Documente Academic

Documente Profesional

Documente Cultură

FT003 - Aggregate Impact Value Test

Încărcat de

jjksite voyantsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FT003 - Aggregate Impact Value Test

Încărcat de

jjksite voyantsDrepturi de autor:

Formate disponibile

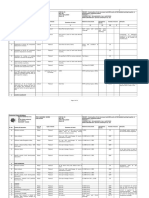

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG.

III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. Test report number

Type of material Coarse aggregate Date of sampling 22-02-1019

Source Nalhati Sampled by Jointly

Location QA/QC Lab, Plot-A Date of testing 23-02-1019

Proposed use Concrete Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 356.6 361.6

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 318.4 320.4

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 38.2 41.2

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 10.71 11.39

Average Value of A.I.V % 11

Remarks:

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. Test report number

Type of material Coarse aggregate Date of sampling 25-02-1019

Source Radha Madhab Stone Industry-Nalhati Sampled by Jointly (Crusher Visit)

Location QA/QC Lab, Plot-A Date of testing 05-03-1019

Proposed use Suitability for Concrete Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 349.8 352.2

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 310.9 312.5

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 38.9 39.7

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 11.12 11.27

Average Value of A.I.V % 11

Remarks:

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

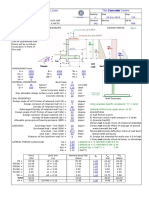

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. SIGS/LW/00143 Test report number

Type of material GSB Materials Date of sampling 01.03.2019

Source Nalahati Sampled by Jointly

Location Chainage 6+100 (Budha Park) Date of testing 04.03.2019

Proposed use Temporary diversion Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 367.2 366.4

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 318.2 320.7

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 48.2 45.4

Loss of material W4 = W1 - (W2 + W3) % 0.8 0.3

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 13.13 12.39

Average Value of A.I.V % 13

Remarks:

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. Lab Activity dated 15.03.19 Test report number

Type of material Coarse aggregate Date of sampling 25.02.2019

Source Nalhati Radha Madhab Stone Industry Sampled by Jointly

Location QA/QC Lab, Plot-A Date of testing 15-03-1019

Proposed use Concrete Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 353 354

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 304.8 308.6

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 48.2 45.4

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 13.65 12.82

Average Value of A.I.V % 13.24

Remarks: Max limit of AIV is 30% for wearing course and 45% max. for non wearing course

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. Lab Activity dated 15.03.19 Test report number

Type of material Coarse aggregate Date of sampling 15-03-1019

Source Batching Plant Bin Sampled by Jointly (Crusher Visit)

Location QA/QC Lab, Plot-A Date of testing 15-03-1019

Proposed use Concrete Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 358 359

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 311.0 311.0

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 47.0 48.0

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 13.13 13.37

Average Value of A.I.V % 13

Remarks: Max limit of AIV is 30% for wearing course and 45% max. for non wearing course

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. Lab Activity dated 08.04.19 Test report number

Type of material Coarse aggregate Date of sampling 08.04.19

Source Batching Plant Bin Sampled by Jointly

Location QA/QC Lab, Plot-A Date of testing 08.04.19

Proposed use Concrete Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 358 356

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 309.4 310.2

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 48.6 45.8

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 13.58 12.87

Average Value of A.I.V % 13

Remarks: Max limit of AIV is 30% for wearing course and 45% max. for non wearing course

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

SECOND ISWAR GUPTA SETU PROJECT, [WBHDCL-PKG. III]

Employer: West Bengal Highway Development Corporation Ltd.

Engineer/Supervision Consultant: LASA -YEC JV

Contractor: LARSEN & TOUBRO LIMITED

HEAVY CIVIL INFRASTRUCTURE LT/HCI/SIGS/QMS/FT/003

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

RFI No. SIGS/LW/00143 Test report number

Type of material GSB Materials Date of sampling 01.03.2019

Source Nalahati Sampled by Jointly

Location Chainage 6+100 (Budha Park) Date of testing 04.03.2019

Proposed use Temporary diversion Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 367.2 366.4

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 318.2 320.7

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 48.2 45.4

Loss of material W4 = W1 - (W2 + W3) % 0.8 0.3

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 13.13 12.39

Average Value of A.I.V % 13

Remarks:

Performed by Reviewed by Witnessed by

L&T-QC L&T-QA Employer/Engineer's Representative

Name: Name: Name:

Signature Signature Signature

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

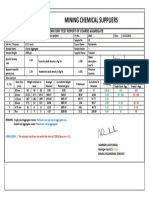

AGGREGATE IMPACT VALUE TEST [As per IS 2386, (Part - IV)]

Contractor MS Black Stone Test report number -

Type of material Coarse Agg For DBM Date of sampling 02.12.2019

Source Hot Mix Plant Plant Bin Sampled by Jointly

Location QA/QC Lab at HMP Date of testing 02.12.2019

Proposed use DBM Tested by Jointly

Description Test 1 Test 2

Weight of Oven dry sample passing 12.5mm and

retained on 10mm IS sieves, W1. (gm) 358 357

Weight of fraction retained on 2.36mm sieve after the

test, W2. (gm) 312.4 314.7

Weight of fraction passing through 2.36mm sieve after

the test, W3. (gm) 45.6 42.3

Loss of material W4 = W1 - (W2 + W3) % 0.0 0.0

Aggregate Impact Value (A.I.V) = (W3/W1) x 100 % 12.74 11.85

Average Value of A.I.V % 12.3

Remarks: Max limit of AIV is 27% As per MORTH Table 500-8

Performed by Witnessed by Reviewed By

Black Stone QA/QC Voyants QC Voyants QA/QC

Name: Name: Name:

Signature Signature Signature

Date: Date: Date:

LT/HCI/SIGS/QMS/FT/003 Rev. No.- 0 Rev. Date: - 01/03/2019

S-ar putea să vă placă și

- Sample Fabrication & Erection ProcedureDocument91 paginiSample Fabrication & Erection ProcedureRiyan Esapermana100% (1)

- Sieve Analysis and Abrasion Test ResultsDocument12 paginiSieve Analysis and Abrasion Test Results906rahulÎncă nu există evaluări

- AISC-Steel Design Guide 07 - Industrial BuildingsDocument103 paginiAISC-Steel Design Guide 07 - Industrial BuildingsJOSE PROENÇA100% (2)

- Residential Construction Schedule TemplateDocument11 paginiResidential Construction Schedule TemplateEcho JanuaryÎncă nu există evaluări

- FQP GeneralDocument21 paginiFQP GeneralgaladrialÎncă nu există evaluări

- Fencing Permit: Office of The Building OfficialDocument2 paginiFencing Permit: Office of The Building Officialjohn limÎncă nu există evaluări

- 1.summary of Concrete Mix DesignsDocument2 pagini1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaÎncă nu există evaluări

- Final Report Wo NDTDocument40 paginiFinal Report Wo NDTAshish100% (1)

- Grain Size Analysis For SoilsDocument11 paginiGrain Size Analysis For SoilsyogananthanÎncă nu există evaluări

- Soil ReportDocument86 paginiSoil ReportSubhajit Maitra100% (1)

- GeoVES - V1 VES SoftwareDocument5 paginiGeoVES - V1 VES SoftwareAurangzeb JadoonÎncă nu există evaluări

- Notes:: Project Title: Client Contract No.Document7 paginiNotes:: Project Title: Client Contract No.Anonymous CQ4rbzLVEÎncă nu există evaluări

- Foundation Soil Engineers: S.P.T S.P.T. GraphDocument5 paginiFoundation Soil Engineers: S.P.T S.P.T. GraphIsmail PatwaryÎncă nu există evaluări

- Client Caterpillar Signs PMC Compaction Test by Sand ReplacementDocument1 paginăClient Caterpillar Signs PMC Compaction Test by Sand ReplacementBrahammanand BairwaÎncă nu există evaluări

- Estimate of Slab Culvert in ExcelDocument6 paginiEstimate of Slab Culvert in ExcelNingappa Chanaveer Gundu100% (2)

- SDBC Without FillerDocument9 paginiSDBC Without Fillerer_kenedyÎncă nu există evaluări

- Trichy Tollway Private Limited: Ijm (India) Infrastructure LimitedDocument24 paginiTrichy Tollway Private Limited: Ijm (India) Infrastructure LimitedSureshKumarÎncă nu există evaluări

- Consolidation PDFDocument113 paginiConsolidation PDFalnisÎncă nu există evaluări

- RCC62 v3-4Document12 paginiRCC62 v3-4YajÎncă nu există evaluări

- Direct Shear Test-AdcDocument1 paginăDirect Shear Test-AdcPriodeep ChowdhuryÎncă nu există evaluări

- REGIONAL LABORATORY P.W.D. ZONE JODHPUR MIX DESIGNDocument11 paginiREGIONAL LABORATORY P.W.D. ZONE JODHPUR MIX DESIGNer_kenedyÎncă nu există evaluări

- Tm-22 m35 RCCDocument19 paginiTm-22 m35 RCCVeera ManiÎncă nu există evaluări

- RMM CalibrationDocument18 paginiRMM CalibrationPrasanna S KulkarniÎncă nu există evaluări

- Seismic Design ConsiderationsDocument5 paginiSeismic Design ConsiderationserleosÎncă nu există evaluări

- Sr-380 Gtifr Pc-04 38bhs Rev2Document608 paginiSr-380 Gtifr Pc-04 38bhs Rev2Amit RawatÎncă nu există evaluări

- Architects List1Document23 paginiArchitects List1Gaurav MadanÎncă nu există evaluări

- Bills of Quantities For A 2-Classroom Block With Office and StoreDocument17 paginiBills of Quantities For A 2-Classroom Block With Office and StoreMasolo Lawrence100% (2)

- Sieve Analysis For Coarse Aggregates - Kico Project-091222Document1 paginăSieve Analysis For Coarse Aggregates - Kico Project-091222mitendra singh100% (1)

- CFSM - Cape Flattery - Silica Sands - Project Profile PDFDocument1 paginăCFSM - Cape Flattery - Silica Sands - Project Profile PDFCarlos Hurtado GarcíaÎncă nu există evaluări

- Sand Replacement TestDocument8 paginiSand Replacement Testkrishna buildconÎncă nu există evaluări

- Arch BridgesDocument4 paginiArch BridgesronakÎncă nu există evaluări

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 paginiFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsÎncă nu există evaluări

- 9asoil Report - PW (R) D - 24HWD - 5.000kmpDocument26 pagini9asoil Report - PW (R) D - 24HWD - 5.000kmpBURDWAN COMMUNITYÎncă nu există evaluări

- Proposed Gangway Jetty Geotechnical ReportDocument36 paginiProposed Gangway Jetty Geotechnical ReportSnehashish BasuÎncă nu există evaluări

- Consolidation Test Specimen DataDocument6 paginiConsolidation Test Specimen DataSyafrizal ThaherÎncă nu există evaluări

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocument2 paginiDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryÎncă nu există evaluări

- Ahelwari ESR Geotechnical ReportDocument18 paginiAhelwari ESR Geotechnical Reportpradeepsharma62Încă nu există evaluări

- Proforma –C Checklist for PMGSY Road WorksDocument62 paginiProforma –C Checklist for PMGSY Road WorksTarun100% (1)

- 169 1 Fine Aggregate SandDocument1 pagină169 1 Fine Aggregate SanddhwaniÎncă nu există evaluări

- JewarDocument35 paginiJewarHussain Basu100% (1)

- Mix Design PosterDocument1 paginăMix Design PosterAbhilash KumarÎncă nu există evaluări

- Axial Capacity of Pile FoundationDocument32 paginiAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- Geotech Report SummaryDocument81 paginiGeotech Report SummaryHemant YesajiÎncă nu există evaluări

- As3 Triaxial SG-SJ ValoresDocument39 paginiAs3 Triaxial SG-SJ ValoresSantiago Maldonado LeoroÎncă nu există evaluări

- Hydrometer Calc 2Document1 paginăHydrometer Calc 2Kanaiyalal N. ShethÎncă nu există evaluări

- Soil Test Report KhagariaDocument28 paginiSoil Test Report KhagariaSajan SinghÎncă nu există evaluări

- Geotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestDocument5 paginiGeotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestYusi SulastriÎncă nu există evaluări

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 paginiTest Report: M/S Pcil & MBPCL Joint VentureImran KhanÎncă nu există evaluări

- Bitumen Test FormetDocument12 paginiBitumen Test FormetBilal Ahmed BarbhuiyaÎncă nu există evaluări

- Soil Investigation ReportDocument15 paginiSoil Investigation ReportShallborn PaulÎncă nu există evaluări

- Shear TestDocument3 paginiShear TestRajesh Kumar SrivastavaÎncă nu există evaluări

- Description: ClintDocument20 paginiDescription: Clintchitranjan4kumar-8Încă nu există evaluări

- Calculations For Safe Bearing CapacityDocument3 paginiCalculations For Safe Bearing Capacityimran khanÎncă nu există evaluări

- Highway Lab Report (Full) PDFDocument84 paginiHighway Lab Report (Full) PDFWai KiatÎncă nu există evaluări

- Members Subjected To Combined ForcesDocument20 paginiMembers Subjected To Combined Forceshema kumarÎncă nu există evaluări

- Direct Shear TestDocument22 paginiDirect Shear Testরীতংকর সাহাÎncă nu există evaluări

- Ev2 Test PDFDocument1 paginăEv2 Test PDFBinod SharmaÎncă nu există evaluări

- 13.11.2021 CSL Full ReportDocument22 pagini13.11.2021 CSL Full ReportJulius GuingabÎncă nu există evaluări

- Calculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100Document8 paginiCalculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100SilverfangÎncă nu există evaluări

- Technology Data's For PMGSYDocument20 paginiTechnology Data's For PMGSYmagbool100% (1)

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Document11 paginiSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndÎncă nu există evaluări

- Atterberg's LimitDocument1 paginăAtterberg's LimitShesha ShayanÎncă nu există evaluări

- Material Testing Division: Soil Testing Information Office Use OnlyDocument16 paginiMaterial Testing Division: Soil Testing Information Office Use OnlyPramukh Test houseÎncă nu există evaluări

- RMC Plant Calibration 18 Sept. 2021Document4 paginiRMC Plant Calibration 18 Sept. 2021SUNIL JHILMILÎncă nu există evaluări

- BITUMEN LAB TEST CHARGESDocument7 paginiBITUMEN LAB TEST CHARGESRenga PandiÎncă nu există evaluări

- Bardiya Soil ReportDocument50 paginiBardiya Soil ReportSubash BastolaÎncă nu există evaluări

- SoilTest Report (Baneswor)Document30 paginiSoilTest Report (Baneswor)Surendra MaharjanÎncă nu există evaluări

- Combine Flakiness & Elongation TestDocument1 paginăCombine Flakiness & Elongation TestFariha AzadÎncă nu există evaluări

- Aggregate Impact Value TestDocument4 paginiAggregate Impact Value TestAyan DuttaÎncă nu există evaluări

- UntitledDocument25 paginiUntitledshivshankar kushwahaÎncă nu există evaluări

- UntitledDocument22 paginiUntitledshivshankar kushwahaÎncă nu există evaluări

- National Highways Authority of India Construction Project Laboratory Test ResultsDocument12 paginiNational Highways Authority of India Construction Project Laboratory Test ResultsvikasÎncă nu există evaluări

- Box Culvert at CH-17+130 of JJK Road 2Document1 paginăBox Culvert at CH-17+130 of JJK Road 2jjksite voyantsÎncă nu există evaluări

- Maximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041Document19 paginiMaximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041jjksite voyantsÎncă nu există evaluări

- Maximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041Document19 paginiMaximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041jjksite voyantsÎncă nu există evaluări

- In FODocument1 paginăIn FOjjksite voyantsÎncă nu există evaluări

- Project schedule and percentage complete curveDocument3 paginiProject schedule and percentage complete curvejjksite voyantsÎncă nu există evaluări

- Project schedule and percentage complete curveDocument3 paginiProject schedule and percentage complete curvejjksite voyantsÎncă nu există evaluări

- MF2 CLASS 'O' Fire Retardant Radiant Barrier FoilDocument1 paginăMF2 CLASS 'O' Fire Retardant Radiant Barrier FoilSYARULNIZAM ROSLANÎncă nu există evaluări

- Qud 0014 R1 PDFDocument1 paginăQud 0014 R1 PDFcdnaveenÎncă nu există evaluări

- Civil Engineering: Year ofDocument4 paginiCivil Engineering: Year ofdipinnediyaparambathÎncă nu există evaluări

- Faires Solucionario Diseo de Elementos de Maquinas 4ta Edicion 2 PDF FreeDocument641 paginiFaires Solucionario Diseo de Elementos de Maquinas 4ta Edicion 2 PDF FreeJay Gaspar Jr.Încă nu există evaluări

- 2.1 History of The Company: Part Two 2. Company BackgroundDocument7 pagini2.1 History of The Company: Part Two 2. Company Backgroundhabtamu100% (2)

- Entry Level Manufacturing JobsDocument2 paginiEntry Level Manufacturing JobssumitÎncă nu există evaluări

- Meeting Minutes May 2021 Operations DepartmentDocument12 paginiMeeting Minutes May 2021 Operations DepartmentErika Nell LachicaÎncă nu există evaluări

- ECN Minor/Major Change Classification For Product/Process ChangeDocument1 paginăECN Minor/Major Change Classification For Product/Process ChangeBalaji SÎncă nu există evaluări

- ADWEA Approved Vendor List 6.4.2011Document262 paginiADWEA Approved Vendor List 6.4.2011anish_am2005Încă nu există evaluări

- Hi Flow GroutDocument2 paginiHi Flow Groutpravi3434Încă nu există evaluări

- Complete Guide to RCC Design - Flanged Beam AnalysisDocument8 paginiComplete Guide to RCC Design - Flanged Beam AnalysisYusufÎncă nu există evaluări

- 5 Food Recycling Law in Japan and Its Implementationku PDFDocument11 pagini5 Food Recycling Law in Japan and Its Implementationku PDFSiti AishahÎncă nu există evaluări

- Design Steps For Continuous BeamsDocument5 paginiDesign Steps For Continuous BeamsSabbir Hossain RoneyÎncă nu există evaluări

- Construction Procedures of Slip-Form PavementDocument5 paginiConstruction Procedures of Slip-Form PavementSerdarÎncă nu există evaluări

- EUprofileDocument5 paginiEUprofilepnpriyanksharmaÎncă nu există evaluări

- Design of Stairs 2 ACIDocument8 paginiDesign of Stairs 2 ACIKarim TammourÎncă nu există evaluări

- ASP SST Fittings DataCatalog-1013Document16 paginiASP SST Fittings DataCatalog-1013JMÎncă nu există evaluări

- Ferro-Cement Water Tank Design and ConstructionDocument51 paginiFerro-Cement Water Tank Design and Constructionsomnath213Încă nu există evaluări