Documente Academic

Documente Profesional

Documente Cultură

Accepted Manuscript: Prediction of Meat Quality Traits in Nelore Cattle by Near-Infrared Reflectance Spectros

Încărcat de

Ricardo ParedesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Accepted Manuscript: Prediction of Meat Quality Traits in Nelore Cattle by Near-Infrared Reflectance Spectros

Încărcat de

Ricardo ParedesDrepturi de autor:

Formate disponibile

Prediction of meat quality traits in Nelore cattle by near-infrared reflectance spectroscopy1

A. F. B. Magalhães,* G. H. de A. Teixeira,* A. C. H. Ríos,* D. B. dos S. Silva,* L. F. M. Mota,*

M. M. M. Muniz,* C. de L. M. de Morais,†,‡ K. M. G. de Lima,† L. C. Cunha Júnior,* F.

Baldi,* R. Carvalheiro,* H. N. de Oliveira,* L. A. L. Chardulo,§ L. G. de Albuquerque*2

t

ip

*São Paulo State University (Unesp), School of Agricultural and Veterinarian Sciences,

cr

Department of Animal Sciense, Jaboticabal – São Paulo, Brazil, 14884-900.

us

†Federal University of Rio Grande do Norte, Institute of Chemistry, Biological Chemistry and

Chemometric, Natal – Rio Grande do Norte, Brazil, 59072-970.an

‡University of Central Lancashire, School of Pharmacy and Biomedical Sciences, Preston –

M

Lancashire, United Kingdom, PR1 2HE.

§São Paulo State University (Unesp), College of Veterinary and Animal Science, Botucatu – São

d

Paulo, Brazil, 18618-970.

te

ep

1

The authors would like to thank São Paulo Research Foundation (FAPESP; Grant 2009/16118-

5) for funding this study. The first author thanks to National Postdoctoral Program (PNPD) of

c

Coordination for the Improvement of Higher Education Personnel (CAPES) for financial

Ac

support. GHAT, KMGL, FB, RC, HNO, LALC and LGA are researches of Brazilian National

Council for Scientific and Technological Development (CNPq).

²Corresponding author: lgalb@fcav.unesp.br

© The Author(s) 2018. Published by Oxford University Press on behalf of the American Society of Animal

Science. All rights reserved. For permissions, please e-mail: journals.permissions@oup.com.

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

ABSTRACT: The main definition for meat quality should include factors that affect consumer

appreciation of the product. Physical laboratory analyses are necessary to identify factors that

affect meat quality and specific equipment is used for this purpose, which is expensive and

destructive, and the analyses are usually time consuming. An alternative method to performing

several beef analyses is near-infrared reflectance spectroscopy (NIRS), which permits to reduce

t

ip

costs and to obtain faster, simpler, and non-destructive measurements. The objective of this study

was to evaluate the feasibility of NIRS to predict shear force (WBSF), marbling, and color

cr

(*a=redness; b*=yellowness and L*=lightness) in meat samples of uncastrated male Nelore

us

cattle, that were approximately 2-year-old. Samples of longissimus thoracis (n=644) were

an

collected and spectra were obtained prior to meat quality analysis. Multivariate calibration was

performed by partial least squares regression. Several preprocessing techniques were evaluated

M

alone and in combination: raw data, reduction of spectral range, multiplicative scatter correction,

and 1st derivative. Accuracies of the calibration models were evaluated using the root mean

d

square error of calibration (RMSEC), root mean square error of prediction (RMSEP), coefficient

te

of determination in the calibration (R²C) and prediction (R²P) groups. Among the different

ep

preprocessing techniques, the reduction of spectral range provided the best prediction accuracy

for all traits. The NIRS showed a better performance to predict WBSF (RMSEP = 1.42kg, R²P =

c

0.40) and b* color (RMSEP = 1.21, R²P = 0.44), while its ability to accurately predict L*

Ac

(RMSEP = 1.98, R²P = 0.16) and a* (RMSEP = 1.42, R²P = 0.17) was limited. NIRS was

unsuitable to predict subjective meat quality traits such as marbling in Nelore cattle.

Key words: marbling, meat color, preprocessing techniques, shear force.

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

INTRODUCTION

Several definitions of meat quality exist but, according to Williams (2008), the main

definition should include factors that affect consumer appreciation of the product. Among these

factors, meat tenderness is considered a determinant trait for consumer satisfaction since

consumers are willing to pay more for a better-quality product, i.e., they would pay a premium

t

ip

for a steak with guaranteed tenderness (Shackelford et al., 2001). Fat content is also important

because it affects flavor, juiciness, and possibly toughness (Williams, 2008). Finally, meat color

cr

is an essential visual attribute that consumers consider for purchasing (Liu et al., 2003). Physical

us

laboratory analyses are necessary to identify factors that affect meat quality. Specific equipment

an

are used for this purpose, which are expensive and destructive, and the analyses are usually time

consuming (Leroy et al., 2003). For example, tenderness, analyzed by Warner-Bratzler shear

M

force (WBSF) requires about 24 hours, while fat can be analyzed by marbling score, usually

faster than WBSF, or by chemical analysis, which determine true extractable lipid content, but

d

much greater time is required. Meat color is faster than WBSF and fat content, but specific

te

equipment is necessary to perform this analysis.

ep

An alternative method to performing several beef analyses is the near-infrared

spectroscopy (NIRS), which permits to reduce costs and to obtain faster, simpler, and non-

c

destructive measurements (Liu et al., 2003; Prevolnik et al., 2004). For this technique, a

Ac

spectrometer of reflectance in the near infrared region is used, which consists of an optical

reading chamber that produces the spectra and software to develop the statistical models

(Campestrini, 2005). Calibration equations are estimated and validated by regression analysis

and, if the equation is accurate (prediction ability of the equation), it is possible to predict new

values for meat quality without the need for standard laboratory analysis.

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

The objective of the present study was to evaluate the feasibility of NIRS to predict

tenderness, marbling, and meat color in Nelore beef.

MATERIAL AND METHODS

Meat samples analysis

t

ip

A total of 644 meat samples were obtained from approximately 2-year-old uncastrated male

Nelore cattle at three farms. The animals were raised on pasture and feedlot finished for

cr

approximately 90 days prior to slaughter in a commercial slaughterhouse, under the approval of

us

ethics committee of the São Paulo State University (UNESP), School of Agricultural and

Veterinarian Sciences, Jaboticabal – SP, Brazil (Nº 18.340/16). After slaughter, the carcasses

an

were cooled in a cold storage chamber (0 – 2°C) for 48 hours post-mortem. Samples of

M

longissimus thoracis muscle (2.54 cm thick) with bone were taken between the 12th and 13th rib

of the left half-carcasses and vacuum packaged, frozen at -20°C.

d

To perform the analyses, the process of samples thawing was performed: samples

te

were transferred from freezer to a refrigerator for 12 hours; the samples were removed from the

ep

vacuum package and kept at room temperature (~25°C). The meat temperature was monitored

and when the temperature reached 5°C the NIR spectra were obtained using a Spectrum 100N

c

FT-IR spectrometer (PerkinElmer, Shelton, USA) equipped with a fiber optic probe accessory.

Ac

Spectral data were collected as relative absorbance in a wavenumber range from 4,000 to 10,000

cm-1 (2,500 – 1,000 nm) range at 2 cm-1 intervals and 64 scans. The mean spectrum of each

sample was obtained averaging six spectra per sample and the absorbance data were stored as log

1/R (R = reflectance). Spectra collection and reference analysis (meat quality analysis) were

performed on the same sample.

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Meat quality was analyzed immediately after collection of the NIR spectra. A visual

grading system (USDA, 1989) was used to determine the marbling score of the longissimus

thoracis muscle samples, which received scores ranging from 0 to 9, where 1 = practically

absent; 2 = traces; 3 = slight; 4 = small; 5 = modest; 6 = moderate; 7 = slightly abundant; 8 =

moderately abundant; 9 = abundant. Meat color (L*, lightness; a*, redness; b*, yellowness) was

t

ip

measured using CIELab system with a help of a Chroma Meter CR-400 (Konica Minolta

Sensing, Inc., Tokyo, Japan) with standard D65 light source, observer angle 10°, and aperture

cr

size of 5 cm, as described by Borges et al. (2014). Prior the evaluation, the equipment was

us

calibrated using a black and a white standard plate and color readings were taken at three

an

locations of the longissimus thoracis muscle sample. The average was then calculated from these

measurements.

M

Finally, WBSF was performed using standard procedure proposed by Wheeler et al.

(1995) in which the samples were baked until they reach an internal temperature of 71ºC. The

d

temperature was measured using thermocouple wires (Equipe, Sorocaba-SP, Brazil) inserted into

te

the center of each steak and coupled to the temperature recorder. Shear force was measured with

ep

a Warner-Bratzler Shear Force machine (GR-Manufacturing, Kansas, USA). Shearing was

performed on 1.27 cm in diameter removed longitudinally to the muscle fibers. Eight

c

measurements were collected per sample to increase precision of the results, expressed as

Ac

kilogram (kg).

Chemometrics

The calibration set was composed by 644 NIR spectra obtained from meat samples of

different Nelore animals (independent matrix X). The dependent matrix (Y) was composed by

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

the information coming from the analyzed meat quality traits (reference analysis) WBSF,

marbling, and color (a*, b*, and L*). Multivariate calibration was performed using partial least

squares regression (PLSR) with full cross-validation using the software Unscrambler X.1

(CAMO Software, Oslo, Norway).

To improve the accuracy, several preprocessing techniques were tested. The techniques

t

ip

using raw spectra and spectral preprocessing techniques were evaluated alone and in

combination. The spectral preprocessing techniques applied to the spectra were performed

cr

according to (Nicolaï et al., 2007) and consisted of raw data (RAW), reduction of spectral range

us

(RSR), normalization by multiplicative scatter correction (MSC), and 1st derivative (1D)

an

transformation. In RAW, all collected spectra were used and only "mean centering" was

considered, which is a standard procedure used to subtract the mean from each variable, thus

M

ensuring that all results are interpreted in terms of variation around the mean. In RSR, only

wavenumbers ranging from 2,420 to 1,097 nm were selected to reduce the spectral noise that is

d

found at the beginning and at the end of the original spectra (4,000 – 10,000 cm-1). For

te

normalization, MSC was used which removes the effects of light scattering by linearizing the

ep

spectrum. 1D transformation was performed using the Savitzky-Golay smoothing algorithm

(Næs et al., 2004). This transformation was used to remove baseline shifts and superposed peaks.

c

The performance of the calibration models was evaluated by calculating the root mean

Ac

square error of calibration (RMSEC) and root mean square error of prediction (RMSEP) using

the following equation:

̂

RMSEC or RMSEP = √∑ (1)

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

where is the reference value of sample ; ̂ is the value predicted by the model, and is the

number of samples. In addition, the coefficient of determination (R²), which represents the

proportion of variance explained by the response variable in the calibration group (R²C) and in

the prediction group (R²P), was calculated (Nicolaï et al., 2007).

t

ip

RESULTS AND DISCUSSION

Meat quality evaluation

cr

Among the studied traits, WBSF showed the highest coefficient of variation (30%) and

us

the mean value was slightly above the limit of “tender” beef (Shackelford et al., 1997; Destefanis

an

et al., 2008; Rodas-González et al., 2009) (Table 1). Our WBSF results were slightly higher than

the values reported in the literature for Nelore cattle meat (Bonin et al., 2014; Magalhães et al.,

M

2016; Baldassini et al., 2017) and for Bos taurus beef (O’Connor et al., 1997; Riley et al., 2005),

while marbling had a low coefficient of variation and the mean value was similar to previous

d

determinations in Nelore beef (Francisco et al., 2015; Baldassini et al., 2017), which used the

te

same marbling score as our study. Comparison marbling scores is difficult because of the use of

ep

different scoring systems. In the United States 11 marbling scores are considered and each score

resulted in over a 100-point scale (Burrow, 2001), or 9 marbling scores are also used, as we used

c

in this study (USDA, 1989; USDA, 2016). While in Australia, the score ranges from 1 to 7. In

Ac

these systems, the meat samples are obtained between the 12th and 13th rib. The Japanese

system uses 12 marbling scores collected between the 6th and 7th rib (Burrow, 2001).

Regarding meat color traits, the coefficients of variation were intermediate for a* and b*

and low for L*. The L* parameter indicates lightness, where 0 corresponds to black color and

100 to white color. The mean value found in this study was similar to that reported for Nelore

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

cattle (Costa et al., 2013; Baldassini et al., 2017) and Bos Taurus (Cecchinato et al., 2011; Prieto

et al., 2014), but lower than that obtained by Baldin et al. (2013) and Bonin et al. (2014) also for

the Nelore breed. For a* parameter, a lower value corresponds to less red meat and a greater

value to more red meat. Thus, the mean value found in this study corresponds to less red meat

than those reported in the literature for the Nelore breed (Baldin et al., 2013; Costa et al., 2013;

t

ip

Baldassini et al., 2017). For b* parameter, a lower value indicates less yellow meat and a higher

value more yellow meat. The mean value found in this study was higher than that reported by

cr

Baldassini et al. (2017) and lower than Baldin et al. (2013) reported for Nelore breed. These

us

differences in meat color can be attributed to the strong influence of the environmental factor in

an

these traits, as antemortem and postmortem handling, i.e. chilling rate, packaging methods, time

and temperature at storage, exposure to oxygen and microbial load, animal age, nutritional diet,

M

glycogen storage, antioxidant accumulation, pH, oxygen consumption, and metmyoglobin

activity (Faustman and Cassens, 1990; Mancini and Hunt, 2005).

d

te

NIR spectra and chemometric analysis

ep

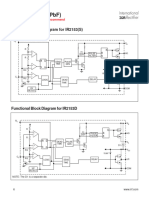

Chemometric analysis was performed using raw data and the following preprocessing

techniques: RSR, MSC and 1D. Figure 1 depicts these spectral preprocessing techniques and

c

Table 2 shows the results of PLS regression for each preprocessing technique evaluated.

Ac

The NIR spectra of the meat samples exhibited the most intense absorption bands at 5,200

and 7,000 cm-1, corresponding to the combination of O-H vibrations and first overtone of O-H

stretching, respectively (Figure 1). This trend is due to the presence of H2O in the meat samples

(Schwanninger et al., 2011) as the water content of beef is approximately 70.62% (Strasburg et

al., 2008). Small absorption bands were present at 5,700 and 8,500 cm-1, corresponding to the

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

first and second overtone of C-H stretching, respectively (Figure 1) (Schwanninger et al., 2011).

Several factors can affect the spectral profile, masking its chemical information, such as light

scattering, instrumental noise, tissue heterogeneities, ambient effects, and other sources of

variability (Nicolaï et al., 2007; Rinnan et al., 2009). Such effects can be attenuated by using

preprocessing techniques, which improve the signal-to-noise ratio of spectral data (Hibbert,

t

ip

2016). Additionally, the use of multivariate calibration techniques during chemometric analysis

removes redundant information that does not contribute to sample variability in the original data

cr

by reducing it to a few sets of variables that explain most of the variance (Hibbert, 2016). This

us

approach maintains only the most important information during the calibration procedure.

an

Although Nicolaï et al. (2007) reported that the NIR region covers the wavelength range

from 780 to 2,500 nm, we used the range of 1,100 to 2,500 nm as done in other studies

M

evaluating meat quality (Rødbotten et al., 2000; Prieto et al., 2008; Cecchinato et al., 2011).

Studies have used different wavelength ranges to analyze meat quality, including the visible

d

range (380 nm to 780 nm) (Leroy et al., 2003; Liu et al., 2003; Prieto et al., 2014), and the NIR

te

range of 833 to 2,500 nm to evaluate meat quality in two modes: reflectance and transmission

ep

(Leroy et al., 2003). The authors concluded that the use of a wider wavelength range in NIRS

(reflectance or transmission) did not improve the accuracy of predicting WBSF. For meat color

c

(L* and b*), NIRS showed good potential in the reflectance mode.

Ac

Among the different spectral preprocessing techniques, the model considering RSR (Fig.

1c) provided the best predictions for all traits (Table 2), followed by RAW (Fig. 1a) and MSC

(Fig. 1b). The worst results were obtained for the model using 1D without RSR (Fig. 1e). It

should be noted that RSR provided good results when applied alone or in combination with other

techniques. RSR in the range of 4,132 to 9,112 cm-1 was used to exclude extreme wavelengths

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

from the spectral range, avoiding high noise levels and water absorbance which do not contribute

to the accuracy of the prediction.

The reduction in data variability caused by MSC and 1D preprocessing (Figure 1)

resulted in low accuracy of the calibration (Table 2) for all traits studied. These preprocessing

techniques may have been too rigorous for the data type used here and may have removed

t

ip

valuable information, reducing the accuracy of the calibration model.

Different results have been reported in other NIRS studies of meat quality traits, which

cr

found the MSC technique with first and second derivative and SNV-D (Standard Normal Variate

us

and Detrend) (Prieto et al., 2008) to be more accurate for a* and b* than RAW and RSR.

an

However, Prieto et al. (2014) obtained similar results for L* considering only raw data (400–

2498 nm). For WBSF, Prieto et al. (2008) identified MSC as the best preprocessing technique,

M

while Prieto et al. (2014) reported SNV-D to be the best method. It is important to note that these

studies were performed using different breeds, the reference traits were measured in different

d

ways, and NIR spectra were obtained in different wavelength ranges. Thus, the use of diverse

te

data sets results in different accuracies of the prediction model, reinforcing the need to study the

ep

applicability of NIRS in the Nelore breed.

Using full cross-validation, the best WBSF calibration and prediction was obtained using

c

an NIR spectral window of 4,132 to 9,112 cm-1 (2,420 – 1,097 nm) since this window provided

Ac

lower calibration (RMSEC = 1.34 kg) and prediction errors (RMSEP = 1.42 kg), with highest

R2C (0.47) and R2P (0.40) (Table 2). Our prediction accuracy of NIRS for WBSF were close to

found by several authors (Rødbotten et al., 2000; Leroy et al., 2003; Prieto et al., 2008;

Cecchinato et al., 2011; De Marchi et al., 2013) and they were worse than those reported by Park

et al. (1998) and Prieto et al. (2014). It is important to note that all studies cited here to compare

10

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

our results used different approaches, i.e. spectra measured in the reflectance and transmittance

mode or in different wavelength ranges, type of meat used, and different instruments were used

for spectrum collection. For example, Prieto et al. (2014) used ground beef for spectrum

collection and a wider wavelength range (400–2498 nm), while De Marchi et al. (2013) used

both, ground and intact beef, with spectroscopy of visible, NIRS and near infrared transmittance.

t

ip

These authors reported that the type of sample used for infrared scanning was crucial for the

prediction of WBSF, with better predictions of WBSF in intact compared with homogenized

cr

samples. According to (Liu et al., 2003), direct comparison of the prediction results for meat

us

quality is difficult because of the different conditions of meat, with samples varying in the state

an

of freshness, aging, frozenness and thawing. Nevertheless, most studies generally reported a

moderate prediction ability of NIRS for WBSF, probably because this trait was measured by

M

physical analysis, while NIRS is based on the radiation absorbed by chemical bonds. Thus, NIRS

is less reliable for predicting physical meat quality traits than chemical analyses (Prevolnik et al.,

d

2004).

te

Among all traits studied, the lowest prediction ability of NIRS was observed for

ep

marbling. Data regarding the ability of NIRS to predict marbling are limited in cattle because

most studies have used chemical analysis to measure the percentage of intramuscular fat. Chan et

c

al. (2002) used NIRS to predict marbling scores in swine and reported an R² of 0.35, which was

Ac

higher than the 0.02 found here (Table 2). Two problems may explain the inefficiency of NIRS

to predict marbling. The first refers to the reference analysis of marbling, which is a subjective

trait and scores are therefore used for its evaluation, which increases the chance of error. For a

more precise a reliable measurement, extractable lipid should be used instead of marbling. In

addition, as can be seen in Table 1, the standard deviation and coefficient of variation were low,

11

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

therefore being difficult to use NIRS to predict traits with small variation. The second problem

might be related to the beef used for spectrum collection. We used intact meat samples which,

according to Rødbotten et al. (2000), have a heterogeneous distribution of fat. Thus,

homogeneous mixtures such as ground or minced meat would be more adequate to collect NIR

spectra since they increase the chance of detecting the “true” composition of fat. Furthermore,

t

ip

the small variation among the samples (standard-deviation of 0.15) most likely decreased the

predictive performance and robustness of the calibration model, generating a low R2.

cr

Regarding color traits, higher prediction accuracies were obtained for b* and lower

us

accuracies for a* and L* (Table 2). The prediction accuracies for the color traits were lower than

an

those reported in other studies (Liu et al., 2003; Prieto et al., 2014). This difference in the results

found for these traits may be related to the spectral region used for prediction in this study (2500

M

to 1000 nm). This NIR region is associated with high energy vibrational transitions related to the

vibration of chemical bonds and not with electronic transitions observed in the visible range.

d

According to Van Den Oord and Wesdorp (1971), the visible spectrum (630 and 580 nm) is

te

associated with the percentage of oxymyoglobin, one of the forms of myoglobin (pigments that

ep

determine meat color). In addition to the spectral range, another factor that could explain the low

prediction accuracy of meat color is the time elapsed between the objective color measurements

c

and NIRS analysis (Prieto et al., 2014). In the present study, this interval was not measured but

Ac

was probably not the same for all traits, which could explain the low accuracy obtained for the

L* and a* parameters. According to Prieto et al. (2014), the time elapsed between spectrum

collection and reference analysis can modify the oxidation states of the myoglobin pigments in

meat, thus giving rise to changes in color.

12

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

CONCLUSIONS

NIRS showed a better ability to predict WBSF and b* color when RSR in the range of

4,132 to 9,112 cm-1 was used as preprocessing technique, while its ability to accurately predict

t

ip

L* and a* was limited. The ability of NIRS to predict subjective meat quality traits such as

marbling in Nelore cattle is low because of the presence of heterogeneities in the meat samples,

cr

low precision of the reference analysis and low variation between samples.

us

NIRS is a useful tool to be applied in the meat industry, predicting the traits of tenderness

an

and meat color. However, NIRS should not be applied to predict subjective meat quality traits.

Reference analysis to analyze beef fat should be improved in order to evaluate the ability of

M

NIRS to predict fat content in bovines.

d

LITERATURE CITED

te

ep

Baldassini, W. A., L. A. L. Chardulo, J. A. V. Silva, J. M. Malheiros, V. A. D. Dias, R.

Espigolan, F. S. Baldi, L. G. Albuquerque, T. T. Fernandes, and P. M. Padilha. 2017. Meat

c

quality traits of Nellore bulls according to different degrees of backfat thickness: A multivariate

Ac

approach. Anim. Prod. Sci. 57:363–370. doi:10.1071/AN15120.

Baldin, S. R., D. D. Millen, C. L. Martins, A. S. C. Pereira, R. S. Barducci, and M. A. de Beni.

2013. Desempenho, características de carcaça e carne de bovinos nelore e canchim, confinados

com dietas suplementadas com vitaminas D e E. Acta Sci. - Anim. Sci. 35:403–410.

doi:10.4025/actascianimsci.v35i4.18801.

13

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Bonin, M. N., J. B. S. Ferraz, J. P. Eler, F. M. Rezende, D. C. Cucco, M. E. Carvalho, R. C. G.

Silva, R. C. Gomes, and E. C. M. Oliveira. 2014. Sire effects on carcass and meat quality traits

of young Nellore bulls. Genet. Mol. Res. 13:3250–3264. doi:10.4238/2014.April.29.3.

Borges, B. O., R. A. Curi, F. Baldi, F. L. B. Feitosa, W. B. F. De Andrade, L. G. De

Albuquerque, H. N. De Oliveira, and L. A. L. Chardulo. 2014. Polymorphisms in candidate

t

ip

genes and their association with carcass traits and meat quality in Nellore cattle. Pesqui.

cr

Agropecu. Bras. 49:364–371. doi:10.1590/S0100-204X2014000500006.

us

Faustman, C., R.G. Cassens. 1990. The biochemical basis for discoloration in fresh meat: a

review. J. Muscle Foods. 1:217–243. doi:https://doi.org/10.1111/j.1745-4573.1990.tb00366.x.

an

Campestrini, E. 2005. Utilização de Equipamento NIRS (NearInfraredReflectanceSpectroscopy)

M

nos Estudos de Valores Nutricionais (Composição Química e Digestibilidae) de Alimentos para

não ruminantes. Rev. Eletrônica Nutr. 240–251. Available from:

d

http://www.nutritime.com.br/arquivos_internos/artigos/025V2N5P240_251_SET2005.pdf

te

Cecchinato, A., M. de Marchi, M. Penasa, A. Albera, and G. Bittante. 2011. Near-infrared

ep

reflectance spectroscopy predictions as indicator traits in breeding programs for enhanced beef

c

quality. J. Anim. Sci. 89:2687–2695. doi:10.2527/jas.2010-3740.

Ac

Chan, D. E., P. N. Walker, and E. W. Mills. 2002. Prediction of pork quality characteristics using

visible and near–infrared spectroscopy. 45:1519–1527.

Costa, D. P. B. da, R. de O. Roça, Q. P. B. da Costa, D. P. D. Lanna, E. da S. Lima, and W. M.

de Barros. 2013. Meat characteristics of Nellore steers fed whole cottonseed. Rev. Bras. Zootec.

42:183–192. doi:10.1590/S1516-35982013000300006.

14

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Destefanis, G., A. Brugiapaglia, M. T. Barge, and E. Dal Molin. 2008. Relationship between

beef consumer tenderness perception and Warner-Bratzler shear force. Meat Sci. 78:153–156.

doi:10.1016/j.meatsci.2007.05.031.

Francisco, C. L., F. D. Resende, J. M. B. Benatti, A. M. Castilhos, R. F. Cooke, and A. M. Jorge.

2015. Impacts of temperament on Nellore cattle: physiological responses, feedlot performance,

t

ip

and carcass characteristics. J. Anim. Sci. 93:5419–5429. doi:10.2527/jas.2015-9411.

cr

Hibbert, D. B. 2016. Vocabulary of concepts and terms in chemometrics (IUPAC

us

Recommendations 2016). Pure Appl. Chem. 88:407–443. doi:10.1515/pac-2015-0605.

an

Leroy, B., S. Lambotte, O. Dotreppe, H. Lecocq, L. Istasse, and A. Clinquart. 2003. Prediction of

technological and organoleptic properties of beef Longissimus thoracis from near-infrared

M

reflectance and transmission spectra. Meat Sci. 66:45–54. doi:10.1016/S0309-1740(03)00002-0.

d

Liu, Y., B. G. Lyon, W. R. Windham, C. E. Realini, T. D. D. Pringle, and S. Duckett. 2003.

te

Prediction of color, texture, and sensory characteristics of beef steaks by visible and near infrared

reflectance spectroscopy. A feasibility study. Meat Sci. 65:1107–1115. doi:10.1016/S0309-

ep

1740(02)00328-5.

c

Magalhães, A. F. B., G. M. F. de Camargo, G. A. Fernandes, D. G. M. Gordo, R. L. Tonussi, R.

Ac

B. Costa, R. Espigolan, R. M. de O. Silva, T. Bresolin, W. B. F. de Andrade, L. Takada, F. L. B.

Feitosa, F. Baldi, R. Carvalheiro, L. A. L. Chardulo, and L. G. de Albuquerque. 2016. Genome-

Wide Association Study of Meat Quality Traits in Nellore Cattle. PLoS One. 11:e0157845.

doi:10.1371/journal.pone.0157845. Available from:

http://dx.plos.org/10.1371/journal.pone.0157845

15

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Mancini, R. A., and M. C. Hunt. 2005. Current research in meat color. Meat Sci. 71:100–121.

doi:10.1016/j.meatsci.2005.03.003.

De Marchi, M., M. Penasa, A. Cecchinato, and G. Bittante. 2013. The relevance of different near

infrared technologies and sample treatments for predicting meat quality traits in commercial beef

cuts. Meat Sci. 93:329–335. doi:10.1016/j.meatsci.2012.09.013. Available from:

t

ip

http://dx.doi.org/10.1016/j.meatsci.2012.09.013

cr

Næs, T., Isaksson, T., Fearn, T., Davies, T. 2004. A User-friendly Guide to Multivariate

us

Calibration and Classification. NIR publications, Charlton, Chichester, UK.

an

Nicolaï, B. M., K. Beullens, E. Bobelyn, A. Peirs, W. Saeys, K. I. Theron, and J. Lammertyn.

2007. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy:

M

A review. Postharvest Biol. Technol. 46:99–118. doi:10.1016/j.postharvbio.2007.06.024.

O’Connor, S. F., J. D. Tatum, D. M. Wulf, R. D. Green, and G. C. Smith. 1997. Genetic Effects

d

te

on Beef Tenderness in Bos indicus Composite and Bos taurus Cattle. J. Anim. Sci. 75:1822–

1830. doi:1997.7571822x.

ep

Park, B., Y. R. Chen, W. R. Hruschka, S. D. Shackelford, and M. K. 1998. Near-Infrared

c

Reflectance Analysis for Predicting Beef Longissimus Tenderness. J. Anim. Sci. 76:2115–2120.

Ac

Prevolnik, M., M. Čandek-Potokar, and D. Škorjanc. 2004. Ability of NIR spectroscopy to

predict meat chemical composition and quality - A review. Czech J. Anim. Sci. 49:500–510.

Prieto, N., S. Andrés, F. J. Giráldez, A. R. Mantecón, and P. Lavín. 2008. Ability of near infrared

reflectance spectroscopy (NIRS) to estimate physical parameters of adult steers (oxen) and

16

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

young cattle meat samples. Meat Sci. 79:692–699. doi:10.1016/j.meatsci.2007.10.035.

Prieto, N., Ó López-Campos, J. L. Aalhus, M. E. R. Dugan, M. Juárez, and B. Uttaro. 2014. Use

of near infrared spectroscopy for estimating meat chemical composition, quality traits and fatty

acid content from cattle fed sunflower or flaxseed. Meat Sci. 98:279–288.

doi:10.1016/j.meatsci.2014.06.005. Available from:

t

ip

http://dx.doi.org/10.1016/j.meatsci.2014.06.005

cr

Riley, D. G., D. D. Johnson, C. C. Chase, R. L. West, S. W. Coleman, T. A. Olson, and A. C.

us

Hammond. 2005. Factors influencing tenderness in steaks from Brahman cattle. Meat Sci.

70:347–356. doi:10.1016/j.meatsci.2005.01.022.

an

Rinnan, Å., F. van den Berg, and S. B. Engelsen. 2009. Review of the most common pre-

M

processing techniques for near-infrared spectra. TrAC - Trends Anal. Chem. 28:1201–1222.

doi:10.1016/j.trac.2009.07.007. Available from: http://dx.doi.org/10.1016/j.trac.2009.07.007

d

te

Rodas-González, A., N. Huerta-Leidenz, N. Jerez-Timaure, and M. F. Miller. 2009. Establishing

tenderness thresholds of Venezuelan beef steaks using consumer and trained sensory panels.

ep

Meat Sci. 83:218–223. doi:10.1016/j.meatsci.2009.04.021. Available from:

c

http://dx.doi.org/10.1016/j.meatsci.2009.04.021

Ac

Rødbotten, R., B. N. Nilsen, and K. I. Hildrum. 2000. Prediction of beef quality attributes from

early post mortem near infrared reflectance spectra. Food Chem. 69:427–436.

doi:10.1016/S0308-8146(00)00059-5.

Schwanninger, M., J. C. Rodrigues, and K. Fackler. 2011. A review of band assignments in near

infrared spectra of wood and wood components. J. Near Infrared Spectrosc. 19:287–308.

17

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

doi:10.1255/jnirs.955.

Shackelford, S. D., T. L. Wheeler, and M. Koohmaraie. 1997. Tenderness Classification of Beef:

I. Evaluation of Beef Longissimus Shear Force at 1 or 2 Days Postmortem as a Predictor of Aged

Beef Tenderness. J. Anim. Sci. 75:2417–2422.

t

Shackelford, S. D., T. L. Wheeler, M. K. Meade, J. O. Reagan, B. L. Byrnes, and M.

ip

Koohmaraie. 2001. Consumer impressions of tender select beef. J. Anim. Sci. 79:2605–2614.

cr

doi:10.2527/2001.79102605x.

us

Strasburg, G., Xiong, Y.L., Chiang, W. 2008. Physiology and chemistry of edible muscle tissues.

an

4th ed. (O. R. Damodarn, S., Parkin, K.L., Fennema, editor.). Fennema’s Food Chemistry. CRC

Press: Boca Raton.

M

USDA. 1989. Official USDA marbling photographs. National Cattlemen’s Beef Association.

d

U.S. Depth. of Agriculture, Washington, DC. U.S.A.

te

USDA. 2016. United States standards for grades of carcass beef. A. M. Serv. 17.

ep

Wheeler, T. L., Koomaraie, M., Shackelford, S. D. 1995. Standardized Warner-Bratzler shear

force procedures for meat tenderness measurement. Clay Cente.

c

Ac

Van den Oord, A. H. A. and Wesdorp, J. J. 1971. Colour rating and pigment composition of

beef: Relation between colour measurement by reflectance spectrophotometry, subjective colour

evaluation, and the relative concentration of oxymyoglobin and ferric myoglobin in chilled

retail-packed beef. Int. J. Food Sci. Technol. 6:15–20. doi:10.1111/j.1365-2621.1971.tb01588.x.

Williams, J. L. 2008. Genetic Control of Meat Quality Traits. In: F. Toldrá, editor. Meat

18

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Biotechnology. Springer Science & Business Media, New York. p. 21–61.

t

ip

cr

us

Table 1. Descriptive statistics for meat quality traits (n = 644) in Nellore beef.

Trait1 Mean Standard deviation Coefficient of variation (%)

WBSF (kg) 6.15

an 1.84 30

M

Marbling 2.96 0.15 5

a* 9.37 1.56 17

d

b* 10.49 1.62 15

te

L* 34.93 2.16 6

ep

1

WBSF=Warner-Bratzler shear force; a*=redness; b*=yellowness; L*=lightness.

c

Ac

19

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

t

ip

cr

us

Table 2. Calibration statistics for the determination of meat quality traits by NIRS

Trait1 Preprocessing technique2

an RMSEC3 RMSEP3 R2C4 R2P4

WBSF RAW 1.44 1.53 0.38 0.31

M

RSR 1,34 1,42 0.47 0.40

MSC 1,51 1,60 0.32 0.24

d

MSC + RSR 1,37 1,47 0.44 0.36

te

1D 1,80 1,84 0.04 0.00

ep

1D + RSR 1,44 1,58 0.38 0.26

MSC + 1D 1,80 1,84 0.04 0.00

c

Ac

MSC + 1D + RSR 1,40 1,58 0.41 0.26

Marbling RAW 0.15 0.15 0.00 0.00

RSR 0.15 0.15 0.00 0.00

MSC 0.15 0.15 0.01 0.00

MSC + RSR 0.15 0.15 0.01 0.00

20

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

1D 0.15 0.15 0.01 0.00

1D + RSR 0.15 0.15 0.03 0.01

MSC + 1D 0.15 0.16 0.02 0.00

MSC + 1D + RSR 0.15 0.15 0.04 0.02

a* RAW 1.40 1.43 0.20 0.16

t

ip

RSR 1.40 1.42 0.20 0.17

MSC 1.47 1.49 0.11 0.10

cr

MSC + RSR 1.47 1.48 0.11 0.10

us

1D 1.54 1.58 0.03 0.00

1D + RSR

MSC + 1D

an 1.52

1.54

1.53

1.58

0.05

0.02

0.04

0.00

M

MSC + 1D + RSR 1.53 1.54 0.04 0.02

b* RAW 1.54 1.97 0.49 0.45

d

RSR 1.89 1.21 0.46 0.44

te

MSC 1.26 1.33 0.39 0.32

ep

MSC + RSR 1.27 1.30 0.39 0.36

1D 1.48 1.55 0.16 0.08

c

Ac

1D + RSR 1.21 1.34 0.44 0.31

MSC + 1D 1.51 1.58 0.12 0.04

MSC + 1D + RSR 1.21 1.31 0.44 0.34

L* RAW 1.92 1.98 0.21 0.16

RSR 1.95 1.98 0.19 0.16

21

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

MSC 2.09 2.12 0.06 0.04

MSC + RSR 2.01 2.07 0.14 0.09

1D 2.13 2.18 0.03 0.00

1D + RSR 2.12 2.14 0.04 0.02

MSC + 1D 2.13 2.19 0.02 0.00

t

ip

MSC + 1D + RSR 2.12 2.14 0.04 0.02

1

WBSF=Warner-Bratzler shear force; a*=redness; b*=yellowness; L*=lightness;

cr

2

RAW=raw data; RSR= reduction of spectral range; MSC=multiplicative scatter correction;

us

1D=1st order derivative.

3

4

an

RMSEC and RMSEP: root mean square error of calibration and prediction;

R2C and R2P: determination coefficient of calibration and prediction.

M

d

te

c ep

Ac

22

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

t

ip

cr

us

an

M

ed

pt

ce

Ac

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

Figure 1. NIR spectra (absorbance x wavenumber (cm-1)) obtained for the different

preprocessing techniques: RAW - raw data (a); RSR - reduction of spectral range (b); MSC -

multiplicative scatter correction (c); MSC + RSR (d); 1D – 1st order derivative (e); 1D + RSR (f);

MSC + 1D (g); MSC + 1D + RSR (h).

t

ip

cr

us

an

M

d

te

c ep

Ac

24

Downloaded from https://academic.oup.com/jas/advance-article-abstract/doi/10.1093/jas/sky284/5053846

by University of Pennsylvania Libraries user

on 14 July 2018

S-ar putea să vă placă și

- Non-Destructive Prediction of Texture of Frozenthaw Raw Beef by Ramanspectroscopy - Chen2019 PDFDocument7 paginiNon-Destructive Prediction of Texture of Frozenthaw Raw Beef by Ramanspectroscopy - Chen2019 PDFKateřina InachisÎncă nu există evaluări

- Three Dimensional Chemometric Analyses of Hyperspectral Images For Beef Tenderness ForecastingDocument12 paginiThree Dimensional Chemometric Analyses of Hyperspectral Images For Beef Tenderness ForecastingPrincess Tiffany Dantes MendozaÎncă nu există evaluări

- Carnes de Calidad y El DescongeladoDocument5 paginiCarnes de Calidad y El Descongeladopedro RomeroÎncă nu există evaluări

- Food Research International: Raúl Grau, Antonio J. Sánchez, Joel Girón, Eugenio Iborra, Ana Fuentes, Jose M. BaratDocument7 paginiFood Research International: Raúl Grau, Antonio J. Sánchez, Joel Girón, Eugenio Iborra, Ana Fuentes, Jose M. BaratAnonymous VcLYi0Încă nu există evaluări

- Predicting Post-Mortem Meat Quality in Porcine Longissimus Lumborum UsingDocument7 paginiPredicting Post-Mortem Meat Quality in Porcine Longissimus Lumborum UsingFauzan MuhammadÎncă nu există evaluări

- Non Destructive DetectionDocument8 paginiNon Destructive DetectioneifaÎncă nu există evaluări

- Real Time PRC Quantitative MeatDocument5 paginiReal Time PRC Quantitative MeatMuhammad Javed IqbalÎncă nu există evaluări

- 1 s2.0 S0309174018307496 MainDocument9 pagini1 s2.0 S0309174018307496 MainYasmin AntunesÎncă nu există evaluări

- Automated Computer Vision System To Predict Body Weight and Av - 2020 - LivestocDocument10 paginiAutomated Computer Vision System To Predict Body Weight and Av - 2020 - Livestocisaacrodrigues.alunoÎncă nu există evaluări

- Application of Bioelectrical Impedance Analysis in Prediction of Light Kid Carcass and Muscle Chemical CompositionDocument7 paginiApplication of Bioelectrical Impedance Analysis in Prediction of Light Kid Carcass and Muscle Chemical CompositionXaralyn XaviereÎncă nu există evaluări

- SBE 2000 4 MS Brøndum PDFDocument10 paginiSBE 2000 4 MS Brøndum PDFsonuÎncă nu există evaluări

- Sbe 2000 4 Ms BrøndumDocument10 paginiSbe 2000 4 Ms BrøndumsonuÎncă nu există evaluări

- Meat and Poultry QualityDocument49 paginiMeat and Poultry QualityCaio RibeiroÎncă nu există evaluări

- At-Line Prediction of Fatty Acid Profile in Chicken Breast Using NIR Reflectance Spectrosc-6Document5 paginiAt-Line Prediction of Fatty Acid Profile in Chicken Breast Using NIR Reflectance Spectrosc-6Loredana Veronica ZalischiÎncă nu există evaluări

- HalalDocument5 paginiHalalRoni Adi WijayaÎncă nu există evaluări

- Publicación JamónDocument7 paginiPublicación Jamóncrisgano84599513Încă nu există evaluări

- Novaković 2017 IOP Conf. Ser. Earth Environ. Sci. 85 012063Document7 paginiNovaković 2017 IOP Conf. Ser. Earth Environ. Sci. 85 012063Vi BaudeÎncă nu există evaluări

- Genome Scan For Meat Quality Traits in Nelore Beef CattleDocument9 paginiGenome Scan For Meat Quality Traits in Nelore Beef CattleBayu DewantoroÎncă nu există evaluări

- (2017) NIR SpectrosDocument16 pagini(2017) NIR SpectrosNghĩa Tê GiácÎncă nu există evaluări

- Application of Bioelectrical Impedance Analysis To Assess Rabbit's Body Composition From 25 To 77 Days of AgeDocument12 paginiApplication of Bioelectrical Impedance Analysis To Assess Rabbit's Body Composition From 25 To 77 Days of AgeXaralyn XaviereÎncă nu există evaluări

- Meat Science: S.M. Stewart, T. Lauridsen, H. Toft, D.W. Pethick, G.E. Gardner, P. Mcgilchrist, M. ChristensenDocument13 paginiMeat Science: S.M. Stewart, T. Lauridsen, H. Toft, D.W. Pethick, G.E. Gardner, P. Mcgilchrist, M. ChristensenEdhgar KoyÎncă nu există evaluări

- Identification of Meat Species by TaqMan-based Real-Time PCR AssayDocument6 paginiIdentification of Meat Species by TaqMan-based Real-Time PCR AssayMet RizalÎncă nu există evaluări

- Halal IngDocument6 paginiHalal IngRoni Adi WijayaÎncă nu există evaluări

- Meat and Fish Flesh Quality Improvement With Proteomic ApplicationsDocument8 paginiMeat and Fish Flesh Quality Improvement With Proteomic Applicationspbm dkpjambiÎncă nu există evaluări

- Review JurnalDocument5 paginiReview JurnalSapphire SapphireÎncă nu există evaluări

- Journal of Food Engineering: Malay Kishore Dutta, Ashish Issac, Navroj Minhas, Biplab SarkarDocument9 paginiJournal of Food Engineering: Malay Kishore Dutta, Ashish Issac, Navroj Minhas, Biplab SarkarCelicia LopezÎncă nu există evaluări

- Ijcpd 4 113Document6 paginiIjcpd 4 113info.akshatishanÎncă nu există evaluări

- J Sci Food Agric - 2018 - Temizkan - Differential Expression Analysis of Meat Tenderness Governing Genes in DifferentDocument6 paginiJ Sci Food Agric - 2018 - Temizkan - Differential Expression Analysis of Meat Tenderness Governing Genes in DifferentAnia KononiukÎncă nu există evaluări

- FTIR Meat Science-BaksoDocument5 paginiFTIR Meat Science-BaksoShenina KnightleyÎncă nu există evaluări

- Chemical Composition of Different Muscle Zones in Pirarucu (Arapaima Gigas)Document6 paginiChemical Composition of Different Muscle Zones in Pirarucu (Arapaima Gigas)مهند كمالÎncă nu există evaluări

- Texture Methods For Evaluating Meat and Meat Analogue Structu 2021 Food ContDocument14 paginiTexture Methods For Evaluating Meat and Meat Analogue Structu 2021 Food ContStephane JournouxÎncă nu există evaluări

- Using Factor Scores in Multiple Linear Regression Model For Predicting The Carcass Weight of Broiler Chickens Using Body MeasurementsDocument5 paginiUsing Factor Scores in Multiple Linear Regression Model For Predicting The Carcass Weight of Broiler Chickens Using Body MeasurementsVedika AryaÎncă nu există evaluări

- Estimation For Fish Mass Using Image Analysis and Neural NetworkDocument11 paginiEstimation For Fish Mass Using Image Analysis and Neural NetworkLeandro Magno Correa da SilvaÎncă nu există evaluări

- Artigos - DEXADocument5 paginiArtigos - DEXADhones AndradeÎncă nu există evaluări

- Inferences On The Effects of Selection For Feed Conversion Over Meat Quality Traits in BroilerDocument7 paginiInferences On The Effects of Selection For Feed Conversion Over Meat Quality Traits in Broilersurendra korrapatiÎncă nu există evaluări

- 09OIUDocument6 pagini09OIUAnonymous FW5PVUpÎncă nu există evaluări

- 1 s2.0 S0032579119470119 Main PDFDocument7 pagini1 s2.0 S0032579119470119 Main PDFZayin ValerieÎncă nu există evaluări

- MIR - Craig 2018. Mid Infrared Spectroscopy and Chemometrics As Tools For The Classification Ofroasted Coffees by Cup QualityDocument10 paginiMIR - Craig 2018. Mid Infrared Spectroscopy and Chemometrics As Tools For The Classification Ofroasted Coffees by Cup QualityMauricio CastroÎncă nu există evaluări

- Ultrasonic Determination of The Composition of A Meat-Based ProductDocument5 paginiUltrasonic Determination of The Composition of A Meat-Based ProductHarry YucraÎncă nu există evaluări

- Usage of The Neural Network To Predict Meat Tender-Ness ApproachDocument5 paginiUsage of The Neural Network To Predict Meat Tender-Ness ApproachGabriel FuriniÎncă nu există evaluări

- Evaluation of Pork Color by Using Computer Vision: J. Lu, J. Tan, P. Shatadal, D.E. GerrardDocument4 paginiEvaluation of Pork Color by Using Computer Vision: J. Lu, J. Tan, P. Shatadal, D.E. GerrardEmely Coronado DuermeÎncă nu există evaluări

- Eye White Percentage As A Predictor of Temperament in Beef CattleDocument9 paginiEye White Percentage As A Predictor of Temperament in Beef CattleAisyah NovasariÎncă nu există evaluări

- Data-In-Brief Samadi Wajizah Munawar 2019Document14 paginiData-In-Brief Samadi Wajizah Munawar 2019ar guaÎncă nu există evaluări

- Pork Quality Control TeagascDocument23 paginiPork Quality Control TeagascLuís Homero ArteagaÎncă nu există evaluări

- Direct and Indirect Means of Predicting Forage Quality Through Near Infrared Reflectance SpectrosDocument12 paginiDirect and Indirect Means of Predicting Forage Quality Through Near Infrared Reflectance SpectrosColo VoltaÎncă nu există evaluări

- Biomass Compositional Analysis LaboratoryDocument2 paginiBiomass Compositional Analysis Laboratoryfq285528Încă nu există evaluări

- Journal of Food Composition and AnalysisDocument10 paginiJournal of Food Composition and AnalysisMd. Badrul IslamÎncă nu există evaluări

- Data in BriefDocument8 paginiData in BrieffadhilÎncă nu există evaluări

- Metabolic Fingerprinting of Royal Jelly: Characterization and Proof of AuthenticityDocument6 paginiMetabolic Fingerprinting of Royal Jelly: Characterization and Proof of AuthenticitycostytzuÎncă nu există evaluări

- Estradiol and Progesterone Fecal Metabolites Analysis in Crab-Eating-FoxDocument5 paginiEstradiol and Progesterone Fecal Metabolites Analysis in Crab-Eating-FoxTiago AmaralÎncă nu există evaluări

- Foods 11 02312 v3Document26 paginiFoods 11 02312 v3Bikash sharmaÎncă nu există evaluări

- Poultrysci85-PemuterDocument7 paginiPoultrysci85-PemuterLailatul RohmahÎncă nu există evaluări

- 1 s2.0 S0032579119321170 MainDocument7 pagini1 s2.0 S0032579119321170 MainGuilherme Costa VenturiniÎncă nu există evaluări

- ISSN: 2277-4998: IJBPAS, August, 2013, 2 (8) : 1665-1677Document13 paginiISSN: 2277-4998: IJBPAS, August, 2013, 2 (8) : 1665-1677api-313248492Încă nu există evaluări

- Attenuated Total Reflectance Fourier Transform Spectroscopy (ATR-FTIR) and Chemometrics For Discrimination of Espresso CoffeDocument8 paginiAttenuated Total Reflectance Fourier Transform Spectroscopy (ATR-FTIR) and Chemometrics For Discrimination of Espresso Coffejohn silverÎncă nu există evaluări

- 1 s2.0 S0737080611001559 Main PDFDocument2 pagini1 s2.0 S0737080611001559 Main PDFLaviniaMenicucciÎncă nu există evaluări

- Fish Survival Prediction in An Aquatic Environment Using Random Forest ModelDocument9 paginiFish Survival Prediction in An Aquatic Environment Using Random Forest ModelIAES IJAIÎncă nu există evaluări

- Systematic Review of Emerging and Innovative Technologies For - 2017 - Meat ScieDocument18 paginiSystematic Review of Emerging and Innovative Technologies For - 2017 - Meat Sciedanielklouda64Încă nu există evaluări

- Food Control: Nicolette Pegels, Isabel González, Irene Martín, María Rojas, Teresa García, Rosario MartínDocument8 paginiFood Control: Nicolette Pegels, Isabel González, Irene Martín, María Rojas, Teresa García, Rosario Martínkhoi moleÎncă nu există evaluări

- Recent Advances in Animal Nutrition – 1979: Studies in the Agricultural and Food SciencesDe la EverandRecent Advances in Animal Nutrition – 1979: Studies in the Agricultural and Food SciencesÎncă nu există evaluări

- KPI AssignmentDocument7 paginiKPI AssignmentErfan Ahmed100% (1)

- Best Mutual Funds For 2023 & BeyondDocument17 paginiBest Mutual Funds For 2023 & BeyondPrateekÎncă nu există evaluări

- RCA LCD26V6SY Service Manual 1.0 PDFDocument33 paginiRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- Central University of Karnataka: Entrance Examinations Results 2016Document4 paginiCentral University of Karnataka: Entrance Examinations Results 2016Saurabh ShubhamÎncă nu există evaluări

- Test Bank For Psychology 6th Edition Don HockenburyDocument18 paginiTest Bank For Psychology 6th Edition Don HockenburyKaitlynMorganarwp100% (42)

- Imabalacat DocuDocument114 paginiImabalacat DocuJänrëýMåmårìlSälängsàngÎncă nu există evaluări

- CII Sohrabji Godrej GreenDocument30 paginiCII Sohrabji Godrej GreenRITHANYAA100% (2)

- SG110CX: Multi-MPPT String Inverter For SystemDocument2 paginiSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithÎncă nu există evaluări

- Been There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerDocument8 paginiBeen There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerNanis DimmitrisÎncă nu există evaluări

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 paginiCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiÎncă nu există evaluări

- Johnson & Johnson Equity Research ReportDocument13 paginiJohnson & Johnson Equity Research ReportPraveen R V100% (3)

- Csir Life Sciences Fresh Instant NotesDocument4 paginiCsir Life Sciences Fresh Instant NotesAlps Ana33% (3)

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocument3 paginiTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louÎncă nu există evaluări

- Claim of FactDocument11 paginiClaim of FactXeb UlritzÎncă nu există evaluări

- Unit 1 Module 3 Rep in PlantsDocument26 paginiUnit 1 Module 3 Rep in Plantstamesh jodhanÎncă nu există evaluări

- Genuine Fakes: How Phony Things Teach Us About Real StuffDocument2 paginiGenuine Fakes: How Phony Things Teach Us About Real StuffGail LeondarWrightÎncă nu există evaluări

- The New Order of BarbariansDocument39 paginiThe New Order of Barbariansbadguy100% (1)

- Universitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanDocument7 paginiUniversitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanTheresia Calcutaa WilÎncă nu există evaluări

- How Chargers WorkDocument21 paginiHow Chargers WorkMuhammad Irfan RiazÎncă nu există evaluări

- SCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Document104 paginiSCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Athulya ThondangattilÎncă nu există evaluări

- IR2153 Parte6Document1 paginăIR2153 Parte6FRANK NIELE DE OLIVEIRAÎncă nu există evaluări

- ST Arduino Labs CombinedDocument80 paginiST Arduino Labs CombineddevProÎncă nu există evaluări

- Practice Problems - Electrochemical CellDocument5 paginiPractice Problems - Electrochemical CellYehia IbrahimÎncă nu există evaluări

- Mecha World Compendium Playbooks BWDocument12 paginiMecha World Compendium Playbooks BWRobson Alves MacielÎncă nu există evaluări

- NHD Process PaperDocument2 paginiNHD Process Paperapi-203024952100% (1)

- Boundary Value Analysis 2Document13 paginiBoundary Value Analysis 2Raheela NasimÎncă nu există evaluări

- Derma Notes 22pages. DR - Vishwa Medical CoachingDocument23 paginiDerma Notes 22pages. DR - Vishwa Medical CoachingΝίκος ΣυρίγοςÎncă nu există evaluări

- Yetta Company ProfileDocument6 paginiYetta Company ProfileAfizi GhazaliÎncă nu există evaluări

- AIIMS 2015 Solved PaperDocument436 paginiAIIMS 2015 Solved PaperSurya TejaÎncă nu există evaluări

- Saiva Dharma ShastrasDocument379 paginiSaiva Dharma ShastrasfunnybizÎncă nu există evaluări