Mandatory InstrumentsEmanuel HuardÎncă nu există evaluări

- United States Naval Aviation 1919-1941Document353 paginiUnited States Naval Aviation 1919-1941Saniyaz Manas100% (14)

- Project On Steel Industry For OPMDocument18 paginiProject On Steel Industry For OPMsunilsony123Încă nu există evaluări

- Chapter 18: Hierarchy of Intersection ControlDocument39 paginiChapter 18: Hierarchy of Intersection ControlAbdhul Khadhir ShalayarÎncă nu există evaluări

- R Point and Manufacturer Design Seat Back AngleDocument10 paginiR Point and Manufacturer Design Seat Back AngleAmolPagdalÎncă nu există evaluări

- Asobo Boeing 787 Dreamliner Startup ProcedureDocument5 paginiAsobo Boeing 787 Dreamliner Startup Procedureraghavbhatia460Încă nu există evaluări

- Med PTMDocument133 paginiMed PTMHarvinder SahotaÎncă nu există evaluări

- Street LightingDocument18 paginiStreet Lightinglomash AdhikariÎncă nu există evaluări

- Nasehat Bagi Pavement Engineer Vol-1Document106 paginiNasehat Bagi Pavement Engineer Vol-1sonysaza100% (1)

- Invoice Parts ReportDocument308 paginiInvoice Parts Reportrahul siddharth100% (1)

- Module 2 TranspoDocument95 paginiModule 2 TranspomarcusluismacusiÎncă nu există evaluări

- Maldives Tourism Industry GuideDocument19 paginiMaldives Tourism Industry GuideJen SchätzÎncă nu există evaluări

- Footstep GeneratorDocument3 paginiFootstep GeneratormanikandanÎncă nu există evaluări

- Mechanical Department in Indian RailwayDocument5 paginiMechanical Department in Indian RailwaySoumen BhattaÎncă nu există evaluări

- Highway Eng I, Chapter ThreeDocument87 paginiHighway Eng I, Chapter Threefentawmelaku1993Încă nu există evaluări

- Mapping Energy Consumption in Food ManufacturingDocument11 paginiMapping Energy Consumption in Food ManufacturingCata RodriquezÎncă nu există evaluări

- MM Standard Gondola enDocument1 paginăMM Standard Gondola enKinan W. MukhtiÎncă nu există evaluări

- Cornwall Ontario Canal EssayDocument1 paginăCornwall Ontario Canal EssayTerence SkeetÎncă nu există evaluări

- 0508 CT GTRZ06911 ChartDocument1 pagină0508 CT GTRZ06911 Chartvasttracts3844Încă nu există evaluări

- Metodolgie RiscDocument19 paginiMetodolgie RiscCip GrecuÎncă nu există evaluări

- Geometric Design of TravelwaysDocument25 paginiGeometric Design of Travelwaysokaraman2002100% (1)

- HPS Pagar - 300Document31 paginiHPS Pagar - 300AndiPettaÎncă nu există evaluări

- Transportasi Distribusi MigasDocument25 paginiTransportasi Distribusi MigasDian Permatasari100% (1)

- Product:Denso Condensor: Denso Cool Gear Code Product Code Product NO. Brand Car ModelDocument1 paginăProduct:Denso Condensor: Denso Cool Gear Code Product Code Product NO. Brand Car ModelSafety WaxyÎncă nu există evaluări

- Mooring AnalysisDocument37 paginiMooring AnalysisJOSÉ FERNANDOÎncă nu există evaluări

- Journey Date: 07-07-2023 08:30 PM Seat No: I3, I4 (2) : Shyamoli ParibahanDocument1 paginăJourney Date: 07-07-2023 08:30 PM Seat No: I3, I4 (2) : Shyamoli ParibahanMd Bappy HossanÎncă nu există evaluări

- Om Enterprises QuotationDocument4 paginiOm Enterprises Quotationrilhouse2406Încă nu există evaluări

- Weber ManualDocument28 paginiWeber ManualMedardo SilvaÎncă nu există evaluări

- Rap GSB and WMM PDFDocument4 paginiRap GSB and WMM PDFvenkateswara rao PothinaÎncă nu există evaluări