Documente Academic

Documente Profesional

Documente Cultură

Low Power Vs High Power LEDs

Încărcat de

Anonymous MDkp0hnb3lTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Low Power Vs High Power LEDs

Încărcat de

Anonymous MDkp0hnb3lDrepturi de autor:

Formate disponibile

LED Light Technology, LLC Tele: 770-559-0750

1004 Bay Tree Lane A Female Owned Company Fax: 770-783-8097

Duluth, Georgia 30097 www.LEDLightTech.com

Low Power Verses High Power LEDs

Low power LEDs are not illumination grade products and any retrofit products using them are

doomed to degrade or fail far short of the 25,000 to 100,000 hour life claims made for some of

these retrofit light bulbs. The core failure mode is the epoxy package. Optical epoxies will turn

brown somewhere between 8,000 and 12,000 hours when exposed to the blue light from the LED

die. Toss in white color point stability issues, i.e. they will most likely blue shift within the first

1,000 hours and you have a very unhappy set of end users out there!

For year’s now low power LED's have been used as indicators to let you know that your TV, VCR

or computer is on, if something was charging, etc. Now, due to scientific technical advancements,

high power LED's are capable of producing light levels even brighter and more efficient than light

bulbs.

At Light Technology, we sell and manufacture LED based lighting products using high power

LEDs. LED Light Technology founders have more than 25 years experience in the general

lighting and LED lighting industries. As lighting professionals we know how best to utilize high

power LED products to retrofit existing lighting systems to save energy, reduce air conditioning

loads and eliminate changing light bulbs and ballasts for many years.

LEDs use science to produce light rather than heat like traditional light sources. High power LEDs

consume up to 80% less electricity than light bulbs. Traditional light bulbs are very inefficient, for

example incandescent bulbs convert 95% of the electricity to heat and only about 5% to light. It’s

a very expensive way to heat a building. LEDs convert about 95% of the electricity to light and

last about fifty times longer than light bulbs. This is a scientific advancement based on the laws of

physics not to be underestimated.

The story only begins with lumens per watt (LPW). LPW has been the vanguard of the industry

measurement right up until this robust disruptive LED technology of creating light using science

instead of heat arrived on the scene.

During our President, Dan Falzone’s years at GE and Philips Lighting they always believed that

customers buy light, not light bulbs…light bulbs are just the medium. The true measurement that

we now operate on is foot candle levels at the work plane or road surface rather than lumens

produced by the light source. It is appropriate to consider that LEDs are directional rather than

multi-directional as traditional light sources are. LEDs emit light in a ~90° emission pattern

whereas traditional light sources emit light in a 360° pattern.

In traditional lighting fixtures the light is bounced from a reflector losing lumens and useful light,

some of the light is bounced multiple times and never reaches the work plane, but the fixtures

sure are bright in the ceiling. Since LED light is directed only downward from the semi-conductor

material, it delivers a greater number of useful lumens on the work plane while wasting little or

none in the fixture.

Recently the LED industry has announced that high LEDs in the lab have achieved more than

125LPW. That is a great milestone but they are not yet commercially available. At this time we

have full supply of 80 to 100 LPW LEDs. When this amount of light is properly arranged on a

circuit board and combined with secondary optics that shape and deliver more lumens to the work

plane you can begin to understand that what is really important is useful light rather than only

generated light.

Here is a real world example:

LED Light Technology, LLC Tele: 770-559-0750

1004 Bay Tree Lane A Female Owned Company Fax: 770-783-8097

Duluth, Georgia 30097 www.LEDLightTech.com

Existing fluorescent fixture consuming ~90 watts.

After Retrofit with LED fixture consuming ~35 watts.

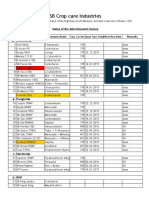

À Area/Light Source Fluorescent ~90W LED~35W

À Room Window Area 33 FC 56FC

À Room Center 21 FC 60 FC

À Room Near Door 18 FC 56 FC

À Average 24FC 57FC

Another way to look at this is Foot Candles/Watt (FC/W). In this Case FC/W if

fluorescent=0.26FC/W and LED=1.63FC/W

This demonstrates that in this case LEDs are 6.2 times more efficient and delivers more uniform

light levels across the room.

So we can reduce energy consumed by ~60%, deliver ~twice the useful light and eliminate

maintenance for 50,000 hours. LED Light Technology knows of no better way to reduce owning

and operating costs of a lighting system than conversion to LEDs.

S-ar putea să vă placă și

- Led DriverDocument38 paginiLed DriverManish Gaur0% (1)

- Microbiological Quality Ice CreamDocument9 paginiMicrobiological Quality Ice CreamocortezlariosÎncă nu există evaluări

- CPD 6 2014 - Sustainable Lighting - Features - Building DesignDocument6 paginiCPD 6 2014 - Sustainable Lighting - Features - Building DesignTommy YapÎncă nu există evaluări

- YhhjjDocument52 paginiYhhjjSam CunananÎncă nu există evaluări

- Certificate ProjectDocument14 paginiCertificate Projectsonakshisaxena1100% (1)

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocument16 paginiBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- In Philips Professional LED Lighting Catalogue 2012Document94 paginiIn Philips Professional LED Lighting Catalogue 2012theseusgarcia1100% (1)

- LED Lighting for your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularDe la EverandLED Lighting for your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularEvaluare: 4 din 5 stele4/5 (1)

- The Advantages of Magnetic Induction LampsDocument7 paginiThe Advantages of Magnetic Induction LampsnntoolÎncă nu există evaluări

- CCTV BasicsDocument12 paginiCCTV Basicsdorobantu_alexandru100% (1)

- IESNADocument44 paginiIESNAManola Alejandra Modragon SalazarÎncă nu există evaluări

- HI - Light Magazine 2Document19 paginiHI - Light Magazine 2Waleed Mohammed FekryÎncă nu există evaluări

- Chapter S1 (Celestial Timekeeping and Navigation)Document28 paginiChapter S1 (Celestial Timekeeping and Navigation)Марко Д. Станковић0% (1)

- 25742-Designing With LEDs Ebook 09-29-2010Document30 pagini25742-Designing With LEDs Ebook 09-29-2010gsanchez57Încă nu există evaluări

- Project Report: Led Street LightingDocument16 paginiProject Report: Led Street LightingSiddharth JoonÎncă nu există evaluări

- LED Lighting SystemsDocument22 paginiLED Lighting Systemsdavidhourri100% (1)

- LET-English-Structure of English-ExamDocument57 paginiLET-English-Structure of English-ExamMarian Paz E Callo80% (5)

- Ceylon Electricity BoardDocument85 paginiCeylon Electricity BoardAnonymous MDkp0hnb3lÎncă nu există evaluări

- 5G NR Essentials Guide From IntelefyDocument15 pagini5G NR Essentials Guide From IntelefyUzair KhanÎncă nu există evaluări

- Induction and LED Lighting: An Overview of Interior ApplicationsDocument18 paginiInduction and LED Lighting: An Overview of Interior ApplicationsShantkumar S SambargimathÎncă nu există evaluări

- Led PresentationDocument28 paginiLed PresentationhemadribabuÎncă nu există evaluări

- Design of 132-33kV SSDocument13 paginiDesign of 132-33kV SSSemifallen100% (3)

- How To Calculate The Lux Level in A RoomDocument21 paginiHow To Calculate The Lux Level in A RoomSonu Pathak100% (1)

- Top 10 Benefits of LED LightingDocument8 paginiTop 10 Benefits of LED LightingVIKAS BHANDAREÎncă nu există evaluări

- Led Lighting Is ThornDocument88 paginiLed Lighting Is ThornhansdubarryÎncă nu există evaluări

- Benefits and Drawbacks of LEDsDocument2 paginiBenefits and Drawbacks of LEDsnittu12Încă nu există evaluări

- Low Pressure SodiumDocument10 paginiLow Pressure SodiumCyrus JainÎncă nu există evaluări

- Led Light For Energy EfficencyDocument29 paginiLed Light For Energy EfficencySantanu Kumar RanaÎncă nu există evaluări

- The Transition To Led Illumination: A Case Study On Energy ConservationDocument5 paginiThe Transition To Led Illumination: A Case Study On Energy ConservationTarun ImandiÎncă nu există evaluări

- LED Lighting Technologies and TrendDocument4 paginiLED Lighting Technologies and TrendCierrie ManaoisÎncă nu există evaluări

- LED vs. Fluorescent: The ROI AdvantageDocument12 paginiLED vs. Fluorescent: The ROI AdvantagePubudu Charaka KudahettiÎncă nu există evaluări

- Microsoft Word - What Is An LEDDocument2 paginiMicrosoft Word - What Is An LEDprasoon1234Încă nu există evaluări

- LED Hue Lamps: LED HUE Lamp Is A Light-Emitting Diode (LED) Product That Is Assembled Into ADocument8 paginiLED Hue Lamps: LED HUE Lamp Is A Light-Emitting Diode (LED) Product That Is Assembled Into AJonathan FernandezÎncă nu există evaluări

- Light Emitting Diode: Practical UseDocument6 paginiLight Emitting Diode: Practical UseMalathy PrapakarÎncă nu există evaluări

- Electrical Services AssignmentDocument6 paginiElectrical Services AssignmentAshfaque SalzÎncă nu există evaluări

- White Led ThesisDocument5 paginiWhite Led Thesisaragunikd100% (2)

- Why Energy Efficient Lighting ?: More Light From Less PowerDocument38 paginiWhy Energy Efficient Lighting ?: More Light From Less PowersixfacerajÎncă nu există evaluări

- Energy Savings: Top 8 Things You Didn'T Know About LedsDocument3 paginiEnergy Savings: Top 8 Things You Didn'T Know About LedsJohn Edenson VelonoÎncă nu există evaluări

- LED PresentationDocument15 paginiLED PresentationSunidhi MohapatraÎncă nu există evaluări

- LEDDocument4 paginiLEDBhaskar Rao PÎncă nu există evaluări

- Power Generation High Temperature Led Lighting r1Document6 paginiPower Generation High Temperature Led Lighting r1Wilson Xavier Orbea BrachoÎncă nu există evaluări

- Assets Application - Notes Indication Getting To Know LEDsDocument8 paginiAssets Application - Notes Indication Getting To Know LEDsyugimoto2005Încă nu există evaluări

- About LVDDocument19 paginiAbout LVDAmit SarkarÎncă nu există evaluări

- Solar LED Street Lighting by VLEDocument17 paginiSolar LED Street Lighting by VLEBlaze_HydÎncă nu există evaluări

- What Is Useful Life For White Light Leds? Lighting Research CenterDocument12 paginiWhat Is Useful Life For White Light Leds? Lighting Research CenterAbigail RamosÎncă nu există evaluări

- LED LightingDocument9 paginiLED LightingmachinejigÎncă nu există evaluări

- VarshaDocument51 paginiVarshaAswithareddy AswithareddyÎncă nu există evaluări

- Position PaperDocument2 paginiPosition PapersieyasÎncă nu există evaluări

- Solid State LightingDocument9 paginiSolid State LightingEmanuele100% (2)

- Somai Tech (Pty) LTD) : Your Answer To Energy Efficient Lighting!Document2 paginiSomai Tech (Pty) LTD) : Your Answer To Energy Efficient Lighting!Caleb SomaiÎncă nu există evaluări

- Led Lighting Thesis PDFDocument6 paginiLed Lighting Thesis PDFWriteMyEnglishPaperForMeSterlingHeights100% (2)

- Inside Innovation Backgrounder Lumens Per WattDocument3 paginiInside Innovation Backgrounder Lumens Per WattOm EliasÎncă nu există evaluări

- LED vs. Fiber Optic Illumination: Our Thanks To Luxo For Allowing Us To Reprint The FollowingDocument2 paginiLED vs. Fiber Optic Illumination: Our Thanks To Luxo For Allowing Us To Reprint The FollowingAkbar MassudiÎncă nu există evaluări

- Report LED Environmental ScienceDocument11 paginiReport LED Environmental ScienceLo M'hÎncă nu există evaluări

- LED Lighting: Getting It Right: Did You Know?Document4 paginiLED Lighting: Getting It Right: Did You Know?jayveeÎncă nu există evaluări

- Power Light New Generation enDocument8 paginiPower Light New Generation enSuraj WeerakkodyÎncă nu există evaluări

- JKFJMRFIMRFKDMDDocument22 paginiJKFJMRFIMRFKDMDRobert Oconer AguilarÎncă nu există evaluări

- Facilities Led LightsDocument3 paginiFacilities Led LightsJonathanÎncă nu există evaluări

- LEDs 2Document58 paginiLEDs 2Mahmoud AlsaidÎncă nu există evaluări

- Ele432 Report LedDocument2 paginiEle432 Report LedRAJAÎncă nu există evaluări

- Wiva Catalog Led 2015 en PDFDocument86 paginiWiva Catalog Led 2015 en PDFMaja Dimitrovska-JurukovskaÎncă nu există evaluări

- Term Paper On LedDocument8 paginiTerm Paper On Ledafmaamehdbosuo100% (1)

- Ons LedDocument35 paginiOns LeddenisandreiÎncă nu există evaluări

- Recessed DownlightDocument2 paginiRecessed DownlighthenlopÎncă nu există evaluări

- Sight Glass Lighting: Application HandbookDocument20 paginiSight Glass Lighting: Application Handbookkresimir.mikoc9765Încă nu există evaluări

- LED Street LightingDocument4 paginiLED Street LightingmswgtsÎncă nu există evaluări

- Seminar On LEDDocument25 paginiSeminar On LEDOPEYEMI FIADE100% (1)

- LED LIGHTING Research Report AbstractDocument14 paginiLED LIGHTING Research Report AbstractAkachi Okoro0% (1)

- LED Lighting for Your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularDe la EverandLED Lighting for Your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularÎncă nu există evaluări

- LI Ion4Document68 paginiLI Ion4Anonymous MDkp0hnb3lÎncă nu există evaluări

- Acti9 iPF K - A9L15692Document3 paginiActi9 iPF K - A9L15692Anonymous MDkp0hnb3lÎncă nu există evaluări

- Aus Cable Laying Standard1Document34 paginiAus Cable Laying Standard1Anonymous MDkp0hnb3lÎncă nu există evaluări

- Fire Detection Systems 0710 PDFDocument27 paginiFire Detection Systems 0710 PDFParveshi PusunÎncă nu există evaluări

- Apollo Pocket Guide Final Aw - Lo Res SpreadsDocument13 paginiApollo Pocket Guide Final Aw - Lo Res Spreadsbeho2000Încă nu există evaluări

- Sounder Cum Strobe - AVL135-SignedDocument1 paginăSounder Cum Strobe - AVL135-SignedAnonymous MDkp0hnb3lÎncă nu există evaluări

- PUSTRON BriefDocument2 paginiPUSTRON BriefAnonymous MDkp0hnb3lÎncă nu există evaluări

- SUMIP BriefDocument2 paginiSUMIP BriefAnonymous MDkp0hnb3lÎncă nu există evaluări

- Axis p3245-V NetworkDocument3 paginiAxis p3245-V NetworkAnonymous MDkp0hnb3lÎncă nu există evaluări

- Subox GRP Enclosure SystemsDocument12 paginiSubox GRP Enclosure SystemsAnonymous MDkp0hnb3lÎncă nu există evaluări

- INFOR-TYCO - ACS-24 - Sounder Cum Strobe - Rev 1Document4 paginiINFOR-TYCO - ACS-24 - Sounder Cum Strobe - Rev 1Anonymous MDkp0hnb3lÎncă nu există evaluări

- Sumip FRP Cable Tray CatalgueDocument12 paginiSumip FRP Cable Tray CatalgueAnonymous MDkp0hnb3lÎncă nu există evaluări

- Selling IP Surveillance Against Analog CCTVDocument3 paginiSelling IP Surveillance Against Analog CCTVOmar Nasri KmailÎncă nu există evaluări

- SUMIP GRP Lighting Pole CatalogueDocument6 paginiSUMIP GRP Lighting Pole CatalogueAnonymous MDkp0hnb3lÎncă nu există evaluări

- Azure 2 0TR Cassette PDFDocument1 paginăAzure 2 0TR Cassette PDFAnonymous MDkp0hnb3lÎncă nu există evaluări

- Gemscab PVC Cables PDFDocument28 paginiGemscab PVC Cables PDFJaved AliÎncă nu există evaluări

- Draft Specification of Lan Switch: Specification No. Rdso/Spn/Tc/83/2014 Revision 1.0Document27 paginiDraft Specification of Lan Switch: Specification No. Rdso/Spn/Tc/83/2014 Revision 1.0Anonymous MDkp0hnb3lÎncă nu există evaluări

- Caret Iitk IexDocument52 paginiCaret Iitk IexAishwarya SankaranÎncă nu există evaluări

- Supply and Installation of LED LIGHTS at BRBNMPL, Mysore: Invitation For Expression of Interest (EOI) ForDocument6 paginiSupply and Installation of LED LIGHTS at BRBNMPL, Mysore: Invitation For Expression of Interest (EOI) ForAnonymous MDkp0hnb3lÎncă nu există evaluări

- Axis ComparDocument10 paginiAxis Comparashish_gbpec9210Încă nu există evaluări

- Acrylic Polycarbonate CompatibilityDocument2 paginiAcrylic Polycarbonate CompatibilityfcordÎncă nu există evaluări

- Video Surv Storage Tp571!3!1202 UsDocument3 paginiVideo Surv Storage Tp571!3!1202 UsGeorge JaneÎncă nu există evaluări

- MAXPRO® NVR PE (Professional Edition)Document6 paginiMAXPRO® NVR PE (Professional Edition)Anonymous MDkp0hnb3lÎncă nu există evaluări

- View Your World in Full HD: Network Video Surveillance RecorderDocument4 paginiView Your World in Full HD: Network Video Surveillance RecorderAnonymous MDkp0hnb3lÎncă nu există evaluări

- Optiview-Vms SpecsDocument1 paginăOptiview-Vms SpecsAnonymous MDkp0hnb3lÎncă nu există evaluări

- Pelco by Schneider Electric Security Cameras & Surveillance SystemsDocument8 paginiPelco by Schneider Electric Security Cameras & Surveillance SystemsAnonymous MDkp0hnb3lÎncă nu există evaluări

- Work Permits New Guideline Amendments 2021 23.11.2021Document7 paginiWork Permits New Guideline Amendments 2021 23.11.2021Sabrina BrathwaiteÎncă nu există evaluări

- Limestone Standards PDFDocument2 paginiLimestone Standards PDFJacqueline BerueteÎncă nu există evaluări

- Multibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFDocument122 paginiMultibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFnecromareÎncă nu există evaluări

- Team 6 - Journal Article - FinalDocument8 paginiTeam 6 - Journal Article - FinalAngela Christine DensingÎncă nu există evaluări

- Kamal: Sales and Marketing ProfessionalDocument3 paginiKamal: Sales and Marketing ProfessionalDivya NinaweÎncă nu există evaluări

- NJEX 7300G: Pole MountedDocument130 paginiNJEX 7300G: Pole MountedJorge Luis MartinezÎncă nu există evaluări

- 2022 NEDA Annual Report Pre PubDocument68 pagini2022 NEDA Annual Report Pre PubfrancessantiagoÎncă nu există evaluări

- Analysis of MMDR Amendment ActDocument5 paginiAnalysis of MMDR Amendment ActArunabh BhattacharyaÎncă nu există evaluări

- Manual TV Hyundai HYLED3239iNTMDocument40 paginiManual TV Hyundai HYLED3239iNTMReinaldo TorresÎncă nu există evaluări

- Motion To Dismiss Guidry Trademark Infringement ClaimDocument23 paginiMotion To Dismiss Guidry Trademark Infringement ClaimDaniel BallardÎncă nu există evaluări

- Visual Inspection ReportDocument45 paginiVisual Inspection ReportKhoirul AnamÎncă nu există evaluări

- Ceo DualityDocument3 paginiCeo Dualitydimpi singhÎncă nu există evaluări

- OM Part B - Rev1Document45 paginiOM Part B - Rev1Redouane BelaassiriÎncă nu există evaluări

- BBAG MPR and STR LISTSDocument25 paginiBBAG MPR and STR LISTShimanshu ranjanÎncă nu există evaluări

- S P99 41000099DisplayVendorListDocument31 paginiS P99 41000099DisplayVendorListMazen Sanad100% (1)

- Products ListDocument11 paginiProducts ListPorag AhmedÎncă nu există evaluări

- Ep Docx Sca SMSC - V2Document45 paginiEp Docx Sca SMSC - V290007Încă nu există evaluări

- PPT-QC AcDocument34 paginiPPT-QC AcAmlan Chakrabarti Calcutta UniversityÎncă nu există evaluări

- Rwamagana s5 Mathematics CoreDocument4 paginiRwamagana s5 Mathematics Coreevariste.ndungutse1493Încă nu există evaluări

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Document12 paginiWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeÎncă nu există evaluări

- Sidomuncul20190313064235169 1 PDFDocument298 paginiSidomuncul20190313064235169 1 PDFDian AnnisaÎncă nu există evaluări

- CP3 - June2019 2Document5 paginiCP3 - June2019 2Sifei ZhangÎncă nu există evaluări

- Wood ReportDocument36 paginiWood Reportメルヴリッ クズルエタÎncă nu există evaluări

- DR Afwan Fajri - Trauma - Juli 2023Document82 paginiDR Afwan Fajri - Trauma - Juli 2023afwan fajriÎncă nu există evaluări