Documente Academic

Documente Profesional

Documente Cultură

Pakistan Cement Industry - Ready For Reconstruction

Încărcat de

Atif MunirTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pakistan Cement Industry - Ready For Reconstruction

Încărcat de

Atif MunirDrepturi de autor:

Formate disponibile

Ready for

Reconstruction

Atif Munir, Cement Pakistan Company, highlights the

Pakistani cement industry’s existing performance and future

role following the devastating floods.

Introduction

By 30 June 2010, the end of the fiscal year, the total sales

volume of the Pakistan cement industry stood at 34.2

million t, its highest ever figure. Its growth was respectable,

at 9.3%, while the total sales volume of the preceding year

was 31.2 million tonnes. The local sales volume grew by

a healthy 14.6%, and also achieved its highest ever figure

in national history, at 23.5 million t. This growth occurred

despite the fact that government expenditure on public

sector development projects decreased during that period.

The local growth can be explained by sales in the

rural economy, which occurred as a result of improved

agriculture support prices, along with private sector sales.

As far as exports were concerned, 10.6 million t of cement

and clinker were exported, in comparison to 10.7 million t

in the previous year, while the industry’s export sales broke

even.

The 2010 figures, however, were in contrast to this

period of growth, as there was a drop of 19% in the total

dispatches of cement to 2.4 million t during August 2010,

in comparison to the same stage of the previous year,

according to figures distributed by the All Pakistan Cement

Workers of Maple Leaf Cement factory busy in maintenance of Manufacturers Association (APCMA).

road affected by recent flood water near their cement plant in

Mianwali.

[Oct 10] worldcement.com 1

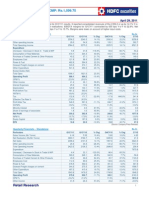

Table 1. Cement and clinker exports (t)

Cement Clinker

Years Afghanistan India Other countries Other countries Total %

via land via sea and land via sea via sea increase (Dec)

2001-2002 106 620 - - - 106 620 100.00

2002-2003 430 322 - - 41 500 471 822 342.53

2003-2004 1 118 293 - - - 1 118 293 137.02

2004-2005 1 407 900 - 157 270 - 1 565 170 39.96

2005-2006 1 413 994 - 91 165 - 1 505 159 -3.83

2006-2007 1 725 526 - 1 071 928 390 973 3 188 427 111.83

2007-2008 2 777 826 786 672 3 045 995 1 106 127 7 716 620 142.02

2008-2009 3 148 306 634 455 6 061 035 908 690 10 752 486 39.34

2009-2010 4 013 671 722 967 5 637 163 283 436 10 657 237 -0.89

There was no recovery in August 2010 however, as a

direct result of the flooding, and also due to the slowdown

in the construction industry that usually occurs during the

month of Ramadan. There is some expectation that sales

may recover during the beginning of the 2011 financial

year; this is due to the fact that extensive rebuilding will

be necessary in regions that have suffered severe damage

during the recent floods. This would be a similar situation

to what was witnessed in the aftermath of the earthquake

that occurred in 2005, when cement sales increased

dramatically during the rebuilding stage.

Prior to 2011, however, further decreases in cement

dispatches are expected. In August 2010 for example,

cement dispatches reduced by between 20 – 30%. As a

knock-on effect of this decline, the sale price of cement

during September and October is expected to see a

Fauji Cement new 7200 tpd cement plant is expected to start reduction of about Rs10-20 per bag. Prices should return

production by the end of year 2010. to their original figures once rebuilding starts during the

coming months, while the cement sales figures should be

Local sales restored by the latter half of 2011.

In June 2010, sales of cement in Pakistan were counted at Additional funds should be supplied to the industry

2.09 million t. By July 2010, however, a reduction of 16% in as a result of aid donations targeted at rebuilding, from

cement sales was recorded, with the figure standing at just organisations such as the World Bank (WB), the United

1.75 million t, according to data acquired by the APMCA. Nations, and other charitable agencies. In excess of

This is not hugely surprising however, and does not go US$1 billion has been pledged to date, with US$900

against previous trends, as cement sales typically decrease million of that in the form of a loan from the WB. The

during the monsoon season in Pakistan, which occurs in infrastructure, housing and agriculture industries have

July. This trend is further supported by the sales figures of been the most severely affected, according to preliminary

July 2009, where sales decreased by 12%. In 2010 however, estimates released by the WB.

the decrease in cement sales has been more dramatic and When compared with data from 2009, a fall of 25% is

can be explained by the increased rainfall and resultant evident in the local dispatches figures, which are currently

floods that affected the region at the end of July. While the at approximately 1.51 million t. Again, this is as a result

rainfall and floods affected construction in Pakistan, the of the floods and their disruption of communications.

floods themselves hugely disrupted communications and Throughout the month of August, the provinces of Khyber-

logistics, which also detrimentally affected the local cement Pakhtunkhwa, Punjab and Sindh were under flood waters,

sales figures. which affect the movement of cement dispatches and raw

Export figures also showed a decline, with a monthly materials in those regions. Khyber-Pakhtunkhwa (KP) has

reduction of 15% and a reduction of 31% y-o-y. The total suffered the most, with many bridges and roads being

figure for July was 775 000 t. There are two principal completely wiped out. Local dispatches in this area are

reasons for this decline. As far as the monthly figures are therefore expected to remain low.

concerned, this was a result of the lack of an inland freight Dispatch figures are expected to gradually recover, with

subsidy. The reduction in yearly figures was as a result of some slight improvements in October, although dispatches

higher overall prices in the sector. When export and local will remain low in comparison to previous years’ figures.

sales figures are combined, the total dispatches come to It is also not possible to determine what losses or damages

250 000 t, which comes to a reduction of 16% on a monthly have been inflicted on manufacturers in regions that have

basis. The total decline y-o-y is 12%. been affected by the floods, as reviews have not yet been

2 worldcement.com [Oct 10]

Table 2. Pakistani cement industry (operational units data)

July to Production % Local % Exports % Total % Capacity Surplus

June capacity increase dispatches increase (million t) increase despatches increase utilisation capacity

(million t) (million t) (Dec) (Dec) (million t) % age (million t)

2000-2001 15.534 -5.16 9.933 -0.04 - 0.00 9.933 -0.04 63.95 5.600

2001-2002 15.723 1.22 9.833 -1.01 0.107 100.00 9.940 0.06 63.22 5.783

2002-2003 16.321 3.81 10.980 11.66 0.430 303.60 11.410 14.80 69.91 4.911

2003-2004 16.936 3.77 12.545 14.25 1.160 169.52 13.705 20.11 80.92 3.231

2004-2005 17.909 5.75 14.788 17.88 1.565 34.95 16.353 19.33 91.32 1.555

2005-2006 20.955 17.01 16.907 14.33 1.505 -3.83 18.412 12.59 87.87 2.543

2006-2007 30.251 44.36 21.034 24.41 3.188 111.83 24.223 31.56 80.07 6.028

2007-2008 37.157 22.83 22.577 7.33 7.717 142.02 30.293 25.06 81.53 6.863

2008-2009 41.760 12.39 20.533 -9.05 10.752 39.34 31.286 3.28 74.92 10.475

2009-2010 44.824 7.33 23.538 14.63 10.657 -0.89 34.195 9.30 76.29 10.628

carried out. This information is not expected to be available

until after the Eid holidays.

Exports

There was a huge slowdown in the growth of cement

exports in Pakistan during the first nine months of the

fiscal year 2009 - 2010. In this period, exports of this kind

grew by 64%. However, in 9MFY10 this figure stood at just

4%. This can be explained by examining the slowdown in

construction in six Gulf Arab nations, which make up the

Gulf Cooperation Council (GCC). This had a knock-on

effect on the cement export figures in Pakistan. However, DG Khan Cement Khairpur plant achieved record 342 operational

there was significant growth in the cement export figures to days during 2009-2010.

other African nations.

As a result of this demand for cement in Africa, many cement production in Pakistan is becoming increasingly

Pakistani cement manufacturing companies are actively expensive. This is naturally affecting its sale price and its

targeting this market. However, this has spurred local competitiveness.

cement manufacturers in Africa to try to impede sales of Observers have pointed out that exports of surplus

Pakistani cement in their countries. Many African cement Pakistani cement to Africa and to the Gulf have taken

manufacturers are lobbying their governments in the hope place, which should have boosted the export figures. In

of having an import duty imposed on foreign cement. Saudi Arabia however, restrictions on exporting that the

Some have insisted that the levy be increased to 35%, or the government had placed against its cement makers were

equivalent of US$5/t. This duty would significantly impede recently lifted. As there is plenty of crude oil available to

Pakistani cement exports in Africa. local cement makers in Saudi Arabia and in Iran, their

The overall slowdown in cement exports is a result of cement manufacturing expenses are much lower than those

various factors, including the reduction in demand from of the manufacturers in Pakistan. The Pakistani cement

the GCC nations. Other factors include a decrease in prices manufacturers attempt to market their products as being of

internationally, along with an increase in inland charges, a considerably higher quality than those produced in Saudi

which has discouraged cement manufacturers in northern Arabia, but they are unable to compete with the lower prices

Pakistan from exporting their wares. An inland freight being charged by these manufacturers due to their higher

subsidy has been supplied by the Pakistani government, but production costs.

its effects have not yet been seen.

When exports are analysed, it can be seen that the Affects of the flooding

biggest importer of cement from Pakistan is Afghanistan. Extensive damage was inflicted on livestock and agriculture,

During the fiscal year of 2009, 28% of the total cement while infrastructure was severely damaged. The floods did

exports from Pakistan went to Afghanistan. However, the not drastically affect the cement industry in Pakistan, nor

floods also affected exports to Afghanistan, holding them did they affect the textile, oil, power and auto industries.

up for approximately one week. There are currently also The financial and banking sectors are also unaffected, and

difficulties exporting over the eastern border to India, due are operating as normal.

to obstructions being created by the Indian government. The floods have had a dramatic effect on demand for

When compared to August 2009, exports in August cement in Pakistan throughout the first two months of the

2010 saw a 6% reduction. The figure stands at 890 000 t, fiscal year 2010 - 11. The manufacturing plants in general

which is slightly higher than the July figure. This is not were not severely damaged however, although some were

an indicator of continued improvement however, as close to the flooded regions. It is expected that cement

[Oct 10] worldcement.com 3

As the floods occurred immediately before the month of

Ramadan, the cement manufacturers within Pakistan had

already built up a surplus in imports so as to have sufficient

The floods have had a dramatic effect stocks built up at the ports within the country. The effects

on demand for cement in Pakistan of the flooding on the political situation were also severe,

throughout the first two months of the as the government was having some success in dealing with

Taliban insurgencies. Although the floods decimated the

fiscal year 2010 - 11. The manufacturing

country’s communications, wiping out roads, bridges, power

plants in general were not severely stations and cutting off villages and towns completely, it is

damaged however, although some were expected that rebuilding could begin within a few months,

close to the flooded regions. possibly in November or December.

Future

As of now, the future prospects of the Pakistan cement

industry are good. A manifold increase in cement exports

sales will begin to recover in the second half of fiscal year to African nations and the Middle East should occur.

2010 - 11, although sales pressure has increased during Additionally, there is massive reconstruction taking place in

August 2010 and there is price stress in the North. Prices both Iraq and Afghanistan, which should rely extensively on

are expected to hold for now and improve later in the cement imports from Pakistan.

current fiscal year. Afghanistan in particular should be an extremely long-

As previously stated, the figures of FY 2010 - 11 were term source of revenue, as it does not possess the required

in sharp contrast to those of fiscal year 2010. Although the limestone to manufacture its own cement. Although the

total effect of the severe flooding in Pakistan on cement current demand for cement in Afghanistan lies at 2.5

sales has not yet been completely assessed, there is a million t, this could increase to 15 million t.

decrease of 16% in yearly cement volumes. It is possible that the cement industry in Pakistan may

As far as recovery is concerned, the cement industry undergo extensive growth in 2014, as a result of projected

tends to rely on growth in agriculture income, along with regional and local demand. In the last ten years, cement

government spending on infrastructure. However in 2011, demand has risen to 33.2 million t, an increase of 235%.

there will be no demand from these two important sectors. Production however has increased to 44.8 million t, leaving

On the contrary, further fallout from the flooding will a surplus of 11.6 million t.

result in large demands on the government finances, while The supply of 44.8 million t is divided between North

the majority of farmers in Pakistan will have limited funds and South. Currently, 8.9 million t are produced in the

due to the extensive destruction of crops and the resultant South, while the remaining 35.9 million t is produced in the

decrease in income. North. A further 2 million t of cement should be produced

If the situation is compared to the flooding that by the Fauji Cement project, which should begin operations

occurred in 1993, it can be seen that the internal demand this year. Once the supply increases to 46.8 million t,

for cement increased in that fiscal year, but then suffered a Pakistan will be amongst the world’s top 20 producers of

decrease throughout the following two years. In FY 1996 cement.

however, demand rose by 13%. Comparisons can also be The future cement export potential of Pakistan is 5

drawn between the current flooding and the earthquake million t to 27 countries. There is also a 10 million t export

that affected the region in October 2005, when the demand potential of bagged cement. However, some difficulties may

for cement did not suffer any significant decrease. It further surface due to rises in indirect taxes, with 1% special excise

increased by 14% in FY 2006, and then by 24% in FY 2007. duty being levied, along with Rs700/t fixed excise duty. This

Returning to the current situation, it can be seen that means that cement produced in countries such as China

the abnormally heavy monsoon rains and flooding in July and India is more competitive than that being supplied by

had a significant effect on the demand for cement. This Pakistan.

was more noticeably reflected in the sales from August In order for Pakistan to be competitive in international

2010. For example, local sales decreased by 25% on a yearly markets, it is necessary for the government to provide the

basis; some of this can be attributed to seasonal factors. necessary fiscal and infrastructural support. There must be

In genera,l construction within Pakistan slows during this a significant rebate increase on exports and a port charges

period as a result of the effects of the monsoon, and due to reduction, e.g. a reduction in the cost of dock labour and in

the holy month of Ramadan. port duties. There is also a need for separate berths to be

Although an increase of demand for cement is expected provided at each port in order to efficiently export cement

within Pakistan during the coming fiscal year, there is and clinker.

already a 20 million t surplus waiting to be distributed. Half The future energy supply to the cement manufacturing

of this will be exported, while 10 million t will be utilised in plants is also in need of review by the companies involved.

the extensive rebuilding that will occur within Pakistan. Historically, energy was generated with furnace oil, but

The effects of the flooding on the inhabitants of Pakistan this has now shifted towards coal. Additionally, alternative

have been extensive. There are approximately 8 million fuel sources, such as scrap tyres and municipal waste are

people in desperate need of emergency aid, and more than being examined as a means of alternative fuel at a lower

4 million people are currently homeless. There is therefore cost. In the future, alternative fuel sources could potentially

an urgent need for cement to rebuild destroyed and account for 25% of the energy consumed by the cement

damaged buildings and roads. manufacturing plants in Pakistan. For example, Fauji

4 worldcement.com [Oct 10]

Table 3. Installed production capacity

Name of unit Production capacity

Clinker Cement

Askari Cement Limited - Wah 1 050 000 1 102 500

Askari Cement - Nizampur 1 500 000 1 575 000

Bestway Cement Limited - Hattar 1 170 000 1 228 500

Bestway Cement Limited - Chakwal 3 428 571 3 600 000

Cherat Cement Company Limited-Nowshera 1 000 000 1 050 000

Dandot Cement Limited - Jehlum 480 000 504 000

Dewan Hattar Cement Limited - Hattar 1 080 000 1 134 000

D.G.Khan Cement Limited - D.G.Khan 2 010 000 2 110 500

D.G.Khan Cement Limited - Chakwal 2 010 000 2 110 500

Fauji Cement Company Limited - Fateh Jang 1 110 000 1 165 500

Fecto Cement Limited - Sangjani 780 000 819 000

Flying Cement Limited - Lilla 1 200 000 1 260 000

GharibWal Cement Limited - Jehlum 2 550 000 2 677 500

Kohat Cement Company Limited - Kohat 2 550 000 2 677 500

Lucky Cement Limited - Pezu 3 725 714 3 912 000

Maple Leaf Cement Factory Limited - Daudkhel 3 510 000 3 685 500

Mustehkum Cement Limited - Hattar 1 080 000 1 134 000

Lafarge Pakistan Cement Company Limited - Chakwal 1 950 000 2 047 500

Pioneer Cement Limited - Khushab 1 933 571 2 030 250

Sub total (North) 34 117 857 35 823 750

South zone

A.C. Rohri Cement Limited - Rohri 230 000 241 500

Al-Abbas Cement Limited - Nooriabad, Dadu 450 000 472 500

Attock Cement Pakistan Limited - Hub Chowki, Lasbela 1 710 000 1 795 500

Dadabhoy Cement Industries Limited - Nooriabad, Dadu 504 762 530 000

Dewan Cement Limited - Dhabeji 750 000 787 500

Javedan Cement Limited 600 000 630 000

Lucky Cement Limited, - Indus Highway, Karachi 3 428 571 3 600 000

Pakistan Slag Cement Limited - 157 500

Thatta Cement Limited - Thatta 300 000 315 000

Zeal Pak Cement Limited - Hyderabad 342 857 360 000

Sub total (South) 8 316 190 8 889 500

Grand total (North + South) 42 434 047 44 713 250

Fauji Cement 2010 - 2011 2 160 000 2 268 000

Projected 2010 - 2011 44 594 047 46 981 250

Cement under dynamic management is actively exploring spares and equipment. This can be achieved by reducing

different alternative fuels. Fauji cement has installed the dependence on original plant supplier companies and by

country’s first RDF system, and is now successfully replacing involving OEM suppliers for maintenance requirements.

a portion of conventional fuel with scrap tyres and RDF. While extensive damage has been caused by the recent

As mentioned, coal is currently the main fuel source flooding, there is a definite need for planned and directed

for the various cement manufacturing plants in Pakistan. investment on infrastructure, transport and construction

However, the vast majority of the coal that is used in these within Pakistan, especially if the nation is to its ambition of a

factories is imported. As the demand for cement increases, gross GDP growth of 6% within the coming five years. It is

so too will the demand for coal. Therefore experts essential for the future development of industry in Pakistan

recommended that the Pakistani government invest in coal that trade corridors, highways and dams be provided.

reserves in Thai and Balochistan, so as to anticipate and

accommodate this future demand for coal. Sources

In addition, cement manufacturers should reduce their 1. Cement Pakistan Company – www.cement.com.pk

procurement spending by improving their sourcing of 2. All Pakistan Cement Manufacturers Association (APCMA)

[Oct 10] worldcement.com 5

S-ar putea să vă placă și

- Transforming Borneo: From Land Exploitation to Sustainable DevelopmentDe la EverandTransforming Borneo: From Land Exploitation to Sustainable DevelopmentÎncă nu există evaluări

- Cement IndustryDocument6 paginiCement Industrye6l3nn100% (1)

- Construction Sector Report - December 2022Document9 paginiConstruction Sector Report - December 2022unibooksÎncă nu există evaluări

- Cement Industry Report PDFDocument2 paginiCement Industry Report PDFmananÎncă nu există evaluări

- Cement Industry Economic AnalysisDocument22 paginiCement Industry Economic AnalysisManoj Bharadwaj Subedi100% (1)

- Concrete Market: by BR Uc e A. Supr Enant and Wa RD R - Ma Li SCHDocument8 paginiConcrete Market: by BR Uc e A. Supr Enant and Wa RD R - Ma Li SCHRamalingam PrabhakaranÎncă nu există evaluări

- Profile On The Production of Mosaic TilesDocument26 paginiProfile On The Production of Mosaic TilesabateÎncă nu există evaluări

- Construction Materials: Worst May Be Over, We Remain WaryDocument7 paginiConstruction Materials: Worst May Be Over, We Remain Warynkr_03Încă nu există evaluări

- Sheet GlassDocument28 paginiSheet GlassHabtu AsratÎncă nu există evaluări

- Doc4 Stone (Crushed)Document2 paginiDoc4 Stone (Crushed)Julian Andres Vargas ParraÎncă nu există evaluări

- On Shree Cement Jun 2010Document39 paginiOn Shree Cement Jun 2010Ana JainÎncă nu există evaluări

- Profile On The Production of Sodium Silicate PDFDocument27 paginiProfile On The Production of Sodium Silicate PDFNebiyu Samuel100% (1)

- Critical Analysis of Pakistan Cement IndustryDocument42 paginiCritical Analysis of Pakistan Cement Industrytanseer_0493% (15)

- Financial Statement AnalysisDocument48 paginiFinancial Statement Analysisiqbalahmed9993Încă nu există evaluări

- Cement Production Output and Prices Trends in Mozambique: Daniel BaloiDocument6 paginiCement Production Output and Prices Trends in Mozambique: Daniel BaloiMustafa YılmazÎncă nu există evaluări

- Cemen T: Key Points Financial Year '09 Prospects Sector Do's and Dont's Indian Cement IndustryDocument12 paginiCemen T: Key Points Financial Year '09 Prospects Sector Do's and Dont's Indian Cement IndustryshanmumuthuÎncă nu există evaluări

- Cement Sector Report PDFDocument9 paginiCement Sector Report PDFMd Mostafa Kamal FaisalÎncă nu există evaluări

- Decoration (Wall Papers) - CDocument25 paginiDecoration (Wall Papers) - CRobel KefelewÎncă nu există evaluări

- Through Speculation On Possible Substitution Between NR and SRDocument3 paginiThrough Speculation On Possible Substitution Between NR and SRHimanshu KuriyalÎncă nu există evaluări

- Cement January 2020Document24 paginiCement January 2020holistic fitnessÎncă nu există evaluări

- Analysis of Cement Sector in Pakistan Focusing Lucky Cement LTDDocument7 paginiAnalysis of Cement Sector in Pakistan Focusing Lucky Cement LTDM Faisal Panawala100% (1)

- Total Production: Technological ChangeDocument6 paginiTotal Production: Technological Changeagrawalrohit_228384Încă nu există evaluări

- Bind - VX Hy 2023 Abridged Press Statement and Audit ReportDocument6 paginiBind - VX Hy 2023 Abridged Press Statement and Audit ReportKristi DuranÎncă nu există evaluări

- Industrial CanvasDocument27 paginiIndustrial CanvasTed Habtu Mamo AsratÎncă nu există evaluări

- Composite Flour Manf Plant NDocument16 paginiComposite Flour Manf Plant NNigatuÎncă nu există evaluări

- Report On Cement IndustryDocument33 paginiReport On Cement Industrykanu vij67% (9)

- Polyster YarnDocument29 paginiPolyster YarnTed Habtu Mamo AsratÎncă nu există evaluări

- Research Report: Cement Sector of Bangladesh - Update: OutlookDocument2 paginiResearch Report: Cement Sector of Bangladesh - Update: OutlookMrittunjayÎncă nu există evaluări

- Cement Industry in India and Its Contribution To Indian GDPDocument18 paginiCement Industry in India and Its Contribution To Indian GDPkoon00721100% (1)

- CareratingCement January 2017Document7 paginiCareratingCement January 2017Krina ParekhÎncă nu există evaluări

- Strategic Financial Management - Pakistan Cement IndustryDocument21 paginiStrategic Financial Management - Pakistan Cement IndustryAli AhmedÎncă nu există evaluări

- Insight - Cement Sector Update - 07-Apr-22Document4 paginiInsight - Cement Sector Update - 07-Apr-22ShujaatAhmedÎncă nu există evaluări

- Profile On The Production of Wire NailDocument25 paginiProfile On The Production of Wire Nailgetachew ligerÎncă nu există evaluări

- SpecialSection 1 PDFDocument7 paginiSpecialSection 1 PDFArsalan GillÎncă nu există evaluări

- CF Eclectica Agriculture Fund - Performance Attribution Report - January 2011Document2 paginiCF Eclectica Agriculture Fund - Performance Attribution Report - January 2011pick6Încă nu există evaluări

- Inddec 10Document12 paginiInddec 10Surbhi SarnaÎncă nu există evaluări

- Cement Market Review For 2021Document5 paginiCement Market Review For 2021Chamith VirangaÎncă nu există evaluări

- Business Plan Owner: Alemu Tola: Olana Cement Based Construction MaterialsDocument29 paginiBusiness Plan Owner: Alemu Tola: Olana Cement Based Construction MaterialsLeulÎncă nu există evaluări

- CC CC CC C !""#$ %&' (!""!) (CC '&&+ '&!&) (Document4 paginiCC CC CC C !""#$ %&' (!""!) (CC '&&+ '&!&) (Rahat Ul AminÎncă nu există evaluări

- Financial Analysis of Top Cement CompaniesDocument46 paginiFinancial Analysis of Top Cement CompaniesSyedFaisalHasanShahÎncă nu există evaluări

- Project Final Report On Cement Sector PakistanDocument15 paginiProject Final Report On Cement Sector PakistanMudassar Nazar0% (1)

- Project Profile On Production of Aluminum Frames and ProfilesDocument16 paginiProject Profile On Production of Aluminum Frames and ProfilesmekonnenÎncă nu există evaluări

- Cement Industry: Prateep Nigam Priyank Shah Prasenjit Roy Priyanka Babbar Priyadarshini TripathyDocument33 paginiCement Industry: Prateep Nigam Priyank Shah Prasenjit Roy Priyanka Babbar Priyadarshini Tripathyprateepnigam355Încă nu există evaluări

- 19-cs11 - Construction Building Materials - Commentary October 2019Document21 pagini19-cs11 - Construction Building Materials - Commentary October 2019Harrison LangÎncă nu există evaluări

- 111aluminium Sulphate From KaolinDocument17 pagini111aluminium Sulphate From KaolinBetsy SeyoumÎncă nu există evaluări

- 208-Article Text-2956-1-10-20220711Document18 pagini208-Article Text-2956-1-10-20220711Yanda NstÎncă nu există evaluări

- Indian Ceramic Tile IndustryDocument22 paginiIndian Ceramic Tile IndustryPULKIT GOSWAMI MBA IB 2018-20 (DEL)Încă nu există evaluări

- Acc LTD (Acc) CMP: Rs.1,099.75: Q1CY11 Result Update April 29, 2011Document4 paginiAcc LTD (Acc) CMP: Rs.1,099.75: Q1CY11 Result Update April 29, 2011Mohammed Asif ValsangkarÎncă nu există evaluări

- Macau Construction Cost Review July 2009Document9 paginiMacau Construction Cost Review July 2009Bill LeeÎncă nu există evaluări

- Future Indonesia Coal IndustryDocument2 paginiFuture Indonesia Coal IndustryIbash PurwansahÎncă nu există evaluări

- Industry Report 1Document10 paginiIndustry Report 1sumantha sahaÎncă nu există evaluări

- Cementplant-Proposal - Business PlanDocument11 paginiCementplant-Proposal - Business PlanMalshedz82% (11)

- AlumDocument18 paginiAlumBetsy SeyoumÎncă nu există evaluări

- Infocus: Inside This Issue Rebased Performance of Regional IndicesDocument22 paginiInfocus: Inside This Issue Rebased Performance of Regional IndicesIshar KarÎncă nu există evaluări

- Philippine Cement Industry - DTIDocument4 paginiPhilippine Cement Industry - DTIJessah Mae E. ReyesÎncă nu există evaluări

- Enset Starch ProductionDocument15 paginiEnset Starch Productionmarafiuddin100% (1)

- Tire Industry AnalysisDocument14 paginiTire Industry AnalysisSoniya DhyaniÎncă nu există evaluări

- Analysis of Pakistan Cement SectorDocument43 paginiAnalysis of Pakistan Cement SectorLeena SaleemÎncă nu există evaluări

- Economic Highlights: Industrial Production Slowed Down in FebruaryDue To Shorter Working Days - 08/04/2010Document3 paginiEconomic Highlights: Industrial Production Slowed Down in FebruaryDue To Shorter Working Days - 08/04/2010Rhb InvestÎncă nu există evaluări

- M3289UKDocument48 paginiM3289UKAtif MunirÎncă nu există evaluări

- Alit Inform ArticleDocument5 paginiAlit Inform ArticleAtif MunirÎncă nu există evaluări

- Alternative Fuel - Pakistan Cement IndustryDocument6 paginiAlternative Fuel - Pakistan Cement IndustryecorporatesÎncă nu există evaluări

- Comprehensive Report On Pakistan Cement Industry.Document5 paginiComprehensive Report On Pakistan Cement Industry.ecorporatesÎncă nu există evaluări

- Campus Design: School of Architecture & Planning at PondicherryDocument9 paginiCampus Design: School of Architecture & Planning at Pondicherrynadhir sulaimanÎncă nu există evaluări

- Right To Freedom From Torture in NepalDocument323 paginiRight To Freedom From Torture in NepalAnanta ChaliseÎncă nu există evaluări

- Building Envelop Design GuidDocument195 paginiBuilding Envelop Design GuidCarlos Iriondo100% (1)

- nghe thực tế 1Document282 pagininghe thực tế 1Lê Thị Bách HợpÎncă nu există evaluări

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDocument8 paginiRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosÎncă nu există evaluări

- Principles of Marketing: Quarter 1 - Module 6: Marketing ResearchDocument17 paginiPrinciples of Marketing: Quarter 1 - Module 6: Marketing ResearchAmber Dela Cruz100% (1)

- Lozada Vs MendozaDocument4 paginiLozada Vs MendozaHarold EstacioÎncă nu există evaluări

- Chapters Name in Sanskrit and English Setting The SceneDocument3 paginiChapters Name in Sanskrit and English Setting The Sceneishvarchandra dasÎncă nu există evaluări

- Chapter 8 Supplier Quality ManagementDocument71 paginiChapter 8 Supplier Quality ManagementAnh NguyenÎncă nu există evaluări

- Planning and Design of A Cricket StadiumDocument14 paginiPlanning and Design of A Cricket StadiumTenu Sara Thomas50% (6)

- Federal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisDocument41 paginiFederal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisWaseem KhanÎncă nu există evaluări

- TAX Report WireframeDocument13 paginiTAX Report WireframeHare KrishnaÎncă nu există evaluări

- Official Memo: From: To: CCDocument4 paginiOfficial Memo: From: To: CCrobiÎncă nu există evaluări

- Mudbound: Virgil Williams and Dee ReesDocument125 paginiMudbound: Virgil Williams and Dee Reesmohan kumarÎncă nu există evaluări

- The Relationship Between Law and MoralityDocument12 paginiThe Relationship Between Law and MoralityAnthony JosephÎncă nu există evaluări

- Romeuf Et Al., 1995Document18 paginiRomeuf Et Al., 1995David Montaño CoronelÎncă nu există evaluări

- The Role of Religion in The Causation of Global Conflict & Peace and Other Related Issues Regarding Conflict ResolutionDocument11 paginiThe Role of Religion in The Causation of Global Conflict & Peace and Other Related Issues Regarding Conflict ResolutionlorenÎncă nu există evaluări

- 10-02-20. Deed of Donation SSF Equipment - SSF On Vermicomposting (Formerly Large Scale Vermi Composting Production)Document3 pagini10-02-20. Deed of Donation SSF Equipment - SSF On Vermicomposting (Formerly Large Scale Vermi Composting Production)Catherine BenbanÎncă nu există evaluări

- Waa Sik Arene & Few Feast Wis (FHT CHT Ste1) - Tifa AieaDocument62 paginiWaa Sik Arene & Few Feast Wis (FHT CHT Ste1) - Tifa AieaSrujhana RaoÎncă nu există evaluări

- English Solution2 - Class 10 EnglishDocument34 paginiEnglish Solution2 - Class 10 EnglishTaqi ShahÎncă nu există evaluări

- Correlation SecretDocument23 paginiCorrelation SecretDavid100% (1)

- Ogl 350 Paper 2Document5 paginiOgl 350 Paper 2api-672448292Încă nu există evaluări

- Financial Accounting Theory Craig Deegan Chapter 7Document9 paginiFinancial Accounting Theory Craig Deegan Chapter 7Sylvia Al-a'maÎncă nu există evaluări

- Jamb Crk-Past QuestionDocument59 paginiJamb Crk-Past QuestionFadele1981Încă nu există evaluări

- Network Monitoring & Forensics: Jim IrvingDocument102 paginiNetwork Monitoring & Forensics: Jim IrvingKarel GoldmannÎncă nu există evaluări

- British Council IELTS Online Application SummaryDocument3 paginiBritish Council IELTS Online Application Summarys_asadeÎncă nu există evaluări

- How To Play Casino - Card Game RulesDocument1 paginăHow To Play Casino - Card Game RulesNouka VEÎncă nu există evaluări

- HARRISON 1993 - The Soviet Economy and Relations With The United States and Britain, 1941-45Document49 paginiHARRISON 1993 - The Soviet Economy and Relations With The United States and Britain, 1941-45Floripondio19Încă nu există evaluări

- Ficha Álvaro y Jesús 3Document8 paginiFicha Álvaro y Jesús 3Alex8mRÎncă nu există evaluări

- 173544avaya Aura AES 7-0 JTAPI Programmers GuideDocument88 pagini173544avaya Aura AES 7-0 JTAPI Programmers GuideAhmed SakrÎncă nu există evaluări