Documente Academic

Documente Profesional

Documente Cultură

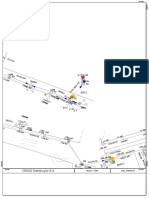

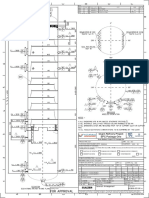

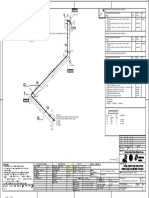

10ENA01BR003 Sheet2-Model

Încărcat de

Valesh MonisTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10ENA01BR003 Sheet2-Model

Încărcat de

Valesh MonisDrepturi de autor:

Formate disponibile

1 2 3 4 5 6 7 8

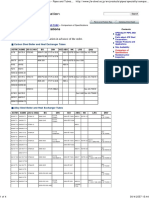

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 300 PAAZZBOZZABAABSAAZZUS 2.6 M D01

A106-B, Seamless, S-STD CC-10ENA01AS001

2 Tee, , Beveled end, 300X300 MDJZZBOZZAAEADCZZUS 1 D01 E 340680 195

ASME-B16.9, A234-WPB, S-STD N 354153

A EL +1994 14 SEE ISO A

3 Sockolet® Size on Size, 300X50 MEUAWBVZZAEYABQZZUS 2 D01 TI10ENA01CT501 17 10ENA01BR003 SHT 03

CL3000, Beveled end, CP-10ENA01AS002

E 340380 16 178 E 341701

ASME-B36.10M, A105 16 N 354153

N 354153

4 Threadolet for Thermowell 300X25 MEVAWBUZZABAABQZZUS 1 D01 EL +1994 EL +1666

F7 G11 B13

mouting, Threaded Boss type E 341626 4

<6> 9 300X25DN

M33x2, A105, CL 3000

328

ORIENT

107

5 90 degree elbow, long radius, 300 MCMZZBOZZAAEADCZZUSA 2 D01 F7 G11 B13 186

300DN U

, Beveled end, ASME-B16.9, 16

A234-WPB, S-STD

<5> 9 6

6 Weld neck flange, CL300, 300 FAAAMABZZAADABQZZUS 4 D01 74

Raised-face flanged end,

16

6

ASME-B16.5, A105, Undefined 1 04

107

0

7 Socket weld flange, CL300, 50 FABAMABZZAADABQZZUS 2 D01 30

328

S8

Raised-face flanged end, 3 10ENA01BQ025

ASME-B16.5, A105 300X50DN 0

B 50 E 340680 B

PIPE SUPPORTS

8 Design Pipe Assembly 300 DesignPipeH_5 3 D01 3

ERECTION MATERIALS 300X50DN

9 Pipe, PE, ASME-B36.10M, 50 PAAZZBPZZABAABSAAZZUS 0.3 M 186

E 340380

A106-B, Seamless, S-40

10 Spiral wound, one ring, CL300, 300 GMAMAQAABFMUS 5 D01

4.5mm, ASME-B16.20, 316-W,

graph-F, CS-CR

11 Spiral wound, one ring, CL300, 50 GMAMAQAABFMUS 2 D01

4.5mm, ASME-B16.20, 316-W,

graph-F, CS-CR

12 Stud Bolt, ASME-B18.2.1, ASTM 1.1/8 BAZZZZZZAAYBFZZZUS1 80 D01

A193-B7, hot dip galvanized,

With 2heavy Hex nuts A194 59

Gr.2H and 2 washers - 180 mm 47 6

1

C Length 52 C

P5

13 Stud Bolt, ASME-B18.2.1, ASTM 5/8 BAZZZZZZAAYBFZZZUS1 16 D01

A193-B7, hot dip galvanized,

With 2heavy Hex nuts A194

Gr.2H and 2 washers - 100 mm

Length

INSTRUMENTS

14 TEMPERATURE INDICATOR 25 1 D01 P5

TI10ENA01CT501

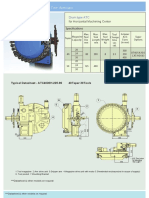

15 Globe valve, short pattern, 300 VAMAMABZZAAFADAAKZZUS 1 D01 5 457

CL300, Raised-face flanged 2 457

<4> 1 89 5

end, ASME-B16.10, A216-WCB,

1 30 129

Gear operator 18 2

16 Ball valve, short pattern, 300 VAJAMABZZAAFADAAKBFUS 1 D01 457 254 711

CL300, Beveled end, 346 <2

457 > 15

ASME-B16.10, A216-WCB, Gear 15 539 1 STEM UP

D 96 >

1 129

10ENA01AA008

D

operator

S8 <1

F6 G10 B12

10ENA01BQ030 61

7

254 12 F6 G10 B12

76

254 129 300DN

SEE SHT 2 F6 G10 B12 58

300X300DN 7 129

10ENA01BR003 SHT 01

E 334864 N 352557 502

<3 16

N 352171 >

EL +1666 1 STEM UP

S8 10ENA01AA009

10ENA01BQ049

G10 B12

F6 G10 B12

E SEE SHT E

10ENA01BR003 SHT 01

E 335756

6 107 50 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS N 348982 OWNER

5 107 50 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS EL +1666

4 885 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS DISTRIBUTION W/C

3 1203 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS MATRIX

2 302 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

1 181 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

10ENA01BR003 02 of 03

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P5

FILE NAME 10ENA01BR003.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

S-ar putea să vă placă și

- 1000+ Free Ebooks and DVDs Download at www.gitara1.comDocument96 pagini1000+ Free Ebooks and DVDs Download at www.gitara1.comoscar calvete100% (3)

- Manual de FM200 - ANSUL (DESPROTEGIDO)Document170 paginiManual de FM200 - ANSUL (DESPROTEGIDO)ulises ranses pillaca ugarte0% (1)

- CRM in BanksDocument31 paginiCRM in Banksauthori71% (7)

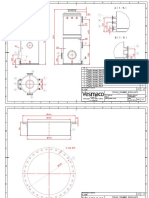

- 660 Gallon TankDocument2 pagini660 Gallon Tankleeconner3Încă nu există evaluări

- GATE EC 10 Volume Set by RK KanodiaDocument629 paginiGATE EC 10 Volume Set by RK KanodiaSiva Prakash89% (44)

- Rifai-R-RatheebDocument181 paginiRifai-R-RatheebNiyas mkdÎncă nu există evaluări

- Catalogo Bombas NETZSCHDocument1 paginăCatalogo Bombas NETZSCHJesus BolivarÎncă nu există evaluări

- SMART CITIES DEVELOPMENT: TECHNOLOGIES, INITIATIVESDocument19 paginiSMART CITIES DEVELOPMENT: TECHNOLOGIES, INITIATIVESRennie Mae B. ChuaÎncă nu există evaluări

- Fabrication and Erection Materials Bill of MaterialsDocument1 paginăFabrication and Erection Materials Bill of MaterialsValesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Fabrication Materials Spool 26110208 SummaryDocument1 paginăFabrication Materials Spool 26110208 SummaryReno Reza GumilangÎncă nu există evaluări

- Fabrication Materials ListDocument6 paginiFabrication Materials ListcelonevesÎncă nu există evaluări

- Fabrication Materials ListDocument6 paginiFabrication Materials ListcelonevesÎncă nu există evaluări

- 10ENA01BR004 Sheet5-ModelDocument1 pagină10ENA01BR004 Sheet5-ModelValesh MonisÎncă nu există evaluări

- 2300 52 AAA BD 280 282181 01 - RevS2Document1 pagină2300 52 AAA BD 280 282181 01 - RevS2CosminMarianÎncă nu există evaluări

- Pipe installation bill of materialsDocument1 paginăPipe installation bill of materialsroy blas neyraÎncă nu există evaluări

- SCM Sof Smop 56 Is 0323 0001 - 61030001 - 01Document1 paginăSCM Sof Smop 56 Is 0323 0001 - 61030001 - 01Reno Reza GumilangÎncă nu există evaluări

- SCM Sof Smop 56 Is 0321 0210 - 26110210 - 01Document1 paginăSCM Sof Smop 56 Is 0321 0210 - 26110210 - 01Reno Reza GumilangÎncă nu există evaluări

- CroquiDocument1 paginăCroquiPabllo FernandesÎncă nu există evaluări

- 2300 52 AAA CW 280 281307 04 - RevS2Document1 pagină2300 52 AAA CW 280 281307 04 - RevS2CosminMarianÎncă nu există evaluări

- FABRICATION MATERIALS SPOOL 61080043-1 AND 61080043-2Document1 paginăFABRICATION MATERIALS SPOOL 61080043-1 AND 61080043-2Reno Reza GumilangÎncă nu există evaluări

- Ti10010627 DSDocument1 paginăTi10010627 DSChetan KumarÎncă nu există evaluări

- F001.ang10.wp513 3 01SS001 N 0001Document1 paginăF001.ang10.wp513 3 01SS001 N 0001Reno Reza GumilangÎncă nu există evaluări

- PIPE AND TUBE - Comparison of SpecificationsDocument4 paginiPIPE AND TUBE - Comparison of Specificationsnate anantathatÎncă nu există evaluări

- Piping Isometric - 3Document1 paginăPiping Isometric - 3CosminMarianÎncă nu există evaluări

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 paginiSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliÎncă nu există evaluări

- AL-811 (Circa 2000) SchematicDocument2 paginiAL-811 (Circa 2000) SchematicSalvi AlonsoÎncă nu există evaluări

- Certificado Tee sch40Document1 paginăCertificado Tee sch40benedicto soto mestanzaÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- D A42 1362 0001J 17 Isometric ExtractedDocument3 paginiD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoÎncă nu există evaluări

- SCRUBBER D3000-H9370 FlangeDocument7 paginiSCRUBBER D3000-H9370 FlangebecemÎncă nu există evaluări

- Drum Type HMCDocument1 paginăDrum Type HMCEliane SouzaÎncă nu există evaluări

- Drum Type HMC PDFDocument1 paginăDrum Type HMC PDFSweta GajjarÎncă nu există evaluări

- EOS00684Document1 paginăEOS00684VEERAMANIÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Bill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5Document1 paginăBill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5chandraditya firmansyahÎncă nu există evaluări

- BBS FormatDocument2 paginiBBS Formatjogdeep GogoiÎncă nu există evaluări

- SAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiDocument3 paginiSAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiSungJun ParkÎncă nu există evaluări

- SCM Sof Smop 56 Is 0321 0207 - 26110207 - 01Document1 paginăSCM Sof Smop 56 Is 0321 0207 - 26110207 - 01Reno Reza GumilangÎncă nu există evaluări

- 2948 3sie200l4 2dDocument3 pagini2948 3sie200l4 2dEddo CarrionÎncă nu există evaluări

- 2948 3sie200l4 2dDocument3 pagini2948 3sie200l4 2dEddo CarrionÎncă nu există evaluări

- Bill of Materials: RDMP Ru V BalikpapanDocument1 paginăBill of Materials: RDMP Ru V BalikpapanPT Bumi Liputan PusakaÎncă nu există evaluări

- Bill of Materials: RDMP Ru V BalikpapanDocument1 paginăBill of Materials: RDMP Ru V BalikpapanPT Bumi Liputan PusakaÎncă nu există evaluări

- Ocr TestDocument8 paginiOcr TestAirÎncă nu există evaluări

- 340c-103 Internal Full DrawingDocument11 pagini340c-103 Internal Full Drawingalhad.maÎncă nu există evaluări

- LW931J ModelDocument5 paginiLW931J Modelucup.mongkey92Încă nu există evaluări

- UGH Drain PipeDocument2 paginiUGH Drain PipeQuoc LeHoaiÎncă nu există evaluări

- 01Document1 pagină01Reno Reza GumilangÎncă nu există evaluări

- Installation guide for OT1000-1600EM electromagnetic contactorDocument8 paginiInstallation guide for OT1000-1600EM electromagnetic contactorDave ChaudhuryÎncă nu există evaluări

- Book No - BG4Z008Document19 paginiBook No - BG4Z008lilespy3Încă nu există evaluări

- RevisianDocument11 paginiRevisianIbnu - CHCÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 paginiSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uÎncă nu există evaluări

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 paginăJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongÎncă nu există evaluări

- ATX FEEL 300W modelESP-200ATXTC312KDocument1 paginăATX FEEL 300W modelESP-200ATXTC312KMariusz KaźmierczakÎncă nu există evaluări

- Description Code No. No. Description Code No. No.: O.S. Genuine Parts & AccessoriesDocument1 paginăDescription Code No. No. Description Code No. No.: O.S. Genuine Parts & AccessoriesMarcelo ArevaloÎncă nu există evaluări

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part18Document1 paginăPO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part18ahmed saadÎncă nu există evaluări

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part18Document1 paginăPO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part18ahmed saadÎncă nu există evaluări

- CPC sheet piles specification guideDocument2 paginiCPC sheet piles specification guideAdita Rian PradanaÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- (09-2) - L-ZL (26) 26RG01B.001 PDFDocument1 pagină(09-2) - L-ZL (26) 26RG01B.001 PDFRaznan RamliÎncă nu există evaluări

- SectionsDocument1 paginăSectionsfourÎncă nu există evaluări

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part22Document1 paginăPO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part22ahmed saadÎncă nu există evaluări

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part22Document1 paginăPO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part22ahmed saadÎncă nu există evaluări

- Power supply circuit diagramDocument1 paginăPower supply circuit diagramSalvi Alonso100% (1)

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- 10ENA01BR004 Sheet5-ModelDocument1 pagină10ENA01BR004 Sheet5-ModelValesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pipe Support Fabrication and Erection Materials ListDocument1 paginăPipe Support Fabrication and Erection Materials ListValesh MonisÎncă nu există evaluări

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 paginăPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocument1 paginăRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisÎncă nu există evaluări

- 10ENA01BR003 Sheet3-ModelDocument1 pagină10ENA01BR003 Sheet3-ModelValesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Document1 paginăPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- 10ENA01BR003 Sheet1-ModelDocument1 pagină10ENA01BR003 Sheet1-ModelValesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Fabrication materials and pipe supports bill of materialsDocument1 paginăFabrication materials and pipe supports bill of materialsValesh MonisÎncă nu există evaluări

- Fabrication materials and pipe supports bill of materialsDocument1 paginăFabrication materials and pipe supports bill of materialsValesh MonisÎncă nu există evaluări

- Fabrication materials and pipe supports bill of materialsDocument1 paginăFabrication materials and pipe supports bill of materialsValesh MonisÎncă nu există evaluări

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Document2 paginiTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisÎncă nu există evaluări

- TCE LDO Isometric Drawings for Aden Power Plant Phase 1Document1 paginăTCE LDO Isometric Drawings for Aden Power Plant Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 paginăPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisÎncă nu există evaluări

- Contoh Panel LVMDP, SDPDocument4 paginiContoh Panel LVMDP, SDPrema irmaÎncă nu există evaluări

- Applied Hydraulics and Pneumatics - IMPORTANT QUESTIONSDocument2 paginiApplied Hydraulics and Pneumatics - IMPORTANT QUESTIONShasn50% (1)

- DATA CENTER EXAM COVERS HOSPITALITY INDUSTRY TRENDS AND INNOVATIONSDocument3 paginiDATA CENTER EXAM COVERS HOSPITALITY INDUSTRY TRENDS AND INNOVATIONSRegina IldefonsoÎncă nu există evaluări

- East West University: Letter of TransmittalDocument22 paginiEast West University: Letter of TransmittalJunaid Ahmed SaminÎncă nu există evaluări

- ITARAS User Manual: AdientDocument14 paginiITARAS User Manual: AdientAlberto BautistaÎncă nu există evaluări

- Mobile Device ForensicsDocument38 paginiMobile Device ForensicsV Yaswanth KumarÎncă nu există evaluări

- Account Closure Form - v2Document1 paginăAccount Closure Form - v2OTHER Work100% (1)

- Digital Technology For Infrastructure Asset ManagementDocument8 paginiDigital Technology For Infrastructure Asset ManagementHitachi America, Ltd.Încă nu există evaluări

- Aws WJ 201411Document161 paginiAws WJ 201411Remmy Torres VegaÎncă nu există evaluări

- Integration PDFDocument12 paginiIntegration PDFMd. Raihan Habib Rafi Mazumder 191-35-2768Încă nu există evaluări

- Special Characters and SymbolsDocument4 paginiSpecial Characters and SymbolsAnne AnziyaÎncă nu există evaluări

- w05 MailDocument33 paginiw05 MailMin LwinÎncă nu există evaluări

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Document12 pagini2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)SivaÎncă nu există evaluări

- Visa Quick Reference Guide For CPP ReportingDocument8 paginiVisa Quick Reference Guide For CPP Reportingstan nedÎncă nu există evaluări

- Kompetensi Manajerial Kepala Sekolah Dalam Meningkatkan Prestasi Non Akademik Siswa SMPDocument20 paginiKompetensi Manajerial Kepala Sekolah Dalam Meningkatkan Prestasi Non Akademik Siswa SMPYohana SibaraniÎncă nu există evaluări

- Tsjj0181e PDFDocument1 paginăTsjj0181e PDFDuy KhaÎncă nu există evaluări

- Marija Zdravkovic-Ls-Our Precious FoodDocument7 paginiMarija Zdravkovic-Ls-Our Precious Foodapi-426829038Încă nu există evaluări

- Hl2sneal00m Ver.d SCHDocument60 paginiHl2sneal00m Ver.d SCHJuli HernandezÎncă nu există evaluări

- Communications Systems - PLM-8CS PLENA Matrix 8 Zone Call StationDocument3 paginiCommunications Systems - PLM-8CS PLENA Matrix 8 Zone Call StationSaad KhÎncă nu există evaluări

- PC Monitor Manual PDFDocument8 paginiPC Monitor Manual PDFFagner Fernandes AraujoÎncă nu există evaluări

- Veeam Availability Suite 9.5 Enterprise Plus Vs Commvault 11Document3 paginiVeeam Availability Suite 9.5 Enterprise Plus Vs Commvault 11XiwenDingÎncă nu există evaluări

- Girl On Fire - Alicia Keys Sheet Music For Vocals (Solo)Document3 paginiGirl On Fire - Alicia Keys Sheet Music For Vocals (Solo)Jéssica E DiegoÎncă nu există evaluări

- Smart Manufacturing Begins With The Connected Enterprise - Rockwell AutomationDocument5 paginiSmart Manufacturing Begins With The Connected Enterprise - Rockwell AutomationEnrique RomeroÎncă nu există evaluări

- Form o - Quality AssuranceDocument93 paginiForm o - Quality AssuranceonutocsÎncă nu există evaluări