Documente Academic

Documente Profesional

Documente Cultură

Model 840 Series Controller: Product Information Sheet

Încărcat de

Matti HynniTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Model 840 Series Controller: Product Information Sheet

Încărcat de

Matti HynniDrepturi de autor:

Formate disponibile

INFRA-RED LIGHT CURTAIN

MODEL 840 SERIES CONTROLLER

§ Patented Power Reduction Software, giving extended component life

PRODUCT § ISSUE

New Static Mode Software, for installation with detectors fixed to the lift car

INFORMATION § Light immunity to over 100,000 lux

SHEET § Generates 40 parallel beams with optional 194 criss-cross beams with any

740 series Detector

§ Different Timeout functions

§ Advanced troubleshooting diagnostics using LED display

§ Conforms to CE EMC Industrial Specification

INTRODUCTION

The Model 840 series Controller is used to drive any which is provided for quick relay replacement if

Model 740 Detectors to generate a curtain of infrared necessary.

beams between the lift car doors. It can be

programmed to generate either a 40-beam parallel light All Model 840 versions comply with CE EMC

curtain or an optional 194-beam criss-cross pattern. Industrial Specification.

The very dense 194-beam pattern is capable of picking

up smaller obstructions between the doors and so Model 840 Series Controller Operation

offers extra protection and safety. Refer to beam

patterns shown in Fig 1a and 1b. The Transmitter Detector (TX), which is mounted

on the door or slampost on one side of the lift

Any interruption to the infra-red beams across the lift opening, has an array of eighty infra-red transmitter

door opening activates a relay which, through the diodes. These diodes are connected as pairs which

door operator, can stop or reverse the closure of the effectively produce 40 beams of IR at heights

lift doors. ranging from 18mm to 1800mm above the bottom of

the detector profile. The Receiver Detector (RX),

Note that the sightguards should not be used with the mounted on the other side of the opening, has a

Model 740 series Detectors when 194-beams are complementary array of 40 receiver diodes.

selected.

Each pair of transmitter diodes is illuminated in

The Model 840 Controllers use one of the latest RISC sequence, using a high frequency driver to generate

micro-controllers with innovative software to: control modulated infra-red beams. This virtually eliminates

the detectors, perform self-test checks, measure the interference from any variation in ambient light.

received infra-red signal, update trigger thresholds

and make trigger decisions. With the Pana40 Plus beam pattern, each of the

receiver diodes opposite an active transmitter pair

The Controller’s printed circuit board and metal housing is interrogated. The received signal is then

have been designed to allow easy access and processed before being read by the micro-controller

installation. and compared with an updated trigger threshold

value.

The Controller is normally fitted on top of the lift car. A

pluggable terminal block is provided to allow easy With the Pana194 Plus beam pattern, the receiver

wiring installation and also provides a method to diodes are interrogated in a different sequence, i.e.

remove the supply voltage from the Controller as a with diagonal offsets.

safety precaution. The main trigger relay has a socket

Fig1a 40-beam parallel pattern

Fig 1b: 194-beam criss-cross light curtain pattern

generated by Model 840

generated by Model 840

ALL VERSIONS 840, 841, 843 COME WITH THE FOLLOWING SPECIFICATIONS AS STANDARD

Power Reduction Software Tone Switch

A Tone switch and beeper are fitted as standard

This innovative and patented software gives a on the Model 840 Controllers. When the Tone

high degree of reliability; and it extends the life switch is enabled, the Controller emits an audible

of the detectors. tone whenever the unit is triggered. In the OFF

position, no tone is heard when the unit is

When the detectors are separated by about triggered.

180mm or less for a period of 10 seconds and are

unobstructed, the system will enter sleep mode If either Detector is unplugged and the Tone switch

operation. is switched on, the Detector emits an intermittent

tone. This is a useful troubleshooting aid for

In this mode, the detectors scan every 2 seconds Service Engineers.

and the trigger function is inhibited.

LED Display for Diagnostics

If, as a result of a test scan, a triggered beam is

detected or the door is opening, the receiver gain This is provided to give the Service Engineer

is set high and normal scanning is resumed information on the Controller’s status. There is a

immediately with the trigger function enabled. window in the Controller housing that allows the

display to be viewed without removing the lid

Static Mode Software (single character LED display for 840-841, two

single character LED display for 842).

Where the Pana40 Plus Detectors are fitted to the

lift car or at the back of the car doors on brackets,

Display Mode Switch

the ‘Static Mode Software’ should be selected.

This is achieved by the use of a jumper link in the

When switched to Normal Mode, the display

Controller. This software ensures that reflections

shows the status of the Controller. It shows if the

caused by the movement of the car doors do not

Controller is scanning, triggered or in one of the

cause unnecessary ‘false’ triggers.

timeout states (Figs 2a - 2c).

Fail Safe Operation

The Model 840 Controller has been designed to

fail-safe in the event of a system fault or the loss

of the supply voltage and will hold the lift doors

open until the fault is cleared.

System Self Test

The Controllers software continuously checks the

presence of the Detectors and measures the

regulated power supply voltage. If the Controller

senses that a Detector has become unplugged or

the cables are cut it will cause the lift doors to be Fig 2a: Fig 2b: Fig 2c:

held open. Scanning State Triggered State Timeout State

Normal Timeout

In addition to the Normal Mode, the unit has a special

If the timeout switch is switched on, this feature Test Mode. When switched on, and with the doors

will allow up to 5 non-adjacent obstructed beams set apart, the Controller runs a diagnostic check.

to be ignored after a pre-set time (10-70 seconds), Some examples are shown below (Figs 3a - 3c).

set by a potentiometer. The faults are then displayed using a variety of

fault codes.

Beeper only Timeout

Model 841

When a beam is broken, the beeper will sound

intermittently for one minute after the timeout period The Model 841 incorporates a mains input voltage

(10-70 seconds) has expired, regardless of the selection switch to select 115V or 230V AC. The

beeper switch position. Controller can also be operated from a 11-25V DC

supply.

The relay will remain in its triggered state as long

as the trigger is present.

Fig 3a: Fig 3b: Fig 3c:

Transmitter Board 2 Fault Receiver Board 3 Fault Erased Beam Fault

THE 843 HAS THESE ADDITIONAL FEATURES

Model 843

• Tele-Monitoring

The Model 843 is fitted with two relays; Relay 1 is The second relay gives the option of connecting

a single pole change-over relay as used in the to a Tele-Monitoring station, connection is made

840/841, and operates in the same way. Relay 2 is through the 12 way terminal block fitted to the

a double pole change-over relay and gives the controller.

option of “Canadian Timeout” or an output to a “Tele-

Monitoring” station. If a system fault occurs the second relay switches

state. This will make or break a connection at the

There is a 12-way terminal block fitted to the Tele-Monitoring station, indicating a system fault,

controller, which makes available connections to i.e. power failure or unplugged detector cables.

the AC power supply, Relay 1 and contacts for

Relay 2. • Voltage Requirements

The Model 843 requires an AC voltage of either

• Canadian Timeout Function 190-265V AC or 98-125V AC there is no DC input.

This timeout is designed to close the doors at a

reduced speed, if the cables becoming unplugged • Display Mode Switch

or any beams are obscured.

When the test mode switch is in the ‘ON’ position

and the system is in the “Canadian Timeout” state,

The timeout pot is factory set to 20 seconds and

the LED display will alternate between ‘n’ and ‘u’

when this has elapsed the trigger is cancelled on

to indicate the “Canadian Timeout” function is

the main relay. The beeper then sounds a fast

active. Example shown below.

intermittent tone for one minute, regardless of the

state of the beeper switch. Once the main trigger

is cancelled the second output relay changes state

to signal the doors to close at a reduced speed. If

this timeout option is required please quote Part

Number 843 005.

“Canadian Timeout”

Please refer to the Ordering Information Table for product part numbers and descriptions

MODEL 840/841/843 SERIES CONTROLLER SPECIFICATIONS

Dimension: 202mm x 186mm x 52mm

Weight: 1150g (840/841); 1170g (843)

Packed weight inc cables: 1750g (840/841); 1770g (843)

Extension cable (2 per set): Length4m; Weight 196g

Voltage requirements: 195-265V AC or 93-127V AC or 83-115V AC, depending on Model 840 ordered.

195-265V AC or 93-127V AC, selectable by switch for Model 841.

190-265V AC, or 98-125V AC, for Model 843.

Models 840 & 841 may be supplied with 11-25V DC voltage

Power Consumption: 5VA max with Detectors fitted

Door operator relay: 240V AC 10A

Case material: Steel

Indicators: 13mm (1/2") single character 8-segment LED display showing controller status

or fault code depending on Mode switch position.

Mode: Switched NORMAL/TEST

Trigger duration: 250ms typical

Timeout: Switched ON/OFF 10-70 seconds adjustable by pot (Canadian timeout set

to 20secs also available on Model 843)

Beeper: Switched ON/OFF

Pana40 Plus typical scan time: 45ms (40 beams)

Pana194 Plus typical scan time: 200ms (194 beams)

Operating temperature range: -10ºC a 65 ºC as per BS2011 Pt.2.1 Ab e BS2011 Pt.2.2 Bb

High temperature/high humidity: +55 ºC 6 x 24 hr cycles as per BS2011 Pt.2 Db:1981 variant 2

Vibration: 20-500Hz 1.0g rms 4 hrs 3 axis as per BS2011 Pt.2.1 Fd

EMC compliance to: Emissions to EN 50081 Part 1. Immunity to EN 50082 Part 2

As a result of our policy of continual improvement, the information in this document is subject to

change without notice and it is intended only as general guidance on product performance and

suitability; this information shall not form part of any contract.

MEMCO LTD, CLYDE HOUSE

REFORM ROAD, MAIDENHEAD

BERKS SL6 8BY, ENGLAND

TELEPHONE: +44 1628 770734

FACSIMILE: +44 1628 621947

www.memco.co.uk

DSHEET64(I)/SPA/12.10.2005

S-ar putea să vă placă și

- GBA 26800 H IV OVF 20 Service - ToolDocument31 paginiGBA 26800 H IV OVF 20 Service - ToolPeter80% (15)

- GBA 26800 H IV OVF 20 Service - ToolDocument31 paginiGBA 26800 H IV OVF 20 Service - ToolPeter80% (15)

- Electrical SwitchgearsDocument63 paginiElectrical Switchgearsmuaz_aminu142292% (12)

- Op D4d2ar&op D4b1aDocument3 paginiOp D4d2ar&op D4b1aMed Iliane YahiaÎncă nu există evaluări

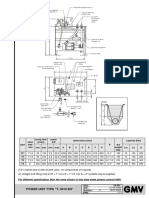

- GMVDocument1 paginăGMVOscar Cuellar100% (1)

- Operation and Service Manual: Status 26.05.1998Document58 paginiOperation and Service Manual: Status 26.05.1998raymon janszenÎncă nu există evaluări

- FincorElectronics Manuals 2300Document51 paginiFincorElectronics Manuals 2300Angelica GómezÎncă nu există evaluări

- Elevator Inspector: Passbooks Study GuideDe la EverandElevator Inspector: Passbooks Study GuideÎncă nu există evaluări

- Ovf20 CR: Repair Instructions ServiceDocument7 paginiOvf20 CR: Repair Instructions ServiceMatti HynniÎncă nu există evaluări

- AlfaSpid RAK Rot1Prog ManualDocument18 paginiAlfaSpid RAK Rot1Prog Manualtrade_123Încă nu există evaluări

- R5 Fcx-IiDocument18 paginiR5 Fcx-IiryanjbonnellÎncă nu există evaluări

- Datasheet Aritco 6000 enDocument2 paginiDatasheet Aritco 6000 enBuzaareÎncă nu există evaluări

- Dielro 101: Manual TécnicoDocument50 paginiDielro 101: Manual Técnicomisubisi100% (1)

- Sod IvarDocument41 paginiSod IvarSacha's ChannelÎncă nu există evaluări

- Manual de PuertasDocument32 paginiManual de PuertasCarlos PrietoÎncă nu există evaluări

- User Manual: Elevator Door ControllerDocument20 paginiUser Manual: Elevator Door ControllerHabboula Mourad100% (1)

- iAstar-AS320 Manual V2.02Document166 paginiiAstar-AS320 Manual V2.02A. PrazÎncă nu există evaluări

- Flex 2: Electric Screw Driven Platform LiftDocument24 paginiFlex 2: Electric Screw Driven Platform LiftCatur Putra SuadnyanaÎncă nu există evaluări

- Lift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0Document6 paginiLift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0raymon janszenÎncă nu există evaluări

- Konel Evo Pro +a3 CeDocument1 paginăKonel Evo Pro +a3 CeSENER AKSOYÎncă nu există evaluări

- Ic卡制卡软件使用说明 EnDocument42 paginiIc卡制卡软件使用说明 EnASIA PTS ELEVATOR INCÎncă nu există evaluări

- VFD-ED-S Eng Manual 20150204 PDFDocument228 paginiVFD-ED-S Eng Manual 20150204 PDFZomaarÎncă nu există evaluări

- Brochure System LiftDocument2 paginiBrochure System LiftMustafaÎncă nu există evaluări

- Fermator Landing Door LD30 Maintenance Manual Premium - 09.18Document60 paginiFermator Landing Door LD30 Maintenance Manual Premium - 09.18alfreliaÎncă nu există evaluări

- SURAPID Elevator Company Profile PDFDocument34 paginiSURAPID Elevator Company Profile PDFLe Huynh LongÎncă nu există evaluări

- Elevator Control Card: User ManualDocument26 paginiElevator Control Card: User ManualГариб Мед100% (1)

- Manual de Instalación Escaleras Hosting-20141011Document51 paginiManual de Instalación Escaleras Hosting-20141011Diego Fernando Carrion TorresÎncă nu există evaluări

- User Manual: Ax Series Lift Control SystemDocument15 paginiUser Manual: Ax Series Lift Control SystemMohd Abu Ajaj100% (1)

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 paginiTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- 0288194 - B02 (19010185《NICE3000new电梯一...Document320 pagini0288194 - B02 (19010185《NICE3000new电梯一...Le Huynh LongÎncă nu există evaluări

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocument7 paginiTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaÎncă nu există evaluări

- A2000 Door Operator Controller: QMA (Shanghai) Electric Co., LTDDocument85 paginiA2000 Door Operator Controller: QMA (Shanghai) Electric Co., LTDJesús David Diaz MontesÎncă nu există evaluări

- Yaskawa L1000ADocument247 paginiYaskawa L1000Arendy kurniawanÎncă nu există evaluări

- Encoders HeindenhainDocument76 paginiEncoders HeindenhainbuenolemesÎncă nu există evaluări

- MicroZed v35 CatalogDocument32 paginiMicroZed v35 CataloghabibullaÎncă nu există evaluări

- Aritco Platform Lifts 2015 JAN en LDocument60 paginiAritco Platform Lifts 2015 JAN en LBuzaareÎncă nu există evaluări

- Fältcom ECII Flex: ManualDocument41 paginiFältcom ECII Flex: ManualMohamed HajjiÎncă nu există evaluări

- Error TableDocument19 paginiError TableJesús David Diaz MontesÎncă nu există evaluări

- Nice 3000Document98 paginiNice 3000NAIMUR RAHAMANÎncă nu există evaluări

- Yaskawa Manuals 285Document518 paginiYaskawa Manuals 285supermannonÎncă nu există evaluări

- MBV191 (N10-VEC01) - Manuel D'installation - GB - Du 13 10 99 (7616) PDFDocument74 paginiMBV191 (N10-VEC01) - Manuel D'installation - GB - Du 13 10 99 (7616) PDFKhaled ZakariaÎncă nu există evaluări

- h200 Factsheet DKDocument54 paginih200 Factsheet DKAhmedÎncă nu există evaluări

- Inversors Manual Asc800Document46 paginiInversors Manual Asc800tiextorÎncă nu există evaluări

- Installation Manual Omega 2016Document50 paginiInstallation Manual Omega 2016Elton GomesÎncă nu există evaluări

- User'S Manual: GMBH, GermanyDocument167 paginiUser'S Manual: GMBH, GermanyAndres Felipe CaceresÎncă nu există evaluări

- CL - Omkar ElectronicsDocument16 paginiCL - Omkar ElectronicsSazzad Hossan RaselÎncă nu există evaluări

- Control Op de Puertas MONT20Document67 paginiControl Op de Puertas MONT20Jenssy SayagoÎncă nu există evaluări

- KM 10Document18 paginiKM 10microcheriet100% (1)

- Zxk-Can3200c-2012 Wee LRDocument2 paginiZxk-Can3200c-2012 Wee LRjose moralesÎncă nu există evaluări

- Ecn 413 Ecn 425 Ern 421 Ern 487Document11 paginiEcn 413 Ecn 425 Ern 421 Ern 487capricornius100% (1)

- Manual Agy-Ev GBDocument214 paginiManual Agy-Ev GBstankovukanovicÎncă nu există evaluări

- MLC 100Document20 paginiMLC 100mahfoud ascenseursÎncă nu există evaluări

- Encoder Basics: Output Signals of Incremental EncodersDocument34 paginiEncoder Basics: Output Signals of Incremental EncodersMelchor VasquezÎncă nu există evaluări

- Tlsv3 Autodialler Basic Functioning: Document Code: Last RevisionDocument6 paginiTlsv3 Autodialler Basic Functioning: Document Code: Last RevisionEmadÎncă nu există evaluări

- LIGHT-CURTAIN-INSTALLATION-GUIDE-peele DoorDocument20 paginiLIGHT-CURTAIN-INSTALLATION-GUIDE-peele DoorRodrigo AntonioÎncă nu există evaluări

- Motala 2000 en Tekniskt BladDocument4 paginiMotala 2000 en Tekniskt BladStacey HayesÎncă nu există evaluări

- Aybey Alc 00Document108 paginiAybey Alc 00erkanÎncă nu există evaluări

- Arcode Geared Sp-16 Cpc-T.enDocument38 paginiArcode Geared Sp-16 Cpc-T.enAbdallh YassenÎncă nu există evaluări

- DOMOFLEX-2 - Installation and Commissioning InstructionsDocument70 paginiDOMOFLEX-2 - Installation and Commissioning InstructionsCatur Putra SuadnyanaÎncă nu există evaluări

- JaguarDocument36 paginiJaguardean_lockeyÎncă nu există evaluări

- Skycom ManualDocument62 paginiSkycom ManualDanÎncă nu există evaluări

- BẢN VẼ MX-GCDocument52 paginiBẢN VẼ MX-GCPhù MỹÎncă nu există evaluări

- ML40P Kullanim KilavuzuDocument23 paginiML40P Kullanim KilavuzumuaadhÎncă nu există evaluări

- Icontrol AC Rel 3 4 42-02-2223 B5Document414 paginiIcontrol AC Rel 3 4 42-02-2223 B5ElputoAmo XDÎncă nu există evaluări

- Fermator Operation Manual PDFDocument8 paginiFermator Operation Manual PDFMuhammad Dzulfiqar100% (1)

- Microzed-V33a Operators ManualDocument50 paginiMicrozed-V33a Operators ManualSamih AlraghbanÎncă nu există evaluări

- Siepc71060618 PDFDocument512 paginiSiepc71060618 PDFdjo990% (1)

- MCS - LCB II List of ParametersDocument25 paginiMCS - LCB II List of ParametersEneko Diaz De Lezana100% (5)

- Manual VF5-09-2015 PDFDocument16 paginiManual VF5-09-2015 PDFAnonymous wRhGOUBeÎncă nu există evaluări

- ASV Stübbe Pumps (2012)Document17 paginiASV Stübbe Pumps (2012)Leo NardoÎncă nu există evaluări

- CT V 900 A Manual Instalare Centrala Control Acces 2 Usi Paradox Centaur Position Technology CdviDocument23 paginiCT V 900 A Manual Instalare Centrala Control Acces 2 Usi Paradox Centaur Position Technology CdviMlÎncă nu există evaluări

- IR CompressorDocument30 paginiIR CompressorkingofngayeÎncă nu există evaluări

- 7SR11 and 7SR12 Argus Catalogue SheetDocument24 pagini7SR11 and 7SR12 Argus Catalogue SheetIsai Soledad CervantesÎncă nu există evaluări

- ETAP User Guide 7.5.2Document3.855 paginiETAP User Guide 7.5.2Feño Beas Rabah100% (3)

- Quotation Voltage StabilizerDocument1 paginăQuotation Voltage StabilizerAnshuman GogoiÎncă nu există evaluări

- Intrusion Systems - Blue Line ISM-BLA1-CM Monochrome Camera ModulesDocument3 paginiIntrusion Systems - Blue Line ISM-BLA1-CM Monochrome Camera ModulesNarcis PatrascuÎncă nu există evaluări

- 1TLS gd2Document6 pagini1TLS gd2Constantin MoldoÎncă nu există evaluări

- Notes On Token Instrument and Double Line Sge Block Instrument (Iriset)Document78 paginiNotes On Token Instrument and Double Line Sge Block Instrument (Iriset)Vikas Srivastav100% (4)

- E86060 k1002 A101 A6 o 7600 06Document132 paginiE86060 k1002 A101 A6 o 7600 06bajricaÎncă nu există evaluări

- Ligo System Installation Guide V3 Newestpage 1 of 14Document14 paginiLigo System Installation Guide V3 Newestpage 1 of 14ZzzdddÎncă nu există evaluări

- Notes On PLC and Industrial NetworksDocument13 paginiNotes On PLC and Industrial NetworksjoshuaÎncă nu există evaluări

- SZ C 611515 Us 1095-10 PDFDocument18 paginiSZ C 611515 Us 1095-10 PDFsteves0118Încă nu există evaluări

- Report On SubstationDocument58 paginiReport On SubstationRajatÎncă nu există evaluări

- Protection PhilosophyDocument50 paginiProtection Philosophyrohan sainiÎncă nu există evaluări

- Trane Clearance SpecsDocument20 paginiTrane Clearance SpecsdaveeeescribdÎncă nu există evaluări

- Mvaa13 CortecDocument9 paginiMvaa13 CortecPraneeth Madhushan BandaraÎncă nu există evaluări

- Keithley 4200A-Scs: Semiconductor Characterization SystemDocument21 paginiKeithley 4200A-Scs: Semiconductor Characterization SystemSourav RoyÎncă nu există evaluări

- Manual For Monitoring Relays Siemens SIRIUS 3UG4 3RR2Document392 paginiManual For Monitoring Relays Siemens SIRIUS 3UG4 3RR2razvan_nÎncă nu există evaluări

- SMT Bd11a 220 12 W T Bs Infranor Digital Drive ManualDocument44 paginiSMT Bd11a 220 12 W T Bs Infranor Digital Drive ManualkamilÎncă nu există evaluări

- ARI-Premio Plus Thrust Actuator PDFDocument50 paginiARI-Premio Plus Thrust Actuator PDFVarshaÎncă nu există evaluări

- 7851A Exhaust Fan Selection Data SheetDocument6 pagini7851A Exhaust Fan Selection Data SheetRama Lakshmi Saradhi100% (1)

- Type MPB/MPG Test Plug and Universal Test BlockDocument4 paginiType MPB/MPG Test Plug and Universal Test Blockryreddy50% (2)

- Alifabs Viper CabinetDocument29 paginiAlifabs Viper CabinetMarcelÎncă nu există evaluări

- At8Psn/At8Pmn Series: Instruction ManualDocument1 paginăAt8Psn/At8Pmn Series: Instruction ManualJohn GarnetÎncă nu există evaluări

- Load Sharer: Application FunctionDocument4 paginiLoad Sharer: Application FunctionAnas BasarahÎncă nu există evaluări

- KEMA - Type Test Certification - Report - of - Performance - RET670 - Version - 2.2Document56 paginiKEMA - Type Test Certification - Report - of - Performance - RET670 - Version - 2.2Tiến MạnhÎncă nu există evaluări