Documente Academic

Documente Profesional

Documente Cultură

17-683287 - NHT Heater OSI

Încărcat de

AKASH BDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

17-683287 - NHT Heater OSI

Încărcat de

AKASH BDrepturi de autor:

Formate disponibile

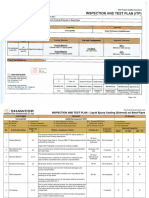

VISAKH REFINERY

FORMAT OF INSPECTION WORK LIST

TECHNICAL DEPARTMENT Doc. No. OCP/TSD/FR/305/Rev.2

Rev. Date : 16-Jan-02

(Ref. Pro.:OCP/TSD/PR/204)

Page 1 of 2

WORK LIST No. : 17-683287 IWL.DESC.: NHT: 72F-01/02: IAT for OSI recommnedations Date: 19/08/2017 10:12

LOCATION : NHT_FUR LOC.DESC.: NHT Furnaces INSP. BY: B M JEELANI

Equipment : REF:

OSI of 72F-01/02 was carried out on 14/08/2017 and following are the major

observations and recommendations.

Sl No. LOCATION/ITEM OBSERVATION RECOMMENDATION

10 72F-01 1. Burner No: 4 burner floor refractory was observed moderately 1. Drop the air register and offer to

damaged. inspection if isolation is not possible

provide steam plying on the oxidized

2. Observed oxidation of air register casing for burner No – 2.

location.

(presently burner is on pilot firing only)

2. Carry out servicing of the ¾” dia purge

3. Observed ¾” dia purge steam line, valve gland leak at PF-1 Near

steam line valves.

Burner No.1&4

3 Carry out repairs to the burner floor

refractory using EIL Type III refractory

in the next available opportunity.

20 72F-02 1. For Burner No. 2 cerewool packing between the floor refractory and 1. Carry out cerewool packing for the

burner blocks was observed dislodged and fallen over the burner tips. burner Nos. 2, 5, 6 in the next available

opportunity.

2. For Burner No. 5 and 6, gaps were observed between the floor

refractory and burner blocks. 2. Carry out replacement of the gasket

between the floor bottom plate (external

3. Burner No: B-5, burner floor refractory was observed moderately

side) and burner mounting plates for

damaged.

burner nos. 5 and 6. Carry out painting

4. Gap between 2 no. tubes was observed less since Jan 2017 for the after cleaning of the soot deposits. Carry

tubes between burner No.7 and 8 no further deterioration since first out repairs to the floor refractory.

time observation.

3. Regular monitoring of the tubes with

5. Glass panes in the peep holes were not clean enough to view tube less gaps between them to be carried out

condition and firebox internal condition. by operations.

6.1¿ dia steam line valve was observed with heavy gland leak at PF-4 4. Carry out cleaning of peep hole

North side. connected glass panes on all platform

levels.

5. Carry out servicing of the 1”dia valve.

1. Carry out cerewool packing for the burner Nos. 2, 5, 6 in the next

available opportunity.

2. Carry out replacement of the gasket between the floor bottom plate

(external side) and burner mounting plates for burner nos. 5 and 6.

Carry out painting after cleaning of the soot deposits. Carry out repairs

to the floor refractory.

Page 1 of 2 Monday, January 28, 2019

WORK LIST No. : 17-683287 IWL.DESC.: NHT: 72F-01/02: IAT for OSI recommnedations

LOCATION : NHT_FUR LOC.DESC.: NHT Furnaces

Equipment : REF:

OSI of 72F-01/02 was carried out on 14/08/2017 and following are the major

observations and recommendations.

Sl No. LOCATION/ITEM OBSERVATION RECOMMENDATION

3. Regular monitoring of the tubes with less gaps between them to be

carried out by operations.

4. Carry out cleaning of peep hole connected glass panes on all

platform levels.

5. Carry out servicing of the 1”dia valve.

30 Insulation/ Painting related jobs Paint failure was observed over the 72F-02 stack casing. Carry out painting of the stack using

system 1.

____________________________

HEAD-INSPECTION

Page 2 of 2 Monday, January 28, 2019

S-ar putea să vă placă și

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantDe la EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryEvaluare: 4 din 5 stele4/5 (5)

- NHT T&I-2019 - IWL For Piping Loop # 54Document1 paginăNHT T&I-2019 - IWL For Piping Loop # 54AKASH BÎncă nu există evaluări

- Condenser and Cooler Inspection ReportsDocument6 paginiCondenser and Cooler Inspection ReportsSampatÎncă nu există evaluări

- METS2CaseStudy19-Fuel System-Why DLNDocument17 paginiMETS2CaseStudy19-Fuel System-Why DLNvahid_strÎncă nu există evaluări

- SEPARATOR S22 Preliminary Revision 00Document17 paginiSEPARATOR S22 Preliminary Revision 00Ahmed MohammedÎncă nu există evaluări

- Duqm Project EPC 2 - Utilities and Offsites Data SheetDocument9 paginiDuqm Project EPC 2 - Utilities and Offsites Data SheetsudhirguduruÎncă nu există evaluări

- Flow-Induced Fatigue Failure in Tubular Heat ExchangersDocument7 paginiFlow-Induced Fatigue Failure in Tubular Heat ExchangersVelpandian ManiÎncă nu există evaluări

- Material ListDocument1 paginăMaterial ListpengcongsxÎncă nu există evaluări

- A Study of Factors Affecting Gun Perforating PerformanceDocument16 paginiA Study of Factors Affecting Gun Perforating PerformanceJesy BreaÎncă nu există evaluări

- OSI Inspection Report: Tüv SüdDocument14 paginiOSI Inspection Report: Tüv Südpragyatiwari2_337587Încă nu există evaluări

- Checklist For Drum Internal PipingDocument2 paginiChecklist For Drum Internal PipingRamalingam PrabhakaranÎncă nu există evaluări

- Mechanical Data Sheet 1-40-41 EA-001 Feed Gas Expander 1 Oil CoolerDocument10 paginiMechanical Data Sheet 1-40-41 EA-001 Feed Gas Expander 1 Oil CoolerDima Fon NmskÎncă nu există evaluări

- Technical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2Document5 paginiTechnical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2ciccioÎncă nu există evaluări

- Technical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2Document5 paginiTechnical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2ciccioÎncă nu există evaluări

- Avon UTC 1535c12Document31 paginiAvon UTC 1535c12juanaÎncă nu există evaluări

- BSI Training Material V2Document61 paginiBSI Training Material V2Nitin AhlawatÎncă nu există evaluări

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pagini6.1 Data Sheet For Pipeline Ball ValveDeepak PalÎncă nu există evaluări

- FR-0120 AIM Activities 07-14-2023Document3 paginiFR-0120 AIM Activities 07-14-2023Mazhar choudharyÎncă nu există evaluări

- 1.EBS1-EPFA76-EBRT-CNPR-1001-D00 EPF Fire Water System Validation ReportDocument4 pagini1.EBS1-EPFA76-EBRT-CNPR-1001-D00 EPF Fire Water System Validation ReportRedhaa .kÎncă nu există evaluări

- Project Name: Location:: ST - John'S Geriatric Centre Hosur Road, BangaloreDocument3 paginiProject Name: Location:: ST - John'S Geriatric Centre Hosur Road, Bangalorewaz ahmedÎncă nu există evaluări

- Exxon IP 7-5-1 Coils For Fired Heaters and BoilersDocument5 paginiExxon IP 7-5-1 Coils For Fired Heaters and BoilersGilvan SilvaÎncă nu există evaluări

- PI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistDocument2 paginiPI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistRajesh Singh100% (1)

- O20361-S-Via-01-Dc-03000 R1Document130 paginiO20361-S-Via-01-Dc-03000 R1Shubham GaglaniÎncă nu există evaluări

- NDT Report - Old.Turbine BearingsDocument3 paginiNDT Report - Old.Turbine BearingsOm Ar TanÎncă nu există evaluări

- Lmi - SH RH Spray Nozzle InspectionDocument28 paginiLmi - SH RH Spray Nozzle InspectionLalit MeenaÎncă nu există evaluări

- Investigation and Repair of Heat Exchanger FlangeDocument12 paginiInvestigation and Repair of Heat Exchanger Flange최승원Încă nu există evaluări

- 2 ND Superheater FailureDocument8 pagini2 ND Superheater FailureRaul MoraÎncă nu există evaluări

- 2.EBS1-EPFA76-EBRT-CNPR-1002-D00 Fire Water Demand ReportDocument4 pagini2.EBS1-EPFA76-EBRT-CNPR-1002-D00 Fire Water Demand ReportRedhaa .kÎncă nu există evaluări

- API 650 Atmospheric Storage Tank Calculation & Design Welding Spacing SheetDocument6 paginiAPI 650 Atmospheric Storage Tank Calculation & Design Welding Spacing SheetAlejandro JoseÎncă nu există evaluări

- Urea reactor liner leakage case studyDocument11 paginiUrea reactor liner leakage case studySai PrasathÎncă nu există evaluări

- Data Sheet Temperature GaugesDocument3 paginiData Sheet Temperature GaugesOchena PothikÎncă nu există evaluări

- UE-BHEL-054-MPP-04 Rev.03Document6 paginiUE-BHEL-054-MPP-04 Rev.03udayakarnaÎncă nu există evaluări

- High Frequency Induction Bending PDFDocument22 paginiHigh Frequency Induction Bending PDFMohd AshrafÎncă nu există evaluări

- DatasheetDocument1 paginăDatasheetDeni HermawanÎncă nu există evaluări

- Work Operation Sequence for Blasting and Surface PreparationDocument1 paginăWork Operation Sequence for Blasting and Surface PreparationAbhishek KadamÎncă nu există evaluări

- In Amenas Gas Project Algeria: P03 20 Jan 04 Issued For Purchase J Neely J Pile J Pile R WalkerDocument3 paginiIn Amenas Gas Project Algeria: P03 20 Jan 04 Issued For Purchase J Neely J Pile J Pile R WalkerDaoued HaouesÎncă nu există evaluări

- Special Maintenance Insturctions (Smi) For Ohe Contact Wire and Associated Fittings. ObjectiveDocument3 paginiSpecial Maintenance Insturctions (Smi) For Ohe Contact Wire and Associated Fittings. ObjectiveAQIBÎncă nu există evaluări

- Heat Exchanger Manual-1Document85 paginiHeat Exchanger Manual-1Akankshya MishraÎncă nu există evaluări

- NCR (21) Code 45 CR 1R1GR08I0151 W.O (Requested)Document3 paginiNCR (21) Code 45 CR 1R1GR08I0151 W.O (Requested)Mohamed HamedÎncă nu există evaluări

- 2BDocument12 pagini2BFaizan AhmedÎncă nu există evaluări

- Response To Spec - FFE Hydrant & Monitor - R02Document4 paginiResponse To Spec - FFE Hydrant & Monitor - R02Reinhard SimbolonÎncă nu există evaluări

- We Design ReportDocument45 paginiWe Design Reportorode franklynÎncă nu există evaluări

- Mech - Data Sheet - Rev 0Document6 paginiMech - Data Sheet - Rev 0mieftahul hudaÎncă nu există evaluări

- GRE Pipes Inspection Test PlanDocument6 paginiGRE Pipes Inspection Test PlanMat RidhanÎncă nu există evaluări

- DQ-10657 Initial Inspection Report 05.02.18Document7 paginiDQ-10657 Initial Inspection Report 05.02.18abidhassan1100% (1)

- EI-013 - e Rev 2 - FireproofingDocument85 paginiEI-013 - e Rev 2 - FireproofingclulloaÎncă nu există evaluări

- L5 PantryDocument8 paginiL5 PantrymohandiazÎncă nu există evaluări

- 5111FA-Assessment Report-Shell & Roof Rev.1Document14 pagini5111FA-Assessment Report-Shell & Roof Rev.1Hosam AhmedÎncă nu există evaluări

- Bimetallic and Alloy Welds in HP Hydrogen and Nitrogen ServiceDocument18 paginiBimetallic and Alloy Welds in HP Hydrogen and Nitrogen Servicevaratharajan g rÎncă nu există evaluări

- BSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0Document5 paginiBSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0AMALENDU PAULÎncă nu există evaluări

- Project Calculations PDFDocument68 paginiProject Calculations PDFcalvin.bloodaxe4478100% (1)

- Technical Data: Sprinkler PI-2 SeriesDocument4 paginiTechnical Data: Sprinkler PI-2 SeriesRodrigo Alemán GarcíaÎncă nu există evaluări

- Api 510 BM1Document4 paginiApi 510 BM1job bahÎncă nu există evaluări

- CPR15Document7 paginiCPR15jasbir.iitdÎncă nu există evaluări

- Journal BeringDocument8 paginiJournal BeringpelakupasarÎncă nu există evaluări

- Yanbu II Power Project Pipe Welding ProcedureDocument7 paginiYanbu II Power Project Pipe Welding Proceduremohd as shahiddin jafriÎncă nu există evaluări

- 03 - K-4101 Case HistoriesDocument28 pagini03 - K-4101 Case Historiesmsaadi717Încă nu există evaluări

- Trouble Shooting Vibration in A Pulverized Coal Fired BoilerDocument13 paginiTrouble Shooting Vibration in A Pulverized Coal Fired Boilerparthi20065768100% (1)

- ARGUS ReportDocument22 paginiARGUS ReportNguyễn Tường MinhÎncă nu există evaluări

- 17-1004082 - MP Steam LineDocument1 pagină17-1004082 - MP Steam LineAKASH BÎncă nu există evaluări

- Procurement of Flexitallic gasket for CCR reactorDocument1 paginăProcurement of Flexitallic gasket for CCR reactorAKASH BÎncă nu există evaluări

- NHT Loop 18 18-1758715Document1 paginăNHT Loop 18 18-1758715AKASH BÎncă nu există evaluări

- NHT Loop 1 19-141034Document1 paginăNHT Loop 1 19-141034AKASH BÎncă nu există evaluări

- NHT T&I-2019 - IWL For Piping Loop #68Document1 paginăNHT T&I-2019 - IWL For Piping Loop #68AKASH BÎncă nu există evaluări

- NHT Loop 20 18-1758723 PDFDocument1 paginăNHT Loop 20 18-1758723 PDFAKASH BÎncă nu există evaluări

- NHT Loop 03 18-1827416Document1 paginăNHT Loop 03 18-1827416AKASH BÎncă nu există evaluări

- NHT Loop 21 18-1758725Document1 paginăNHT Loop 21 18-1758725AKASH BÎncă nu există evaluări

- NHT Loop 22 18-1800176 PDFDocument1 paginăNHT Loop 22 18-1800176 PDFAKASH BÎncă nu există evaluări

- NHT T&I-2019 - IWL For Piping Loop #31Document1 paginăNHT T&I-2019 - IWL For Piping Loop #31AKASH BÎncă nu există evaluări

- NHT Loop 19 18-1800168Document1 paginăNHT Loop 19 18-1800168AKASH BÎncă nu există evaluări

- Loop 59 18-1619530Document1 paginăLoop 59 18-1619530AKASH BÎncă nu există evaluări

- NHT T&I-2019 - IWL For Piping Loop #67Document1 paginăNHT T&I-2019 - IWL For Piping Loop #67AKASH BÎncă nu există evaluări

- Loop 63 PDFDocument1 paginăLoop 63 PDFAKASH BÎncă nu există evaluări

- NHT Loop 05 18-1693783Document1 paginăNHT Loop 05 18-1693783AKASH BÎncă nu există evaluări

- Loop 63 PDFDocument1 paginăLoop 63 PDFAKASH BÎncă nu există evaluări

- NHT Loop 09 18-1728897Document1 paginăNHT Loop 09 18-1728897AKASH BÎncă nu există evaluări

- Chiller Section IWLDocument8 paginiChiller Section IWLAKASH BÎncă nu există evaluări

- SPE 157977 Casing Thermal Stress and Wellhead Growth Behavior AnalysisDocument12 paginiSPE 157977 Casing Thermal Stress and Wellhead Growth Behavior AnalysisAKASH BÎncă nu există evaluări

- Application Form Number:: Application For Supplementary Convocation Degree CertificateDocument2 paginiApplication Form Number:: Application For Supplementary Convocation Degree CertificateAKASH BÎncă nu există evaluări

- Fess305 PDFDocument8 paginiFess305 PDFHari KishanÎncă nu există evaluări

- Unesco - Eolss Sample Chapters: Artificial LiftDocument0 paginiUnesco - Eolss Sample Chapters: Artificial LiftSameh ZaguiaÎncă nu există evaluări

- Fess305 PDFDocument8 paginiFess305 PDFHari KishanÎncă nu există evaluări

- Unesco - Eolss Sample Chapters: Artificial LiftDocument0 paginiUnesco - Eolss Sample Chapters: Artificial LiftSameh ZaguiaÎncă nu există evaluări

- Savitribai Phule Pune University: Application For A Regular Convocation Degree CertificateDocument2 paginiSavitribai Phule Pune University: Application For A Regular Convocation Degree CertificateAKASH B100% (1)

- Syllabus PDFDocument8 paginiSyllabus PDFdahiphalehÎncă nu există evaluări

- Flare Gas 1Document21 paginiFlare Gas 1AKASH BÎncă nu există evaluări

- The Power-Point Presentation For Seminar/project Work Should Contain The Following Slides: Slide NoDocument1 paginăThe Power-Point Presentation For Seminar/project Work Should Contain The Following Slides: Slide NoAKASH BÎncă nu există evaluări

- Metal Forming 2998Document22 paginiMetal Forming 2998RRR180Încă nu există evaluări

- 05 - (直动电磁阀)SVP8 x 08 Series (February 2007)Document4 pagini05 - (直动电磁阀)SVP8 x 08 Series (February 2007)陆军Încă nu există evaluări

- 2018 - UMC-1000 2016 - NewDocument16 pagini2018 - UMC-1000 2016 - NewAbhishek VelagaÎncă nu există evaluări

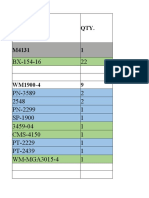

- Spare Part List-M4131Document15 paginiSpare Part List-M4131Saket SamratÎncă nu există evaluări

- U.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012Document41 paginiU.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012InsannulÎncă nu există evaluări

- VG7 XVS - MDocument1 paginăVG7 XVS - Mluis acostaÎncă nu există evaluări

- Demand For 7 Major Products by Region - Construction & Mining EquipmentDocument1 paginăDemand For 7 Major Products by Region - Construction & Mining Equipmentjay.arteÎncă nu există evaluări

- Scissors Lift Case StudyDocument6 paginiScissors Lift Case StudyzenitsuÎncă nu există evaluări

- Method Statement For Steel Structure & Erection PDFDocument16 paginiMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Termooo StandardDocument106 paginiTermooo Standardlaguna028Încă nu există evaluări

- System Scaffolding Technical ManualDocument112 paginiSystem Scaffolding Technical ManualsuvraÎncă nu există evaluări

- Oil Rig SpecDocument1 paginăOil Rig SpecJoao CarlosÎncă nu există evaluări

- 2010-10 EN 353-1 - 2002-Test MethodDocument13 pagini2010-10 EN 353-1 - 2002-Test MethodrmlabsÎncă nu există evaluări

- Prefab structures assignmentDocument17 paginiPrefab structures assignmentSabariKrishÎncă nu există evaluări

- Series Full-Port Brass Ball Valve: DescriptionDocument1 paginăSeries Full-Port Brass Ball Valve: DescriptionGreg FarzettaÎncă nu există evaluări

- PLXRMM1606A - R410A Non-Inverter Wall Mounted FTN-A Series Myanmar PDFDocument8 paginiPLXRMM1606A - R410A Non-Inverter Wall Mounted FTN-A Series Myanmar PDFWai Lwin Ko100% (1)

- High Pressure Homogenizer ManualDocument5 paginiHigh Pressure Homogenizer ManualAhmed AlakhliÎncă nu există evaluări

- HydraulicsDocument8 paginiHydraulicsAlper SakalsizÎncă nu există evaluări

- D38999 Guide - D38999 Mil Spec Connector GuideDocument12 paginiD38999 Guide - D38999 Mil Spec Connector GuideFrederich Bear River100% (1)

- Ball Valves with Flanged Connections for Various Pipe Sizes and Pressure RatingsDocument1 paginăBall Valves with Flanged Connections for Various Pipe Sizes and Pressure Ratingsabdelkader benabdallahÎncă nu există evaluări

- Bit Nozzle (S) Pressure Drop: Nozzle Numbers Nozzle Dia in Decimal in Flow Area inDocument2 paginiBit Nozzle (S) Pressure Drop: Nozzle Numbers Nozzle Dia in Decimal in Flow Area innjileoÎncă nu există evaluări

- Estimate Mechanical WorksDocument9 paginiEstimate Mechanical WorksIsrael MuhiÎncă nu există evaluări

- Tolco Fire Protection Complete CatalogueDocument77 paginiTolco Fire Protection Complete CataloguepinchipinchiÎncă nu există evaluări

- Daily Machine Check List - Lathe MachineDocument6 paginiDaily Machine Check List - Lathe Machineshailendra5508110100% (3)

- Kkibs Brochure - UnlockedDocument20 paginiKkibs Brochure - UnlockedSäbrinä ShukrìÎncă nu există evaluări

- Hydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect CorrectDocument88 paginiHydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect Correctcristian100% (2)

- Straight Line Motion Mechanisms OldDocument28 paginiStraight Line Motion Mechanisms OldVaibhav Vithoba Naik100% (4)

- SW Final Selection ListDocument1 paginăSW Final Selection Listcs pptÎncă nu există evaluări

- Complete Expansion Joint Inspection ReportDocument3 paginiComplete Expansion Joint Inspection ReportsunnyartboyÎncă nu există evaluări

- ACCOLIFT - ELECTRIC CHAIN HOIST - CatalogDocument16 paginiACCOLIFT - ELECTRIC CHAIN HOIST - CatalogBrad BorgesÎncă nu există evaluări