Documente Academic

Documente Profesional

Documente Cultură

ETP Design

Încărcat de

HRK650%(1)0% au considerat acest document util (1 vot)

142 vizualizări12 paginietp design

Titlu original

ETP design

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentetp design

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0%(1)0% au considerat acest document util (1 vot)

142 vizualizări12 paginiETP Design

Încărcat de

HRK65etp design

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 12

WPI TECHNICAL OFFER Page No7,

WPIL-TECH-00 ®

PROJECT : 70 MLD UASB SIP at GHAZIABAD (CHA)

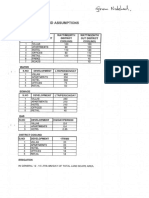

SECTION 3.0

DESIGN CALCULATION FOR PROCESS UNITS

1. DESIGN OF SCREENS

Design Data

AV. Flow 70 MLD 0.81 m3/sec

Peak flow 0.81 x2.25 1,82 m3isec.

‘Velocity thr” screen at peak flow = 06 t01.2 misee (say 1.0 m/sec)

Velocity thr’ screen at av. flow = 03 m/sec

Net Projected area of screen sholud not be less than 25% of X- sectional area of the channel

Bar size and spacing = 6 mm bar at 6mm clear distance.

Design Calculations =

‘Net Area required at peak flow = Qpeak /V peak

= 182/10 = 182. m2

Net Area required at av. flow Quy. Vay.

0.81/03 = 27m

ination of the screen as 60 degrees to base.

2Txsin60 = 2.33m2

hence providing Net Area of 2.7 m2 an

Net projected Area required

Providing Liquid height of 1.5 mtrs-+0.5 mtrs F.B., Total Height 2.0 mtrs

Net width (water way) required = 233/15 1.60 murs.

Now for clear spacing of 6mm,

No. of openings 1600/ 6 = 267 n0s.

No. of Bargs 267-1 266 nos.

Gross width of chennel = No of openings x clear spacing + No of bars x width of bar

267x6 +266 x6

3198 mm = 3.20mi.

Pletform

Inlet

ee

13 12 1S 1.0

Total Length of Screen Chamber = _Dist betn inlet to screen + Projceted length of screen +

plaform + Outlet length

= LOmus+H/tan 60 + 1.5 mers + 1.0 mts

10 +2/tan60415+1 = — 5.0mtrs.

Designed By: STC ‘Checked By : SAP.

Rev. No: 00 Dated

10, 1997

Writ, TECHNICAL OFFER Page Nos

WPIL-TECH-00

PROJECT : 70 MLD UASB STP at GHAZIABAD (CHA)

SSeS Ee Ee ee eee ee eee)

Cheek for Area:

Gross area of Channel Width x LD = 32x 15 = 48 m2

Net Projected Area = (Noof openings x clear spacing) * LD

(267x6 11000) x 1.5

= 2.403 m2 ;

Net projected Area / Gross Area 24/48 50% > 25'fhence design is OK

Cheek for Head Loss :

Head loss through scrcen is given by Krischmer

ho = BGw/b) Hy xsind

where,

h* = head oss in sereen

B = __ Bar Shape factor ~ 2.42 for flats

wo = Bar width = 6mm

b = Bar spacing = 6mm

Ho = ‘Approch velocity head = V"/2g

where V= 1.85 m3/s/ (3.2.x 1.5) = 0.38 m/s at peak flow for

clear screen

and_V = 0.77 m/s when the screen is half clogged at peak flow.

so Hv ~ (0.77))?/(2x9.81) = 0.03 mtrs at peak flow when the screen is half clogged

Head Joss at this condition

h 242-x (616) x 0.03 x Sin 60

0.063 mtrs

6.3 em < 20 cm head loss allowed hence design is Ok

SUMMARY FOR DESIGN OF SCREEN:

MECHANICAL SCREEN +

‘SCREEN CHAMBER SIZE

3.0 M LENGTH x3.2M WIDE x15MLD+

0.5 MFB

6 MM x30 MM MS FLATS AT 6 MM CLEAR

SPACING.

BAR SPECIFICATIONS

ANGLE OF SCREEN

MANUAL SCREEN OF THE SAME SPECIFICATION EXCEPT BAR SPACING AT 10MM

CLEAR TO BE PROVIDED.

INLET CHAMBER OF 3.2 Mx3.2M ALONG WIDIH OF MECHANICAL SCREEN TO BE

PROVIDED

Design Reference : Wastewater Treatment Rao & Datta And CPAEEO Manual

Designed By STC ‘Checked By : SAP

Rev. No. Dated: April 10, 1997

WPIL,

‘WPIL-TECH-00

TECHNICAL OFFER Page Noo

PROJECT : 70 MLD UASB STP at GHAZIABAD (CHA)

HEE

2. DESIGN OF GRIT CHAMBER

Design Data:

Av. Flow 70 MLD = 0.81 m3/sec

Peak flow 081x225 1.82 m3/see,

Detention Time : 60 seconds

Particlesize =: =D = 015mm

SpGrvity : S 2.65

“Temp 20 Deg, cent.

Correction factor for inlet & outlet = Brow

‘Velocity of flow in grit chamber 0.3 mis

1"

Design Calculations =

Horizontal Flow velocity of the efiluent is geiven by

Wate {(BB/) +g * (S-1) *D}°*

Where

8 ‘Shape factor for the particle

£ = Friction Factor = 0.03, therefore

Vaoo™ {(8 * 0.06 / 0.03) * 981 * (2.65-1) * 0.015 }°*

19.7 cm/sec (0.197 m’sec)

Now Cis Area of the Grit= Qpeak/ Vy = 1.82/0.197 = 92 m2

Providing 2.Nos of working +2 Standby Channels of Each width = 3.5 mrs.

Liquid Depth inthe channel will be= 9.2/(2* 3.5) = 1.35 mus

Now Total Depth of GritChannels = LD + Space for Grit accumulation + FB

135 + 034035

= 20:mirs.

To Find Length of Grit Chamber

Settling Velocity of Grit

Vs = {(4/3) *(@/CD) * (S-1)* D}*

Where CD is newtons Drag Coef'= 24/R + 3/(R)** + 0.34

where R is Reynolds no. = Vs*D/v

v= Kinematic viscosity of effluent = 1.002 x 10" at 20 Deg. Temp.

‘As settling velocity and Reynolds no, are interdependednt solving this loop with help of computer

we get Vs = 1.65 cm/sec,

‘Checked By : SAP.

Designed By : STC

Rev. No

Dated A

10, 1997

Writ, TECHNICAL OFFER Page No.10

WPIL-TECH-00

PROJECT : 70 MLD UASB STP at GHAZIABAD (CHA)

Now for ideal settling, the smallest grit pa rticle sholud settle dwon before it leaves the chamber.

Vs/Vu - Liquid Depth / L

1.69 / 19.7 = 135 1 L

L theorotical = 15.7 mrs,

Providing 50% additional length as comection for inlet and outlet turbulance.

Lactual = 1s7* 15 24.0 mis.

Design of Proportional Flow Weir:

LD

‘The flow through this weir is given by

Qpeak - C*b* (ag)? * (LD- 2/3)

where C = — constant’ «= 0.61

a as shown in fig isin range generally 35 mm.

therfore

1.85/2 0.61 * b* (2 *9.81%0.035)"" * (1.35 - 0.035/3)

>’ = 1.36 mers.

Now co ordinates of the curve can be found out by

x = b2* (Lele tan Vet)

Designed By: STC ‘Checked By : SAP

Rev.No_ 00 Dated: April_10, 1997

WIL TECHNICAL OFFER ‘Page Nol

WPIL-TECH-00

[ PROJECT + 70 MLD UASB STP ai GHAZIABAD (CHA)

[esceeeneee aea I

Slope for Grit Chamber

Head loss in the t channel is given by Mannings formula

v Va R™ 8%

where Y= Qpeak/area = (1.85/2)/ (3.5 * 1.35) = 0.19 misec

Rea 35" 135/G5H352) = 0.76 mts.

n= friction coeff. = 0.013

therefore

019 = (1/0013 *0.76 S?

s = 8.7x 10%

Hence provide minimum slope to the bottom of Grit Chamber

SUMMARY FOR DESIGN OF GRIT CHAMBER

—

GRIT CHANNEL SIZE Th) M LENGTH x3.5M WIDE x135 MLD

+035 MFB+0.3M GRIT ACCUMULATION

DEPTH,

NO OF CHANNELS 2 WORKING + 2 STANDBY

FLOW CONTROL EQUIPMENT PROPORTIONAL WEIR

OUTLET CHAMBER OF 14.0 MX3.0M ALONG WIDTH OF GRIT CHAMBER

[Daa ene ee Teen Rae Da CED Nene wa

[Designed By: STC ‘Checked By: SAP ty

Dated ‘April_10, 1997

sroqueyy 11D,

Caer TECHNICAL OFFER PageNol2

WPIL-TECH-00

PROJECT + 70 MLD UASB STP at GHAZIABAD (CHA)

_lL —|

DESIGN OF UASB REACTORS

Design Data

Av.Flow =: T0MLD 0.81 m3/see

Peakflow > 081x225 182 m3/see

BOD of influent 200 mit

‘TSS fn influent = 400 melt

YSS in_infuient = 240 melt

SRT = 38 Days

CIC distance between gas domes = 4 mis

Feed inlet. coverage = 4m2 / feed point

Velocity through aperature at peak flow

Velocity in settler zone

Design Calculations ;

5.0 m/hr

less than 1.5 m/hr

Upflow Velocity in the Reactor at peak flow Qpeak / Area

15 = (70,000 * 2.25/24) / (Area)

Area = 4375 m2

Providing 4 Reactors of 40 m. length x 30 m. Total Area provided = 4800 m2

Now,

SRT indays = Total Solids in Reactors (Kgs) / Solid out flow from reactor (Ke/day)

For UASB Reactor Total Solids in Reactor= Av. MLVSS * (Ht, of Sludge Bed + Blanket ) * Area

Ay. MLSS will be @ 5% (50 Ke/m3)

therefore Solids in Reactor = 50 * Hb * 4800

Solid out flow from Reactors = Excess sludge production in Reactor

+ Fixed TSS in influent + Undigsted VSS

= 70000 * 300 *0.08/1000 + 160 * 7000/1000

+0.5*240*70000/1000

= 21280 Kg /day

Now

SRT = — 50* Hb* 4800 / 21280

38 1127 * Hb therefore Hb= 3.4 mrs

it + Height ofsettling zone + FB

Height of Reactor = Sludge Bed Hei

5.5 mtrs (Liquid Depth = 5 mtrs)

= 243405

HRT of Reactor at av flow = = 82 hrs OK

Designed By : STC

Rev.No__: 00

(4*30 * 40 *5)/(70,000/24)

‘Checked By : SAP

Dated: April 10, 1997

Writ, TECHNICAL OFFER Page No.3

WPIL-TECH-00

PROJECT + 70 MLD UASB STP at GHAZIABAD (CHA)

Co _L —_t

Length of Reactor / cle distance

40/4

10 Nos per Reactor

Keeping The Gas Hood at 0.55 mtrs height from deflector Beam

No of Rows of of Gas Domes / Reactor

2 x No of Rows x width of Reactor x 0.55

2 x10 x 30 x0.55

= 330 m2

‘Total Area of Aparture / Reactor

Velocity through Aperature at peak flow = Peak flow per Reactor / Area of Aparture

= @25*70,000/424) | 330

497m/s <5.0m/§ OK

No. of Feeding points per Reactor = ~—=— tea of Reactor /4

= 3054014

= 300 Nos.

Provide 320 Feeding points / Reactor

Expected Results from UASB Reactor :

BOD Reduction 80%

COD Reduction 65%

Gas Production : 0.2 m3 / Kg BOD reduced

SUMMARY FOR DESIGN OF UASB REACTORS :

WO, OF UASB REACTORS: a

‘SIZE OF EACH REACTOR, 40M LENGTH x30M WIDIHx 5MLD + 05M FB

NO. OF GAS DOME ROWS PER | 10

REACTOR

iO OF FEEDING POINTS

3207 REACTOR

[Design Reference : WPIL field Experience in UASB Reactor

Designed By : STC ‘Checked By : SAP

‘Rev. No 00, Dated prl_10, 1997

Wri, TECHNICAL OFFER PageNot

WRIL-TECH-00

PROJECT + 70 MED UASB STP ai GHAZIABAD (CHA)

4 DESIGN OF GAS HOLDER

Design Data

Av. Flow 70 MLD : 0.81 m/sec

Peak flow 081x225 = 1.82 m'seo

BOD of influent = 200 mefit

Design Caleualtions +

BOD reduction in UASB Reactor 80%.

Biogas Production coeff. for sewage

‘Total Biogas Production

Gas Holder Capacity

Providing Dia of the Gas Holder Dome

Height of Gas Holder Dome

Diameter of Gas Holder Basin

Height of Gas Holder Basin

0.2m*/ Kg BOD Reduced

0.2 * 70,000 * 200//1000 * 80%

2240. m’ /day

25% of Gas Produced per day

(As per CPHEEO Manual)

560.m3

140 mts

3.7 mrs.

1440.6 = 14.6 mts

3.6406 = 420 mts.

SUMMARY FOR DESIGN OF UASB REACTORS :

DIAMETER OF GH. DOME 14.0 MTRS.

HEIGHT OF GH. DOME 3.70 MTRS

DIAMETER OF GH. BASIN 14.60 MIRS,

HEIGHT OF GH. BASIN 430 MTRS.

GAS PRODUCTION COEFF. 0.2m3) KGBOD REDUCED

TOTAL GAS PRODUCTION 72240 m3 7 DAY

Design Reference + WPIL field Experi

[Designed By: STC

[Rev.No 00

[ Checked By: SAP

[Dated : April_10, 1997

Writ, TECHNICAL OFFER, Page No.15

WPIL-TECH-00

PROJECT + 70 MLD UASB STP at GHAZIABAD (CHA)

5 DESIGN OF FINAL POLISHING UNIT

Design Data

Ay. Flow 70MLD 0.81 m/sec

Noof FPU’s = 2

HRT 24 Hours.

Design Caleulations :

‘Total Volume Required of the FPU Flow * HRT / 24

70,000 *24/ 24

70,000 m3

No of FPU's 2

Volume of cach FPU 35,000 m3

Providing SWD « 1.50 m,

Ay, Size = 153 mtrs x 153 mtrs

FB. = 030mtrs.

Depth of Sludge accumulation = 0.20 miss

Side slope = V1 8

Bach FPU tohave two compartments to increase length of flow.

SUMMARY FOR DESIGN OF FINAL POLISHING UNIT :

NO.OF FPU's (Working Paraliel_in normal conditions)

"AV SIZE OF EACH FPU 153.0 M LENGTH x 153 M WIDTAx I.5M LD +

M_EB #0.2M. SLUDGE ACCUMULATION DEPTH

SIDE_SLOPE iv; isn

Design Reference : WPIL field Experience in UASB Reactor Poe

‘Designed By : STC ‘Checked By : SAP.

Rev.No_:00 Dated: April 10, 1997

TECHNICAL OFFER,

WPIL-TECH-00

PROJECT + 70 MLD UASB STP at GHAZIABAD (CHA)

6 DESIGN OF SLUDGE DRYING BEDS

Design Data +

‘Av. Flow 70MLD = 081 see

Influent BOD = 200 melt

‘No of Days per eyele = Tdays

‘Number of eycles in years = for 10 months

Depth of application of sludge = 2 ems.

Design Caleulations =

Quantity of sludge produced perday = ‘Sludge Dus to BCOD + Undigested VSS + Fixed

Solids

= 7000 *300 *0.08/1000 + 0.5%240*70000/1000

+ 70000 * 160/100

= 21280 Kg/day

The Solid Content of the sludge will be about 6 % (60 Kg/ m3)

‘Volume of Sludge Produced = 21280 /60= 355 m3/day

Volume of Sludge * Drying Period / Depth of

aplication

Area of SDB Required

3557 /0.2= 12425 m2

Now as One sudge drying Bed should take sladge from one Reactor and withdraw is 5 days aweek

No. Of SDB required will be 20

Hence Area of One SDB = 12425 /20 = 621.25 Provide Av Size of 25 m™* 25 mts

No of Cycles per Year = No.of Days per year | drying period

10" 30/7

=

SUMMARY FOR DESIGN OF SLUDGE DRYING BEDS +

‘NO.OF _SDB" 20

“AV, SIZE OF EACH SDB. 25 MX 25M.

Design Reference + WPIL field Experience in UASB Reactor —

Designed By STC Checked By SAP 1

Rev.No___ $00 Dated April_10, 1997 1

TECHNICAL OFFER

WPIL-TECH-00

PROJECT =

70 MLD UASB STP at GHAZIABAD (CHA)

7 DESIGN OF SLUDGE SUMP & PUMPS AND DRAIN SUMP & PUMPS

Design Data

Ay. Flow 70MLD

Influent BOD

Design Calculations:

Studge Sump

Quantity of Sludge produced per day

Providing HRT

Volume

Provide Liquid Depth

Diameter of sump

‘Sludge pump

Capacity of Siudge Pumps

Head required

No of Pumps

Drain Sump

Quantity of filtrate

Providing HRT

Volume

Provide Liquid Depth

Diameter of sump

Fillrate Pumps

081 m/sec

200 mg/lit

21280 Kg/ day (with 6 % consistenecy)

ie, 355 m3/day

5 Hrs

80m3

somtrs

45 ons.

355 m3/day

148m3/hr Provide 50 m3/hr

IsMWwc

1 working + 1 stand by

50% Sludge quantity ie. 178 m3/day

Min 4 hrs as per tender

30m3

3.0mus

4.0 mtrs.

Providing filtrate pump of half of the capacity of sludge pump

Capacity of Sludge Pumps

Head requiered

No of Pumps

25 m3/hr

is MWC.

1 working + 1 stand by

SUMMARY FOR DESIGN OF SUMPS & PUMPS :

SIZE OF SLUDGE SUMP 7

‘SIZE OF _DRAIN SUMP

‘SLUDGE PUMPS

DRAIN PUMPS

TSMDIA x 55M. Ht

40M x35 MM

30 m37 Hr, 15 MWC, +1) NOS.

253 7A

TS MWC, (11) NOS.

Designed By STC

“Checked By : SAP

Rev.No 00

Dated: April 10, 1997

|

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Basic Industrial Wastewater Treatment WorkshopDocument94 paginiBasic Industrial Wastewater Treatment Workshophenry_tan5328Încă nu există evaluări

- Basic Industrial Wastewater Treatment WorkshopDocument94 paginiBasic Industrial Wastewater Treatment Workshophenry_tan5328Încă nu există evaluări

- Techno - Commercial Pump Proposal: Va Tech Wabag LTDDocument12 paginiTechno - Commercial Pump Proposal: Va Tech Wabag LTDHRK65Încă nu există evaluări

- UASB Sewage Design PDFDocument25 paginiUASB Sewage Design PDFHRK65Încă nu există evaluări

- University Septic Tanks TextDocument68 paginiUniversity Septic Tanks Textdkm455Încă nu există evaluări

- Water Consumption BasisDocument6 paginiWater Consumption BasisHRK65Încă nu există evaluări

- ICS-A02-1103 (B1) Hydraulic Calculations (090110)Document12 paginiICS-A02-1103 (B1) Hydraulic Calculations (090110)HRK65Încă nu există evaluări

- Metric Refrence ManualDocument49 paginiMetric Refrence ManualHRK65Încă nu există evaluări

- AJKZERODISCHARGEDocument5 paginiAJKZERODISCHARGEHRK65Încă nu există evaluări

- Anaerobic Sludge Digestion PDFDocument27 paginiAnaerobic Sludge Digestion PDFHRK65100% (1)

- Biogas To PowerDocument2 paginiBiogas To PowerHRK65Încă nu există evaluări

- EXAMPLE1 UASBTreatment Process SWUSTDocument8 paginiEXAMPLE1 UASBTreatment Process SWUSTYannis Thomas100% (1)

- Extreme Pressures and HeadsDocument2 paginiExtreme Pressures and HeadsHRK65Încă nu există evaluări

- Daf PDFDocument10 paginiDaf PDFHRK65Încă nu există evaluări

- Utility Estimation For DevelopmentsDocument1 paginăUtility Estimation For DevelopmentsHRK65Încă nu există evaluări

- University Septic Tanks TextDocument68 paginiUniversity Septic Tanks Textdkm455Încă nu există evaluări

- DAF Recent Advances PaperDocument10 paginiDAF Recent Advances PaperShashi BhushanÎncă nu există evaluări

- Pressures at Air ValvesDocument1 paginăPressures at Air ValvesHRK65Încă nu există evaluări

- Technical Data - Post Dilution System For Poly Range - v1.1Document1 paginăTechnical Data - Post Dilution System For Poly Range - v1.1HRK65Încă nu există evaluări

- Air Valve PerformanceDocument2 paginiAir Valve PerformanceHRK65Încă nu există evaluări

- FRP Tanks Comp PDFDocument1 paginăFRP Tanks Comp PDFHRK65Încă nu există evaluări

- TANK CYLINDERICAL VERTICAL - OVER GROUND - 2019 Rev1Document11 paginiTANK CYLINDERICAL VERTICAL - OVER GROUND - 2019 Rev1HRK65Încă nu există evaluări

- Polymer Preparation Units Reference ListDocument2 paginiPolymer Preparation Units Reference ListHRK65Încă nu există evaluări

- State Point AnalysisDocument24 paginiState Point AnalysisHRK65Încă nu există evaluări

- Continuous Polymer Preparation SystemsDocument6 paginiContinuous Polymer Preparation SystemsHRK65Încă nu există evaluări

- LUMPP Waste Water Treatment Solutions 260 001 en ADocument2 paginiLUMPP Waste Water Treatment Solutions 260 001 en AHRK65Încă nu există evaluări

- AIRFUNDATUT1 Rev 11Document5 paginiAIRFUNDATUT1 Rev 11HRK65Încă nu există evaluări

- AIRFUNDATUT1 Rev 11Document5 paginiAIRFUNDATUT1 Rev 11HRK65Încă nu există evaluări

- Head Loss CalculationsDocument3 paginiHead Loss CalculationsHRK65Încă nu există evaluări