Documente Academic

Documente Profesional

Documente Cultură

PMT EVA-625 Elevator Vibration Tester

Încărcat de

Tushar ImranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PMT EVA-625 Elevator Vibration Tester

Încărcat de

Tushar ImranDrepturi de autor:

Formate disponibile

EVA-625

The World’s Standard of Measurement . . .

Elevator Ride Quality, Vibration & Sound

Ride Quality Measurement & Analysis for the Elevator/Escalator Industry

Physical Measurement Technologies’ EVA-625 Elevator Vibration Analysis system and EVA Vibration Analysis Tools

software has quickly become the global standard for the measurement of elevator and escalator ride quality, and

vibration & sound. Designed to meet international standards for the recording and analysis of elevator and escalator

vibration and sound, only the EVA system allows all elevators and escalators to be measured, analyzed, and documented

absolutely, easily and at a Very Low Cost. Through continuous refinement & enhancement, the EVA system remains

the product of choice for the measurement and analysis of elevator/escalator ride quality, and vibration & sound, while

PMT has become the world’s number one supplier of high accuracy instrumentation for the vertical transportation

industry.

Quantify Elevator/Escalator ISO18738 Ride Quality

Measure Acceleration/Deceleration, Speed, Jerk

Identify & Locate Rail & Joint Misalignment

Diagnose Bad Roller Guides

Document Pre/Post Modernization Changes

Troubleshoot Sheave, Ropes, Counterweight

Assess Drive & Controller Function

Machine Vibration Analysis

Safety/Buffer/Emergency Stop Measurements

Document Elevator Performance Baseline

Year to Year Elevator Operation Comparison

Escalator Step/Skirt Index Measurement (w/IMD-1)

Flash Drive Data Storage

Elevator & Escalator System Quality Control, Diagnosis, & Inspection

Elevator ride quality is a first indicator of quality design, installation, and service. The EVA system includes powerful

tools to assist in quality improvement in all areas of the elevator mechanical and control system. The highly accurate

response of the EVA system, and the analysis capabilities offered by the EVA Vibration Analysis Tools software allow

technician to engineering level personnel to rapidly identify problem areas and perform corrective actions. Only the

EVA system provides the ability to measure the vibration and sound that people feel and hear and analyze the broad-

band vibration and sound that is the result of the function of all dynamic aspects of the elevator system. With a little

practice, problems with roller guides, rail joints, motor control systems, and other dynamic elements can be identified in

minutes and repairs targeted precisely. Quality of installation and service can be improved dramatically. Because of the

simplicity of the EVA system and the information that is returned, the EVA-625 offers unmatched capabilities as an

inspection and fast survey tool. The condition of the elevator can easily be compared year after year.

PMT

Physical Measurement Technologies, Inc.

P.O. Box 400

4 Ling Street

Marlborough, NH 03455 USA

Voice: 603.876.9990 Fax: 603.876.9995

Website: www.pmtvib.com

The Absolute Measure of Elevators and Escalators

V.10.40 03/2016

EVA-625 Overview

Ride Quality Measurement & Analysis for the Elevator Industry, Inspection, QC

The EVA system was created specifically to meet the needs of the elevator and escalator industry worldwide. Designed using the

latest technology and continuously upgraded & improved, the EVA system is the first real standard for quantitative measurement of

acceleration and sound level data, and the absolute determination of Ride Quality & diagnosis of elevator system problems. The

broad response of the EVA-625 allows diagnosis of mechanical & control elements of elevator and escalator systems. Failing and

worn assemblies can be identified before breakdowns occur and safety is compromised. The EVA-625 should be a big part of

your Total Quality System.

High Accuracy Acceleration and Sound Measurement, at Low Cost - The EVA system is designed to

be highly accurate in the short and long term. The EVA-625 is the first production instrument designed for the elevator

industry that conforms to international standards for the measurement of elevator vibration and sound. The EVA system

architecture (Division of Data Collection & Analysis) ensures against obsolescence and reduces costs. By separating the

data analysis from the instrument, software upgrades keep the system current and on the leading edge of

elevator/escalator analysis.

EVA System Highlights

EVA-625

Ride Quality Measurement & Diagnostic Tool for Elevator Service, Analysis, & Inspection

Highly Accurate, Broad Band 3 Axis Acceleration With Frequency Response Down to 0 Hertz

A -Weighted, Fast Response, Sound Level Recording

Elevator, Escalator, Real Time Vibration &Tachometer Operation Modes

Conforms to International Measurement Standards

RSB Removable Tri-Axial Acceleration Sensor Block

Extremely Easy to Use, Portable, Battery Operated, Rugged, Reliable, Small Size, Light Weight

Low Cost – Includes EVA Software, Sensors, Battery Charger, Serial Cable, 1 Year Warranty

Optional Tachometer For Elevator Door and Escalator Handrail/Step Speed Comparison

Optional +/-10g Range Accelerometer for Safety Gear/Buffer/Emergency Stop Analysis

Optional IMD-1 Escalator Step/Skirt Index Measurement Device

Robust Hardware Design for Accurate Response to Vibration & Long Term Reliability

EVA Vibration Analysis Tools Software

Operations under Windows NT, Windows XP, Windows Vista

ISO Human Response (ISO18738), Acceleration, Sound Level, Speed, Jerk, Distance Time Histories Display

Spectral Analysis Capability, Software Selectable Filters & Sampling Rate

ISO Human Response Analysis & User Selectable Digital Filtering

User Defined Units of Measure & Graphical Scaling, Box Zoom & Scroll,

Project Specification Analysis, Data Base Compilation

Multiple Report Printing including Peak to Peak Vibration, Max/Average, Sound Max/Average

Elevator Performance Measurements

Field Operations with a Field Tough Instrument - The EVA system is particularly easy to operate, both in the

field and in the office. About the size of a notebook computer, operation is simple and fast. The system can be configured for use on

site, without having to carry a PC with you. Simply place the EVA-625 on the floor of the elevator, turn it on, press the record

switch, and ‘take a ride’. The data is automatically written to a Flash Drive for virtually unlimited storage. An entire bank of

elevators can be recorded in minutes. The EVA system is rugged enough so that it can go anywhere at anytime with few concerns.

Shipping and field operations with a high accuracy instrument are no longer a worry.

Removable 3-Axis Acceleration Sensor - An important EVA-625 design innovation is the removable triaxial

accelerometer package (RSB). It can be left within the EVA case for simple ride quality analysis, or the sensor can be removed for

attachment to specific elevator mechanical elements. This allows isolated measurements of the vibration response of specific

elevator structural members and components such as roller guides, motors, and gear boxes.

The Absolute Measure of Elevators and Escalators

V.10.40 03/2016

EVA Vibration Analysis Tools - Science in the Software

Elevator Tools- ISO18738-1

The included EVA Vibration Analysis Tools software is a powerful suite of analytical tools for elevators and escalators in a fully

integrated Windows™ based environment. It offers unmatched analysis of all elevator/escalator motion and sound levels, yet is

easily used by the engineering or non-technical staff. Using PMT proprietary methods for automatically extracting information from

the vibration recordings, ride quality levels, speed, elevator location, acceleration/deceleration, jerk, and sound levels can be

evaluated in seconds. An extremely important feature of the software is the ISO Ride Quality Analysis. It must be remembered that

ride quality is not measured by the vibration and sound that the instrument records, but rather by the vibration and sound that people

feel and hear. PMT is the first and only company to apply ISO2631 based filtering of the vibration data to get a measure of the

vibration that people feel. When diagnosing for ride quality purposes, it is important to improve the vibration that people feel.

Analytical capabilities include time history zoom and expand with data measurement, elevator travel time measurement, comparison

of data with respect to user imposed vibration limits, spectral analysis (FFT), and RMS vibration and sound level measurement (A-

weighted, fast response). Of course, the EVA software also prints standard reports on your office printer.

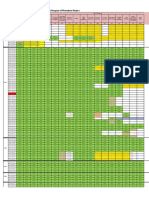

International Services Building Elevator 23 International Services Building Elevator 23

Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95 Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95

Run Sound: 61.5 Ave. Sound: 57.6 Max Sound: 74.6 Run Sound: 61.5 Ave. Sound: 57.6 Max Sound: 74.6

Sound(dBA)

75 75

60.0 60.0

50 50

Max Pk/Pk: 47.3 A95: 26.5 0-Pk: 33.1 Max Pk/Pk: 9.4 A95: 4.5 0-Pk: 6.9 6.0

25 5

6.0

0 -6.0 0

X

-25 -5 -6.0

25 Max Pk/Pk: 29.0 A95: 15.9 0-Pk: 21.6 Max Pk/Pk: 9.8 A95: 5.7 0-Pk: 7.8

6.0

5

6.0

0 0

Y

-6.0

-5 -6.0

200 Max Pk/Pk: 54.3 A95: 32.2 0-Pk: 171.8

20 Max Pk/Pk: 15.5 A95: 11.8 0-Pk: 20.8

6.0

6.0

-0 0

Z

-6.0 -6.0

1 2 3 4 1 2 3 4

0 5 10 15 20 25 0 5 10 15 20 25

Seconds Seconds

`The above graphical output (on left) is actual unfiltered data from an elevator . All measurements and analyses are derived from the unfiltered

data. The graphs are divided into 4 windows; the top window is sound level as a function of time. The second window, is the x channel (front to

back) vibration time history, the 3 window is the y axis (side to side) time history, and the bottom window is the z axis (vertical) vibration time

history. The graphical output (on the right) is the ISO filtered data, the measure of ride quality.

International Services Building Elevator 23 International Services Building Elevator 23

Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95 Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95

3.0

1.5

Max Accel: 1.417 Max Decel: -0.965

Max Velocity: 2.56

2.5

Z Velocity m/sec

Z Accel. m/sec^2

1.0

2.0

0.5

1.5

0.0

1.0

-0.5

0.5

-1.0

0.0

-1.5 1 2 3 4 1 2 3 4

0 5 10 15 20 25 0 5 10 15 20 25

Seconds Seconds

International Services Building Elevator 23 International Services Building Elevator 23

Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95 Units: milli(g) File: 5TWG3E71.VE2 10:13:15 04/03/95

3.0

45

Max Distance: 40.26

2.5 Max Jerk: 2.7

40

2.0

1.5 35

Z Distance m

Z Jerk m/s^3

1.0 30

0.5

25

0.0

20

-0.5

-1.0 15

-1.5 10

-2.0

5

-2.5

0

1 2 3 4 1 2 3 4

-3.0

0 5 10 15 20 25 5 10 15 20 25

Seconds Seconds

Above are the acceleration time history (top left), jerk time history (bottom left), velocity time history (top right), and distance time

history (bottom right). These are derived from the unfiltered vertical axis time history and are a measure of elevator performance.

While in the EVA Vibration Analysis Tools software, the information can be expanded for study in great detail. Using the distance

time history, ‘bumps’ as seen in the ISO data can be located in the hoistway with a high degree of accuracy.

The Absolute Measure of Elevators and Escalators

V.10.40 03/2016

Spectrum - X Channel Probably the most powerful tool for diagnosing problems is

File: 5TWG3E71.VE2 10:13:15 04/03/95

Frequency (Hz) the Fourier transform. This allows the vibration to be

0 20 40 60 80 100 120

0.75

analyzed with respect to frequency content. For example, 6

Max = 0.696 @4.000Hz

Roller Guide inch roller guides on a 2.5 m/s elevator will rotate about

milli(g)

0.50

5.3 times per second (5.3 Hz). If roller guides are creating a

0.25

significant level of vibration, then this will show up in the

0.00 spectrum (vibration level versus frequency) of the signal.

5

This is an example that shows both a high vibration level at

milli(g)

0 about 5 Hz (roller guides) and 26 Hz (gear mesh)

7 8 9 10 11 12 13 14 15

Seconds

Escalator Tools – ISO 18738-2

The EVA-625 and EVA Vibration Analysis Tools are also optimized to evaluate escalator vibration on hand rails and steps

(ISO18738-2), as well as to meet the special requirements of measuring sound levels at the landings, incline section, and machine. It

also leads the operator in measurement of ambient sound level. An optional extension of the EVA-625 is the ETCH01 Tachometer

module. This is used for the measurement of handrail & step speed so that differences can be evaluated and addressed. An important

feature of the ETCH01 Tachometer and the optimized EVA software is the ability to quickly and accurately measure stopping

distances.

Options

ETCH01 Tachometer Module – Although the EVA system accurately calculates elevator velocity and distance in elevator

systems without the need of a tachometer, there are times when speed must be measured precisely in constantly moving systems

such as escalators. To meet these needs, the ETCH01 tachometer is an extension to all EVA-625 systems. This provides the ability

to measure & record, or display in real time, direct drive speed measurements for escalator handrails & steps, escalator stops,

elevator doors, or any moving system.

E10

E10G01 Z Axis +/-10g Range Accelerometer – Using the +/-10g accelerometer and 1024SPS sampling allows high

accuracy measurements of peak and average deceleration as well as stopping distances for evaluation of safety gear,

buffer, and electrical stops.

IMD-1 Escalator Step Skirt Index Measurement Device – The EVA-625 can be used with the IMD-1 to record and

analyze the newly defined escalator step/skirt index. The combination of EVA-625 and IMD-1 allows the measurement

of loaded gap (step edge to skirt distance) and coefficient of friction of escalator skirt panels dynamically.

Warranty & Support

The EVA system is provided with a full one year warranty. Software updates will be available to each registered user as new versions become available. PMT is also

establishing a world-wide distributor network to provide quick & reliable local support for the EVA system. PMT will provide unlimited telephone, emai support to

all EVA owners at no charge.

EVA-625 Specifications

Microprocessor: 8XC52 Family Running @ 11 MHz A/D Converter: 13 Bit Self Calibrating

Display: 4 Line by 20 Column Liquid Crystal Anti-Aliasing Filters: (Acceleration Channels)

Keyboard: 1 X 4 Sealed Membrane Software Selectable: 80 Hz or 160 Hz Cutoff

Communications: Serial RS232, 57600 Baud Sampling Rate: Software Selectable: 256 or 512 SPS/Channel

Clock: Integrated Battery Backed Real Time Clock Frequency Response: Acceleration Selectable 0 to 80/ 0 to 160 Hz

Battery: 12 V, Rechargeable Lead Acid Cel, 30 Hrs per Charge Frequency Response: Mic. A-Weighted Fast Response 8 KHz

Battery Charger: Universal Voltage Type 2S True RMS Sound Level Measurement

Sensors: 3 Accelerometers (x,y,z Triaxial arrangement) Range: Acceleration: +1.5g to –1.5g, Mic: 40 to 90db(A)

1 Condenser Microphone Resolution: Acceleration 600 micro(g), (.0006g), Mic: 1 dB

Accelerometer Technology: Piezoresistive, DC to 400 Hz Data Storage: Over 700 Seconds of 4 Channel Data (Serial Version)

PC Requirements: Windows XP, Windows Vista, Win 7, Win 8

Packaging: Weight: 4.3 (kg), 9.5 (lb)

Case: Structural Resin, Water Proof Accelerometer Housing: Stainless Steel

Dimensions: 27.3L x 24.7W x 12.7D (cm) (Removable Reorientation, Attachment to Structural Member)

10.7L x 9.7W x 5.0D (in) Chassis, Microphone Housing: Anodized Aluminum

Contact: Physical Measurement Technologies, Inc., 4 Ling Street, Marlborough, NH 03455 USA 1.603.876.9990 (tel) 1.603.876.9995 (fax)

www.pmtvib.com

The Absolute Measure of Elevators and Escalators

V.10.40 03/2016

S-ar putea să vă placă și

- EVA-625 Elevator Vibration Analysis System: Ride Quality Measurement & Analysis For The Elevator/Escalator IndustryDocument5 paginiEVA-625 Elevator Vibration Analysis System: Ride Quality Measurement & Analysis For The Elevator/Escalator IndustryBastian PetersÎncă nu există evaluări

- CEN TC 10 standards for lifts and safetyDocument20 paginiCEN TC 10 standards for lifts and safetyIván López PavezÎncă nu există evaluări

- N10P Mium 10991487enDocument92 paginiN10P Mium 10991487enAnton LyakhovÎncă nu există evaluări

- An Introduction: Otis at A GlanceDocument18 paginiAn Introduction: Otis at A GlanceavinashaviaviÎncă nu există evaluări

- Final QualityDocument25 paginiFinal QualityAkshat BansalÎncă nu există evaluări

- Waterfront Elevator Installation ProgressDocument7 paginiWaterfront Elevator Installation ProgressLakshan FonsekaÎncă nu există evaluări

- ElevatorDocument21 paginiElevatormmzzzÎncă nu există evaluări

- G2S PDF P3Document4 paginiG2S PDF P3Karthik BalaÎncă nu există evaluări

- Installation and Operating Instructions Overspeed Governor Type 7/8/9Document16 paginiInstallation and Operating Instructions Overspeed Governor Type 7/8/9RuiÎncă nu există evaluări

- Rev.1 ChecklistDocument1 paginăRev.1 ChecklistTian Fung WangÎncă nu există evaluări

- SIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorDocument402 paginiSIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorNguyễn Hữu Tuân100% (1)

- Lubrication and Elevator RopesDocument7 paginiLubrication and Elevator RopesRui Miguel Salvador100% (1)

- Z Type Escalator For USADocument10 paginiZ Type Escalator For USAa_salehiÎncă nu există evaluări

- Simplicity Series Minivator 1000/2000Document24 paginiSimplicity Series Minivator 1000/2000Mitch Knapp100% (1)

- Division 14 - Elevator Design Standards 1 GeneralDocument28 paginiDivision 14 - Elevator Design Standards 1 GeneralAnsara Pasir TumbohÎncă nu există evaluări

- Blank - Gold Maintenance Contract India PDFDocument5 paginiBlank - Gold Maintenance Contract India PDFJaganath PaniÎncă nu există evaluări

- Escalator OptionsDocument2 paginiEscalator Optionsjk.dasguptaÎncă nu există evaluări

- PresentationDocument19 paginiPresentationChang Chang100% (1)

- ZJ - Esclators PDFDocument8 paginiZJ - Esclators PDFShapolaÎncă nu există evaluări

- Escalator Planning GuideDocument24 paginiEscalator Planning GuideFERNSÎncă nu există evaluări

- Job Entry: Project Number: Job Reference: Job Title: Job Date: Loca OnDocument2 paginiJob Entry: Project Number: Job Reference: Job Title: Job Date: Loca OneduardoÎncă nu există evaluări

- Elevator Modernization Case StudyDocument22 paginiElevator Modernization Case Studyvaratharajank100% (1)

- Mitsubishi Lifts BrochureDocument28 paginiMitsubishi Lifts Brochurenaveenarora298040Încă nu există evaluări

- Amendement A3 Doc LiftinstituutDocument37 paginiAmendement A3 Doc LiftinstituutAidolan UlrichÎncă nu există evaluări

- ELEVATOR MAINTENANCE PMSDocument6 paginiELEVATOR MAINTENANCE PMSAndrie Eka saputraÎncă nu există evaluări

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDocument15 paginiThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapÎncă nu există evaluări

- 42-02-G004 B4 Motion GroupDocument86 pagini42-02-G004 B4 Motion GroupElputoAmo XDÎncă nu există evaluări

- Elevator Inspector: Passbooks Study GuideDe la EverandElevator Inspector: Passbooks Study GuideÎncă nu există evaluări

- Passenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPDocument13 paginiPassenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPyounesÎncă nu există evaluări

- HSVF Trouble Manual (Ver-0) 20111223 PDF Elevator TroubleshootingDocument1 paginăHSVF Trouble Manual (Ver-0) 20111223 PDF Elevator TroubleshootingGajendra mani PradhanÎncă nu există evaluări

- CDD983 01Document20 paginiCDD983 01Patrick KeeneÎncă nu există evaluări

- MitsubishiDocument270 paginiMitsubishipaijo klimpritÎncă nu există evaluări

- Installation Project Kone 3000 Minispace: GeneralDocument7 paginiInstallation Project Kone 3000 Minispace: Generalmanuel changÎncă nu există evaluări

- Guangzhou elevator parts supplier quotationDocument1 paginăGuangzhou elevator parts supplier quotationSolrac ToneÎncă nu există evaluări

- Vision Elevators Company ProfileDocument8 paginiVision Elevators Company ProfileMotlatjo RakgothoÎncă nu există evaluări

- Quick Reference Installation Guide: The Peelle CompanyDocument62 paginiQuick Reference Installation Guide: The Peelle CompanyRodrigo Antonio100% (1)

- Step Chain MaintenanceDocument4 paginiStep Chain MaintenanceRenato KaindoyÎncă nu există evaluări

- Carrier 30GTN PDDocument38 paginiCarrier 30GTN PDBudhi HermawanÎncă nu există evaluări

- Method Statement For Lift WorksDocument29 paginiMethod Statement For Lift WorksMuhammad AdamÎncă nu există evaluări

- S-72 - S-384 Stand-Alone Exchanges: Installation ManualDocument54 paginiS-72 - S-384 Stand-Alone Exchanges: Installation ManualcckmÎncă nu există evaluări

- Customer Information EN81-20Document2 paginiCustomer Information EN81-20Carolina Sansón0% (1)

- Mitsubishi Z EscalatorDocument11 paginiMitsubishi Z EscalatorFERNSÎncă nu există evaluări

- Escalator: Installation ManualDocument53 paginiEscalator: Installation ManualSamih AlraghbanÎncă nu există evaluări

- Thyssen Krupp Synergy-Elevator PDFDocument16 paginiThyssen Krupp Synergy-Elevator PDFAgnelo FernandesÎncă nu există evaluări

- TKE Mod SolutionsDocument32 paginiTKE Mod SolutionsLono BradyÎncă nu există evaluări

- Elevator Intercom Installation Guide 984 0012FS FULL SIZE R111407Document11 paginiElevator Intercom Installation Guide 984 0012FS FULL SIZE R111407asibrahimÎncă nu există evaluări

- 0 - Start Up Routine ManualDocument2 pagini0 - Start Up Routine ManualMoises PerelloÎncă nu există evaluări

- Elevator Anatomy Case ComponentsDocument1 paginăElevator Anatomy Case ComponentsVeenit TomarÎncă nu există evaluări

- DrakaTechTipNo.1 CompensatingChain PDFDocument2 paginiDrakaTechTipNo.1 CompensatingChain PDFKar Keong LewÎncă nu există evaluări

- Hydrofit General Contractors Guide 2012Document79 paginiHydrofit General Contractors Guide 2012Jawad MerhyÎncă nu există evaluări

- Elevator Modernization Case Study PDFDocument22 paginiElevator Modernization Case Study PDFAnwar PariyarathÎncă nu există evaluări

- IRIS NV Elevator Maintenance StandardDocument35 paginiIRIS NV Elevator Maintenance StandardAndiosoÎncă nu există evaluări

- ElevatorDocument46 paginiElevatorSuat YilmazÎncă nu există evaluări

- 1S9H52 27-4-09 AVRy ENDocument190 pagini1S9H52 27-4-09 AVRy ENMoran MartinesÎncă nu există evaluări

- PLC Based Elevator Control System-1Document26 paginiPLC Based Elevator Control System-1Belete GetachewÎncă nu există evaluări

- AU6860B Datasheet v01Document14 paginiAU6860B Datasheet v01david29xÎncă nu există evaluări

- Catalog ElenessaDocument14 paginiCatalog ElenessaThanh Hưng Nguyễn100% (1)

- Elevator Mechanic's Helper: Passbooks Study GuideDe la EverandElevator Mechanic's Helper: Passbooks Study GuideÎncă nu există evaluări

- Elevator Mechanic: Passbooks Study GuideDe la EverandElevator Mechanic: Passbooks Study GuideÎncă nu există evaluări

- Elevator Apprentice: Passbooks Study GuideDe la EverandElevator Apprentice: Passbooks Study GuideÎncă nu există evaluări

- System Galaxy Quick Guide: Configuration and OperationDocument47 paginiSystem Galaxy Quick Guide: Configuration and OperationTushar ImranÎncă nu există evaluări

- GDO-D2 Door Operator Controller ManualDocument17 paginiGDO-D2 Door Operator Controller ManualTushar Imran100% (2)

- BRK TestDocument1 paginăBRK TestTushar ImranÎncă nu există evaluări

- ARL-300 Error Codes - enDocument4 paginiARL-300 Error Codes - enDaceDrop79% (29)

- Install Shaft Encoder ManualDocument14 paginiInstall Shaft Encoder ManualMohammad Kazim60% (5)

- ARL-300 Error Codes - enDocument4 paginiARL-300 Error Codes - enDaceDrop79% (29)

- UCMPDocument2 paginiUCMPTushar ImranÎncă nu există evaluări

- MSP-16-Exp Hardware Manual V100.enDocument4 paginiMSP-16-Exp Hardware Manual V100.enTushar Imran100% (4)

- ARL-300 & ADrive Relevelling For Electric Lifts - en PDFDocument4 paginiARL-300 & ADrive Relevelling For Electric Lifts - en PDFHenri Kleine100% (1)

- Arcube Quick Installation Guide V101.enDocument22 paginiArcube Quick Installation Guide V101.enTushar Imran78% (9)

- Arcube Open-Loop Slip Compensation - enDocument1 paginăArcube Open-Loop Slip Compensation - enTushar ImranÎncă nu există evaluări

- Arcube Parameter Manual V10.enDocument17 paginiArcube Parameter Manual V10.enTushar Imran100% (9)

- ARCUBE Activation Guide.V101.enDocument5 paginiARCUBE Activation Guide.V101.enTushar Imran100% (3)

- Right choice for maximum yieldDocument223 paginiRight choice for maximum yieldRobert Mohovic100% (1)

- 3200 BrochureDocument3 pagini3200 BrochureTushar ImranÎncă nu există evaluări

- L1000 Technical ManualDocument522 paginiL1000 Technical ManualTushar ImranÎncă nu există evaluări

- L7 UsersManualDocument299 paginiL7 UsersManualTushar ImranÎncă nu există evaluări

- Helix - Vector Portable Demo Configuration - 16 - July - 14Document18 paginiHelix - Vector Portable Demo Configuration - 16 - July - 14ticojfsÎncă nu există evaluări

- Terrain Modeling Practice WorkbookDocument33 paginiTerrain Modeling Practice WorkbookAnkit BhattÎncă nu există evaluări

- VarAC V8.0.6 Is Here! With Path Finder, Simple - Advanced UI Mode, Offline Image Shrinker, UI Themes and Much MoreDocument7 paginiVarAC V8.0.6 Is Here! With Path Finder, Simple - Advanced UI Mode, Offline Image Shrinker, UI Themes and Much MoreuwpowerÎncă nu există evaluări

- AuditDocument7 paginiAuditАндрей МиксоновÎncă nu există evaluări

- Light Steel Technical SpecsDocument9 paginiLight Steel Technical Specspantermotor4877Încă nu există evaluări

- DVM Pro 2.0 Improvements - v2.0.0.36Document9 paginiDVM Pro 2.0 Improvements - v2.0.0.36Sahil Imran 38Încă nu există evaluări

- Akarsh Nair: Educational QualificationDocument3 paginiAkarsh Nair: Educational QualificationDheer SinghÎncă nu există evaluări

- IDEA Installation GuideDocument23 paginiIDEA Installation GuidebayuschÎncă nu există evaluări

- Case Construction Agricultural Ce Ag Latin America Epc 02 2021 Spare Parts Catalog DVD ComboDocument22 paginiCase Construction Agricultural Ce Ag Latin America Epc 02 2021 Spare Parts Catalog DVD Combomrsashleymorris090185qiy100% (112)

- Computer ShortcutsDocument2 paginiComputer ShortcutsRittik Ranjan Prasad XII B88% (8)

- Abishek Kumar NewDocument3 paginiAbishek Kumar Newvisioneer solutionÎncă nu există evaluări

- Logo Verification ReportDocument1 paginăLogo Verification ReportAdrian AmzarÎncă nu există evaluări

- Windows 7 SP1 Activation Via Phone or DAZ LoaderDocument6 paginiWindows 7 SP1 Activation Via Phone or DAZ LoaderEduardo ZimmerÎncă nu există evaluări

- UC 4.1 Milestone Release NotesDocument2 paginiUC 4.1 Milestone Release NotesRakez .BÎncă nu există evaluări

- Cloning VM in Virtualbox - Windows PDFDocument55 paginiCloning VM in Virtualbox - Windows PDFmiguelangel.mirandarios1109Încă nu există evaluări

- 3 Working Methods To Install Windows 11 On Unsupported PCsDocument11 pagini3 Working Methods To Install Windows 11 On Unsupported PCsSamrat BanerjeeÎncă nu există evaluări

- Haake Rheowin: User GuideDocument17 paginiHaake Rheowin: User GuideMax Alva SolisÎncă nu există evaluări

- F 31719784Document4 paginiF 31719784Nick LuftÎncă nu există evaluări

- List A ActualDocument4 paginiList A ActualJORGE_AZURDUY_V1379Încă nu există evaluări

- Schneider PLCUSB Driver - Release NotesDocument14 paginiSchneider PLCUSB Driver - Release Notescarissa,sakila,fadil csfÎncă nu există evaluări

- TEL - ExcelDocument41 paginiTEL - ExcelVijesh SoniÎncă nu există evaluări

- History of Microsoft OfficeDocument2 paginiHistory of Microsoft OfficeRichie BlasabasÎncă nu există evaluări

- A R P Senior Secondary School, Halduchaur Half Yearly Examination (2022-23) Subject: Computer TIME: 2:30 HRS Class: Vii Max. Marks 60Document2 paginiA R P Senior Secondary School, Halduchaur Half Yearly Examination (2022-23) Subject: Computer TIME: 2:30 HRS Class: Vii Max. Marks 60Ajay bishtÎncă nu există evaluări

- Resume Format in PhilippinesDocument3 paginiResume Format in PhilippinesAlnerdz Bueno17% (6)

- Assa Abloy RP300 Machine Protection Door - enDocument10 paginiAssa Abloy RP300 Machine Protection Door - enjonathansierraeÎncă nu există evaluări

- Create Excel UserForms For Data Entry in 6 Easy Steps - Tutorial and Practical Example3Document184 paginiCreate Excel UserForms For Data Entry in 6 Easy Steps - Tutorial and Practical Example3georgemashepaÎncă nu există evaluări

- Pricelist Kanakomputer Gejayan Web Januari 2023 Update 22Document7 paginiPricelist Kanakomputer Gejayan Web Januari 2023 Update 22Gigih HasnantyoÎncă nu există evaluări

- Sample Resume for Software Testing EngineerDocument3 paginiSample Resume for Software Testing EngineermartinÎncă nu există evaluări

- Resident X WalkThrough 0.4Document19 paginiResident X WalkThrough 0.4AlexeiÎncă nu există evaluări

- How To Connect Canon LBP 2900 To Windows 8.1 - Canon LBP 2900 RPC - Microsoft CommunityDocument5 paginiHow To Connect Canon LBP 2900 To Windows 8.1 - Canon LBP 2900 RPC - Microsoft CommunityalzindiÎncă nu există evaluări