Documente Academic

Documente Profesional

Documente Cultură

MEE1005 Materials-Engineering-and-Technology ETH 1 AC37

Încărcat de

SHUBHAM KUMARTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MEE1005 Materials-Engineering-and-Technology ETH 1 AC37

Încărcat de

SHUBHAM KUMARDrepturi de autor:

Formate disponibile

MEE1005 Materials Engineering and Technology

LT P JC

20244

Pre Requisite: None

Module Topics L Hrs SLO

1 Structure of Materials

Introduction to engineering materials – significance of structure property

correlations in all classes of engineering materials, Unit Cells, Metallic Crystal

Structures, Density Computations, Crystal Systems, Crystallographic Points, 7

1, 2

Crystallographic Directions, Crystallographic Planes, Linear and Planar

Densities, Close-Packed Crystal Structures, Crystalline and Non-crystalline

Materials, Single Crystals, Polycrystalline Materials, Imperfection in solids –

Point, Line, Surface and Volume defects - Polymorphism and Allotropy.

2 Constitution of Alloys

Mechanism of Crystallization- Nucleation-Homogeneous and Heterogeneous

Nucleation- Growth of crystals- Planar growth – dendritic growth – Cooling

curves - Diffusion - Construction of Phase diagram -Binary alloy phase diagram 6 1,2

– Cu-Ni alloy; Cu-Zn alloy and Pb-Sn alloy; Iron-Iron carbide phase diagram –

Invariant reactions – microstructural changes of hypo and hyper-eutectoid steel-

TTT and CCT diagram.

3 Heat Treatment and Surface Heat treatment

Heat treatment – Overview – Objectives – Annealing and types, normalizing,

quenching, austempering and martempering – microstructure changes –Surface

4 2,5,6

hardening processes - Carburizing –, nitriding – cyaniding and carbonitriding,

induction and flame hardening, Laser and Electron beam hardening– principles

and case depths.

4 Ferrous and Non-ferrous metals

Steels – Types of Steels - White, Grey, Malleable and Nodular - Properties and

application of cast irons, Effect of alloying elements on structure and properties

4 1,2

of steels - Properties and uses of Silicon and Hadfield Manganese steels, High

speed steels - Stainless steel and Types - Non Ferrous metals - Aluminum,

Magnesium, Copper, Nickel, Titanium and their alloys.

5 Mechanical behavior of Materials

Strengthening mechanisms – Hardness measurements – Tensileproperties of the

materials – Fracture of metals – Ductile Fracture, Brittle Fracture, Ductile to

5

Brittle Transition Temperature (DBTT) –Fatigue – Endurance limit of ferrous 2,5,6

and non-ferrous metals -Fatigue test, S-N curves, factors affecting fatigue,

structural changes accompanying fatigue; Creep and stress rupture– mechanism

of creep – stages of creep and creep test.

6 Introduction to Advanced Materials

Properties and Applications of Engineering polymers- Ceramics – properties

4 1

and applications of various ceramics – Composites – and their types; properties

and processing of composites – Manufacture of fibres.

Total Lecture Hours 30

# Mode: Flipped Class Room, [Lecture to be videotaped], Use of physical and computer

models to lecture, Visit to Industry and study the metallurgical equipment, Min of 2

lectures by industry experts.

Practical

1. Overview of Materials Characterization – Optical Microscopy, Scanning Electron

Microscopy, X-Ray Diffraction and Energy Dispersive X-ray analysis

2. Perform the metallographic studies and identify the given steel samples.

3. Perform the metallographic studies and identify the given cast iron samples

4. Conduct the metallographic examination on the given non-ferrous samples

5. Design the heat treatments that result in the following microstructures

(a) Coarse pearlite (b) Medium/Fine pearlite (c) 100% Martensite (d) Martensite and 2,6,9,

retained austenite 30 13,14

6. Perform the hardness examination on the given samples using Rockwell Hardness and

Tester and find out the equivalent Vickers hardness in HV. 17

7. Conduct the tensile studies on the given sample and infer whether the given sample is

ductile or brittle. Evaluate the elastic and plastic properties of the given sample.

8. Perform the high cycle fatigue on the given standard sample. Report the inference.

9. Use metallographic analysis software to establish the phases and average grain size of

the given samples.

10. Demonstration on the development of composites

Project 60 5,9,1

# Generally a team project of Five [Non 4 and

# Concepts studied in Modules 2, 4, 6 should have been used Conta 17

# Down to earth application and innovative idea should have been attempted ct hrs]

# Report in Digital format with all drawings using software package to be submitted.

Sample projects such as

1. How to identify the given unknown sample? What are the metallurgical and

mechanical tests to be conducted to assess the properties of the sample?

2. A fractured sample is given for assessment to interpret the reasons for fracture.

What are the various metallurgical tests to be carried out to infer the same?

3. Design a sub-sized sample as per ASTM standard. Conduct the tensile test and

assess the tensile properties. Comment on the sample on its character.

4. Immerse the given sample in 3.5% NaCl solution to study the corrosion after 100

hours. Study the microstructure and phases present using optical microscopy and

XRD

5. Compare the microstructures of the given steel sample before and after heat

treatment. Also measure the hardness of the samples

6. Design and fabricate the sample for conducting fatigue test. Conduct the high

cycle fatigue and estimate the service life time.

7. Perform high temperature corrosion studies on the given sample at 500C in air

oxidation and analyze the microstructure before and after corrosion

8. Perform a stress-relieving heat treatment on the welded samples. How do you

ensure the stresses are relieved?

9. Conduct the corrosion studies on the given sample using electrochemical cell.

What is the inference drawn from the polarization curves?

10. Perform XRD analysis on the heat treated samples and identify the phases.

11. Perform the metallographic examination on the given sample and determine the

ASTM grain size number.

12. Design a heat treatment for the steel that results in microstructure that contains

pearlite and martensite. Also investigate the hardness and compare it with the fully

quenched sample.

13. Perform a simple arc welding on the given samples. Identify the microstructure at

different zones of interest.

14. Prepare the ASTM sub-sized sample for conducting the impact test. Find out the

mode of fracture using SEM analysis.

# Assessment on a continuous basis with a min of 3 reviews.

TextBooks:

1. W.D. Callister, David G. Rethwisch, (2010) Materials Science and Engineering: An Introduction, 8th

ed., Wiley & Sons.

Reference Books:

1. Donald R. Askeland, Pradeep P. Fulay, Wendelin J. Wright (2010), The Science and Engineering of

Materials 6th Edition, Cenage Publications.

2. William F. Smith and Javad Hashemi (2006), Foundations of Materials Science and Engineering 5th

Edition, McGraw Hill.

3. Sidney H Avner (2008) “Introduction to Physical Metallurgy, 2nd Edition, Tata McGraw Hill

Publishing Company Limited

4. ASM Handbook, Metallography and Microstructure, ASM International, Volume 9, 2004.

5. Jon L. Dossett, Howard E. Boyer (2006), Practical Heat Treating: 2nd Edition, ASM International.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

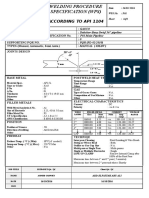

- Welding Procedure Specification (WPS) : According To Api 1104Document1 paginăWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Vertical Machining Centre (VMC)Document3 paginiVertical Machining Centre (VMC)anil chejaraÎncă nu există evaluări

- Unlearn: 101 Simple Truths For A Better Life: Click HereDocument5 paginiUnlearn: 101 Simple Truths For A Better Life: Click HereSHUBHAM KUMARÎncă nu există evaluări

- Tata Motors Pestle AnalysisDocument2 paginiTata Motors Pestle Analysispushpraj rastogi100% (1)

- WPSDocument2 paginiWPSJuli Agus50% (2)

- Syllabus For Basic German (B.Tech) (University Core) : Listening: Students Will Be Able To Understand Routine QuestionsDocument1 paginăSyllabus For Basic German (B.Tech) (University Core) : Listening: Students Will Be Able To Understand Routine QuestionsSHUBHAM KUMARÎncă nu există evaluări

- FALLSEM2019-20 MAT2003 TH VL2019201003283 Reference Material I 26-Sep-2019 Nonlinearprogramming2013-130317205452-Phpapp01 PDFDocument25 paginiFALLSEM2019-20 MAT2003 TH VL2019201003283 Reference Material I 26-Sep-2019 Nonlinearprogramming2013-130317205452-Phpapp01 PDFSHUBHAM KUMARÎncă nu există evaluări

- Q. No. Session QT Section Key Marks Biotechnology (BT)Document2 paginiQ. No. Session QT Section Key Marks Biotechnology (BT)SHUBHAM KUMARÎncă nu există evaluări

- FALLSEM2019-20 MEE1016 TH VL2019201007280 Reference Material I 12-Aug-2019 Quiz 1 B2 PDFDocument1 paginăFALLSEM2019-20 MEE1016 TH VL2019201007280 Reference Material I 12-Aug-2019 Quiz 1 B2 PDFSHUBHAM KUMARÎncă nu există evaluări

- FALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsDocument21 paginiFALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsSHUBHAM KUMARÎncă nu există evaluări

- Operations Research - Da-2Document2 paginiOperations Research - Da-2SHUBHAM KUMARÎncă nu există evaluări

- Scotchbrite Sanding Mops - (Cromwells)Document1 paginăScotchbrite Sanding Mops - (Cromwells)stuart3962Încă nu există evaluări

- Roboze ArgoDocument12 paginiRoboze ArgoGregorio PisaneschiÎncă nu există evaluări

- High-Voltage Vacuum ContactorsDocument9 paginiHigh-Voltage Vacuum ContactorstanujaayerÎncă nu există evaluări

- Master Catalog 2015Document231 paginiMaster Catalog 2015Ulfa HafizdyaÎncă nu există evaluări

- Design and Fabrication of Syringe Needle CrusherDocument9 paginiDesign and Fabrication of Syringe Needle CrusherNareswarinosaÎncă nu există evaluări

- Take Home Quiz DestilasiDocument2 paginiTake Home Quiz DestilasiLutherJericoÎncă nu există evaluări

- Section II A SA-216 - SA-216MDocument4 paginiSection II A SA-216 - SA-216MSocrates MoralesÎncă nu există evaluări

- 5-Compressive Strength of Clay BricksDocument3 pagini5-Compressive Strength of Clay BricksZhiwar oramari50% (2)

- Electromagnetic Engine 1Document18 paginiElectromagnetic Engine 1vikasÎncă nu există evaluări

- Stage Batomelong-450Document67 paginiStage Batomelong-450Jems MansuetoÎncă nu există evaluări

- Flanged Bolt Couplings Strength of Materials ReviewDocument4 paginiFlanged Bolt Couplings Strength of Materials Reviewmark cuananÎncă nu există evaluări

- Elerenta Inspection ReportDocument17 paginiElerenta Inspection Reportsamynathan_bvs100% (1)

- Manual Horno HaierDocument20 paginiManual Horno HaierWillman UzcateguiÎncă nu există evaluări

- A10 J SCH VD 132971 Alarm ListDocument13 paginiA10 J SCH VD 132971 Alarm ListzhangÎncă nu există evaluări

- USAID-ICED II - 01 Biomass Potential, Market, Feedstock, Lesson Learnt - 191111Document66 paginiUSAID-ICED II - 01 Biomass Potential, Market, Feedstock, Lesson Learnt - 191111Rais Rijal100% (2)

- BOQ Petron Clark (1.10.19)Document4 paginiBOQ Petron Clark (1.10.19)Mark Lester MolinoÎncă nu există evaluări

- 2017 Market RatesDocument57 pagini2017 Market RatesALEXÎncă nu există evaluări

- AL-800 AL-840: Parts GuideDocument22 paginiAL-800 AL-840: Parts GuidesamuelÎncă nu există evaluări

- General Notes: FC' 3000 Psi Fy 60000 Psi Lap Length Location FC' 3000 Psi Fy 40000 PsiDocument1 paginăGeneral Notes: FC' 3000 Psi Fy 60000 Psi Lap Length Location FC' 3000 Psi Fy 40000 PsiUsama EjazÎncă nu există evaluări

- LNG VaporizerDocument4 paginiLNG Vaporizernangkarak8201Încă nu există evaluări

- Ariston AML 125 Washer Dryer Manual (ENG)Document12 paginiAriston AML 125 Washer Dryer Manual (ENG)Grant Dickson50% (2)

- Broshure Face Master 1.7 2 PDFDocument2 paginiBroshure Face Master 1.7 2 PDFlorenzo henerÎncă nu există evaluări

- VR8304 Intermittent Pilot Combination Gas Control: ApplicationDocument8 paginiVR8304 Intermittent Pilot Combination Gas Control: ApplicationGregorio Mata MartínezÎncă nu există evaluări

- Preparation of High Solids, Low Viscosity Carbonless Paper Gelatin Base McrocapsulesDocument5 paginiPreparation of High Solids, Low Viscosity Carbonless Paper Gelatin Base McrocapsulesSintong Leonardo SitungkirÎncă nu există evaluări

- Procedure of Integrity Test of Absolute Hapa FiltersDocument2 paginiProcedure of Integrity Test of Absolute Hapa FiltersMujib Ur Rehman MalikÎncă nu există evaluări

- Company Profile - en - Mailversion KlumppDocument2 paginiCompany Profile - en - Mailversion KlumppJulio NeumannÎncă nu există evaluări