Documente Academic

Documente Profesional

Documente Cultură

Asme Section Ii A-2 Sa-836 Sa-836m

Încărcat de

david perezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Asme Section Ii A-2 Sa-836 Sa-836m

Încărcat de

david perezDrepturi de autor:

Formate disponibile

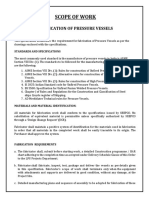

2007 SECTION II, PART A SA-836 /SA-836M

SPECIFICATION FOR FORGINGS, TITANIUM-

STABILIZED CARBON STEEL, FOR GLASS-LINED

PIPING AND PRESSURE VESSEL SERVICE

SA-836 /SA-836M

(Identical with ASTM Specification A 836 /A 836M-95b.)

1. Scope 2.3 Military Standard:

1.1 This specification covers nonstandard as-forged fit- MIL-STD-163 Steel Mill Products, Preparation for Ship-

tings, valve components, and parts for glass-lined piping ment and Storage

and pressure vessel service. Mechanical properties are cer-

tified on the basis of test material subjected to heat treat-

3. Ordering Information

ments to simulate glass-coating operations.

3.1 It is the purchaser’s responsibility to specify in

1.2 The values stated in either inch-pound units or SI the purchase order all ordering information necessary to

units are to be regarded separately as standard. Within the purchase the needed material. Examples of such informa-

text, the SI units are shown in brackets. The values stated tion include but are not limited to the following:

in each system are not exact equivalents; therefore, each 3.1.1 Quantity,

system must be used independently of the other. Combining

values from the two systems may result in nonconformance 3.1.2 Dimensions (Tolerance and surface finishes

with the specification. The inch-pound units shall apply should be included),

unless the “M” designation of this specification is specified 3.1.3 Specification number and class (The year date

in the order. should be included),

3.1.4 Supplementary requirements, and

3.1.5 Additional requirements (see 10.1, 13.1, 13.2,

2. Referenced Documents 13.3, and 15.2).

2.1 ASTM Standards:

A 275 /A 275M Test Method for Magnetic Particle Exami-

4. Materials and Manufacture

nation of Steel Forgings

A 370 Test Methods and Definitions for Mechanical Test- 4.1 Material for forgings shall consist of ingots, or

ing of Steel Products forged, rolled, or strand cast blooms, billets, slabs, or bars.

A 700 Practices for Packaging, Marking, and Loading 4.2 The material shall be forged by hammering, press-

Methods for Steel Products for Domestic Shipment ing, rolling, extruding, or upsetting, such that the finished

A 751 Test Methods, Practices, and Terminology for product will be a forging as defined in the Terminology

Chemical Analysis of Steel Products Section of Specification A 788.

A 788 Specification for Steel Forgings, General Require-

4.3 A sufficient discard shall be made from the source

ments material to secure freedom from injurious piping and undue

E 165 Practice for Liquid Penetrant Inspection Method segregation.

E 709 Practice for Magnetic Particle Examination

4.4 When specified in the order, the manufacturer shall

2.2 ASME Boiler and Pressure Vessel Code: submit for approval by the purchaser a sketch showing the

Section IX Welding Qualifications shape of the rough forging before machining.

1483 --`,```,,,``,,,,``,`,`,,,`,,``,,-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Occidental Chemical Corp New sub account/5910419101

No reproduction or networking permitted without license from IHS Not for Resale, 02/25/2008 08:10:48 MST

SA-836 /SA-836M 2007 SECTION II, PART A

4.5 Forgings shall be protected against sudden or too dimensions shall be proportional to those shown in Fig. 4

rapid cooling from the rolling or forging while passing of Test Methods and Definitions A 370. The gage length

through the critical range. for measuring elongation shall be four times the diameter

4.6 Heat treatment of forgings is neither required nor of the specimen.

prohibited. However, the test material for qualifying the 7.4 For the purpose of determining conformance to

forging or the welding procedure shall be heat treated to Table 3, specimens shall be obtained from the production

simulate glass-coating operations. forgings, or from separately forged test blanks prepared

from the stock used to make the finished product. Such

5. Chemical Composition test blanks shall receive approximately the same working

as the finished product.

5.1 Cast or Heat Analysis — An analysis of each cast

or heat shall be made by the manufacturer to determine

the percentages of the elements specified in Table 1. The

analysis shall be made from a test sample, preferably taken 8. Workmanship, Finish, and Appearance

during the pouring of the cast or heat. The chemical compo- 8.1 The forgings shall be free of injurious imperfections

sition thus determined shall conform to the requirements as defined below and shall have a workmanlike finish. At

in Table 1. the discretion of the inspector representing the purchaser,

5.2 Product Analysis: finished forgings shall be subject to rejection if surface

5.2.1 The purchaser may make a product analysis imperfections acceptable under 8.3 are not scattered but

on forgings supplied to this specification by any of the appear over a large area in excess of what is considered a

commonly accepted methods that will positively identify workmanlike finish.

the material. Samples for analysis may be taken from mid-

8.2 Depth of Injurious Imperfections — Selected typical

way between center and surface of solid forgings, midway

linear and other typical surface imperfections shall be

between inner and outer surfaces of hollow forgings, mid-

explored for depth. When the depth encroaches on the

way between center and surface of full-size prolongations,

minimum wall thickness of the finished forging, such

or from broken mechanical test specimens. The chemical

imperfections shall be considered injurious.

composition thus determined shall conform to Table 1

within the permissible variations of Table 2. 8.3 Machining or Grinding Imperfections Not Classified

5.2.2 Test Methods, Practices, and Terminology as Injurious —Surface imperfections not classified as inju-

A 751 apply. rious shall be treated as follows:

8.3.1 Forgings showing seams, laps, tears, or slivers

6. Mechanical Properties not deeper than 5% of the nominal wall thickness or 1⁄16 in.

6.1 The test material shall conform to the requirements [2 mm], whichever is less, need not have these imperfec-

as to tensile properties prescribed in Table 3. tions removed. If the imperfections require removal, they

shall be removed by machining or grinding.

6.2 Testing shall be performed in accordance with Test

Methods and Definitions A 370. 8.3.2 Mechanical marks or abrasions and pits shall

be acceptable without grinding or machining provided the

depth does not exceed the limitations set forth in 8.2 and

7. Test Specimens if not deeper than 1⁄16 in. [2 mm]. If such imperfections are

7.1 The test material to be used for qualifying the deeper than 1⁄16 in. but do not encroach on the minimum

forgings shall be heat treated with the forgings represented wall thickness of the forging they shall be removed by

by the test material, if the forgings are heat treated, then, grinding to sound metal.

the test material shall be normalized three times from a

minimum temperature of 1550°F [845°C] prior to testing. 8.3.3 When imperfections have been removed by

This heat treatment simulates glass-coating operations. grinding or machining, the outside dimension at the point

of grinding or machining may be reduced by the amount

7.2 The tension test specimens shall be machined to removed. When impracticable to secure a direct measure-

the form and dimensions of the standard 2 in. [50 mm] ment, the wall thickness at the point of grinding, or at

gage length tension test specimen shown in Fig. 4 of Test imperfections not required to be removed, shall be deter-

Methods and Definitions A 370, except as specified in 7.3. mined by deducting the amount removed by grinding, from

7.3 In the case of small sections that will not permit the nominal finished wall thickness of the forging; the

taking standard test specimens as specified in 7.2, the ten- remainder shall not be less than the minimum specified or

sion test specimen shall be as large as feasible and its required wall thickness.

1484 --`,```,,,``,,,,``,`,`,,,`,,``,,-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Occidental Chemical Corp New sub account/5910419101

No reproduction or networking permitted without license from IHS Not for Resale, 02/25/2008 08:10:48 MST

2007 SECTION II, PART A SA-836 /SA-836M

9. Number of Tests and Retests 11. Inspection

9.1 One tension test shall be made from each heat. 11.1 The manufacturer shall afford the purchaser’s

inspector all reasonable facilities necessary to satisfy him

9.2 If any test specimen is defectively machined, it

that the material is being produced and furnished in accor-

may be discarded and another specimen substituted.

dance with this specification. Mill inspection by the pur-

9.3 When one or more representative test specimens chaser shall not interfere unnecessarily with the

do not conform to specification requirements for the tested manufacturer’s operations. All tests and inspections shall

characteristic, only a single retest for each nonconforming be made at the place of manufacture, unless otherwise

characteristic may be performed to establish product agreed to.

acceptability. Retests shall be performed on twice the num-

ber of representative specimens that were originally non-

conforming. When any retest specimen does not conform 12. Rejection and Rehearing

to specification requirements for the characteristic in ques- 12.1 Each forging that develops injurious defects dur-

tion, the lot represented by that specimen shall be rejected, ing shop working or application shall be rejected and the

or the test material shall be reheat-treated in accordance manufacturer notified.

with 4.6 and 7.1, and tested in accordance with Sections

6, 7, and 9. 12.2 Samples representing material rejected by the pur-

chaser shall be preserved until disposition of the claim has

been agreed upon by the manufacturer and the purchaser.

10. Repair by Welding

10.1 Approval by the purchaser shall be required prior

13. Certification

to weld repair.

13.1 When specified in the purchase order or contract,

10.2 The welding procedure and welders shall be quali- a producer’s or supplier’s certification shall be furnished to

fied in accordance with Section IX of the ASME Boiler the purchaser that the material was manufactured, sampled,

and Pressure Vessel Code. The welded test plate used to tested, and inspected in accordance with this specification

qualify the procedure shall be normalized three times at and has been found to meet the requirements. The specifi-

1550°F [845°C] prior to testing to simulate glass-coating cation designation included on test reports shall include

operations. year of issue and revision letter, if any.

10.3 The composition of the weld deposits shall be 13.2 When specified in the purchase order or contract,

similar to the base metal and in accordance with the proce- a report of the test results shall be furnished.

dure qualification for the applicable material. Welding shall

be accomplished with a weld procedure designed to pro- 13.3 Upon request of the purchaser in the contract or

duce low hydrogen in the weldment. Short-circuit gas metal order, a report of the test results and chemical analyses

arc welding is permissible only with the approval of the shall be furnished.

purchaser.

10.4 Unacceptable imperfections shall be removed by 14. Marking of Forgings

mechanical means or thermal cutting or gouging methods. 14.1 Identification marks consisting of the manufactur-

Cavities prepared for welding shall be examined by one er’s symbol or name (Note), designation of service rating,

of the following methods to verify removal of the imper- this specification number, class, and size shall be legibly

fection: forged or stamped on each forging, and in such a position

10.4.1 Magnetic particle examination in accordance as not to injure the usefulness of the forgings. The specifi-

with Test Method A 275 /A 275M or Practice E 709, or cation number marked on the forgings need not include

10.4.2 Liquid penetrant examination in accordance specification year of issue and revision letter.

with Practice E 165. NOTE — For purposes of identification marking, the manufacturer is

considered the organization that certifies the piping component was manu-

10.5 Weld repaired area(s) shall be blended uniformly factured, sampled, and tested in accordance with this specification and

to the base metal and shall be examined by the method the results have been determined to meet the requirements of this specifi-

used in 10.4. cation.

10.6 Repair by welding shall neither exceed 10% of 14.2 Bar Coding — In addition to the requirements in

the surface area of the part, nor 331⁄3% of the wall thickness 14.1, bar coding is acceptable as a supplementary identifi-

of the finished product at the location of repair, without cation method. The bar coding system, if applied at the

prior approval by the purchaser. discretion of the supplier, should be consistent with one

1485 --`,```,,,``,,,,``,`,`,,,`,,``,,-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Occidental Chemical Corp New sub account/5910419101

No reproduction or networking permitted without license from IHS Not for Resale, 02/25/2008 08:10:48 MST

SA-836 /SA-836M 2007 SECTION II, PART A

of the published industry standards for bar coding. If used 15.2 When specified in the contract or order, and for

on small parts, the bar code may be applied to the box or direct procurement by or direct shipment to the govern-

a substantially applied tag. ment, when level A is specified, preservation, packaging,

and packing shall be in accordance with the Level A

requirements of MIL-STD-163.

16. Keywords

15. Packaging, Marking, and Loading for Shipment

16.1 pipe fittings, steel; piping applications; pressure

15.1 Packaging, marking, and loading for shipment containing parts; pressure vessel service; steel flanges; steel

shall be in accordance with Practices A 700. forgings-carbon; steel valves

TABLE 1

CHEMICAL REQUIREMENTS

Element Composition, %

Carbon, max 0.20

Manganese, max 0.90

Phosphorus, max 0.05

Silicon, max 0.35

Sulfur, max 0.05

Titanium, min 4 ⴛ carbon content

Titanium, max 1.00

TABLE 2

PERMISSIBLE VARIATIONS IN PRODUCT ANALYSIS

Permissible Variations Over the Maximum Limit or Under the Minimum

Limit, %A,B

Over 200 to Over 400 to

400 in.2 [1290 800 in.2 [2580 Over 800 to

200 in.2 [1290 to 2580 cm2], to 5160 cm2], 1600 in.2 [5160 Over 1600 in.2

cm2] and Under incl incl to 10 320 cm2] [10 320 cm2]

Manganese

Up to and

including

0.90 0.04 0.05 0.06 0.07 0.08

Phosphorus 0.008 0.010 0.010 0.015 0.015

Sulfur 0.010 0.010 0.010 0.015 0.015

Silicon 0.03 0.04 0.04 0.05 0.06

A

Product cross-sectional area is defind as (a) maximum cross-sectional area of rough machined forging

(excluding boring), (b) maximum cross-sectional area of the unmachined forging, or (c) maximum cross-

sectional area of the billet, bloom or slab.

B

Area taken at right angles to the axis of the original ingot or billet.

TABLE 3

TENSILE REQUIREMENTS

Class I

Tensile strength, min, ksi [MPa] 55 [380]

Yield strength, A min, ksi [MPa] 25 [175]

Elongation in 2 in. or 50 mm, min, % 22

Reduction of area, min, % 35

A

Determined by either 0.2% offset method or the 0.5% exten-

sion-under-load method.

1486

--`,```,,,``,,,,``,`,`,,,`,,``,,-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Occidental Chemical Corp New sub account/5910419101

No reproduction or networking permitted without license from IHS Not for Resale, 02/25/2008 08:10:48 MST

S-ar putea să vă placă și

- Specification for Titanium-Stabilized Carbon Steel ForgingsDocument5 paginiSpecification for Titanium-Stabilized Carbon Steel Forgingslucecita1902Încă nu există evaluări

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 paginiAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xÎncă nu există evaluări

- Carbon Steel Forgings For Pressure Vessel ComponentsDocument4 paginiCarbon Steel Forgings For Pressure Vessel ComponentsRishabh AroraÎncă nu există evaluări

- Carbon Steel Forging SpecificationDocument6 paginiCarbon Steel Forging SpecificationAnilÎncă nu există evaluări

- Specification For Carbon Steel Forgings, For General-Purpose PipingDocument6 paginiSpecification For Carbon Steel Forgings, For General-Purpose PipingMauricio Esteban Fernandez RamirezÎncă nu există evaluări

- Astm A 836 - A 836M - 02 - Qtgzni9bodm2tqDocument3 paginiAstm A 836 - A 836M - 02 - Qtgzni9bodm2tqEjat ISÎncă nu există evaluări

- Specification For Carbon Steel Forgings For Pressure Vessel ComponentsDocument6 paginiSpecification For Carbon Steel Forgings For Pressure Vessel Componentsmr.aghelÎncă nu există evaluări

- ASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFDocument4 paginiASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFmitchialiÎncă nu există evaluări

- Asme Section Ii A-2 Sa-723 Sa-723mDocument6 paginiAsme Section Ii A-2 Sa-723 Sa-723mdavid perezÎncă nu există evaluări

- ASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsDocument7 paginiASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsJuan Luis FerretÎncă nu există evaluări

- Norma ASTM A516-2006pdfDocument4 paginiNorma ASTM A516-2006pdfRafael DiasÎncă nu există evaluări

- Age-Hardening Stainless Steel Forgings: Standard Specification ForDocument7 paginiAge-Hardening Stainless Steel Forgings: Standard Specification ForamerÎncă nu există evaluări

- Specification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceDocument4 paginiSpecification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceedwinbadajosÎncă nu există evaluări

- Ferritic Malleable Iron Castings: Standard Specification ForDocument6 paginiFerritic Malleable Iron Castings: Standard Specification ForAAYÎncă nu există evaluări

- Asme Section Ii A Sa-437 Sa-437m PDFDocument6 paginiAsme Section Ii A Sa-437 Sa-437m PDFdavid perezÎncă nu există evaluări

- Specification for Martensitic Stainless and Alloy Steel CastingsDocument6 paginiSpecification for Martensitic Stainless and Alloy Steel CastingsRajeev KumarÎncă nu există evaluări

- Asme Section Ii A-2 Sa-905Document6 paginiAsme Section Ii A-2 Sa-905Anonymous GhPzn1xÎncă nu există evaluări

- Astm A395-1999 (2018)Document8 paginiAstm A395-1999 (2018)senthil selvarajÎncă nu există evaluări

- Designation A516 A516M 10 PDFDocument4 paginiDesignation A516 A516M 10 PDFSiddharth GuptaÎncă nu există evaluări

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 paginiPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicemarykongÎncă nu există evaluări

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 paginiPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceRodolfoÎncă nu există evaluări

- Specification For Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and TemperedDocument4 paginiSpecification For Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and TemperededwinbadajosÎncă nu există evaluări

- Pressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature ServiceDocument3 paginiPressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature ServiceManivasagan VasuÎncă nu există evaluări

- Carbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsDocument2 paginiCarbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsRichard AlcaldeÎncă nu există evaluări

- Astm A216-A216m-04Document4 paginiAstm A216-A216m-04NadhiraÎncă nu există evaluări

- Aluminum Alloy Die and Hand Forging SpecificationDocument10 paginiAluminum Alloy Die and Hand Forging SpecificationAnilÎncă nu există evaluări

- Astm A351 2006Document5 paginiAstm A351 2006Almas AthifÎncă nu există evaluări

- Astma 516Document3 paginiAstma 516EdirwinJoseChirinosÎncă nu există evaluări

- ASME SA-516 Pressure Vessel Plate SpecificationDocument7 paginiASME SA-516 Pressure Vessel Plate SpecificationSTRUCPIPE CALIDAD100% (1)

- Astm A 515Document3 paginiAstm A 515edwinbadajosÎncă nu există evaluări

- Astm A351Document6 paginiAstm A351Rahul SinghÎncă nu există evaluări

- A351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsDocument5 paginiA351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsPhong ThanhÎncă nu există evaluări

- Asme Section Ii A-2 Sa-995Document4 paginiAsme Section Ii A-2 Sa-995Anonymous GhPzn1xÎncă nu există evaluări

- A351a 351m 03 PDFDocument6 paginiA351a 351m 03 PDFkannan vÎncă nu există evaluări

- Carbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsDocument2 paginiCarbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsfaroukÎncă nu există evaluări

- Astm A 351 - 05Document5 paginiAstm A 351 - 05srihariÎncă nu există evaluări

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument3 paginiPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicespartacusmanaÎncă nu există evaluări

- Astm A-516Document3 paginiAstm A-516NOE MARINÎncă nu există evaluări

- Steel Forgings, Austenitic, For Pressure and High Temperature PartsDocument7 paginiSteel Forgings, Austenitic, For Pressure and High Temperature PartsJerry BeanÎncă nu există evaluări

- Astm 487Document6 paginiAstm 487JOSEPH REFUERZOÎncă nu există evaluări

- Specification For Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument6 paginiSpecification For Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature Servicecesar jaramilloÎncă nu există evaluări

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKDocument10 paginiSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKFerry SiegersÎncă nu există evaluări

- Castings, Austenitic, Austenitic-Ferritic (Duplex), For Pressure-Containing PartsDocument5 paginiCastings, Austenitic, Austenitic-Ferritic (Duplex), For Pressure-Containing PartsElpidio ManansalaÎncă nu există evaluări

- A780 09Document4 paginiA780 09DuongthithuydungÎncă nu există evaluări

- A705A705MDocument7 paginiA705A705MAnderson TadeuÎncă nu există evaluări

- Zinc Coating, Hot-Dip, Requirements For Application To Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners (Metric)Document5 paginiZinc Coating, Hot-Dip, Requirements For Application To Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners (Metric)DeepakRajurkarÎncă nu există evaluări

- Continuous Grain Flow Forged Carbon and Alloy Steel Crankshafts For Medium Speed Diesel EnginesDocument5 paginiContinuous Grain Flow Forged Carbon and Alloy Steel Crankshafts For Medium Speed Diesel EnginesAli Saleh Saad AL-isawiÎncă nu există evaluări

- Ferritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesDocument8 paginiFerritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesAmit PathakÎncă nu există evaluări

- ASTM A 487 (Impeller) PDFDocument6 paginiASTM A 487 (Impeller) PDFnugrohowiwitÎncă nu există evaluări

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDocument10 paginiAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDhanush NairÎncă nu există evaluări

- Sa 420Document10 paginiSa 420Widya widyaÎncă nu există evaluări

- A562 PDFDocument4 paginiA562 PDFSofiaJabadanEspulgarÎncă nu există evaluări

- Specification For Pressure Vessel Plates, Alloy Steel, MolybdenumDocument4 paginiSpecification For Pressure Vessel Plates, Alloy Steel, Molybdenumdaniel pacheco do nascimento PachecoÎncă nu există evaluări

- ASTM-A439-A439M-18-2022-Document4 paginiASTM-A439-A439M-18-2022-Milady OyuelaÎncă nu există evaluări

- A437A437Document3 paginiA437A437Fallo SusiloÎncă nu există evaluări

- A 592 - A 592M - 89 R99 Qtu5mi9bntkytqDocument3 paginiA 592 - A 592M - 89 R99 Qtu5mi9bntkytqClaudia Patricia Magaña RabanalesÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemÎncă nu există evaluări

- Technical Note: Approximate Stress Intensity Factor and NotchDocument2 paginiTechnical Note: Approximate Stress Intensity Factor and Notchdavid perezÎncă nu există evaluări

- A New Approach To Improving The Properties of Brazed JointsDocument8 paginiA New Approach To Improving The Properties of Brazed Jointsdavid perezÎncă nu există evaluări

- Technical Note: Fatigue Assessment of Local Stress Spot Welds Parameters Based OnDocument3 paginiTechnical Note: Fatigue Assessment of Local Stress Spot Welds Parameters Based Ondavid perezÎncă nu există evaluări

- A Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum AlloyDocument9 paginiA Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum Alloydavid perezÎncă nu există evaluări

- A Method For Studying Weld Fusion Boundary Microstructure Evolution in Aluminum AlloysDocument8 paginiA Method For Studying Weld Fusion Boundary Microstructure Evolution in Aluminum AlloystazzorroÎncă nu există evaluări

- Improved Ferrite Number Prediction in Stainless Steel Arc Welds Using Artificial Neural Networks Part 1: Neural Network DevelopmentDocument8 paginiImproved Ferrite Number Prediction in Stainless Steel Arc Welds Using Artificial Neural Networks Part 1: Neural Network Developmentdavid perezÎncă nu există evaluări

- WJ 2000 01 s18 PDFDocument6 paginiWJ 2000 01 s18 PDFdavid perezÎncă nu există evaluări

- Asme Section II A Sa-105 Sa-105mDocument6 paginiAsme Section II A Sa-105 Sa-105mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section Ii A Sa-414 Sa-414m PDFDocument4 paginiAsme Section Ii A Sa-414 Sa-414m PDFdavid perezÎncă nu există evaluări

- Sa 31Document4 paginiSa 31Wagner Renato AraújoÎncă nu există evaluări

- Asme Section Ii A Sa-134 PDFDocument6 paginiAsme Section Ii A Sa-134 PDFdavid perezÎncă nu există evaluări

- Asme Section Ii A Sa-409 Sa-409m PDFDocument10 paginiAsme Section Ii A Sa-409 Sa-409m PDFdavid perezÎncă nu există evaluări

- Sa 36.sa 36MDocument6 paginiSa 36.sa 36MWagner Renato AraújoÎncă nu există evaluări

- Asme Section Ii A Sa-20 Sa-20m PDFDocument44 paginiAsme Section Ii A Sa-20 Sa-20m PDFdavid perezÎncă nu există evaluări

- Sa 29.sa 29MDocument26 paginiSa 29.sa 29MWagner Renato AraújoÎncă nu există evaluări

- Asme Section II A Sa-358 Sa-358mDocument10 paginiAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section II A Sa-403 Sa-403mDocument12 paginiAsme Section II A Sa-403 Sa-403mAnonymous GhPzn1x100% (1)

- Asme Section II A Sa-387 Sa-387mDocument8 paginiAsme Section II A Sa-387 Sa-387mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section Ii A Sa-352 Sa-352m PDFDocument8 paginiAsme Section Ii A Sa-352 Sa-352m PDFdavid perezÎncă nu există evaluări

- Asme Section II A Sa 395 PDFDocument12 paginiAsme Section II A Sa 395 PDFIksan MustofaÎncă nu există evaluări

- Asme Section Ii A Sa-388 Sa-388m PDFDocument10 paginiAsme Section Ii A Sa-388 Sa-388m PDFdavid perezÎncă nu există evaluări

- Asme Section Ii A Sa-426 PDFDocument6 paginiAsme Section Ii A Sa-426 PDFAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section Ii A Sa-351 Sa-351m PDFDocument8 paginiAsme Section Ii A Sa-351 Sa-351m PDFdavid perezÎncă nu există evaluări

- Asme Section Ii A Sa-376 Sa-376m PDFDocument10 paginiAsme Section Ii A Sa-376 Sa-376m PDFdavid perezÎncă nu există evaluări

- Asme Section II A Sa-369 Sa-369mDocument6 paginiAsme Section II A Sa-369 Sa-369mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section II A Sa-353 Sa-353mDocument6 paginiAsme Section II A Sa-353 Sa-353mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section II A Sa-354Document8 paginiAsme Section II A Sa-354Anonymous GhPzn1xÎncă nu există evaluări

- Asme Section Ii A Sa-423 Sa-423m PDFDocument6 paginiAsme Section Ii A Sa-423 Sa-423m PDFdavid perezÎncă nu există evaluări

- Asme Section II A Sa-435 Sa-435mDocument4 paginiAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xÎncă nu există evaluări

- Asme Section Ii A Sa-450 Sa-450m PDFDocument12 paginiAsme Section Ii A Sa-450 Sa-450m PDFdavid perezÎncă nu există evaluări

- Weatherford Welding EngineerDocument1 paginăWeatherford Welding EngineerBHARANIÎncă nu există evaluări

- 97a2-Electric Arc WeldingDocument16 pagini97a2-Electric Arc WeldingVijay KumarÎncă nu există evaluări

- Philippine coffee pulper standardDocument16 paginiPhilippine coffee pulper standardStepz Carnazo50% (2)

- Austempered Ductile Cast Iron Properties and ApplicationsDocument10 paginiAustempered Ductile Cast Iron Properties and Applicationshrk100Încă nu există evaluări

- OPSS 1850 Apr13Document8 paginiOPSS 1850 Apr13Muhammad UmarÎncă nu există evaluări

- Module 8 Welding Metallurgy For The WIDocument39 paginiModule 8 Welding Metallurgy For The WIOskar Giancarlo Sifuentes Eche100% (1)

- Scope of Work-Fabrication of Pressure VesselsDocument3 paginiScope of Work-Fabrication of Pressure VesselsAsad Khan100% (2)

- IIW IWE SyllabusDocument27 paginiIIW IWE SyllabusAnonymous hNpF6IÎncă nu există evaluări

- Jsa For Piping and Erection RevisedDocument1 paginăJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Quality AssuaranceDocument150 paginiQuality Assuarancelamia97100% (1)

- MITSUBADocument7 paginiMITSUBAROBINSON FERNEYÎncă nu există evaluări

- Carbon Steel Spiralweld Pipe Miter Bends - NaylorPipe-Catalog PDFDocument16 paginiCarbon Steel Spiralweld Pipe Miter Bends - NaylorPipe-Catalog PDFanescobar0001Încă nu există evaluări

- Introduction To Phased Array Ultrasonic Technology Applications: Olympus GuidelineDocument5 paginiIntroduction To Phased Array Ultrasonic Technology Applications: Olympus GuidelineKevin HuangÎncă nu există evaluări

- 6) before, during, after weldingDocument7 pagini6) before, during, after weldingDivyang MistryÎncă nu există evaluări

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pagini8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- 2 1773452 8 - Heat Shrink CatalogDocument10 pagini2 1773452 8 - Heat Shrink CatalogAzzeddine BendahakÎncă nu există evaluări

- Workshop TechnologyDocument62 paginiWorkshop TechnologyMuhammadJawadÎncă nu există evaluări

- Short FormsDocument10 paginiShort FormssridharchebroluÎncă nu există evaluări

- Nickel-Iron For Cast Iron: Data SheetDocument3 paginiNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaÎncă nu există evaluări

- V.2 DriverDocument51 paginiV.2 DriverraandkadeewanaÎncă nu există evaluări

- Failure Mechanisms of C-Steels (API 571)Document18 paginiFailure Mechanisms of C-Steels (API 571)Mohmed AllamÎncă nu există evaluări

- Astm A297-1998 PDFDocument3 paginiAstm A297-1998 PDFMohammed TariqÎncă nu există evaluări

- A Study On Low Magnetic PermeabilityDocument28 paginiA Study On Low Magnetic PermeabilitymishikhanÎncă nu există evaluări

- Presentation IRB 140Document25 paginiPresentation IRB 140Nelson PereiraÎncă nu există evaluări

- A 487Document6 paginiA 487arockia1977100% (2)

- Welding Inspection ReportDocument2 paginiWelding Inspection Reportsharif1974Încă nu există evaluări

- Method Statment For Hot Water System HD XXXDocument11 paginiMethod Statment For Hot Water System HD XXXJohan YazidÎncă nu există evaluări

- Calizar Technical Report 8Document14 paginiCalizar Technical Report 8Jazztine Andrei GecoleaÎncă nu există evaluări

- Chapter 1 5 2Document48 paginiChapter 1 5 2Christian Marata Belonio III83% (12)

- Welding StandardDocument22 paginiWelding Standardsonnu151Încă nu există evaluări