Documente Academic

Documente Profesional

Documente Cultură

JLR Customer Specific Requirements For Ppap: Scope

Încărcat de

Vladimir RadulovićDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JLR Customer Specific Requirements For Ppap: Scope

Încărcat de

Vladimir RadulovićDrepturi de autor:

Formate disponibile

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

OVERVIEW CONTENT AUTHOR CONTENT OWNER

Rob Gordon (rgordon9) Rob Gordon (rgordon9)

This standard defines Jaguar Land Rover Limited's (JLR)

Customer Specific Requirements for the Production Part LAST PUBLISHED NEXT REVIEW DATE

18/12/2019 44183.61

Approval Process (PPAP).

OWNING FUNCTION(S) OWNING LOCATION

STA United Kingdom

SCOPE

WHY

1.1 OBJECTIVE/PURPOSE

To define deviations, additions or clarifications on JLR's requirements for use of AIAG's PPAP version 4.0 as used by

production suppliers. The AIAG PPAP process shall be the core tool for completing PPAP in support of JLR's Design and

Approve the Manufacturing Process procedure.

1.2 RISKS

Failure to follow these requirements can jeopardise the quality of event of PPAP and the Design and Approve the

Manufacturing Process.

WHAT

2.1 SCOPE AND EXCLUSIONS

These CSR's apply only to the use of the PPAP process for production suppliers to JLR, referred to as "the organisation".

2.2 RETENTION OF RECORDS

The organisation shall ensure that all documents and records either specified by Jaguar Land Rover Limited or created by the

organisation in order to demonstrate compliance with PPAP, have copies filed in the PPAP file.

The PPAP file and contents may use any suitable media (hard copy or electronic etc.) but shall comply with the IATF16949

requirement “7.5.3 - Control of documented information”. Upon completion, the PPAP file shall be retained according to

IATF16949 requirement “7.5.3.2.1 - Record retention” and shall be retained for the life of the part plus 12 years.

WHO

3.1 CONSULTATION PARTICIPANTS

Russ Perry (rperry19)

3.2 APPROVERS

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 1 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

Russ Perry (rperry19)

WHERE

4.1 APPLICABILITY

Applicability Operational

Functions/Departments STA

JLR Locations United Kingdom, Europe Region, China Region, North America

Region, Overseas Region

4.2 APPLICABLE KEY WORK SYSTEM(S)

6.08.01 Global Quality Strategy Development

4.3 APPLICABLE IT SYSTEM(S)

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 2 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

NARRATIVE

1. Applicability (PPAP section “Introduction”)

The "authorised customer representative" is the Supplier Technical Assistance (STA) engineer assigned to the organisation

site. STA Engineers are identified in Jaguar Land Rover Limited SIM (Supplier Improvement Metrics) on the Jaguar Land Rover

Limited Supplier Portal for each organisation manufacturing site.

Note: In this document, in alignment with PPAP 4.0, unless otherwise noted, the term "organisation" refers to the manufacturing

sites of external suppliers manufacturing production parts and products for Jaguar Land Rover Limited.

2 .Submission of PPAP (PPAP section 1.1)

The organisation shall submit PPAP as stated in Jaguar Land Rover Limited's Phased PPAP Requirements Handbook,

available through the Jaguar Land Rover Limited Supplier Portal.

The organisation shall ensure that all documents and records either specified by Jaguar Land Rover Limited or created by the

organisation in order to demonstrate compliance with PPAP, have copies filed in the PPAP file.

The PPAP file and contents may use any suitable media (hard copy or electronic etc.) but shall comply with the IATF16949

requirement “7.5.3 - Control of documented information”. Upon completion, the PPAP file shall be retained according to

IATF16949 requirement “7.5.3.2.1 - Record retention” and shall be retained for the life of the part plus 12 years.

The organisation shall maintain version control over documents as defined by IATF16949. The records in the PPAP file shall be

the document version used at the time of PSW and shall clearly distinguish between this and subsequent versions up to the

latest live version where documents are subject to ongoing review and update.

3 .Design Record (PPAP section 2.2.1)

For a design record to be acceptable, the design must be released and authorised for production in the Jaguar Land Rover

Limited Worldwide Engineering Release System (WERS).

The organisation shall ensure that the release level of the product specified by Jaguar Land Rover Limited Product

Development Engineering matches the product release level specified in the Supply Confirmation Plan from Jaguar Land Rover

Limited.

3.1. Branding

Organisations shall comply with the E108 Jaguar Land Rover Limited Automotive Parts and Accessories Branding directive,

available through the Jaguar Land Rover Limited Supplier Portal and specified in the PLMJLR.00.0028 Branding and Coding

drafting standard, available through the Jaguar Land Rover Limited Supplier Portal.

4. Reporting of Part Material Composition (PPAP section 2.2.1.1)

Jaguar Land Rover Limited materials reporting requirement and compliance details are specified in Jaguar Land Rover

Limited’s Restricted Substance Materials Standard (RSMS) STJLR.99.9999.

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 3 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

Materials reporting must be done via an IMDS (International Material Data System) submission.

The current Jaguar Land Rover Limited RSMS package is released each year in the "News" section of IMDS.

5. Marking of Polymeric Parts (PPAP section 2.2.1.2)

Design record requirements for marking of polymeric parts are specified in the drafting standard PLMJLR.00.0029, which is

cascaded as part of the Environmental Statement of Work.

6. Customer Engineering Approval (PPAP section 2.2.3)

The organisation shall obtain documented Jaguar Land Rover Limited Product Development Engineering approval of DV

(Design Verification) and PV (Production Validation) tests of the initial sample parts. The organisation shall conduct the PV

testing on parts/products which were produced at "run at rate" (refer to the Jaguar Land Rover Limited Phased PPAP

Requirements Handbook for a definition of "run-at-rate").

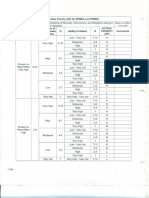

7. Failure Mode and Effects Analysis (PPAP sections 2.2.4 and 2.2.6)

Organisations shall meet the requirements of the Jaguar Land Rover Limited FMEA handbook when developing DFMEAs, and

PFMEAs (available through Jaguar Land Rover Limited Supplier Portal).

7.1. Design FMEA

Authorisation to create a single DFMEA for a family of similar parts or materials used in similar applications, environments, etc.

is available from Jaguar Land Rover Limited Product Development Engineering. Design FMEA(s) for safety and regulatory

component(s) prepared by design responsible organisations require Jaguar Land Rover Limited Product Development

Engineering approval.

All design Special Characteristics shall be recorded on the Special Characteristics Summary Sheet (SCSS) and a copy must be

retained in the PPAP file.

Jaguar Land Rover Limited reserves the right to review all organisation-developed DFMEAs.

7.2. Process FMEA

Characteristic traceability is required from the DFMEA through the PFMEA to the Control Plan. Such traceability can be

documented on the "Special Characteristic Summary Sheet" available through the Jaguar Land Rover Limited Supplier Portal.

Jaguar Land Rover Limited reserves the right to review all organisation-developed PFMEAs.

8. Control Plan (PPAP section 2.7)

For all PPAP submission levels (1 through 5), Control plan(s) for safety and regulatory (inverted delta) component(s) require

Jaguar Land Rover Limited Product Development Engineering review.

The Control Plan shall include provisions for on-going monitoring of process capability, stability and control.

Jaguar Land Rover Limited reserves the right to review all organisation-developed Control Plans.

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 4 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

8.1. Extraordinary Control Plans.

An Extraordinary Control Plan is an appendix to the Pre-Production Control Plan and defines non-standard processes and

controls implemented in support of Interim PSW’s. It shall utilise the same document format as the Pre-Production Control Plan.

These must be used for all deviations to the Pre-Production Control Plan where a non-standard process and/or process

controls are being used.

It must define what the non-standard process(es) are and what the means of control is to ensure the product fully conforms to

the Design Record or agreed deviation as defined on a WERS Alert.

The supplier must formally incorporate this document into their record system for traceability purposes and include it in the

PPAP file.

The document reference number, issue level and date for the Extraordinary Control Plan shall be defined on the PPAP

Checklist as part of the request for a WERS Alert. This metadata will be recorded in the WERS Alert itself to ensure traceability.

When the non-standard processes and/or process controls are removed and the production process fully complies with PPAP

requirements, the Extraordinary Control Plan shall be withdrawn and the Pre-Production or Production Control Plan followed.

The Extraordinary Control Plan shall identify a withdrawn date and be retained by the supplier in their record system for the life

of the PPAP file.

9. Measurement Systems Analysis Studies (PPAP 2.2.8)

Where measurement analysis studies are performed using software, the software is to be validated using standard input data

sets and checked using corresponding expected output results.

The preferred method for calculating Gauge R&R is by using the ANOVA method, since the ANOVA method allows

identification of the operator contribution, whereas the Average and Range or Range methods do not. Refer to the AIAG

published SPC manual, and the ANOVA method is available through commercial statistical software packages and the AIAG

APQP forms disk available from AIAG.

The organisation shall report the number of distinct categories (ndc). All variable gauge R&R studies should have a minimum

of 5 distinct categories (See Measurement Systems Analysis Reference Manual published by AIAG, refer to "ndc" in the index).

Gauge R&R as a percent of study < 10% is acceptable (the parts used for the Gauge R&R study must be representative of a

production run). If Gauge R&R as a percent of study is greater than 10%, but less than 30%, contact STA to determine if the

Gauge R&R is acceptable. If Gauge R&R > 30%, it is unacceptable and the organisation shall implement a corrective action

plan to improve measurement capability.

10. Material Test Results (PPAP section 2.2.10.1)

Where Jaguar Land Rover Limited specifies that materials are to be purchased from an approved supplier, the organisation

should contact the buyer to determine appropriate materials suppliers.

11. Initial process studies - Actions to be taken when acceptance criteria are not satisfied (PPAP 2.2.11.6)

The modified control method shall include techniques to incorporate mistake proofing methods into the manufacturing process

to prevent the shipment of non compliant product to Jaguar Land Rover Limited facilities.

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 5 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

Note: examples of mistake proofing methods include the modification of manufacturing processes to detect and discard non

compliant product (e.g., poke-yoke), or a gauge to ensure product compliance to specification where the process does not meet

the capability requirements. This is not the addition of a temporary manual inspection process at the end of the line.

The organisation shall continue to determine sources of variation, improve the process with permanent corrective actions, and

improve the process to meet the capability requirements.

11.1. The following are examples of measurement equipment mistake proofing methods

2.1 For Variable Gauges:

Two sided tolerances:Tolerances used for 100% inspection gauges can be reduced by the extent of the gauge R&R as a

percent of tolerance of the gauge(s) being used in the 100% inspection methodology. The typical practice is to remove half the

gauge R&R as a percent of tolerance from the upper specification limit and the other half from the lower specification limit.

Example: A variable gauge is used to check a product characteristic of 600 microns +/- 40 microns (this equates to 80 microns

specification tolerance spread). Additionally, this variable gauge has a gauge R&R as a percentage of tolerance of 20%. The

upper limit compensated for gauge capability would be 632 microns (600+40- 80 x 0.2/2) (Upper Specification – (Specification

tolerance spread x (% tolerance Gauge R&R)/2) and the lower limit compensated for gauge capability would be 568 microns

(600-40 + 80 x 0.2/2) (Lower Specification + (Specification tolerance spread x (% tolerance Gauge R&R)/2). This example

assumes the gauge error is equally distributed. Continue process variation reduction efforts until a Ppk greater than 1.67 is

achieved, or until STA approval is received.

One-sided tolerances: For a "less than" tolerance specification (e.g. length less than 20 mm) subtract three gauge R&R

standard deviations from the tolerance specification. For a greater than tolerance specification (e.g. plating thickness greater

than 10 microns) add three gauge R&R standard deviations to the tolerance specification. The converse applies if it is a "less

than" tolerance.

"Greater than" example: A variable gauge is used to check the length of a product characteristic. The product specification is

greater than 150 microns. The gauge R&R standard deviation is 2 microns. The specification compensated for gauge error

would be greater than 156 microns (150 + 3 x 2)

"Less than" example: A variable gauge is used to check the length of product characteristic. The product specification is less

than 150 microns. The gauge R&R standard deviation is 2 microns. The specification compensated for gauge error would be

less than 144 microns (150 - 3x2)

If business reasons exist to deviate from the recommendations listed above, contact STA to obtain concurrence.

Continue process variation reduction efforts until an acceptable process capability is achieved, or until STA approval is

received.

12. Qualified Laboratory Documentation (PPAP 2.2.12)

As per IATF16949 requirements.

13. Appearance Item Approvals (AAR) (PPAP 2.2.13)

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 6 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

All parts/products having appearance criteria shall be reviewed and approved by the appropriate Jaguar Land Rover Limited

activity. For the current AAR process contact your Customer Authorised representative.

After approval signatures have been obtained from the designated Jaguar Land Rover Limited representative, the AAR form

shall be included with the Warrant.

Note 1: Appearance items are: all interior, exterior, luggage compartment, and select under bonnet components which are

visible to the customer. Appearance approval includes, but is not limited to: overall appearance, surface quality, colour, texture,

and gloss.

Note 2: Visual "match-to-master" is the specified requirement for AAR sign-off. Numeric evaluations should only be used for on-

going quality control after visually acceptable parts/products are attained.

Note 3: There shall be no customer discernible texture, colour or gloss mismatch between mating or adjacent parts where the

design theme has designated they should appear harmonious.

14. Part Submission Warrant (PPAP sections 2.18 and 5)

See the Jaguar Land Rover Limited Phased PPAP Requirements Handbook available through the Jaguar Land Rover Limited

Supplier Portal for PPAP level and PSW submission requirements.

Warrants for Priority components (during vehicle launch) shall be reviewed and approved by both STA and PD as appropriate.

For post Job#1 PPAP submissions, the organisation is not to ship production quantities to the Jaguar Land Rover Limited

facilities until after PPAP and functional trial approval or functional trial waiver are obtained. The functional trial approval or

functional trial waiver is obtained after PPAP approval, and is managed by Plant Vehicle Team (PVT).

Note: For a supplier resource, or other reason for submission as deemed appropriate by the customer authorised

representative, a line trial should be carried out prior to submission of the Warrant. This additional Line Trial prior to Warranting

does not negate the need to carry out a functional trial approval once the part is warranted.

For PPAP submissions during a vehicle launch, the launch builds constitute the "functional trials" and therefore provide

approval to ship parts subject to plant releases.

Organisations are permitted to submit multiple part numbers (same family of parts) on a single PSW with all part specifics (e.g.,

prefix, base, and suffix) clearly noted on the PSW or on an attachment to the PSW.

The organisation must allow for STA approval timing (at least one week) ahead of the sample promise date.

15. Change Notification (PPAP section 3)

Tier 1 and Jaguar Land Rover Limited Directed Tier 2 (or lower tier) suppliers to Jaguar Land Rover Limited are required to

obtain Jaguar Land Rover Limited approval prior to implementation of any organisation-initiated or supplier-initiated change per

the Jaguar Land Rover Limited SREA (Supplier Request for Engineering Approval) Process. The requirements of section 3.1 in

PPAP are met by following the SREA process (the SREA requirements are available through the Jaguar Land Rover Limited

Supplier Portal).

16. Records Retention (PPAP section 6)

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 7 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

The PPAP file and PSW records shall be retained for the life of the active part plus 12 calendar years.

17. Appendix A – Completion of the Part Submission Warrant (PPAP sections 2.18 and 3)

See Jaguar Land Rover Limited's Phased PPAP Handbook for instructions on PPAP and PSW submission requirements,

available through Jaguar Land Rover Limited Supplier Portal.

18. Appendix G – Tyres – Specific Requirements

Organisations supplying tyres to Jaguar Land Rover Limited shall meet all requirements of PPAP.

The tyre appendix is not applicable to organisations supplying tyres to Jaguar Land Rover Limited.

19. Special Characteristics (PPAP Glossary)

Jaguar Land Rover Limited special characteristics are defined in the Jaguar Land Rover Limited FMEA handbook.

20. Labelling Requirement

For all shipments of new or changed product the organisation is required to follow local current practice – contact the local

Jaguar Land Rover Limited MP&L (Material Planning and Logistics) for assistance.

Note: Critical Characteristics are those product requirements (e.g., dimensions, performance tests) which are part

characteristics or process characteristics that can affect compliance with government regulations or safe vehicle/product

function, and which require specific organisation, assembly, shipping, or monitoring and are included on Control Plans. Critical

Characteristics are identified either by the inverted delta symbol (▼) or CC designation.

REVISION HISTORY

Date of Written / Revised by Issue Summary of and reason for the new issue / revision.

Issue/Revision level

1st Sep 2010 R.Gordon 1.0 Initial release of JLR document.

1st Mar 2016 R.Gordon 2.0 Section 8.1 updated to describe the requirement for and use

of Extraordinary Control Plans for non-standard processes.

9th Jun 2017 R.Gordon 3.0 Sections 2 and 16 updated to reflect JLR’s revised record

retention requirements for the PPAP file.

References to ISO/TS16949 updated to IATF16949.

12th July 2019 R.Gordon 3.1 Annual file review, no process changes.

9th Dec 2019 R.Gordon 3.2 Transferred contents to JLR Way template format, no process

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 8 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

changes.

18th Dec 2019 R.Gordon 3.4 Correction of issue level number.

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 9 OF 1 0

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

OPERATIONAL

JLR-STN-550990, ISSUE LEVEL 3.4

JLR CUSTOMER SPECIFIC REQUIREMENTS FOR PPAP

THE JAGUAR LAND ROVER WAY

APPENDICES

Appendix 1: Other Translations

English (Master)

Appendix 2: Variations

There are no other variations available for this document.

Appendix 3: Waivers

There are no waivers for this document.

Appendix 4: Internal Controls

No internal controls apply to this document.

SECURI T Y CL ASSI F I CATI O N Pro p ri e t a ry

RET ENT I O N JL R- RM P I T EM 25 . 0 1 S + 1 2

JL R- ST N- 55 0 9 9 0 UNCO NT ROL L ED WHEN DO WNLO ADED O R PRI NT ED PAG E 10 O F 10

JL R Cu st o me r Sp e c i f ic Re qu i re me n t s fo r PPAP

I SSUE 3 .4 , L AST REVI EWED 1 8 / 1 2/ 2 0 1 9

S-ar putea să vă placă și

- TML SQ Manual-Version 2.1 PDFDocument64 paginiTML SQ Manual-Version 2.1 PDFRAJASEKARSUBHU100% (3)

- Template Q-Offer v1 2Document25 paginiTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- Volkswagen Group CSR IATF 16949 Jan 2018Document6 paginiVolkswagen Group CSR IATF 16949 Jan 2018NarasimharaghavanPuliyurKrishnaswamyÎncă nu există evaluări

- VDA - AK 8D Definition of Failure Cause Categories For 8D ReportingDocument8 paginiVDA - AK 8D Definition of Failure Cause Categories For 8D ReportingCiprian Raileanu100% (1)

- FORD 8D FormatDocument3 paginiFORD 8D Formatuvhajare100% (2)

- VW 60564 enDocument5 paginiVW 60564 enRicardo VitorianoÎncă nu există evaluări

- enDocument50 paginienIonelMiocÎncă nu există evaluări

- Manual KPM-QS Users Guide V2 2Document40 paginiManual KPM-QS Users Guide V2 2EnriqueÎncă nu există evaluări

- Warnings Errors in ImdsDocument62 paginiWarnings Errors in ImdsJesús AlejandroÎncă nu există evaluări

- Supplier Quality A Complete Guide - 2020 EditionDe la EverandSupplier Quality A Complete Guide - 2020 EditionÎncă nu există evaluări

- CQI.9.Heat Treat System AssessmentDocument51 paginiCQI.9.Heat Treat System AssessmentDung Tran KienÎncă nu există evaluări

- AIAG - CQI-9 - Heat Treatment System AssessmentDocument72 paginiAIAG - CQI-9 - Heat Treatment System Assessmentvenkateswaran100% (2)

- APQP WhitePaperDocument14 paginiAPQP WhitePaperAbhinav TushantÎncă nu există evaluări

- Requirements Comparison TS16949 VDA61Document22 paginiRequirements Comparison TS16949 VDA61TarunaiÎncă nu există evaluări

- Supplier Quality Requirements: Key Elements Procedures # 2Document14 paginiSupplier Quality Requirements: Key Elements Procedures # 2Juan DavidÎncă nu există evaluări

- Volkswagen Group Customer Specific Requirements March 2022 1Document6 paginiVolkswagen Group Customer Specific Requirements March 2022 1Tania HernandezÎncă nu există evaluări

- Ashok LeylandDocument2 paginiAshok Leylandindu296Încă nu există evaluări

- ANPQP 2.1 - ChangesDocument25 paginiANPQP 2.1 - ChangeskoalaboiÎncă nu există evaluări

- Autoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088Document4 paginiAutoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088krishnamartial8269Încă nu există evaluări

- Vda 6-3Document7 paginiVda 6-3julio_0489Încă nu există evaluări

- 6 Iatf 16949 Certification Cheat SheetDocument5 pagini6 Iatf 16949 Certification Cheat Sheet88No1FanÎncă nu există evaluări

- Volkswagen Group Customer Specific Requirements Feb 2022Document6 paginiVolkswagen Group Customer Specific Requirements Feb 2022Ivonete VieiraÎncă nu există evaluări

- Dead Endclamp Failure AnalysisDocument26 paginiDead Endclamp Failure AnalysisRK KumarÎncă nu există evaluări

- Rule Quality Automotive enDocument16 paginiRule Quality Automotive enLhabib AlaouaÎncă nu există evaluări

- GQS-0001-18 Aluminium MDI CansDocument14 paginiGQS-0001-18 Aluminium MDI Cansmd akbarÎncă nu există evaluări

- SFMEA Check ListDocument16 paginiSFMEA Check ListIgnacioÎncă nu există evaluări

- Customer Specific Requirements - PPAP (2014!03!05)Document7 paginiCustomer Specific Requirements - PPAP (2014!03!05)diablo2250Încă nu există evaluări

- 01 - APQP Training Material PDFDocument62 pagini01 - APQP Training Material PDFMohit SinghÎncă nu există evaluări

- Q1 2nd EditionDocument20 paginiQ1 2nd EditionAndres Vargas RoldanÎncă nu există evaluări

- IATF 16949 GM CSR Jan 2023Document27 paginiIATF 16949 GM CSR Jan 2023Jesus Jay MedinaÎncă nu există evaluări

- VDA-RGA Questionaire V2.0Document70 paginiVDA-RGA Questionaire V2.0docsenÎncă nu există evaluări

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocument14 paginiIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- FG52806 - 12-04-2010Document13 paginiFG52806 - 12-04-2010Roberto Carlos100% (1)

- International Automotive Task Force TS16949 To IATF16949 Transition StrategyDocument44 paginiInternational Automotive Task Force TS16949 To IATF16949 Transition StrategyyatheendravarmaÎncă nu există evaluări

- IATF - International Automotive Task ForceDocument10 paginiIATF - International Automotive Task ForceBeli NovareseÎncă nu există evaluări

- Bmw Spqm 供应商管理Document30 paginiBmw Spqm 供应商管理isolong100% (1)

- ANPQP - 3.0 - Category 1Document6 paginiANPQP - 3.0 - Category 1jefry sitorusÎncă nu există evaluări

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 paginiFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadÎncă nu există evaluări

- CQI 9 3rd Edition Errata SheetDocument2 paginiCQI 9 3rd Edition Errata SheetANONIMOÎncă nu există evaluări

- Copper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForDocument7 paginiCopper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForgoggerÎncă nu există evaluări

- 1 - What Is ASES, 2 - Explanation of The QuestionnaireDocument50 pagini1 - What Is ASES, 2 - Explanation of The QuestionnaireCarlos AguilarÎncă nu există evaluări

- Escalation Procedure Updated 020915Document30 paginiEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- FMEA TablesDocument7 paginiFMEA TablesMohamedÎncă nu există evaluări

- VDA 6.3-Analysis Tool: User ManualDocument23 paginiVDA 6.3-Analysis Tool: User ManualIstvan KisÎncă nu există evaluări

- IATF 16949 GM CSR Aug 2023Document30 paginiIATF 16949 GM CSR Aug 2023Cisca NattÎncă nu există evaluări

- Service PPAP, 1 EditionDocument8 paginiService PPAP, 1 EditionDesmond MahadeoÎncă nu există evaluări

- Redesigning Enterprise Process For E-BusinessDocument211 paginiRedesigning Enterprise Process For E-BusinessMuarif AsdaÎncă nu există evaluări

- Nissan Green Purchasing Guideline eDocument29 paginiNissan Green Purchasing Guideline eErick HernándezÎncă nu există evaluări

- TRATON Customer Requirements: Quality Assurance Agreement For Purchased Parts & OrganisationsDocument27 paginiTRATON Customer Requirements: Quality Assurance Agreement For Purchased Parts & OrganisationsLeandro RodriguesÎncă nu există evaluări

- Customer Specific Requirements MatrixDocument4 paginiCustomer Specific Requirements Matrixjefry sitorusÎncă nu există evaluări

- D0031 (2012-N) NES: Marking of Polymeric PartsDocument16 paginiD0031 (2012-N) NES: Marking of Polymeric PartsDiego CamargoÎncă nu există evaluări

- Vda FQF Training For SMMT Nec For UploadDocument50 paginiVda FQF Training For SMMT Nec For Upload57641Încă nu există evaluări

- Layout Inspection Report XH5DR June 20 2012Document17 paginiLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Q1 Rules Ref CardDocument10 paginiQ1 Rules Ref Cardparigomo2Încă nu există evaluări

- Aiag Ppap4Document75 paginiAiag Ppap4tamtom75Încă nu există evaluări

- GB8410 2006 enDocument46 paginiGB8410 2006 enDiego Camargo100% (1)

- Checklist Audit ISO TS 16949Document14 paginiChecklist Audit ISO TS 16949Demi RamaÎncă nu există evaluări

- IATF Rules 5th Edition - Sanctioned Interpretations - July2017 PDFDocument2 paginiIATF Rules 5th Edition - Sanctioned Interpretations - July2017 PDFgeocastella100% (1)

- Eco Labelling Programme - Iso 14024Document7 paginiEco Labelling Programme - Iso 14024Maureen Grace LebriaÎncă nu există evaluări

- MMOG FinalDocument26 paginiMMOG FinalSelvaraj SimiyonÎncă nu există evaluări

- SQ-2102 Aug2017Document15 paginiSQ-2102 Aug2017ubllcÎncă nu există evaluări

- Fsqm-080 Ppap ChecklistDocument14 paginiFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- JLR-STN-550990 - JLR Customer Specific Requirements For PPAP V8.1Document11 paginiJLR-STN-550990 - JLR Customer Specific Requirements For PPAP V8.1dhuntÎncă nu există evaluări

- FMEA AIAG-VDA - Commentary and Case Study: February 2020Document9 paginiFMEA AIAG-VDA - Commentary and Case Study: February 2020Mariana SotoÎncă nu există evaluări

- Iso 9000Document22 paginiIso 9000Irfan Ahmed100% (1)

- Supplier - Quality - Manual - F4033735-Jan 2021Document31 paginiSupplier - Quality - Manual - F4033735-Jan 2021Ritesh DevrajÎncă nu există evaluări

- AIAG Core Tools Support Software Launch Mar 26 2019 FINALDocument80 paginiAIAG Core Tools Support Software Launch Mar 26 2019 FINALedgar rosalesÎncă nu există evaluări

- AIAG - Failure Mode and Effects Analysis (FMEA) Reference Manual - 3ed, 2001 (95, 93)Document88 paginiAIAG - Failure Mode and Effects Analysis (FMEA) Reference Manual - 3ed, 2001 (95, 93)Luis Gustavo PachecoÎncă nu există evaluări

- Guia Bolsillo Auditor Interno AutomotrizDocument42 paginiGuia Bolsillo Auditor Interno Automotrizjuande69Încă nu există evaluări

- T2 VSA With RequirementDocument8 paginiT2 VSA With RequirementSandeep K Malhotra100% (3)

- Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon, Structural, High-Strength Low-Alloy, and High-Strength Low-Alloy With Improved Formability, General Requirements ForDocument11 paginiSteel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon, Structural, High-Strength Low-Alloy, and High-Strength Low-Alloy With Improved Formability, General Requirements ForDarwin DarmawanÎncă nu există evaluări

- Honda - CSR-2014 PDFDocument82 paginiHonda - CSR-2014 PDFluqmanÎncă nu există evaluări

- CQI 10 Effective Problem Solving GuidelineDocument208 paginiCQI 10 Effective Problem Solving Guidelinehenrycht100% (4)

- Rough Transition To IATF 16949 Presentation For Customers-EstadisticaDocument35 paginiRough Transition To IATF 16949 Presentation For Customers-EstadisticalabpresaÎncă nu există evaluări

- IATF 16949 Failure Mode and Effects Analysis Statistical Process ControlDocument1 paginăIATF 16949 Failure Mode and Effects Analysis Statistical Process ControlGaneshÎncă nu există evaluări

- The New Standard To Analyse Risks Within The Automotive Supply ChainDocument8 paginiThe New Standard To Analyse Risks Within The Automotive Supply ChainYoga AdiÎncă nu există evaluări

- Supplier APQP Overview Training - ExternalDocument10 paginiSupplier APQP Overview Training - ExternalKarthick MÎncă nu există evaluări

- The Practitioners Guide: 2019 Aiag-Vda FmeasDocument10 paginiThe Practitioners Guide: 2019 Aiag-Vda Fmeaskrishnan100% (3)

- FOPUR06 Supplier Quality Manual Rev 10 PDFDocument39 paginiFOPUR06 Supplier Quality Manual Rev 10 PDFDavid EnriqueÎncă nu există evaluări

- GPAP - PPAP Overview Training - 02!12!10 (Compatibility Mode)Document23 paginiGPAP - PPAP Overview Training - 02!12!10 (Compatibility Mode)Sharat GuptaÎncă nu există evaluări

- APQP GoodDocument70 paginiAPQP Goodtrung100% (1)

- Advanced Product Quality PlanningDocument35 paginiAdvanced Product Quality Planninggerry3854100% (2)

- Supplier Manual TribarDocument17 paginiSupplier Manual TribarAvyan Kelan100% (1)

- What Is A PPAP?: Frequently Asked Questions RegardingDocument4 paginiWhat Is A PPAP?: Frequently Asked Questions RegardingLoganathan ThulasiÎncă nu există evaluări

- Production Part Approval ProcessDocument11 paginiProduction Part Approval ProcessDorian GrayÎncă nu există evaluări

- Introduction and Instructions: ForewordDocument20 paginiIntroduction and Instructions: ForewordDanang WidoyokoÎncă nu există evaluări

- Aptiv Customer Specific Requirements June 20th 2022Document15 paginiAptiv Customer Specific Requirements June 20th 2022Hosam Elden Mostafa MasaranyÎncă nu există evaluări