Documente Academic

Documente Profesional

Documente Cultură

Safety Advice Tower Form: Wind Load Assumptions For Load Bearing Towers

Încărcat de

falparslan5265Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Safety Advice Tower Form: Wind Load Assumptions For Load Bearing Towers

Încărcat de

falparslan5265Drepturi de autor:

Formate disponibile

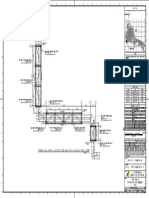

KEYPLAN:

2nd Casting

2nd Casting

1000

1000

1000 1000 1000

1000 1000 1000

1000 1000 1000

474

474

2100

Handrail clamp S 438 440 442

Multi-purpose waling WU12

500

500

500

294 294

2100

438 436 434

353

474

Spindle strut 40/80cm

Handrail clamp S

1000

1000

Tie rod 15.0+wing nut 15.0

384

438

Doka beam H20 eco P

& Rock anchor spread unit

230

292

1524 732 1524 878 1524 878 1524 728 1524

-1.20-

-1.20-

-1.20-

Doka beam H20 eco P Back Stay By Site Back Stay By Site

Spindle strut T7 150/200cm

d3 screw jack U-head

Multipurpose waling WS10

-1.20-

-1.20-

Scaffold Tubes By Site

-1.20-

Diagonal cross 12.100 NOTES:

-1.20-

-1.20-

-1.20-

HT. = 6.00m

Back Stay By Site

DETAIL : A Lifting chain attached to the d3 frame

Safety Advice

5560

5682

-1.20-

-1.20-

-1.20-

Tower form

-1.20-

-1.20-

Back Stay By Site

-1.20-

d3 safety hook

-1.20-

-1.20-

-1.20-

Load bearing tower d3

HT. = 9.00m

-1.20-

-1.20-

-1.20-

8560

8682

-1.20-

-1.20-

-1.20-

384

452

Spindle strut 40/80cm

Multi-purpose waling WU12 Secures the d3 screw jack U-head or screw jack foot to

Spindle strut 40/80cm the d3 frame

Tie rod 15.0+wing nut 15.0

-1.20-

-1.20-

▪ when the towerframes are assembled in the horizon-

-1.20-

Tie rod 15.0+wing nut 15.0

& Rock anchor spread unit

& Rock anchor spread unit tal

Spindle strut T7 150/200cm ▪ when the towerframes are lifted by crane

Multipurpose waling WS10

Multipurpose waling WS10

d3 frame 1.20m

-1.20-

-1.20-

-1.20-

General remarks:

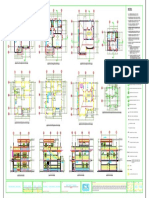

FRONT VIEW DETAIL : B ▪ The gravity latches of the frame must always point

upwards.

SCALE 1:50

Height =6.0m

-0.90-

-0.90-

d3 screw jack foot

-0.90-

While the tableform is being lifted, there must

238

298

NOT be any loose parts, tools or

other items on the tableform!

1000

1000

Wind Load Assumptions for Load Bearing Towers

Wind loads which are assumed:

1000

1000

1000

474

474

a: load case 2 (EN12812) (falsework during loading, e.g. pouring): 64km/h (q=0,2kN/m²)

b: load case 3 (EN12812) (loaded falsework): xx km/h (q= Y,Y kN/m² )

The load bearing towers have to be prevented of tilting and gliding

FRONT VIEW (e.g. with guying; see User Information).

1000

SCALE 1:50

1000

1000

Height =9.0m General notes for load-bearing towers

294 438 438 440 436 442 434 294

500

500

500

- The load-bearing towers have to be placed vertically.

- The load-bearing towers have to be placed on a statically stable base (concrete blocks, sleeper, etc.).

A A Foundation according to statical requirements by contractor.

353

- Necessary camber according to the planning information have to be considered when levelling the

474

1000

1000

1000

formwork.

Calculation criteria

1000

1000

1500-2100

Our design is based on load assumptions as stated below (characteristic loads):

- Dead load of formwork/scaffold is taken into account.

- Live load = 2.50 kN/m²

- Concrete weight = 25 kN/m³

- Maximum concrete pressure Pmax = _ kN/m²

- Horizontal dummy load for working

1524 732 1524 878 1524 878 1524 728 1524 procedure (pumping, vibrating, a.s.o) 2.5% of the vertical load

300

300

- Working wind speed = 64 km/h

Doka beam H20 eco P

- Maximum wind speed = _ km/h

d3 screw jack U-head

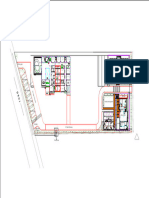

These towers must be PLAN: PIER CAP FORMWORK - D3 TOWERS

-0.90-

-0.90-

-0.90-

The design of formwork and scaffold is according to Eurocodes

re-used from other sets SCALE 1:40

(only when height is above 1.20m) GENERAL ARRANGEMENT All measurements of the structure have to be checked! All measurements in mm!

Diagonal cross 12.100

Back Stay By Site

-1.20-

-1.20-

-1.20-

The stated reaction forces are actual unfactored characteristic loads (ɣ=1)!

Re-use needed only in piers Maximum secondary beam spacing underthe soffit of pier head =160mm

The transfer of the forces into the structure and the stability of the overall construction, must all

Back Stay By Site 33, 34, 41, 43, 61, 71, 72, 73 & 80 Maximum secondary beam spacing for platforms =500mm ! be verified by the structural designer.

-1.20-

-1.20-

-1.20-

DEATIL : B DEATIL : B

-1.20-

-1.20-

-1.20-

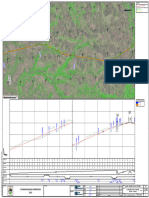

Jubail Railway Network Expansion CTW130

MAX HT. = 11.30m

DEATIL : B DEATIL : B

WS10 - 2.0

WS10 - 2.0

WS10 - 2.0

WS10 - 2.0

1000

1000

10860

10982

-1.20-

-1.20-

-1.20-

KRT-RUB1 Bridge - Pier Cap Slab

DEATIL : A DEATIL : A

1000

1000

1000

D3 shoring arrangement for 2.10m height pier cap slab

474

474

-1.20-

-1.20-

-1.20-

Client:

APPROVAL DRAWING

WS10 - 5.50

WS10 - 5.50

WS10 - 5.50

WS10 - 5.50

WS10 - 5.50

WS10 - 5.50

Yapi Merkezy

1000

not valid for execution

1000

1000

-1.20-

-1.20-

-1.20-

294 438 Approved by site

438 440 436 442 434 294

500

500

500

for execution: Date, Name, Signature

Drawn: ILYAS POOLAKKAL 01.07.2020 Drawing-No.: Rev.:

A A

-1.20-

-1.20-

-1.20-

d3 frame 1.20m Checked: MUHSIN PANTHAKKAN 356-001102-1003

353

474

1000

1000

1000

Revised: Scale: " AS SHOWN "

Advanced Formwork Co. Ltd.

WS10 - 2.0

WS10 - 2.0

-0.90-

-0.90-

-0.90-

1000

WS10 - 2.0

WS10 - 2.0

24.31kN 87.30kN 88.16kN 51.61kN

Dammam Branch

1000

P.O. Box 60120 Dammam 31481 Kingdom of Saudi Arabia

d3 screw jack foot

368

Tel.: +966 13 832 0606 Fax.: +966 13 832 3193

490

www.doka.com

DEATIL : B DEATIL : B

This drawing is based upon the technical data and original DOKA products, or such products which are explicitely designated herein.

We can only warrant for DOKA products on the condition that they are used according product specification.

The unauthorized use, reproduction or processing of this drawing is forbidden, subject to penalty and subject to payment of damages.

1524 732 1524 878 1524 878 1524 728 1524 This drawing must not be communicated neither to third parties nor to competitor companies. Subject to technical alterations.

To avoid risks regarding Health & Safety of users or third persons, "User Information", "Operating Instructions" and

"Fitting Instructions" have to be noted in addition to the information given on the drawings.

FRONT VIEW PLAN: PIER CAP FORMWORK - D3 TOWERS If required ask your Doka partner for these documents. http://www.doka.com/downloadcenter/

SCALE 1:50 SCALE 1:40

Height =11.30m D3 TOWER ARRANGEMENT Scaffold boards for platforms and railings must be fixed according to Health & Safety regulations and local law!

S-ar putea să vă placă și

- Section A-A: Safety Advice Tower FormDocument1 paginăSection A-A: Safety Advice Tower Formfalparslan5265Încă nu există evaluări

- Bài Tập In Phát Cho Sinh Viên: Color Linetype LineweightDocument1 paginăBài Tập In Phát Cho Sinh Viên: Color Linetype LineweightTrương Văn Hữu HiếuÎncă nu există evaluări

- Truss Jack Portal Frame Cross Section at Gl. H: Detail - S1 Detail - S1 Detail - S1Document1 paginăTruss Jack Portal Frame Cross Section at Gl. H: Detail - S1 Detail - S1 Detail - S1LUUVANDONG48XFÎncă nu există evaluări

- Ips-Mbd23908-El-3151-Power Layout at Proposed Pack A.S.R.SDocument1 paginăIps-Mbd23908-El-3151-Power Layout at Proposed Pack A.S.R.SJEET PRATAP PATHAKÎncă nu există evaluări

- 100 PH 323 30004 - 001Document2 pagini100 PH 323 30004 - 001Muhammad Khoirul KhabibiÎncă nu există evaluări

- 100 PH 323 30003 - 002Document1 pagină100 PH 323 30003 - 002Muhammad Khoirul KhabibiÎncă nu există evaluări

- GT-I9505 Galaxy S4 LTEDocument2 paginiGT-I9505 Galaxy S4 LTECarlos Andres EscamillaÎncă nu există evaluări

- CUSCODocument1 paginăCUSCOMIJAIL KEVIN ROMUACCA HUAMANÎncă nu există evaluări

- Issue For Information: Shimo La Maji MachafuDocument1 paginăIssue For Information: Shimo La Maji MachafuAdamu PiusÎncă nu există evaluări

- GF Part 1 F1Document1 paginăGF Part 1 F1Hermogenes MejiaÎncă nu există evaluări

- Steel Bollard Details: Buro HappoldDocument1 paginăSteel Bollard Details: Buro Happoldrichrd villanuevaÎncă nu există evaluări

- 1.REST OF 19.55KW WE Will Decide at Site: DCDB-1/2Document1 pagină1.REST OF 19.55KW WE Will Decide at Site: DCDB-1/2Sujeet KumarÎncă nu există evaluări

- 04 Tel & Data Layout Plan-Tel & DataDocument1 pagină04 Tel & Data Layout Plan-Tel & DataPhúc Đinh TấnÎncă nu există evaluări

- 06 PKG EDWDocument66 pagini06 PKG EDWRajeshÎncă nu există evaluări

- Inbentario de Vehiculos Del Corralon de Gruas HerrosDocument21 paginiInbentario de Vehiculos Del Corralon de Gruas HerrosDiego Antonio Bautista DenisÎncă nu există evaluări

- Detail Opening Grc.eDocument1 paginăDetail Opening Grc.estisolmarinaÎncă nu există evaluări

- 4th Floor (28-06-19) @ 1000 PDFDocument1 pagină4th Floor (28-06-19) @ 1000 PDFNitin AgnihotriÎncă nu există evaluări

- GEN 1003-09 3jan2018Document8 paginiGEN 1003-09 3jan2018Elan Interior DecorsÎncă nu există evaluări

- cc2202 13 Pergola1660741306520Document1 paginăcc2202 13 Pergola1660741306520Ramees MalikÎncă nu există evaluări

- Master Plan': B E Y R O U T HDocument1 paginăMaster Plan': B E Y R O U T HYADNYAYEE PAWARÎncă nu există evaluări

- Abts Industrial Case Study-Layout2Document1 paginăAbts Industrial Case Study-Layout2shantanu daleÎncă nu există evaluări

- B1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDocument1 paginăB1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDessouki SamakÎncă nu există evaluări

- PG 5 A1 - PmaDocument1 paginăPG 5 A1 - Pmamoreno chinchayÎncă nu există evaluări

- 13-Alignment Plan &profile KM 40-50Document1 pagină13-Alignment Plan &profile KM 40-50Tamrayehu KuremaÎncă nu există evaluări

- 18-Alignment Plan &profile KM 90-100Document1 pagină18-Alignment Plan &profile KM 90-100Tamrayehu KuremaÎncă nu există evaluări

- DN#1200-tp 9Document1 paginăDN#1200-tp 9Arbaz KhanÎncă nu există evaluări

- Entry Gate Girls Hostel: 30' Wide DrivewayDocument1 paginăEntry Gate Girls Hostel: 30' Wide DrivewayPRIYA MISHRAÎncă nu există evaluări

- Plano en Planta: Gobierno Regional de PunoDocument1 paginăPlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonÎncă nu există evaluări

- Male CR: Section 1 Section 2Document1 paginăMale CR: Section 1 Section 2alezandro del rossiÎncă nu există evaluări

- 33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)Document1 pagină33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)SUSOVAN BISWASÎncă nu există evaluări

- NEWFLEX - Ban Ve Dau Noi Ha Tang - 230829Document12 paginiNEWFLEX - Ban Ve Dau Noi Ha Tang - 230829ha ducÎncă nu există evaluări

- A1 PDFDocument1 paginăA1 PDFPIERO JESUSÎncă nu există evaluări

- Area Municipal: Rio Chorobamba Via MaleconDocument1 paginăArea Municipal: Rio Chorobamba Via MaleconRosa ContrerasÎncă nu există evaluări

- Tramo 2-1 SANITARIO-8009976Document1 paginăTramo 2-1 SANITARIO-8009976Juan Camilo BautistaÎncă nu există evaluări

- K 2Document1 paginăK 2assis alihÎncă nu există evaluări

- CR 1Document1 paginăCR 1Armand Mikhail TempladoÎncă nu există evaluări

- 6-10 AmbalemaDocument1 pagină6-10 AmbalemaNoel Alirio Tellez IrreñoÎncă nu există evaluări

- Family & Nursery - Elevation BDocument1 paginăFamily & Nursery - Elevation BFa jarÎncă nu există evaluări

- LOTE D-6-2-Layout1Document1 paginăLOTE D-6-2-Layout1JENRRI VILLALOBOS LIMACHIÎncă nu există evaluări

- Plano BogotáDocument1 paginăPlano BogotáLaura Marcela Cristancho TovarÎncă nu există evaluări

- Kecamatan Tanah Abang Kecamatan Setiabudi: Kelurahan SenayanDocument1 paginăKecamatan Tanah Abang Kecamatan Setiabudi: Kelurahan SenayanPTSPÎncă nu există evaluări

- B1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Document1 paginăB1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Dessouki SamakÎncă nu există evaluări

- Franklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDocument1 paginăFranklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDanica Mae AmicayÎncă nu există evaluări

- 2L100x8 2L60x5Document1 pagină2L100x8 2L60x5Châu Thư NguyễnÎncă nu există evaluări

- Zeiss CeilingDocument1 paginăZeiss CeilingShantanuÎncă nu există evaluări

- 03-02-2021 ModelDocument1 pagină03-02-2021 ModelOsamah AdelÎncă nu există evaluări

- Block A Unit 9 & 10 AC LayoutDocument4 paginiBlock A Unit 9 & 10 AC LayoutHANITHA DEVI A/P M KUMAR (Student)Încă nu există evaluări

- Deslinde Final 13042021-PlanoDocument1 paginăDeslinde Final 13042021-PlanoAlejandra MurciaÎncă nu există evaluări

- MC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)Document1 paginăMC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)waseem kausarÎncă nu există evaluări

- 5plex G A012Document1 pagină5plex G A012murugesanÎncă nu există evaluări

- Honda Ambalema Armero (Guayabal) : V. San Juan de RemolinoDocument1 paginăHonda Ambalema Armero (Guayabal) : V. San Juan de RemolinoyregÎncă nu există evaluări

- Nam Khang 1624Document1 paginăNam Khang 1624hoangducbds19Încă nu există evaluări

- FILE - 20180705 - 093600 - Nguyen Duy Trinh 17.9.17 - 96798d5ff42ce18e5838eDocument1 paginăFILE - 20180705 - 093600 - Nguyen Duy Trinh 17.9.17 - 96798d5ff42ce18e5838ehoangducbds19Încă nu există evaluări

- PlanoDocument1 paginăPlanoHELEN GREYS MONTALVAN SOLISÎncă nu există evaluări

- 01 LuDocument1 pagină01 LuSonia Ñaupas NajarroÎncă nu există evaluări

- Milliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomDe la EverandMilliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomÎncă nu există evaluări

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 paginig214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevÎncă nu există evaluări

- REGINADocument1 paginăREGINARoselyn VelascoÎncă nu există evaluări

- VAT Invoice - 2023-02-28 - 00000006062065-2302-9647607Document2 paginiVAT Invoice - 2023-02-28 - 00000006062065-2302-9647607falparslan5265Încă nu există evaluări

- CTW130 OHTL Minutes of Meeting 07.02.2023Document1 paginăCTW130 OHTL Minutes of Meeting 07.02.2023falparslan5265Încă nu există evaluări

- Plan: Abutment Wall Formwork - Top 50: Safety InstructionDocument1 paginăPlan: Abutment Wall Formwork - Top 50: Safety Instructionfalparslan5265Încă nu există evaluări

- 750 UNI 1200 1200 750 UNI 750 UNI 900 900 600 750 UNI: Safety InstructionDocument1 pagină750 UNI 1200 1200 750 UNI 750 UNI 900 900 600 750 UNI: Safety Instructionfalparslan5265Încă nu există evaluări

- CTW 130 - Detailed Design ServicesDocument4 paginiCTW 130 - Detailed Design Servicesfalparslan5265Încă nu există evaluări

- Miktar Malzeme Kodu Kaynak/Maliyet Kod Kaynak Sınıfı/Grup Kod Aktivite Kodu/Kullanım YeriDocument2 paginiMiktar Malzeme Kodu Kaynak/Maliyet Kod Kaynak Sınıfı/Grup Kod Aktivite Kodu/Kullanım Yerifalparslan5265Încă nu există evaluări

- 3 - Pier45&46 - FWDocument2 pagini3 - Pier45&46 - FWfalparslan5265Încă nu există evaluări

- Casagrande B250Document4 paginiCasagrande B250falparslan52650% (1)

- Setting Out Table P9 N E N E: EngineerDocument1 paginăSetting Out Table P9 N E N E: Engineerfalparslan5265Încă nu există evaluări

- Ctw130 Yms PTW 02test PileDocument4 paginiCtw130 Yms PTW 02test Pilefalparslan5265Încă nu există evaluări

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsDocument21 paginiEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoÎncă nu există evaluări

- PricelistDocument4 paginiPricelistMAYMART CASABAÎncă nu există evaluări

- Red Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFDocument1 paginăRed Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFCintiah KenedyÎncă nu există evaluări

- Journal Homepage: - : IntroductionDocument9 paginiJournal Homepage: - : IntroductionIJAR JOURNALÎncă nu există evaluări

- Stahl - PUDSDocument29 paginiStahl - PUDSsusanasusana_Încă nu există evaluări

- Chemical Resistance TableDocument6 paginiChemical Resistance TableEdgarDavidDiazCamposÎncă nu există evaluări

- Grand Vitara 2005Document35 paginiGrand Vitara 2005PattyaaÎncă nu există evaluări

- Purgatory and The AbsoluteDocument18 paginiPurgatory and The AbsoluteCarla MissionaÎncă nu există evaluări

- Tas 5731Document60 paginiTas 5731charly36Încă nu există evaluări

- Aircraft Structures - Ii (AER18R372)Document15 paginiAircraft Structures - Ii (AER18R372)sarathkumar sebastinÎncă nu există evaluări

- Detailed Lesson Plan in Science IiiDocument3 paginiDetailed Lesson Plan in Science Iiicharito riveraÎncă nu există evaluări

- Book 1Document1 paginăBook 1PES SAFETYÎncă nu există evaluări

- DysphagiaDocument4 paginiDysphagiaMicaÎncă nu există evaluări

- Website Catalog MOTORS v2 PDFDocument8 paginiWebsite Catalog MOTORS v2 PDFИгорь КернякевичÎncă nu există evaluări

- Load ScheduleDocument8 paginiLoad SchedulemerebookÎncă nu există evaluări

- The Redesigning of Junction: Tatya Tope Square BhopalDocument15 paginiThe Redesigning of Junction: Tatya Tope Square BhopalAr Raj YamgarÎncă nu există evaluări

- 159 SnackDocument97 pagini159 SnackGuy PlaterÎncă nu există evaluări

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocument22 paginiThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiÎncă nu există evaluări

- Hot Process Liquid SoapmakingDocument11 paginiHot Process Liquid SoapmakingPanacea PharmaÎncă nu există evaluări

- Quran On GeologyDocument10 paginiQuran On GeologyMM NabeelÎncă nu există evaluări

- WorldShop CatalougeDocument200 paginiWorldShop Catalougee2ashÎncă nu există evaluări

- MPI Report 009 Sub Structure B668Document1 paginăMPI Report 009 Sub Structure B668John DolanÎncă nu există evaluări

- Iron FistDocument2 paginiIron FistVictor PileggiÎncă nu există evaluări

- Idlers: TRF Limited TRF LimitedDocument10 paginiIdlers: TRF Limited TRF LimitedAjit SarukÎncă nu există evaluări

- Core12 Mod 1Document1 paginăCore12 Mod 1Michael SaberonÎncă nu există evaluări

- Content For Essay and Paragraph Writing On Maritime HistoryDocument15 paginiContent For Essay and Paragraph Writing On Maritime HistoryRaju KumarÎncă nu există evaluări

- Traffic Cases in GSMDocument18 paginiTraffic Cases in GSMkamal100% (1)

- Acoustic Phonetics PDFDocument82 paginiAcoustic Phonetics PDFAnonymous mOSDA2100% (2)

- An Overview of The IEEE Color BooksDocument6 paginiAn Overview of The IEEE Color BooksOhm666Încă nu există evaluări

- How To Build A GreenhouseDocument67 paginiHow To Build A GreenhouseBolarinwaÎncă nu există evaluări