Documente Academic

Documente Profesional

Documente Cultură

Test Plan 8523a320

Încărcat de

tania0 evaluări0% au considerat acest document util (0 voturi)

208 vizualizări2 paginiThis document provides a test plan for a Ford HSDI fuel pump. It outlines 33 tests to characterize the pump's performance under various operating conditions. Tests will measure specifications like fuel delivery volume, transfer pressure, mechanical advance, back leakage, torque curves, and idle settings both hot and cold. Tolerances are provided for acceptance on each test.

Descriere originală:

Titlu original

TEST PLAN 8523A320

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides a test plan for a Ford HSDI fuel pump. It outlines 33 tests to characterize the pump's performance under various operating conditions. Tests will measure specifications like fuel delivery volume, transfer pressure, mechanical advance, back leakage, torque curves, and idle settings both hot and cold. Tolerances are provided for acceptance on each test.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

208 vizualizări2 paginiTest Plan 8523a320

Încărcat de

taniaThis document provides a test plan for a Ford HSDI fuel pump. It outlines 33 tests to characterize the pump's performance under various operating conditions. Tests will measure specifications like fuel delivery volume, transfer pressure, mechanical advance, back leakage, torque curves, and idle settings both hot and cold. Tolerances are provided for acceptance on each test.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

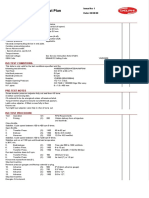

8523A320

Ford HSDI TEST PLAN Issue No: 5

00/00/00

PUMP SPECIFICATION ISO TEST PROCEDURE

Rotation: Clockwise. Test Operation S/C RPM Requirements

Governor type: Mechanical two speed with dual rate idle. 1. Priming (C) 100 Obtain delivery from all injectors

Gov. Link Length: 42.8 ± 0.2 mm. and clear flow of fuel from backleak

Plunger Diameter: 7.0 mm (4 off). and governor cover vent.

Drive Type: Uprated with supported shaft. Stop test machine.

Advance Type: Servo advance with light load via rocking lever. Wait for 30 seconds.

Transfer pressure adjuster in end plate. 2. Priming (C) 100 Obtain delivery from all injectors

Cambox pressurising valve. and clear flow of fuel from backleak

Solenoid shut-off device, 12 volts. and governor cover vent.

Scroll plate max. fuel adjustment, with dual rate torque control. 3. Stabilisation (C) 2400 TP 6,2 - 6,75 bar(90 - 98

Hydraulic excess fuel control with latch valve. Run pump for 3 minutes to stabilise.

Fast idle & cold idle advance linked for waxstat operation. Cambox pressure to be 0.6 - 1.15 bar

Automatic high pressure venting system. (9 - 17

4. Advance (C) 2400 9.0 ± 0.5°, ( 7.2 0.4m).

ISO TEST CONDITIONS. With throttle lever closed.

This data is only valid for the test conditions specified and the (After test, stop test machine.)

following test benches: HA3000/HA2500/HA1150/HA1100MkII/HA875 5. Advance (C) 0 0°.

HA700/HA400/AVM/PGM 6. Transfer Press. (C) 100 Minimum 0.4 bar, ( 6 psi).

Test Fluid: ISO 4113 at 40 ± 2°C. 7. Excess fuel (C) 100 Minimum 5.5 cm3.

Inlet feed pressure: 0.1 bar 8. Max. Delivery (S)* 2000 41.5 ± 1.2 mm3/st.

Nozzles Holder: ISO 7440 + YDB288 Edge filter assy. Run test machine at 600 rpm before next test.

Nozzles: BDL0S6844 9. Transfer Press. (C) 1300 4.1 to 5.0 bar( 60 to 72psi)

Nozzle Opening Pressure: 172 + 3 - 0 bar. 10. Advance (S) 1300 Adjust screw on rocking lever to give

H.P. pipes: 6 x 1.8 x 450 mm 2.50 ± 0.50° ( 2.0 ± 0.4).

Re-shim if necessary.

PRE-TEST NOTES Lock locknut.

T.P. adjusting screw to protrude 10.5 mm from the underside 11. Advance (C) 2000 5.0 to 6.5°, ( 4.0o 5.2m).

of end plate sleeve plug. 12. Advance (S) 2000 6.5 - 7.0 ° (5.2 - 5.6 ust TP.

Remove CIA assembly, fit test plug 7244-572 and 13. Back leakage. (C) 2000 30 to 50 cm3 per 100 strokes.

advance gauge 7244-447 with spindle 7244-574 and Flow rate 600to 1000 cm3/min.

set to 0°. 14. Transfer Press. (C) 2600 7.6 to 9.7 bar(100 to 140psi)

Advance servo spring fitted with 4 mm shim, shim up to 6 mm max. Stop test machine.

Fully screw in pre-load & stroke adjusters, and remove locking Remove pressure gauges and fit stop solenoid or plug.

device from the torque control. 15. Max. Delivery (S)* 2000 43.3 ± 0.5 mm3/st.

TORQUE TRIMMER SHIMMING: Large 0.5 mm originally fitted. Shim up Rotate whole torque control assembly.

to 1.0 mm additional, if required. Small 0.5 mm shim originally Lock collar. Record delivery.

fitted, and may be removed but no additional shimming. Max.spread 1.0 mm3/st

Max speed screw to be positioned so that throttle Stop test machine and remove pre-load spring from torque control

ball centre is 96 mm from flange mounting face, throttle in device. Re-start machine and run up to 1000 rpm to latch out.

max.speed position. 16. Torque Curve (S)* 600 28.9 ± 1.0 mm3/st(Stroke adjuster)

Turn vernier plate and advance cam fully anti-clockwise. Stop test machine and replace pre-load spring. Re-start machine

Anti-stall screw to protrude 12 mm clear of its and vent as in test (1). Run up to 1000 rpm to latch out.

locknut. 17. Torque Curve (S)* 600 Delivery as test (16) ± 1.0 mm3/st

Pre-load adjuster fully backed off

Delphi Diesel Systems 2000 Page 1 -->

8523A320

Ford HSDI TEST PLAN Issue No: 5

00/00/00

without leaking. Shim if required. Wait for 30 seconds.

18. Torque Curve (S)* 600 Screw in pre-load adjuster to obtain Prime as at test (1).

delivery as test(16)+ ( 1.5 ± 0.5) Operate CIA mechanism.

mm3/st. 37. Excess fuel (C) 100 Minimum 5.5 cm3.

19. Delivery (C) 1250 7.9 to 8.9 cm3. 38. Timing S/C Outlet 'X ', Pressure 55 bar

20. Vernier plate (S) 2150 4.0 to 6.0 cm3. Offset 3.5 degrees against the

21. Advance- (S) 1200e t throttle to give 2.7 - 3.2 normal direction of pump rotation.

Low Load delivery. Adjust cam on lever to give Driveshaft torque 80 lbf.in

4.25 - 4.75to 3.8 mm)advance. Note : Outlet 'X' marked with No. 1

22. Governor (S) 2150 5.0 to 5.8 cm3. on outlet clamp plate.

23. Delivery (C) 2200 2.8 to 4.8 cm3.

24. Delivery (C)* 2000 As test (15) ± 0.4 mm3/st. REFER TO STATEMENT AT END OF EXPLANATORY NOTES REGARDING MAXIMUM

25. Throttle - (C) 2000 Throttle ball in max. speed position FUEL AND SPEED SETTING AND VARIATIONS IN ENGINE PERFORMANCE.

position to be 92 - 100mm from flange face. If

not reset to 96 mm, repeat tests

( 19 ) to ( 24 ).

26. Delivery (C)* 1250 As test (19) ± 0.5 mm3/st.

Move throttle lever to closed position.

Run test machine at 300 rpm before next test.

27. Throttle stop (S) 400 Insert 3.5 mm shim between throttle

lever & stop screw. Maximum 1.0 cm3.

Fit idle linkage.

28. Idle delivery (S) 400 Remove shim, set idle lever to give

1.0 to 1.7 cm3. Lock screw.

29. Throttle stop (S) 460 Maximum 0.5 cm3.

30. Anti-stall (S) 800 0.8 cm3.

31. Idle - Hot (C) 410 1.0 ± 0.3 cm3.

32. Idle - Cold (C) 540 4.5 ± 0.5 cm3.

33. Throttle travel (C) 410 20.0 to 31.5 mm.

Run test machine down to 100 rpm and stop.

Screw latch valve adjuster fully in.

34. Latch valve (S) 460 Unscrew latch valve. Delivery to be

4.0 to 7.0 cm3.

Stop test machine.

Wait for 10 seconds.

35. Latch out (C) 410 Delivery to be 9.0 cm3 Minimum.

500 Delivery to be 5.0 to 7.0 cm3.

36. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 0 cm3.

Stop machine, remove advance gauge and test plug, then re-fit CIA

device. Connect linkage to CIA and lever assembly in the "cold"

position, CIA spindle slot to align with marks on CIA body.

Re-energise solenoid.

Prime as at test (1).

Stop test machine.

Delphi Diesel Systems 2000 Page 2

S-ar putea să vă placă și

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 paginiTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 paginiTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215Încă nu există evaluări

- Test Plan Delphi TechnologiesDocument2 paginiTest Plan Delphi TechnologiesFRANCISCOÎncă nu există evaluări

- 8520A060A TestplanDocument2 pagini8520A060A TestplanBaytolga can100% (1)

- Test Plan: Pump SpecificationDocument3 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- 9320a217 TabelaDocument4 pagini9320a217 TabelaLIONN SOFTWARESÎncă nu există evaluări

- Test Plan: 9521A030: Pump SpecificationDocument3 paginiTest Plan: 9521A030: Pump Specificationjohnny sabinÎncă nu există evaluări

- 3042f843 Plano de TesteDocument1 pagină3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 9521A030H DATA CatalogDocument3 pagini9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 9320a225g Plano LHDocument3 pagini9320a225g Plano LHForteLubÎncă nu există evaluări

- 9320A093GDocument4 pagini9320A093GKevin TtitoÎncă nu există evaluări

- 3349F330Document2 pagini3349F330marco rod100% (1)

- Test Plan: Pump SpecificationDocument4 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- Inj - P Ump Cal Ibration DataDocument3 paginiInj - P Ump Cal Ibration DataСергей ВладимировичÎncă nu există evaluări

- DATODocument1 paginăDATOMiguel RojasÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©murillo_rodriguez8382100% (1)

- Dpico: Inj. Pump Calibration DataDocument6 paginiDpico: Inj. Pump Calibration DataGiovaniBalzaniÎncă nu există evaluări

- EE4760Document2 paginiEE4760OFFICE DANACÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration DataMiguel RojasÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- 7540Document10 pagini7540pruebaÎncă nu există evaluări

- Test SheetDocument3 paginiTest SheetNemo NeoÎncă nu există evaluări

- StanadyneDocument4 paginiStanadynemurillo_rodriguez8382Încă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument4 paginiDpico: Inj. Pump Calibration DataGiovaniBalzaniÎncă nu există evaluări

- 606 9291Document2 pagini606 9291Сергей ВладимировичÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- 606 9460Document2 pagini606 9460Alex PakitoÎncă nu există evaluări

- Injection Pump Test Specifications 196000-517#Document4 paginiInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- 104740-0976 - Ford RangerDocument6 pagini104740-0976 - Ford RangerBaytolgaÎncă nu există evaluări

- Pump Test Specifications: InjectionDocument3 paginiPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©LIONN SOFTWARESÎncă nu există evaluări

- Perkins - CAT EngineDocument2 paginiPerkins - CAT EngineAnky IsmasÎncă nu există evaluări

- 093000-1613 Hi̇no PDFDocument2 pagini093000-1613 Hi̇no PDFBaytolgaÎncă nu există evaluări

- 9161Document5 pagini9161BaytolgaÎncă nu există evaluări

- Test PlanDocument4 paginiTest PlanOFFICE DANACÎncă nu există evaluări

- Injection Pump Test Specifications 093000-677#Document3 paginiInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©Mr CupuÎncă nu există evaluări

- 093400-5350 Mitsubishi PDFDocument2 pagini093400-5350 Mitsubishi PDFBaytolgaÎncă nu există evaluări

- 3031 PDFDocument4 pagini3031 PDFMihai-Eugen Popa100% (1)

- STANADYNEDocument4 paginiSTANADYNECHRISTIAN LOZANOÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test SpecificationsMartin Miguel Gomez SalviÎncă nu există evaluări

- 101401-9271 Calibration DataDocument5 pagini101401-9271 Calibration Datamurillo_rodriguez83820% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 paginiS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument4 paginiInjection Pump Test SpecificationsJunior IungÎncă nu există evaluări

- (AD - DIESEL) - (21-01-2020) : Parts ListDocument17 pagini(AD - DIESEL) - (21-01-2020) : Parts ListVyacheslav ShatalovÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument3 paginiDpico: Inj. Pump Calibration DataСергей ВладимировичÎncă nu există evaluări

- lt1000d6 PDFDocument3 paginilt1000d6 PDFJo Ferry0% (1)

- 4720Document3 pagini4720Junior IungÎncă nu există evaluări

- (Oto-Hui - Com) Edc Hino s05Document2 pagini(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500Încă nu există evaluări

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 paginiInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungÎncă nu există evaluări

- f797 PDFDocument2 paginif797 PDFBest Auto TechÎncă nu există evaluări

- F 002 A0z 755 Spare PartsDocument17 paginiF 002 A0z 755 Spare PartsGowtham100% (1)

- 9412Document3 pagini9412Mihai-Eugen Popa100% (1)

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 paginiInjection Pump Calibration Data: 1. Test ConditionsElson DorigonÎncă nu există evaluări

- Control Elec Ecd-V3Document21 paginiControl Elec Ecd-V3Fabian Henao Calle100% (1)

- 02EN1630Document2 pagini02EN1630Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- 745 4410Document2 pagini745 4410murillo_rodriguez8382100% (1)

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocument3 paginiInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- 8961A020WDocument2 pagini8961A020WLTurboÎncă nu există evaluări

- 8921A091WDocument2 pagini8921A091WLTurboÎncă nu există evaluări

- A Second Possible Cause of Sudden Acceleration in Mitsubishi Montero VehiclesDocument16 paginiA Second Possible Cause of Sudden Acceleration in Mitsubishi Montero VehiclesJohn Mark AcederaÎncă nu există evaluări

- Adapt Parms GBDocument250 paginiAdapt Parms GBsergioutreraÎncă nu există evaluări

- R25 Service ManualDocument456 paginiR25 Service ManualLogesh S94% (16)

- Catalogo DipacoDocument393 paginiCatalogo DipacoJuan Gabriel Ochoa100% (3)

- Volvo Ems 2 01Document92 paginiVolvo Ems 2 01Rodrigo Gera100% (15)

- Yamaha 200 - Catalogo - D - Partes - F200bet 2014 1N6S1-200S1Document96 paginiYamaha 200 - Catalogo - D - Partes - F200bet 2014 1N6S1-200S1Esteban Elias Marquez EscalanteÎncă nu există evaluări

- LM1949Document14 paginiLM1949Rogério NevesÎncă nu există evaluări

- Motronic M2.3 PinoutDocument2 paginiMotronic M2.3 Pinouta1113289Încă nu există evaluări

- EX-2 Fuel Pump Timing Setting and AdjustmentDocument2 paginiEX-2 Fuel Pump Timing Setting and AdjustmentAayush Agrawal100% (1)

- 1 Self Diagnosis, Safety Measures, Cleanliness Regulations, DirectionsDocument9 pagini1 Self Diagnosis, Safety Measures, Cleanliness Regulations, DirectionsDanielÎncă nu există evaluări

- Avensis2 0cr-ServmanualDocument46 paginiAvensis2 0cr-ServmanualAmadeus De La CruzÎncă nu există evaluări

- Fuel System Diagnosis: Quick Training Guide - QT811ADocument12 paginiFuel System Diagnosis: Quick Training Guide - QT811AThang TongÎncă nu există evaluări

- Diseal EngineDocument33 paginiDiseal EngineTalha MaqsoodÎncă nu există evaluări

- Ajuste de Valvulas PDFDocument8 paginiAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- FC Edit Pro ManualDocument101 paginiFC Edit Pro Manualcarylangley100% (1)

- qst30 g5Document4 paginiqst30 g5Muhammed Ali NoureddeenÎncă nu există evaluări

- Fuel Injection AZLDocument100 paginiFuel Injection AZLAttila Modi100% (1)

- 6 X 1 AubecuDocument10 pagini6 X 1 AubecuMweene MuukaÎncă nu există evaluări

- Crankshaft Position For Fuel Injector Adjustment and Valve Lash SettingDocument2 paginiCrankshaft Position For Fuel Injector Adjustment and Valve Lash SettingHugo Cipriani100% (4)

- The New Delphi Injector Family - Architecture and PerformanceDocument17 paginiThe New Delphi Injector Family - Architecture and PerformanceMEKATRONIKA ARGENTINAÎncă nu există evaluări

- 1715 Mercedes Benz Mbe Motor 900 Caracteristicas MOTOR - MBE 900Document138 pagini1715 Mercedes Benz Mbe Motor 900 Caracteristicas MOTOR - MBE 900Bernardo Oliva100% (1)

- 1106D Training PresentationDocument64 pagini1106D Training Presentationbagus100% (7)

- Yamaha - Service Manual - F300aDocument572 paginiYamaha - Service Manual - F300aJorge Lopes100% (1)

- Montero v78Document334 paginiMontero v78tallermaeÎncă nu există evaluări

- Isuzu 4jb1Document50 paginiIsuzu 4jb1jads30117992% (13)

- Crdi System PDFDocument20 paginiCrdi System PDFsanath santhoshÎncă nu există evaluări

- Embraer 190 PowerplantDocument27 paginiEmbraer 190 PowerplantEstevam Gomes de Azevedo100% (3)

- Deutz 1008 Construction SpecsDocument6 paginiDeutz 1008 Construction SpecsPedro Alberto BenitesÎncă nu există evaluări

- GdiDocument2 paginiGdiKkbhuvan KkÎncă nu există evaluări

- Fuel Injector SpecsDocument8 paginiFuel Injector SpecsBekir KADIOĞLUÎncă nu există evaluări

- Automotive Electronic Diagnostics (Course 1)De la EverandAutomotive Electronic Diagnostics (Course 1)Evaluare: 5 din 5 stele5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadDe la EverandWhy We Drive: Toward a Philosophy of the Open RoadEvaluare: 4 din 5 stele4/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]De la EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Evaluare: 5 din 5 stele5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDe la EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceÎncă nu există evaluări

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVDe la EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVEvaluare: 5 din 5 stele5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)De la EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Încă nu există evaluări

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDe la EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionÎncă nu există evaluări

- The Official Highway Code: DVSA Safe Driving for Life SeriesDe la EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesEvaluare: 3.5 din 5 stele3.5/5 (25)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceDe la EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceÎncă nu există evaluări

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildDe la EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildEvaluare: 5 din 5 stele5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsDe la EverandTurbo: Real World High-Performance Turbocharger SystemsEvaluare: 5 din 5 stele5/5 (3)

- Top 21 Hypercars: The Best and Fastest Car Ever MadeDe la EverandTop 21 Hypercars: The Best and Fastest Car Ever MadeEvaluare: 3 din 5 stele3/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- Building Honda K-Series Engine PerformanceDe la EverandBuilding Honda K-Series Engine PerformanceEvaluare: 5 din 5 stele5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WDe la EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WEvaluare: 4.5 din 5 stele4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDe la EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyEvaluare: 5 din 5 stele5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDe la EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesEvaluare: 4 din 5 stele4/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)