Documente Academic

Documente Profesional

Documente Cultură

C&H Die Casting Quality Management Systems Manual

Încărcat de

Станислав ПодольскийTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

C&H Die Casting Quality Management Systems Manual

Încărcat de

Станислав ПодольскийDrepturi de autor:

Formate disponibile

C&H Die Casting, Inc.

Quality Management

Systems Manual

222 Lely Drive Carr. A Huinala

Troy, Texas 76579 Km 2.8 Apodaca, N.L.

P.O. Box 1170 Monterrey, Mexico 66634

Temple, Texas 79503 Phone 011-52-818-298-2020

Phone 254-938-2541 Fax 011-52-818-030-4310

FAX 254-938-7117

E-mail: chdie @ chdiecasting.com

Quality Management Systems Manual Date Effective

Revision C Page 1 of 26 05/17/2013

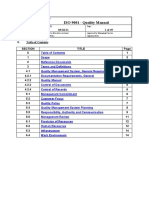

1.1 Table of Contents

Section Title Page

1.0 Scope 5

2.0 Introduction 5

3.0 Strategy Statement 5

4.0 Quality Management System 6

4.1 General Requirements 6

4.1.1 General Requirements - Supplemental 6

4.2 Documentation Requirements 6

4.2.1 General 6

4.2.2 Quality Manual 6

4.2.3 Control of Documents 6

4.2.3.1 Engineering Specifications 7

4.2.4 Control of Records 7

4.2.4.1 Records Retention 7

5.0 Management Responsibility 8

5.1 Management Commitment 8

5.1.1 Process Efficiency 8

5.2 Customer Focus 8

5.3 Quality Policy 8

5.4 Planning 8

5.4.1 Quality Objectives 8

5.4.1.1 Quality Objectives - Supplemental 8

5.4.2 Quality Management System Planning 8

5.5 Responsibility, Authority and Communication 8

5.5.1 Responsibility and Authority 8

5.5.1.1 Responsibility for Quality 8

5.5.2 Management Representative 9

5.5.2.1 Customer Representative 9

5.5.3 Internal Communication 9

5.6 Management Review 9

5.6.1 General 9

5.6.1.1 Quality Management System Performance 9

5.6.2 Review Input 9

5.6.2.1 Review Input - Supplemental 9

5.6.3 Review Output 9

6.0 Resource Management 10

6.1 Provision of Resources 10

6.2 Human Resources 10

6.2.1 General 10

6.2.2 Competence, Training and Awareness 10

6.2.2.1 Product Design Skills 10

6.2.2.2 Training 10

6.2.2.3 Training on the Job 10

6.2.2.4 Employee Motivation & Empowerment 10

Quality Management Systems Manual Date Effective

Revision C Page 2 of 26 05/17/2013

1.1 Table of Contents (cont’d)

Section Title Page

6.3 Infrastructure 10

6.3.1 Plant, Facility & Equipment Planning 11

6.3.2 Contingency Plan 11

6.4 Work Environment 11

6.4.1 Personnel Safety to Achieve Conformity to Product Requirements 11

6.4.2 Cleanliness of Premises 11

7.0 Product Realization 12

7.1 Planning of Product Realization 12

7.1.1 Planning of Product Realization -Supplemental 12

7.1.2 Acceptance Criteria 12

7.1.3 Confidentiality 12

7.1.4 Change Control 12

7.2 Customer-Related Processes 13

7.2.1 Determination of Requirements Related to the Product 13

7.2.1.1 Customer-Designated Special Characteristics 13

7.2.2 Review of Requirements Related to the Product 13

7.2.2.1 Review of Requirements Related to the Product — Supplemental 13

7.2.2.2 Organization Manufacturing Feasibility 13

7.2.3 Customer Communication 13

7.2.3.1 Customer Communication — Supplemental 13

7.3 Design and Development – N/A 13

7.4 Purchasing 14

7.4.1 Purchasing Process 14

7.4.1.1 Statutory and Regulatory Conformity 14

7.4.1.2 Supplier Quality Management System Development 14

7.4.1.3 Customer-Approved Sources 14

7.4.2 Purchasing Information 14

7.4.3 Verification of Purchased Product 14

7.4.3.1 Incoming Product Conformity to Requirements 14

7.4.3.2 Supplier Monitoring 15

7.5 Production and Service Provision 15

7.5.1 Control of Production and Service Provision 15

7.5.1.1 Control Plan 15

7.5.1.2 Work Instructions 15

7.5.1.3 Verification of Job Set-ups 15

7.5.1.4 Preventive and Predictive Maintenance 15

7.5.1.5 Management of Production Tooling 16

7.5.1.6 Production Scheduling 16

7.5.1.7 Feedback of Information From Service 16

7.5.1.8 Service Agreement with Customer 16

7.5.2 Validation of Processes for Production and Service Provision 16

7.5.2.1 Validation of Processes for Production and Service Provision - Supplemental 16

7.5.3 Identification and Traceability 16

7.5.3.1 Identification and Traceability - Supplemental 16

7.5.4 Customer Property 17

7.5.4.1 Customer-Owned Production Tooling 17

Quality Management Systems Manual Date Effective

Revision C Page 3 of 26 05/17/2013

1.1 Table of Contents (cont’d)

Section Title Page

7.5.5 Preservation of Product 17

7.5.5.1 Storage and Inventory 17

7.6 Control of Monitoring and Measurement Equipment 17

7.6.1 Measurement System Analysis (MSA) 17

7.6.2 Calibration / Verification Records 18

7.6.3 Laboratory Requirements 18

7.6.3.1 Internal Laboratory 18

7.6.3.2 External Laboratory 18

8.0 Measurement, Analysis and Improvement 19

8.1 General 19

8.1.1 Identification of Statistical Tools 19

8.1.2 Knowledge of Basic Statistical Concepts 19

8.2 Monitoring and Measurement 19

8.2.1 Customer Satisfaction 19

8.2.1.1 Customer Satisfaction - Supplemental 19

8.2.2 Internal Audit 19

8.2.2.1 Quality Management Systems Audit 20

8.2.2.2 Manufacturing Process Audit 20

8.2.2.3 Product Audit 20

8.2.2.4 Internal Audit Plans 20

8.2.2.5 Internal Auditor Qualifications 20

8.2.3 Monitoring and Measurement of Processes 20

8.2.3.1 Monitoring and Measurement of Manufacturing Processes 20

8.2.4 Monitoring and Measurement of Product 20

8.2.4.1 Layout Inspection and Functional Testing 21

8.2.4.2 Appearance Items 21

8.3 Control of Nonconforming Product 21

8.3.1 Control of Nonconforming Product - Supplemental 21

8.3.2 Control of Reworked Product 21

8.3.3 Customer Information 21

8.3.4 Customer Waiver 21

8.4 Analysis of Data 22

8.4.1 Analysis and Use of Data 22

8.5 Improvement 22

8.5.1 Continual Improvement 22

8.5.1.1 Continual Improvement of the Organization 22

8.5.1.2 Manufacturing Process Improvement 22

8.5.2 Corrective Action 22

8.5.2.1 Problem Solving 22

8.5.2.2 Error-Proofing 22

8.5.2.3 Corrective Action Impact 22

8.5.2.4 Rejected Product Test / Analysis 23

8.5.3 Preventive Action 23

Organizational Charts & Responsibility & Authority for Quality

Temple Texas Facility 24

Monterrey Mexico Facility 25

C&H Process Map 26

Quality Management Systems Manual Date Effective

Revision C Page 4 of 26 05/17/2013

1.0 Scope

C&H Die Casting, Inc. Troy, Texas and C&H Die Casting de Monterrey, Mexico is a closely-held

aluminum die casting foundry offering the fabrication and machining of aluminum die castings. C&H is a

supplier to Chrysler, Delphi and ZF. Products supplied by C&H are designed by C&H’s customers and

hereby notes the exception and exclusion of procedures directly or indirectly relating to the

requirements for product design outlined in Clause 7.3 of the technical specification ISO/TS 16949.

2.0 Introduction

This Quality Assurance Manual was developed to provide information pertaining to Quality Management

System (QMS) activities associated with the supply of goods and services focused on continual

improvement.

The manual was written in accordance with customer and ISO/TS 16949 Quality Management System

Requirements.

The Quality Management System activities are individually detailed in the form of Standard Operating

Procedures (SOPs) which state the company's policy and procedure relative to the QMS process and

the ultimate product.

The Quality Management Systems manual and SOPs are living documents; the policies contained

herein are subject to revision as manufacturing methods, competition within the industry, and customer

expectations evolve.

3.0 Strategy Statement

Objective: Maximize long-term cash generation.

Strategy: Achieve growth and competitive advantage through developing organizational

capabilities and improving performance as viewed from the customers’ perspective.

Tactics: 1. Focus organizational resources on achieving continual improvement in the level of

Complete Customer Service* provided to C&H’s customers.

2. Utilize world-class technology relevant to customer needs in manufacturing

equipment, process controls, and information systems.

3. Develop expertise in and control over value-added processes: close tolerance

machining, finishing, tooling design and construction, and manufacturing systems

engineering.

4. Develop bilateral partnerships with customers and suppliers.

5. Provide a high level of customer service: be responsive, flexible, and reliable when

presented with a customer request.

6. Tap the employees’ potential through efforts to provide a safe work environment,

training, teamwork opportunities, and tools that will allow all employees to do their

best work

*C&H’s quality policy and goal is founded on Complete Customer Service both of

which are included in the Strategy Statement above.

Quality Management Systems Manual Date Effective

Revision C Page 5 of 26 05/17/2013

4.0 Quality Management System

4.1 General Requirements

C&H maintains a documented quality management system and continually improves its effectiveness

relative to the company’s business plan and in accordance with the requirements of ISO/TS 16949.

C&H has determined:

a. processes for the quality management system and their applications

b. process sequences and interactions

c. criteria and methods needed for effective operation and control of processes

d. availability of resources and information necessary to support the processes

e. requirements for monitoring, measuring where applicable and analyzing these processes

f. actions necessary to achieve planned results through continual improvement

Where C&H chooses to outsource processes that affect product conformity to requirements; i.e. tool and

or gage construction, coating, etc, C&H ensures control over such processes.

1

NOTE : Processes needed for the QMS referred to above includes processes for management

activities, provision of resources, product realization, measurement, analysis and improvement.

2

NOTE : An outsourced process is a process that the organization needs for its QMS and which the

organization chooses to have performed by an external party.

4.1.1 General Requirements - Supplemental

C&H is responsible for conformity to all customer, statutory, and regulatory requirements. The type and

extent of control applied to outsourced processes are defined within the QMS and can be influenced by

factors such as:

a. the potential impact of the outsourced process on C&H’s capability to provide product that

conforms to requirements

b. the degree to which the control for the process is shared

c. the capability of achieving the necessary control through the application of SOP 7.0 sections

7.4.1 titled, Purchasing Process; 7.4.1.1 titled Statutory and Regulatory Conformity and 7.4.1.3

titled Customer-Approved Sources

4.2 Documentation Requirements

C&H maintains a documented quality management system that includes:

a. Strategy Statement that defines our quality policy and objectives (See section 3.0)

b. Quality Management Systems Manual

c. procedures and records compliant with customer and ISO/TS 16949:2009 requirements

d. documents, including records to ensure effective process planning, operation and control

4.2.2 Quality Management Systems Manual

C&H has documented and maintains a Quality Management Systems Manual that includes but is not

limited to:

a. the scope of the quality management system, (reference section 1.0)

b. reference to the documented procedures established for the quality management system; i.e.

SOP 4.0 titled, Quality Management System; SOP 5.0 titled, Management Responsibility; SOP

6.0 titled, Resource Management; SOP 7.0 titled, Product Realization and SOP 8.0 titled,

Measurement, Analysis and Improvement

c. the interactions between processes is defined in the Process Map at the end of this manual.

4.2.3 Control of Documents

C&H maintains a procedure that defines the document controls needed to:

a. approve documents for adequacy prior to issue

b. review, update as necessary and re-approve documents

c. ensure changes and current revision status of documents is identified

d. ensure relevant versions of applicable documents are available at points of use

e. ensure that documents remain legible and readily identifiable

f. ensure documents of external origin determined by C&H to be necessary for the planning and

operation of the QMS are identified and their distribution controlled

g. identify obsolete documents retained for reference and prevent unintended use

See section 4.2.4 titled, Control of Records.

Quality Management Systems Manual Date Effective

Revision C Page 6 of 26 05/17/2013

4.0 Quality Management System (cont’d)

4.2.3.1 Engineering Specifications

C&H’s process for the control of documents provides for:

a. the timely review, distribution and implementation of all customer engineering standards /

specifications and changes based on customer-required schedule

b. reviews to occur within 10 business days

c. records showing when documents were updated and when each change was implemented in

production

NOTE: A change in these standards/specifications requires an updated record of customer production

part approval when these specifications are referenced on the design record or if they affect documents

of production part approval process, such as control plan, FMEAs, etc.

4.2.4 Control of Records

Records established to provide evidence that the QMS is effective and compliant to requirements are

controlled. Procedures have been established that includes requirements to identify, store, protect,

retrieve and disposition records according to retention times. Records are legible, identifiable and

retrievable.

NOTE 1 “Disposition” includes disposal.

NOTE 2 “Records” also include customer-specified records.

4.2.4.1 Records Retention

C&H’s system for the control of records satisfies statutory, regulatory and customer requirements.

REFERENCE SOP 4.0 TITLED, QUALITY MANAGEMENT SYSTEM

Quality Management Systems Manual Date Effective

Revision C Page 7 of 26 05/17/2013

5.0 Management Responsibility

5.1 Management Commitment

Top management’s commitment to developing, implementing and continuously improving the

effectiveness of the QMS is evidenced by:

a. communicating to the organization the importance of meeting customer, statutory and

regulatory requirements

b. establishing a quality policy

c. ensuring that quality objectives are established

d. conducting management reviews

e. ensuring the availability of resources

5.1.1 Process Efficiency

Top management participates in the product realization processes and the support processes defined in

section 7.0 to assure their effectiveness and efficiency.

5.2 Customer Focus

Top management determines customer requirements and ensures they are met with the aim of

enhancing customer satisfaction. See section 7.2.1 titled, Determination of Requirements Related to the

Product and section 8.2.1 titled, Customer Satisfaction.

5.3 Quality Policy

Top management ensures that the quality policy:

a. is relevant to the purpose of the organization

b. includes a commitment to comply with requirements while continually improving the

effectiveness of the QMS

c. provides a framework for establishing and reviewing quality objectives

d. is communicated and understood throughout the organization

e. is reviewed for continuing suitability (reference section 3.0 titled, Strategy Statement)

5.4 Planning

5.4.1 Quality Objectives

Top management has established measurable objectives at relevant functions and levels of the

organization. The objectives are consistent with the quality policy and required to meet product

requirements. Reference section 5.6 titled, Management Review.

5.4.1.1 Quality Objectives - Supplemental

The President of C&H maintains a business plan that addresses customer expectations and is

integrated with the Management Review process (reference section 5.6). The business plan is updated

yearly at a minimum.

5.4.2 Quality Management System Planning

Top management ensures that:

a. QMS planning is carried out in order to meet the general requirements listed in section 4.1 as

well as the quality objectives

b. the QMS integrity is maintained when changes to the QMS are planned and implemented

5.5 Responsibility, Authority and Communication

5.5.1 Responsibility and Authority

Top management ensures that responsibilities and authorities are defined and communicated within the

organization. Organizational charts for C&H are provided for reference at the end of this manual.

5.5.1.1 Responsibility For Quality

Managers with responsibility and authority for corrective action are promptly informed when products or

processes which do not conform to requirements. Personnel ultimately responsible for conformity to

product requirements have the authority to stop production and correct quality problems. All shifts are

staffed with personnel responsible for ensuring conformity to product requirements.

Quality Management Systems Manual Date Effective

Revision C Page 8 of 26 05/17/2013

5.0 Management Responsibility (cont’d)

5.5.2 Management Representative

Top management has appointed the (Quality Systems) QS Coordinator as the Management

Representative with the responsibility and authority to:

a. ensure that processes needed for the QMS are established, implemented and maintained

b. report QMS performance and required improvement to top management

c. ensure the awareness of customer requirements is being promoted throughout the organization

5.5.2.1 Customer Representative

Top management has designated personnel with the responsibility and authority to ensure that

customer requirements are addressed. This includes selection of special characteristics, setting quality

objectives and related training, corrective and preventive actions and product development.

5.5.3 Internal Communication

Top management has established appropriate communication processes within the organization and

ensures that communication takes place relative to the effectiveness of the QMS.

5.6 Management Review

5.6.1 General

Top management reviews the QMS at planned intervals to ensure its continuing suitability, adequacy

and effectiveness. The review includes assessing opportunities for improvement, the need for changes

to the QMS, quality policy and quality objectives. Records of the reviews are maintained according to

section 4.2.4 titled, Control of Records.

5.6.1.1 Quality Management System Performance

These reviews include all requirements of the QMS and its performance trends as an essential part of

the continual improvement process. Part of the Management Review includes the monitoring of quality

objectives and the regular reporting and evaluation of the cost of poor quality (see 8.4.1 titled, Analysis

and use of Data and 8.5.1 titled, Continual Improvement). Results are recorded to provide, as a

minimum, evidence of the achievement of the quality objectives specified in the business plan and

customer satisfaction with product supplied. See 8.2.1 titled, Customer Satisfaction.

5.6.2 Review Input

Input to Management Reviews includes but is not limited to:

a. results of audits

b. customer feedback

c. process performance and product conformity

d. status of preventive and corrective action

e. follow-up actions from previous management reviews

f. changes that could affect the QMS

g. recommendations for improvement

5.6.2.1 Review Input - Supplemental

Input to Management Review includes an analysis of actual and potential field-failures and their impact

on quality, safety or the environment.

5.6.3 Review Output

Output from the Management Reviews includes any decisions and actions related to:

a. improving the effectiveness of the QMS and its processes

b. improving the product relative to customer requirements

c. resource requirements

REFERENCE SOP 5.0 TITLED, MANAGEMENT RESPONSIBILIY

Quality Management Systems Manual Date Effective

Revision C Page 9 of 26 05/17/2013

6.0 Resource Management

6.1 Provision of Resources

C&H has determined and provided resources needed to:

a. implement, maintain and continuously improve the effectiveness of the QMS

b. enhance customer satisfaction by meeting customer requirements

6.2 Human Res ources

6.2.1 General

Personnel performing work affecting conformity to product requirements are competent on the basis of

appropriate education, training, skills and experience.

NOTE: Conformity to product requirements can be affected directly or indirectly by personnel performing

any task within the QMS.

6.2.2 Competence, Training and Awareness

C&H:

a. determines the necessary competence for personnel performing work affecting conformity to

product requirements

b. where necessary, provides training or other actions to achieve the necessary competence

c. evaluates the effectiveness of the actions taken

d. ensures that personnel are aware of the relevance and importance of their activities and how

they contribute to the achievement of the quality objectives

e. maintains appropriate records according to section 4.2.4 of education, training, skills and

experience

6.2.2.1 Product Design Skills

C&H ensures that personnel with product design responsibility are competent to achieve design

requirements and are skilled in applicable tools and techniques. Applicable tools and techniques have

been identified by C&H.

NOTE: The word “product” excludes the customer’s product design.

6.2.2.2 Training

C&H has established and maintains documented procedures for identifying training needs and

achieving competence of all personnel performing activities affecting conformity to product

requirements. This includes ensuring that personnel performing specific assigned tasks are qualified, as

required, with particular attention to the satisfaction of customer requirements.

NOTE 1: This applies to all employees having an effect on quality at all levels of the organization.

NOTE 2: An example of customer-specific requirements is the application of digitized mathematically

based data.

6.2.2.3 Training On The Job

C&H provides on-the-job training for personnel in any new or modified job affecting conformity to

product requirements, including contract or agency personnel. Personnel whose work can affect quality

are informed about the consequences to the customer of nonconformity to quality requirements.

6.2.2.4 Employee Motivation & Empowerment

C&H has a process to motivate employees to achieve quality objectives, to make continual

improvements, and to create an environment to promote innovation. The process includes the

promotion of quality and technological awareness throughout the whole organization. Company metrics

are used to measure the extent to which personnel are aware of the relevance and importance of their

activities and how they contribute to the achievement of the quality objectives [see 6.2.2 d)].

6.3 Infrastructure

C&H has determined, provided for and maintains the infrastructure needed to achieve conformity to

product requirements which includes, as applicable:

a. buildings, workspace and associated utilities

b. process equipment (both hardware and software)

c. supporting services (such as transport, communication, or information systems)

Quality Management Systems Manual Date Effective

Revision C Page 10 of 26 05/17/2013

6.0 Resource Management (cont’d)

6.3.1 Plant, Facility & Equipment Planning

C&H uses a multidisciplinary approach (see 7.3.1.1) for developing plant, facility and equipment plans.

Plant layouts are developed to optimize material travel, handling and value-added use of floor space,

and shall facilitate synchronous material flow. Methods have been developed and implemented to

evaluate and monitor the effectiveness of existing operations.

NOTE: This process focuses on lean manufacturing principles and links directly to business plan metrics

for evaluating the effectiveness of the quality management system.

6.3.2 Contingency Plan

C&H maintains contingency plans to satisfy customer requirements in the event of an emergency such

as utility interruptions, labor shortages, key equipment failure and field returns.

6.4 Work Environment

C&H has determined and manages the work environment needed to achieve conformity to product

requirements.

NOTE: The term “work environment” relates to those conditions under which work is performed

including physical, environmental, and other factors (such as noise, temperature, humidity, lighting or

weather).

6.4.1 Personnel Safety To Achieve Conformity To Product Requirements

C&H addresses product safety and the means to minimize potential risks to employees during the

development process for manufacturing activities. Reference section 7.0.

6.4.2 Cleanliness Of Premises

C&H maintains its premises in a state of order, cleanliness and repair consistent with the product and

manufacturing process needs.

REFERENCE SOP 6.0 TITLED, RESOURCE MANAGEMENT

Quality Management Systems Manual Date Effective

Revision C Page 11 of 26 05/17/2013

7.0 Product Realization

7.1 Planning for Product Realization

C&H plans and develops processes needed for product realization. The planning of product realization

is consistent with the requirements of other processes of the QMS (see section 4.1).

In planning product realization, C&H determines the following, as appropriate:

a. quality objectives and requirements for the product

b. the need to establish processes and documents and to provide resources specific to the product

c. required verification, validation, monitoring, measurement, inspection and test activities specific

to the product and the criteria for product acceptance

d. records needed to provide that the realization processes and resulting product meet

requirements (see section 4.2.4).

NOTE: A document specifying the processes of the QMS (including the product realization processes)

and the resources to be applied to a specific product, project or contract, can be referred to as a quality

plan). Requirements listed in section 7.3 titled, Design and Development may be applied.

NOTE Some customers refer to project management or advanced product quality planning as a means

to achieve product realization. Advanced product quality planning embodies the concepts of error

prevention and continual improvement as contrasted with error detection, and is based on a

multidisciplinary approach.

7.1.1 Planning of Product Realization — Supplemental

Customer requirements and references to its technical specifications are included in the planning of

product realization as a component of the quality plan.

7.1.2 Acceptance Criteria

Acceptance criteria are defined by C&H and, where required, approved by the customer. For attribute

data sampling, the acceptance level shall be zero defects (see 8.2.3.1).

7.1.3 Confidentiality

C&H ensures the confidentiality of customer-contracted products and projects under development, and

related product information.

7.1.4 Change Control

C&H maintains a process to control and react to changes that impact product realization. The effects of

any change, including those changes caused by any supplier, are assessed, and verification and

validation activities are defined, to ensure compliance with customer requirements. Changes are

validated before implementation.

For proprietary designs, the impact on form, fit and function (including performance and/or durability) are

reviewed with the customer so that all effects can be properly evaluated. When required by the

customer, additional verification / identification requirements, such as those required for new product

introduction, are met.

NOTE 1 Any product realization change affecting customer requirements requires notification to, and

agreement from, the customer.

NOTE 2 The above requirement applies to product and manufacturing process changes.

Quality Management Systems Manual Date Effective

Revision C Page 12 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.2 Customer-related Processes

7.2.1 Determination of Requirements Related to the Product

C&H determines:

a. requirements specified by the customer, including requirements for delivery and post delivery

activities

b. requirements not stated by the customer but necessary for specified or intended use

c. statutory and regulatory requirements applicable to the product

d. any additional requirements considered necessary by the organization

NOTE: Post delivery activities include, for example, actions under warranty provisions, contractual

obligations such as maintenance services, and supplementary services such as recycling or final

disposal.

NOTE 1 Post-delivery activities include any after-sales product service provided as part of the customer

contract or purchase order.

NOTE 2 This requirement includes recycling, environmental impact and characteristics identified as a

result of the organization's knowledge of the product and manufacturing processes (see 7.3.2.3).

NOTE 3 Compliance to item c) includes all applicable government, safety and environmental

regulations, applied to acquisition, storage, handling, recycling, elimination or disposal of materials.

7.2.1.1 Customer-Designated Special Characteristics

C&H has developed and maintains a process to demonstrate conformity to customer requirements for

designation, documentation and control of special characteristics.

7.2.2 Review of Requirements Related to the Product

C&H reviews the requirements related to each product. The review is conducted prior to any

commitment to supply the product to the customer (e.g. submission of tenders, acceptance of contract

or orders, acceptance of changes to contracts or orders) and ensures that:

a. product requirements are defined

b. contract or order requirements differing from those previously expressed are resolved

c. the company has the ability to meet the defined requirements

Where product requirements are changed, C&H ensures that relevant documents are amended and that

relevant personnel are made aware of the changed requirements. Records are maintained according to

section 4.2.4 titled, Control of Records.

NOTE In some situations, such as internet sales, a formal review is impractical for each order. Instead

the review can cover relevant product information such as catalogues or advertising material.

7.2.2.1 Review of Requirements Related to the Product — Supplemental

C&H will obtain the customer’s authorization before waiving the requirement stated in 7.2.2 for a formal

review (see NOTE at the end of section 7.2.2).

7.2.2.2 Organization Manufacturing Feasibility

C&H investigates, confirms and documents the manufacturing feasibility of the proposed products in the

contract review process, which includes risk analysis. See section 7.2.2.

7.2.3 Customer Communication

C&H has determined and implemented effective arrangements for communicating with customers the

issues related to:

a. product information

b. enquiries, contracts or order handling, including amendments

c. customer feedback, including customer complaints

7.2.3.1 Customer Communication — Supplemental

C&H communicates necessary information, including data, in a customer-specified language and format

(e.g. computer-aided design data, electronic data exchange).

7.3 Design and Development – N/A

Design and Development requirements relating to the product are not applicable to C&H as this time.

Quality Management Systems Manual Date Effective

Revision C Page 13 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.4 Purchasing

7.4.1 Purchasing Process

C&H ensures that purchased product conforms to specified purchase requirements. The type and

extent of control applied to the supplier and the purchased product is dependent upon the effect of the

purchased product on subsequent product realization or the final product.

C&H evaluates and selects suppliers based on their ability to supply products in accordance

requirements specified by the customer and / or C&H. Criteria for selection, evaluation, and re-

evaluation is established. Records of the evaluation results and any actions arising from the evaluation

are maintained as prescribed in section 4.2.4.

NOTE 1 Purchased products above include all products and services that affect customer requirements

such as subassembly, sequencing, sorting, rework and calibration services.

NOTE 2 When there are mergers, acquisitions or affiliations associated with suppliers, the organization

should verify the continuity of the supplier's quality management system and its effectiveness.

7.4.1.1 Statutory and Regulatory Conformity

C&H ensures that all purchased products or materials used in product conform to applicable statutory

and regulatory requirements.

7.4.1.2 Supplier Quality Management System Development

C&H works with suppliers to develop their quality management system with the goal of conformity to this

Technical Specification. Conformity with ISO 9001:2008 is the first step in achieving this goal.

NOTE The prioritization of suppliers for development depends upon, for example, the supplier's quality

performance and the importance of the product supplied.

Unless otherwise specified by the customer, suppliers to the organization shall be third party, registered

to ISO 9001:2008 by an accredited third-party certification body.

7.4.1.3 Customer-Approved Sources

Where specified by the contract (e.g. customer engineering drawing, specification), C&H purchases

products, materials or services from approved sources.

The use of customer-designated sources, including tool/gauge suppliers, does not relieve C&H of the

responsibility for ensuring the quality of purchased products.

7.4.2 Purchasing Information

Purchasing information describes the product to be purchased, including where appropriate:

a. requirements for approval of product, procedures, processes and equipment

b. requirements for qualification of personnel

c. QMS requirements

C&H ensures the adequacy of specified purchase requirements prior to their communication to the

supplier.

7.4.3 Verification of Purchased Product

C&H has established and implemented the inspection or other activities necessary for ensuring that

purchased product meets specified purchase requirements.

Where C&H or C&H’s customers intend to perform verification at the supplier’s premises, C&H states

the intended verification arrangements and methods of product release in the purchasing information.

7.4.3.1 Incoming Product Conformity to Requirements

C&H maintains a process to assure the quality of purchased product (see 7.4.3) utilizing one or more of

the following methods:

a. receipt of, and evaluation of, statistical data by the organization;

b. receiving inspection and/or testing, such as sampling based on performance;

c. second or third-party assessments or audits of supplier sites, when coupled with records of

acceptable delivered product conformity to requirements;

d. part evaluation by a designated laboratory;

e. another method agreed with the customer.

Quality Management Systems Manual Date Effective

Revision C Page 14 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.4.3.2 Supplier Monitoring

C&H monitors supplier performance through the following indicators:

a. delivered product conformity to requirements;

b. customer disruptions, including field returns;

c. delivery schedule performance (including incidents of premium freight);

d. special status customer notifications related to quality or delivery issues.

C&H promotes supplier monitoring of the performance of their manufacturing processes.

7.5 Production and Service Provision

7.5.1 Control of Production and Service Provision

C&H plans and carries out production and service provision under controlled conditions which includes,

as applicable:

a. the availability of information that describes the characteristics of the product

b. the availability of work instructions, as necessary

c. the use of suitable equipment

d. the availability and use of monitoring and measuring equipment

e. the implementation of monitoring and measurement

f. the implementation of product release, delivery and post-delivery activities

7.5.1.1 Control Plan

C&H

a. develops control plans at the system, subsystem, component and/or material level for the

product supplied, including those for processes producing bulk materials as well as parts, and

b. has a control plan for pre-launch and production that takes into account the design FMEA and

manufacturing process FMEA outputs.

The control plan includes

c. the controls used for the manufacturing process control,

d. methods for monitoring of control exercised over special characteristics (see 7.3.2.3) defined by

both the customer and C&H,

e. customer-required information, if any, and

f. a reaction plan (see 8.2.3.1) when the process becomes unstable or not statistically capable.

Control plans are reviewed and updated when any change occurs affecting product, manufacturing

process, measurement, logistics, supply sources or FMEA (see 7.1.4).

NOTE Customer approval may be required after review or update of the control plan.

7.5.1.2 Work Instructions

C&H prepares and maintains documented work instructions for all employees having responsibilities for

the operation of processes that impact conformity to product requirements. The instructions are derived

from sources such as the quality plan, the control plan and the product realization process and

accessible for use at the work stations.

7.5.1.3 Verification of Job Set-ups

Job set-ups are verified whenever performed, such as an initial run of a job, material changeover or job

change.

Work instructions are available for set-up personnel. Where applicable, C&H uses statistics as a method

of verification. Last-off or “end of run” comparisons are also performed for the die casting process.

7.5.1.4 Preventive and Predictive Maintenance

C&H has identified key process equipment and provides resources for machine / equipment

maintenance and has developed an effective planned total preventive maintenance system. As a

minimum, this system includes the following:

a. planned maintenance activities;

b. packaging and preservation of equipment, tooling and gauging;

c. availability of replacement parts for key manufacturing equipment;

d. documenting, evaluating and improving maintenance objectives.

C&H utilizes predictive maintenance methods to continually improve the effectiveness and the efficiency

of production equipment.

Quality Management Systems Manual Date Effective

Revision C Page 15 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.5.1.5 Management of Production Tooling

C&H provides resources for tool and gauge design, fabrication and verification activities.

C&H has established and implemented a system for production tooling management including:

a. maintenance and repair facilities and personnel;

b. storage and recovery;

c. set-up;

d. tool-change programs for perishable tools;

e. tool design modification documentation, including engineering change level;

f. tool modification and revision to documentation;

g. tool identification, defining the status, such as production, repair or disposal.

C&H maintains a system to monitor these activities when work is outsourced.

NOTE This requirement also applies to the availability of tools for vehicle service parts.

7.5.1.6 Production Scheduling

Production is scheduled to meet customer requirements, such as just-in-time supported by an

information system that permits access to production information at key stages of the process and is

order driven.

7.5.1.7 Feedback of Information From Service

A process for communication of information on service concerns to manufacturing, engineering and

design activities has been established and maintained.

NOTE The intent of the addition of “service concerns” to this subclause is to ensure that the

organization is aware of nonconformities that occur outside of its organization.

7.5.1.8 Service Agreement with Customer

When there is a service agreement with the customer, C&H will verify the effectiveness of

a. any organization service centres,

b. any special-purpose tools or measurement equipment, and

c. the training of service personnel.

7.5.2 Validation of Processes for Production and Service Provision

C&H validates all processes for production and service provision where the resulting output cannot be

verified by subsequent monitoring or measurement and, as a consequence, deficiencies become

apparent only after the product is in use or the service has been delivered.

Validation demonstrates the ability of these processes to achieve planned results.

C&H establishes arrangements for these processes including, as applicable:

a. defined criteria for review and approval of the processes

b. approval of equipment and qualification of personnel

c. use of specific methods and procedures

d. requirements for records (see 4.2.4)

e. revalidation

7.5.2.1 Validation of Processes for Production and Service Provision — Supplemental

The requirements of 7.5.2 apply to all processes for production and service provision.

7.5.3 Identification and Traceability

Where appropriate, C&H identifies the product by suitable means throughout product realization

including product status with respect to monitoring and measurement requirements throughout product

realization. Where traceability is a requirement, C&H controls the unique identification of the product

and maintains records (see 4.2.4).

NOTE Inspection and test status is not indicated by the location of product in the production flow unless

inherently obvious, such as material in an automated production transfer process. Alternatives are

permitted, if the status is clearly identified, documented and achieves the designated purpose.

7.5.3.1 Identification and Traceability — Supplemental

The words “Where appropriate” in 7.5.3 does not apply.

Quality Management Systems Manual Date Effective

Revision C Page 16 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.5.4 Customer Property

C&H exercises care with customer property while it is under C&H’s control or being used by C&H. C&H

identifies, verifies, protects and safeguards the customer’s property provided for use or incorporation

into the product. If any customer property is lost, damaged or otherwise found to be unsuitable for use,

the customer will be notified and records created and maintained (see 4.2.4).

NOTE: Customer property can include intellectual property and personal data.

NOTE Customer-owned returnable packaging is included in this sub-clause.

7.5.4.1 Customer-Owned Production Tooling

Customer-owned tools, manufacturing, test, inspection tooling and equipment are permanently marked

so that the ownership of each item is visible, and can be determined.

7.5.5 Preservation of Product

C&H preserves the product during internal processing and delivery to the intended destination in order

to maintain conformity to requirements. As applicable, preservation includes identification, handling,

packaging, storage, protection and applies to the constituent parts of a product.

7.5.5.1 Storage and Inventory

In order to detect deterioration, the condition of product in stock is assessed at appropriate planned

intervals.

C&H uses an inventory management system to optimize inventory turns over time and assure stock

rotation, such as “first-in-first-out” (FIFO). Obsolete product is controlled in a similar manner to

nonconforming product.

7.6 Control of Monitoring and Measuring Equipment

C&H determines the monitoring and measurement to be undertaken and the monitoring and

measurement equipment needed to provide evidence of conformity or product to determine

requirements (see 7.2.1).

C&H establishes processes to ensure that monitoring and measurements can be carried out and are

carried out in a manner that is consistent with the monitoring and measurement requirements.

When necessary to ensure valid results, measuring equipment is:

a. calibrated or verified, or both at specified intervals, or prior to use, against measurement

standards traceable to international or national measurement standards; where no such

standards exist, the basis used for calibration or verification is recorded

b. adjusted or re-adjusted as necessary

c. identified in order to determine its calibration status

d. safeguarded from adjustments that would invalidate the measurement result

e. protected from damage and deterioration during handling, maintenance and storage

In addition, C&H assesses and records the validity of the previous measuring results when the

equipment is found not to conform to requirements. C&H takes appropriate action on the equipment and

any product affected. Records of the results of calibration and verification are maintained (see 4.2.4)

NOTE: Confirmation of the ability of computer software to satisfy the intended application would typically

include its verification and configuration management to maintain its suitability for use.

7.6.1 Measurement System Analysis

Statistical studies are conducted to analyze the variation present in the results of each type of

measuring and test equipment system. This requirement applies to measurement systems referenced

in the Control Plan and / or Quality Control Plan (QCP). The analytical methods and acceptance criteria

used conforms to those in customer reference manuals on measurement systems analysis. Other

analytical methods and acceptance criteria are used when approved by the customer.

Quality Management Systems Manual Date Effective

Revision C Page 17 of 26 05/17/2013

7.0 Product Realization (cont’d)

7.6.2 Calibration / Verification Records

Records of calibration / verification activity for each type of measuring and test equipment, including

employee-owned equipment includes:

a. equipment identification, including the standard against which the equipment is calibrated

b. revisions following engineering changes

c. any out-of-tolerance readings as received for calibration / verification

d. an assessment of the impact of out-of-specification condition

e. statements of conformity to specification after calibration / verification

f. notification to the customer if suspect product or material has been shipped

7.6.3 Laboratory Requirements

7.6.3.1 Internal Laboratory

C&H has defined a laboratory scope that includes its capability to perform the required inspection, test

or calibration services and is included in the quality management system documentation. The technical

requirements implemented by the laboratory address as a minimum:

a. adequacy of laboratory procedures

b. competency of laboratory personnel

c. testing of product

d. capability to perform services correctly and to a relevant process standard

7.6.3.2 External Laboratory

External / commercial / independent laboratory facilities used for inspection, test or calibration services

have defined a scope that includes their capability to perform the required inspection, test or calibration.

C&H maintains evidence that the external laboratory has been accepted by the customer or is

accredited to ISO / IEC 17025 or national equivalent.

NOTE 1: Such evidence may be in the form of a customer assessment or a customer-approved second-

party assessment that demonstrates the laboratory meets the intent of ISO / IEC 17025 or national

equivalent.

NOTE 2: When a qualified laboratory is not available for a given piece of equipment, calibration services

may be performed by the equipment manufacturer. I such cases, C&H will ensure that the requirements

listed in 7.6.3.1 are met.

REFERENCE SOP 7.0 TITLED, PRODUCT REALIZATION

Quality Management Systems Manual Date Effective

Revision C Page 18 of 26 05/17/2013

8.0 Measurement, Analysis and Improvement

8.1 General

C&H plans and implements the monitoring, measurement, analysis and improvement processes needed

to:

a. demonstrate conformity to product requirements

b. ensure conformity of the QMS

c. continually improve the effectiveness of the QMS

This includes determination of applicable methods, including statistical techniques, and the extent of

their use.

8.1.1 Identification of Statistical Tools

The statistical techniques mentioned in section 8.1 and appropriate tools for each process are

determined during advanced quality planning and included in the control plans.

8.1.2 Knowledge of Basic Statistical Concepts

Where appropriate, basic statistical concepts, such as variation, control (stability), process capability

and over-adjustment are understood and utilized.

8.2 Monitoring and Measurement

8.2.1 Customer Satisfaction

C&H has determined methods for obtaining and using information relative to customer satisfaction.

As one of the performance measurements of the QMS, C&H monitors information relating to customer

perception as to whether C&H has met customer requirements.

NOTE: Monitoring customer perception can include obtaining input from sources such as customer

satisfaction surveys, customer data on delivered product quality, user opinion surveys, lost business

analysis, compliments, warranty claims and dealer reports.

NOTE: Consideration is given to both internal and external customers

8.2.1.1 Customer Satisfaction - Supplemental

Customer satisfaction is monitored through continual evaluation of performance of the realization

processes. Performance indicators are based on objective data and as a minimum include:

a. delivered part quality performance,

b. customer disruptions, including field returns,

c. on-time delivery(including incidents of premium freight), and

d. customer notifications related to quality or delivery issues.

The information and data from above is used to monitor the performance of manufacturing processes to

demonstrate compliance with customer requirements for product quality and efficiency of the process.

8.2.2 Internal Audit

C&H conducts internal audits at planned intervals to determine whether the QMS:

a. conforms to the planned arrangements (see 7.1), to the requirements of ISO/TS 16949 and to

the QMS requirements established by C&H

b. is effectively implemented and maintained

Audit programs are planned, taking into consideration the status and importance of the processes and

area to be audited, as well as the results of previous audits. The audit criteria, scope, frequency and

methods used are defined. The selection of auditors and conduct of audits ensure objectivity and

impartiality of the audit process. Auditors do not audit their own work.

Procedures define the responsibilities and requirements for planning audits, conducting audits,

recording and reporting results. Records of the audits and their results are maintained (see 4.2.4).

The management responsible for the area being audited ensures that any necessary corrections and

corrective actions are taken without undue delay to eliminate detected nonconformities and their

causes. Follow-up activities include verification of the actions taken and the reporting of verification

results (see 8.5.2).

NOTE: See ISO 19011, Guidelines on Quality and/or Environmental Management Systems Auditing for

guidance.

Quality Management Systems Manual Date Effective

Revision C Page 19 of 26 05/17/2013

8.0 Measurement, Analysis and Improvement (cont’d)

8.2.2.1 Quality Management Systems Audit

C&H performs audits of the quality management system to verify compliance with this Technical

Specification and any additional quality management system or customer specific requirements.

8.2.2.2 Manufacturing Process Audit

C&H conducts audits of each manufacturing process to determine its effectiveness.

8.2.2.3 Product Audit

C&H performs product audits at appropriate stages of production and delivery to verify conformity to all

specified requirements, such as product dimensions, functionality, packaging and labeling, at a defined

frequency.

8.2.2.4 Internal Audit Plans

Internal audits are scheduled according to an annual plan and cover all quality management related

processes, activities and shifts.

When internal / external nonconformities or customer complaints occur, the Manufacturing Process

Audit (section 8.2.2.2) and or Product Audit (section 8.2.2.3) frequency will be appropriately increased.

8.2.2.5 Internal Auditor Qualifications

C&H utilizes internal auditors who are qualified to audit the requirements of this Technical Specification

(see 6.2.2.2).

8.2.3 Monitoring and Measurement of Processes

C&H applies suitable methods for monitoring and, where applicable, measurement of the QMS

processes. These methods demonstrate the ability of the processes to achieve planned results. When

planned results are not achieved, correction and corrective action are taken, as appropriate.

NOTE: When determining suitable methods, consideration is given to the type and extent of monitoring

or measurement appropriate to each of the processes in relation to the impact on conformity to product

requirements and on the effectiveness of the QMS.

8.2.3.1 Monitoring and Measurement of Manufacturing Processes

C&H performs process studies on all new manufacturing (including assembly or sequencing) processes

to verify process capability and to provide additional input for process control. The results are

documented with specifications, where applicable, for means of production, measurement and test, and

maintenance instructions.

Objectives are established for manufacturing process capability, reliability, maintainability and

availability, as well as acceptance criteria.

C&H maintains the manufacturing process capability or performance as specified by the customer part

approval process requirements. This includes implementation of the process flow diagram and control

plan which includes at a minimum, measurement techniques, sampling plans, acceptance criteria, and

reaction plans when acceptance criteria are not met.

Significant process events, such as tool change or machine repair is also recorded.

The reaction plan addresses characteristics that are either not statistically capable or are unstable which

includes containment of product and 100% inspection, as appropriate.

Corrective action plans are then completed indicating specific timing and assigned responsibilities to

assure that the process becomes stable and capable. Action plans identifying the dates of process

changes are reviewed with and approved by the customer when so required.

8.2.4 Monitoring and Measurement of Product

C&H monitors and measures the characteristics of the product to verify that product requirements have

been met. This is carried out at appropriate stages of the product realization process in accordance with

the planned arrangements (see 7.1). Evidence of conformity with the acceptance criteria is maintained.

Evidence of conformity with acceptance criteria as well as the person(s) authorizing release of product

for delivery to the customer is recorded and maintained (see 4.2.4).

The release of product and delivery of service to the customer do not proceed until all planned

arrangements (see 7.1) have been satisfactorily completed, unless otherwise approved by a relevant

authority, and where applicable by the customer.

Quality Management Systems Manual Date Effective

Revision C Page 20 of 26 05/17/2013

8.0 Measurement, Analysis and Improvement (cont’d)

8.2.4.1 Layout Inspection and Functional Testing

A layout inspection and a functional verification to applicable customer engineering material and

performance standards are performed for each product as specified in the control plans. Results are

available for customer review.

NOTE Layout inspection is the complete measurement of all product dimensions shown on the design

records.

8.2.4.2 Appearance Items

C&H addresses customer designated “appearance items” by providing as appropriate,

a. appropriate resources and lighting, for evaluation,

b. masters for color, grain, gloss, metallic brilliance, texture and / or distinctness of image (DOI),

c. maintenance and control of appearance masters and evaluation equipment, and

d. verification that personnel performing evaluations are competent and qualified to do so.

8.3 Control of Nonconforming Product

C&H ensures that product which does not conform to specified requirements is identified and controlled

to prevent its unintended use or delivery. Procedures are established to define the controls and related

responsibilities and authorities for dealing with nonconforming product.

Where applicable, C&H handles nonconforming product in one or more of the following ways:

a. by taking action to eliminate the detected nonconformity

b. by authorizing its use, release or acceptance under concession by a relevant authority and,

where appropriate, by the customer

c. by taking action to preclude its intended use or application

d. by taking action appropriate to the effects, or potential effects, of the nonconformance when

nonconforming product is detected after delivery of use has started.

When nonconforming product is corrected it is subject to re-verification to demonstrate conformity to the

requirements.

Records of the nature of nonconformities and subsequent actions taken, including concessions obtained

are maintained (see 4.2.4).

8.3.1 Control of Nonconforming Product - Supplemental

C&H classifies product with unidentified or suspect status as nonconforming product (see 7.5.3).

8.3.2 Control of Reworked Product

C&H ensures that all instructions for rework, including re-inspection requirements, are accessible to and

utilized by the appropriate personnel.

8.3.3 Customer Information

C&H promptly contacts the customer any time suspect or nonconforming product has been shipped.

8.3.4 Customer Waiver

C&H request and obtain a customer concession or deviation permit prior to further processing whenever

the product or manufacturing process is different from that which is currently approved.

The expiration date or quantity authorized is recorded and maintained. C&H ensures compliance with

the original or superseding specifications and requirements when the authorization expires. Product

shipped on an authorization is properly identified on each shipping container.

This applies equally to purchased product. C&H reviews and as appropriate, approves requests from

suppliers before submission to the customer.

Quality Management Systems Manual Date Effective

Revision C Page 21 of 26 05/17/2013

8.0 Measurement, Analysis and Improvement (cont’d)

8.4 Analysis of Data

C&H determines, collects and analyzes appropriate data to demonstrate the suitability and effectiveness

of the QMS and to evaluate where continual improvement of the effectiveness of the QMS can be

made. This includes data generated as a result of monitoring and measuring and from other relevant

sources.

The analysis of data provides information relating to:

a. customer satisfaction (see 8.2.1)

b. conformity to product requirements (see 8.2.4)

c. characteristics and trends of processes and products including opportunities for preventive

action (see 8.2.3 and 8.2.4)

d. suppliers (see 7.4)

8.4.1 Analysis and Use of Data

C&H compares trends in quality and operational performance with progress toward objectives and takes

action to support the following:

a. development of priorities for prompt solutions to customer-related problems;

b. determination of key customer-related trends and correlation for status review, decision-making

and longer term planning;

c. an information system for the timely reporting of product information arising from usage.

8.5 Improvement

8.5.1 Continual Improvement

C&H continually improves the effectiveness of the QMS through the use of the quality policy, quality

objectives, audit results, analysis of data, corrective and preventive actions and management review.

8.5.1.1 Continual Improvement of the Organization

C&H has defined a process for continual improvement.

8.5.1.2 Manufacturing Process Improvement

Manufacturing process improvement activities continually focuses on control and reduction of variation

in product characteristics and manufacturing process parameters.

NOTE 1 Controlled characteristics are documented in the control plan.

NOTE 2 Continual improvement is implemented once manufacturing processes are capable and stable,

or product characteristics are predictable and meet customer requirements.

8.5.2 Corrective Action

C&H takes action to eliminate the causes of nonconformities in order to prevent recurrence.

Corrective actions are appropriate to the effects of the nonconformities encountered.

Documented procedures define requirements for:

a. reviewing nonconformities (including customer complaints)

b. determining the causes of nonconformities

c. evaluating the need for action to ensure that nonconformities do not recur

d. determining and implementing action needed

e. records of the results of action taken (see 4.2.4)

f. reviewing the effectiveness of the corrective action taken

8.5.2.1 Problem Solving

C&H has defined a process for problem solving leading to root cause identification and elimination.

When a customer-prescribed problem-solving format exists, C&H uses the prescribed format.

8.5.2.2 Error-Proofing

C&H uses error-proofing methods in the corrective action process.

8.5.2.3 Corrective Action Impact

C&H applies corrective actions and controls implemented to other similar processes and products in

order to eliminate the cause of a nonconformity.

Quality Management Systems Manual Date Effective

Revision C Page 22 of 26 05/17/2013

8.0 Measurement, Analysis and Improvement (cont’d)

8.5.2.4 Rejected Product Test / Analysis

C&H analyzes parts rejected by the customer and initiates corrective action to prevent recurrence.

Actions are taken to minimize the cycle time of this process. Records of these analyses are kept and

made available upon request.

NOTE Cycle time related to rejected product analysis is consistent with the determination of root cause,

corrective action and monitoring the effectiveness of implementation.

8.5.3 Preventive Action

C&H determines the actions to eliminate the causes of potential nonconformities in order to prevent

their occurrence. Preventive actions are appropriate to the effects of the potential problems.

Documented procedures define requirements for:

a. determining potential nonconformities and their causes

b. evaluating the need for action to prevent occurrence of nonconformities

c. determining and implementing actions needed

d. records of results of action taken (see 4.2.4)

e. reviewing the effectiveness of the preventive action taken

REFERENCE SOP 8.0 TITLED, MEASUREMENT, ANALYSIS & IMPROVEMENT

Quality Management Systems Manual Date Effective

Revision C Page 23 of 26 05/17/2013

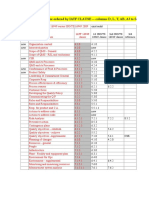

C&H Die Casting Organizational Chart & Responsibility & Authority For Quality

(Temple Facility)

Administration

President & CEO

Dir of Admin & VP Finance Mgr IS Mgr Safety & Environmental Mgr

(Human Resources)

Dir of Sales & Marketing

(QS Coordinator)

Quality Assurance

Dir of QA Svs Quality Eng CMM Tech SPC Tech Gage Tech

(Quality Assurance)

QA Sup D/C chTech

X-Ray Auditors

QA Sup Sec/FA Auditors

Engineering

Director of Project Engineering Continuous Improvement Engineer

(Project Engineer)

Dir of Engineering Tool Eng D/C Eng Sr. Mfg Eng Eng Tech

(Engineering Manager)

Operations

Dir of Manufacturing Prod Superintendents Supervisors Maintenance

(Plant Manager)

P/C Eng P/C Tech Scheduling Purchasing

Operators Data Mgr Shipping Cust Serv

Quality Management Systems Manual Date Effective

Revision C Page 24 of 26 05/17/2013

C&H Die Casting Organizational Chart & Responsibility & Authority For Quality

(Monterrey Facility)

Administration

President & CEO

Dir. of Sales & Marketing

(QS Coordinator)

Accounting Human Resources Purchasing

Quality Assurance

Dir of Quality Assurance Quality Engineer QA Supervisor

ch

X-Ray Technicians Auditors

Manufacturing

Dir of Manufacturing Supervisors Maintenance Die Repair

Operators Scheduling & Shipping

Quality Management Systems Manual Date Effective

Revision C Page 25 of 26 05/17/2013

Quality Management Systems Manual Date Effective

Revision C Page 26 of 26 05/17/2013

S-ar putea să vă placă și

- Sample Quality Management Manual TOC-StandardDocument3 paginiSample Quality Management Manual TOC-Standardazeem dilawarÎncă nu există evaluări

- Project Management: Getting It Right: Planning and Cost Manager’S GuideDe la EverandProject Management: Getting It Right: Planning and Cost Manager’S GuideÎncă nu există evaluări

- ISO 9001 Compliance Audit Schedule ExampleDocument5 paginiISO 9001 Compliance Audit Schedule ExampleMohamedÎncă nu există evaluări

- Systems for Planning and Control in ManufacturingDe la EverandSystems for Planning and Control in ManufacturingEvaluare: 3 din 5 stele3/5 (1)

- 9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17Document8 pagini9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17normalÎncă nu există evaluări

- Project Quality Plan - Package 1Document101 paginiProject Quality Plan - Package 1Syed Mohamed Gani GaniÎncă nu există evaluări

- Project Quality Plan for Closed Relief System & Flare Gas RecoveryDocument60 paginiProject Quality Plan for Closed Relief System & Flare Gas RecoveryrkssÎncă nu există evaluări

- NORSU Quality Manual 2017 Draft PDFDocument34 paginiNORSU Quality Manual 2017 Draft PDFAna Hidayah Syuhada100% (2)

- ISO 9001 Quality Manual SummaryDocument29 paginiISO 9001 Quality Manual SummarysÎncă nu există evaluări

- Engineering Mining Supplies Quality Policy ManualDocument42 paginiEngineering Mining Supplies Quality Policy ManualDanie Grobler100% (1)

- Free 16949 QMDocument52 paginiFree 16949 QMleewodon88% (8)

- Fancort Quality ManualDocument26 paginiFancort Quality ManualAmos FiestaÎncă nu există evaluări

- Isoqual, Inc.: 9001 - Quality ManualDocument33 paginiIsoqual, Inc.: 9001 - Quality ManualErika Licon100% (1)

- PDCA Cycle Diagram ISO 9001 2015Document2 paginiPDCA Cycle Diagram ISO 9001 2015John ThompsonÎncă nu există evaluări

- Iso 9001:2008 Iso/ts 16949:2009Document3 paginiIso 9001:2008 Iso/ts 16949:2009Anonymous di3fxBÎncă nu există evaluări

- QMS Vol. 1 PDFDocument436 paginiQMS Vol. 1 PDFCamilo Jorquera100% (2)

- Quality Manual Rev-27Document103 paginiQuality Manual Rev-27sambhaji100% (1)

- Temecula Quality Plating AS9100 REV C MANUALDocument13 paginiTemecula Quality Plating AS9100 REV C MANUALHoang TanÎncă nu există evaluări

- ISO 9001 Quality Manual SummaryDocument33 paginiISO 9001 Quality Manual Summaryramrom100% (4)

- Quality ManualDocument34 paginiQuality Manualchao gao100% (9)

- PROJECT QUALITY PLAN Rev-00Document33 paginiPROJECT QUALITY PLAN Rev-00shahhassa989% (18)

- IRIS Rev Vs IS022163 Correlation Matrix 1Document6 paginiIRIS Rev Vs IS022163 Correlation Matrix 1Centre For Total Quality ManagementÎncă nu există evaluări

- ISO 9001 - High Level StructureDocument1 paginăISO 9001 - High Level StructureМиша МакухÎncă nu există evaluări

- ISO 9001, 14001 and 45001 documentation requirementsDocument4 paginiISO 9001, 14001 and 45001 documentation requirementsMohamed Mostafa100% (1)

- DQSHolding - 750E1 - High Level Structure ISO 9001Document1 paginăDQSHolding - 750E1 - High Level Structure ISO 9001MTOLLERÎncă nu există evaluări

- Quality Manual SASB - APR - 2019 FinalDocument34 paginiQuality Manual SASB - APR - 2019 FinalVasudevan GovindarajÎncă nu există evaluări

- BOSCH7Document14 paginiBOSCH7Georgiana BusuiocÎncă nu există evaluări

- CRSE SA T 816 Project Quality Plan Rev05.pdf - Uploaded From NirayaDocument104 paginiCRSE SA T 816 Project Quality Plan Rev05.pdf - Uploaded From NirayaAhmad Assad mrednÎncă nu există evaluări

- You Must ISO 9001 2015Document2 paginiYou Must ISO 9001 2015ScribdTranslationsÎncă nu există evaluări

- Quality Systems Manual OverviewDocument36 paginiQuality Systems Manual OverviewpnagarajjÎncă nu există evaluări

- QMS Process IdentificationDocument1 paginăQMS Process IdentificationSaravana kumar NagarajanÎncă nu există evaluări

- QD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBDocument35 paginiQD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBAjibade SukuratÎncă nu există evaluări

- Quality Manual Template: WWW - Iso-9001-Checklist - Co.ukDocument10 paginiQuality Manual Template: WWW - Iso-9001-Checklist - Co.ukNavnath TamhaneÎncă nu există evaluări

- ISO 9001-2008-2015 Correlation Matrix v2Document4 paginiISO 9001-2008-2015 Correlation Matrix v2GiovanniÎncă nu există evaluări

- Setra's Quality Policy and Management SystemDocument50 paginiSetra's Quality Policy and Management SystemRavikumar qsolutionsÎncă nu există evaluări

- ISO 9001:2015 Clause Wise Changes: For Easier Clause Mapping From ISO 9001:2008 To ISO 9001:2015Document9 paginiISO 9001:2015 Clause Wise Changes: For Easier Clause Mapping From ISO 9001:2008 To ISO 9001:2015Dodiya JaydevÎncă nu există evaluări

- BM TRADA ISO 9001 Correlation MatrixDocument10 paginiBM TRADA ISO 9001 Correlation MatrixArfan SaniÎncă nu există evaluări

- Quality Control Manual SofascoDocument91 paginiQuality Control Manual Sofascosiddhartha dua100% (1)

- Iso KlausulDocument16 paginiIso KlausulMelisa HwangÎncă nu există evaluări

- IATF16949 Upgrading Activities ChartDocument6 paginiIATF16949 Upgrading Activities ChartAhmad AzrilÎncă nu există evaluări

- Quality Assurance POLICY & Quality ManualDocument150 paginiQuality Assurance POLICY & Quality Manualayman100% (1)

- Audit FormDocument6 paginiAudit FormmartinusteddyÎncă nu există evaluări

- Proposed Changes To ISO 9001 2015 Correlation MatrixDocument3 paginiProposed Changes To ISO 9001 2015 Correlation MatrixLuisEduardoJÎncă nu există evaluări

- SGB Performance Evaluation - R12 PDFDocument202 paginiSGB Performance Evaluation - R12 PDFnurhuda majid100% (2)

- Q R ManualDocument118 paginiQ R Manualangela1590Încă nu există evaluări

- ISO 9001 2008 and ISO 9001 2015 Correlation MatricesDocument7 paginiISO 9001 2008 and ISO 9001 2015 Correlation MatricesRudy JÎncă nu există evaluări

- Solution 1 - ISO 9001Document2 paginiSolution 1 - ISO 9001Oskar WrobelÎncă nu există evaluări

- Rumane A R Ed Handbook of Construction ManagementDocument5 paginiRumane A R Ed Handbook of Construction ManagementMarcel CoșcodanÎncă nu există evaluări

- Quality Manual qm0492 Iso ts16949 Supplement IDocument20 paginiQuality Manual qm0492 Iso ts16949 Supplement Ix engineeringÎncă nu există evaluări

- Proposed Changes To ISO 9001 2015 Correlation MatrixDocument2 paginiProposed Changes To ISO 9001 2015 Correlation Matrixsharif19740% (1)

- QMS Manual IS 9001 2015Document28 paginiQMS Manual IS 9001 2015Parag WadekarÎncă nu există evaluări

- Iso Presentation Asq 1114 Dec 2010 HandoutDocument25 paginiIso Presentation Asq 1114 Dec 2010 HandoutHarish YadavÎncă nu există evaluări

- IMS Internal Audit Check ListDocument5 paginiIMS Internal Audit Check ListAIM ConsultancyÎncă nu există evaluări

- Procedure No.: AC.01.00 Quality and Certification Division Procedures Procedure: Quality Manual Chapter: OrganizationDocument56 paginiProcedure No.: AC.01.00 Quality and Certification Division Procedures Procedure: Quality Manual Chapter: OrganizationMiljan SavicÎncă nu există evaluări

- 2011 Quality Assurance Perfomance Audit HandbookDocument281 pagini2011 Quality Assurance Perfomance Audit HandbookFachrurroziÎncă nu există evaluări

- Qhse ManualDocument30 paginiQhse ManualtonyÎncă nu există evaluări

- AS9100:2016 Quality ManualDocument36 paginiAS9100:2016 Quality ManualJulio César Rodríguez RodríguezÎncă nu există evaluări

- Updating Ims Program To Meet Iso 9001-2015Document54 paginiUpdating Ims Program To Meet Iso 9001-2015Udoy Hossen KhanÎncă nu există evaluări

- Hertwich Engineering - Multi Chamber Melting Furnace (Ecomelt)Document2 paginiHertwich Engineering - Multi Chamber Melting Furnace (Ecomelt)Станислав ПодольскийÎncă nu există evaluări

- Hertwich Engineering - Multi Chamber Melting Furnace (Ecomelt)Document2 paginiHertwich Engineering - Multi Chamber Melting Furnace (Ecomelt)Станислав ПодольскийÎncă nu există evaluări

- Metallurgical FurnacesDocument46 paginiMetallurgical FurnacesDavid Ballena GuerreroÎncă nu există evaluări

- 25th Secondary Aluminium Conference 2017 Salt SlagDocument48 pagini25th Secondary Aluminium Conference 2017 Salt SlagСтанислав ПодольскийÎncă nu există evaluări

- ASM Subject Guide - Aluminum PDFDocument5 paginiASM Subject Guide - Aluminum PDFzeeshaniqbalÎncă nu există evaluări

- Facade ManualDocument124 paginiFacade ManualDhana Shekar100% (1)

- Measuring Inclusions in Al-Si Alloys with UltrasoundDocument116 paginiMeasuring Inclusions in Al-Si Alloys with UltrasoundСтанислав ПодольскийÎncă nu există evaluări

- Optimization of Recovery Efficiency For Briquetted Aluminum Chips Up To Briquetting ParametersDocument9 paginiOptimization of Recovery Efficiency For Briquetted Aluminum Chips Up To Briquetting ParametersСтанислав ПодольскийÎncă nu există evaluări

- Fulltext01Document188 paginiFulltext01Станислав ПодольскийÎncă nu există evaluări

- Aluminum Electrical Conductor HandbookDocument365 paginiAluminum Electrical Conductor Handbookprem100% (3)

- Practices, Problems and Corrective Measures in Extrusion Press ToolingDocument10 paginiPractices, Problems and Corrective Measures in Extrusion Press ToolingСтанислав ПодольскийÎncă nu există evaluări

- Die Corrections For Changing Flow CharacteristicsDocument28 paginiDie Corrections For Changing Flow CharacteristicsСтанислав ПодольскийÎncă nu există evaluări