Documente Academic

Documente Profesional

Documente Cultură

Taizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis Report

Încărcat de

Fabiola Sugey Gonzales CcamaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Taizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis Report

Încărcat de

Fabiola Sugey Gonzales CcamaDrepturi de autor:

Formate disponibile

Taizhou Zhuoxin Plastics Co., Ltd.

PPR Raw Material Analysis Report

Name: PPR Raw Material

Origin: Hysung, South Korea

Model: R200P

Feature: Pipe Extrusion, Food Grade

Product Data

Property Test Condition Test Method Test Data Data Unit

Density ASTM D792 0.91 g/cm3

Basic MFR 230℃, 2.16kg ASTM D-1238 0.2 g/10min

MFR 190℃, 5.0kg ASTM D-1238 0.4 g/10min

Tension Stress Break Tension ASTM D-638 230 kg/cm2

IZOD 23℃ ASTM D-256 No break kg·cm/cm

Flexural

ASTM D-790 8,500 kg/cm2

Modulus

IZOD -20℃ ASTM D-256 3 kg·cm/cm

Mechanical

Elongation ASTM D-638 >400 %

Tension Stress Yield Tension ASTM D-638 270 kg/cm2

Surface

HS Method >1013 Ω

Resistivity

IZOD 0℃ ASTM D-256 8 kg·cm/cm

Coefficient of

Linear 0-110℃ Dilatometer 1.5×10-4 K-1

Expansion

Thermal

Vicat Softening

ASTM D-1525 130 ℃

Point

Melting Point HS Method 141 ℃

Product Introduction

PP-R(polypropylene random), enjoying good toughness and high strength,

can be easily processed and resist creep under high temperature. In addition,

as it has PP-R’s unique advantage-high transparency, it is widely used in

pipe, sheet, commodity, packing material, household appliance component

and film production.

PP-R pipe is made from extruded random copolymer polypropylene, which

can be injected into pipe fitting. Polypropylene random copolymer is a kind of

polypropylene, whose basic structure of macromolecular chain is modified by

various additional single moleculars. Ethylene, which can change

polypropylene’s physical property, is adopted most often. Compared to PP

homopolymer, random copolymer improves optical property(increases

transparency while decreasing opaque fog), enhances shock resistance and

flexibility. Besides, it lowers melting temperature and heat welding

temperature. Meanwhile, its chemical stability, water vapor isolation and

organ sensation(low odor) is the same as homopolymer. Random copolymer

is applied in blow molding and injection molding plastics, film and sheet

extrusion process, making food and medicine package materials, and daily

necessities.

Production Technique:

PP-R pipe is produced with extrusion technique: PP-R materials in hopper

enter extrusion machine by self-weight; heated, squeezed and mixed in

extruder barrel; squeezd out from die mouth after sufficient plasticization,

enter calibrator; through dragger machine and length measurement, cut by

cutterbar; put into warehouse after examination. Pipe fitting is produced with

injection technique.

Technical Process:

Pipe Production:

PP-R raw material→Vacuum suction and loading→Storing in

hopper→Feeding material→Extrusion and forming→Cooling and

shaping→Dragging→Cutting→Examining→Put in warehouse

Pipe Fitting Production:

PP-R raw material→Transferring and loading material→Storing in

hopper→Feeding material→Heating and melting→Squeezing and

injecting→Cooling and shaping→Opening mold→Examining→Put in

warehouse

Pipe Extrusion Parameter:

1. Screw Speed:5~38r/min

2. Barrel Temperature Distribution: 1~2 Area 180~190℃

3~4 Area 200~210℃

3. Mold Temperature: 200℃

4. Dragging Speed: 2~20m/min

Fittings Injection Parameter:

1. Barrel Temperature Distribution: Rear 160~170℃

Middle 200~230℃

Front 180~200℃

2. Nozzle: 170~190℃

3. Mold: 40~80℃

The defective goods in PP-R pipe production can be broken and reused,

which will increase the availabity of raw materials and reduce production cost,

improving economic performance.

S-ar putea să vă placă și

- Braskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerDocument2 paginiBraskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerBFCÎncă nu există evaluări

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 paginiGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuÎncă nu există evaluări

- WP PPR - Thermopipe SubmittalDocument36 paginiWP PPR - Thermopipe SubmittalMohammad Rashad BarakatÎncă nu există evaluări

- TDS Pe 100 Ub5206h 02 PDFDocument2 paginiTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraÎncă nu există evaluări

- 05 PEXb XP650 - 1. TDS (Data Sheet)Document2 pagini05 PEXb XP650 - 1. TDS (Data Sheet)Mohammad Rashad BarakatÎncă nu există evaluări

- TDS Pe 100 Ub5206h 01 PDFDocument2 paginiTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraÎncă nu există evaluări

- Product Data and Technical Information: Test MethodDocument1 paginăProduct Data and Technical Information: Test MethodMohamadMostafaviÎncă nu există evaluări

- HTLP Heat Shrinkable SleeveDocument2 paginiHTLP Heat Shrinkable SleeveGanesh EshwarÎncă nu există evaluări

- 02 Bab IiDocument2 pagini02 Bab IiariefÎncă nu există evaluări

- TDS SCGC PP P348S Rev Mar2022Document3 paginiTDS SCGC PP P348S Rev Mar2022y.s.6saputroÎncă nu există evaluări

- Green PipeDocument62 paginiGreen Pipecrebdt2017Încă nu există evaluări

- 7000FDocument1 pagină7000FGabs GabrielaÎncă nu există evaluări

- TDS Pe 008 Up4806hDocument2 paginiTDS Pe 008 Up4806hariefÎncă nu există evaluări

- PP-R Pipe GradeDocument6 paginiPP-R Pipe GradeRAJESHÎncă nu există evaluări

- TDS Pe 200 SF5007Document2 paginiTDS Pe 200 SF5007Oktaviandri SaputraÎncă nu există evaluări

- Topilene R200PDocument2 paginiTopilene R200PNguyễn Hồng NamÎncă nu există evaluări

- Topilene R200P PDFDocument2 paginiTopilene R200P PDFAli MÎncă nu există evaluări

- Topilene R200P PDFDocument2 paginiTopilene R200P PDFEmmylouCasanovaÎncă nu există evaluări

- Polypropylene Random Copolymer: Technical Data SheetDocument2 paginiPolypropylene Random Copolymer: Technical Data SheetEmmylouCasanovaÎncă nu există evaluări

- R200P Data SheetDocument2 paginiR200P Data SheetPRIME STEEL RE-ROLLING MILLSÎncă nu există evaluări

- PP Trilene Hi10hoDocument2 paginiPP Trilene Hi10hoLaili AzkiyahÎncă nu există evaluări

- Hdpe H5604FDocument2 paginiHdpe H5604Fakankshas06Încă nu există evaluări

- TDS Pe 201 Sf5008eDocument2 paginiTDS Pe 201 Sf5008eOktaviandri SaputraÎncă nu există evaluări

- BandarImam 0200Document2 paginiBandarImam 0200art72 talÎncă nu există evaluări

- TDS SCGC PP P303S Rev Mar2022Document3 paginiTDS SCGC PP P303S Rev Mar2022y.s.6saputroÎncă nu există evaluări

- Unlock Polypropylene CopolymerDocument1 paginăUnlock Polypropylene CopolymerYuli NugraheniÎncă nu există evaluări

- SCG H5480SDocument2 paginiSCG H5480Sakankshas06Încă nu există evaluări

- Petg Film CurbellDocument1 paginăPetg Film CurbellVinaya Almane DattathreyaÎncă nu există evaluări

- TDS Pe 002 Uf1810t 03Document2 paginiTDS Pe 002 Uf1810t 03qc jrpÎncă nu există evaluări

- P750JDocument1 paginăP750JTan Chen TatÎncă nu există evaluări

- Product: High Density Polyethylene (HDPE) Grade: Film Trade Name: HD-7000FDocument2 paginiProduct: High Density Polyethylene (HDPE) Grade: Film Trade Name: HD-7000F李万福Încă nu există evaluări

- TDS PP 306 Hi10ho 03Document2 paginiTDS PP 306 Hi10ho 03indahÎncă nu există evaluări

- H6105JUDocument1 paginăH6105JUhunghiepvanÎncă nu există evaluări

- TDS - TR144 - Astm (Eng)Document2 paginiTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoÎncă nu există evaluări

- Data Sheet EL-Lene H1000PC Rev - Feb - 09Document2 paginiData Sheet EL-Lene H1000PC Rev - Feb - 09kuntasee.duckÎncă nu există evaluări

- HF10TQ: IPP Film GradeDocument2 paginiHF10TQ: IPP Film GradeLaili AzkiyahÎncă nu există evaluări

- Equate EMDA 6200Document2 paginiEquate EMDA 6200HichamSalamaÎncă nu există evaluări

- 11-Almunaif Prr-Pipes and FittingsDocument44 pagini11-Almunaif Prr-Pipes and FittingsmohammedÎncă nu există evaluări

- TDS-PE-102-UB5502H (Provisional) 2019Document2 paginiTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraÎncă nu există evaluări

- Technical Data SheetDocument2 paginiTechnical Data SheetLeductoan LeÎncă nu există evaluări

- Guida Coprax Eng 2015 LightDocument82 paginiGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- Ppc-Pipe-Hyosung-Topilene HB240PDocument2 paginiPpc-Pipe-Hyosung-Topilene HB240PMohamed RabeaÎncă nu există evaluări

- Nf528t Rev.0Document1 paginăNf528t Rev.0MZY Commercial EnterprisesÎncă nu există evaluări

- Product DatasheetDocument1 paginăProduct Datasheetأبو أميرÎncă nu există evaluări

- 3 - 2 - 4 - Hdpe Film 2-7000F PTT - TDSDocument2 pagini3 - 2 - 4 - Hdpe Film 2-7000F PTT - TDSPhuoc TranÎncă nu există evaluări

- FK1828Document3 paginiFK1828dignityymartÎncă nu există evaluări

- Topilene J800Document1 paginăTopilene J800KevinGarciaÎncă nu există evaluări

- PEADM5372Document2 paginiPEADM5372nicolas yoris marcoglieseÎncă nu există evaluări

- TDS Pe 202 SP4808Document2 paginiTDS Pe 202 SP4808Desri AkbarÎncă nu există evaluări

- Bopp TapeDocument1 paginăBopp TapebouzirpafÎncă nu există evaluări

- Asrene (Hdpe SP4808)Document2 paginiAsrene (Hdpe SP4808)AgusPurwantoÎncă nu există evaluări

- PP Trilene He2.0tfDocument2 paginiPP Trilene He2.0tfLaili AzkiyahÎncă nu există evaluări

- LT DiffusersDocument8 paginiLT DiffusersJam OdonelÎncă nu există evaluări

- High Density Polyethylene: Cynpol Hd5502Document1 paginăHigh Density Polyethylene: Cynpol Hd5502Melissa ValeroÎncă nu există evaluări

- TDS PP 305 HF10TQ 02Document2 paginiTDS PP 305 HF10TQ 02Lungkoneng HRDÎncă nu există evaluări

- Elite NG 5401BDocument3 paginiElite NG 5401BAbdo WalidÎncă nu există evaluări

- TDS Pe 010 Uf1820t 04Document2 paginiTDS Pe 010 Uf1820t 04Lenggana SukriaÎncă nu există evaluări

- Drive Panasonic A5 Manu 01Document48 paginiDrive Panasonic A5 Manu 01aaauserhoyÎncă nu există evaluări

- Classification of Impression Materials: PolysulphidesDocument3 paginiClassification of Impression Materials: PolysulphidesBarış ToprakÎncă nu există evaluări

- En71 SGSDocument46 paginiEn71 SGSMax Arias100% (1)

- Pharmaceutical AerosolDocument42 paginiPharmaceutical AerosolAnaliza Kitongan LantayanÎncă nu există evaluări

- ecoMAX 200 W - DTR - Wydanie1.6 - EN PDFDocument32 paginiecoMAX 200 W - DTR - Wydanie1.6 - EN PDFzlata doraÎncă nu există evaluări

- Cambridge IGCSE: CHEMISTRY 0620/63Document12 paginiCambridge IGCSE: CHEMISTRY 0620/63afyÎncă nu există evaluări

- Basement Parking PDFDocument6 paginiBasement Parking PDFShameel PtÎncă nu există evaluări

- Dd0904 Plant Layout and Material HandlingDocument2 paginiDd0904 Plant Layout and Material HandlingVinod BhagatÎncă nu există evaluări

- Check ValveDocument10 paginiCheck ValvekutecoolÎncă nu există evaluări

- Trelleborg Orkot PDFDocument20 paginiTrelleborg Orkot PDFpepeÎncă nu există evaluări

- GB 17107 Part4Document4 paginiGB 17107 Part4Imran IshakÎncă nu există evaluări

- Design Guidelines For SnapfitDocument6 paginiDesign Guidelines For SnapfitTiago Camargo AlvesÎncă nu există evaluări

- High School Clay For WeeblyDocument71 paginiHigh School Clay For Weeblyapi-293964578100% (6)

- Ch04 Design Calculation of Structures and Fatigue BehaviourDocument20 paginiCh04 Design Calculation of Structures and Fatigue Behaviourmostafa mostafaÎncă nu există evaluări

- Current Efficiency in Electrometallurgy (Revision)Document18 paginiCurrent Efficiency in Electrometallurgy (Revision)harishidaytÎncă nu există evaluări

- DFBN FilterDocument10 paginiDFBN FilterPutut SuprihartonoÎncă nu există evaluări

- El Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Document5 paginiEl Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Marwa KoubaiesÎncă nu există evaluări

- Din 571Document3 paginiDin 571mugiwara ruffyÎncă nu există evaluări

- Impact TestDocument7 paginiImpact TestChukkaÎncă nu există evaluări

- Office Safety ChecklistDocument3 paginiOffice Safety ChecklistJaijeev Pali100% (1)

- Turf TigerDocument30 paginiTurf TigerNicole Dechert100% (1)

- Series of Eyeleting Machine: Chengdu A-OK Electromechanical Equipment Co.,LtdDocument8 paginiSeries of Eyeleting Machine: Chengdu A-OK Electromechanical Equipment Co.,LtdTimmy Shop TimmyCareÎncă nu există evaluări

- Mass Balance CalculationsDocument3 paginiMass Balance CalculationsSiphoÎncă nu există evaluări

- About Dissimilar MetalsDocument1 paginăAbout Dissimilar MetalsIsabel Christina Gonzalez MoralesÎncă nu există evaluări

- Sample Preconditioning: On-Line Liquid AnalysisDocument12 paginiSample Preconditioning: On-Line Liquid AnalysispinitÎncă nu există evaluări

- 2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)Document2 pagini2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)DertySulistyowatiÎncă nu există evaluări

- 4 Way Reversing Valve Series SHF L Data PDFDocument3 pagini4 Way Reversing Valve Series SHF L Data PDFDharani PathyÎncă nu există evaluări

- Recycling Aluminum Aerospace AlloysDocument5 paginiRecycling Aluminum Aerospace Alloysignite182Încă nu există evaluări

- 2014 1275 SCANFiningLARTCDocument19 pagini2014 1275 SCANFiningLARTCdonald55555Încă nu există evaluări

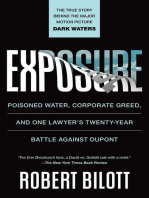

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDe la EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontEvaluare: 4.5 din 5 stele4.5/5 (18)

- Waste: One Woman’s Fight Against America’s Dirty SecretDe la EverandWaste: One Woman’s Fight Against America’s Dirty SecretEvaluare: 5 din 5 stele5/5 (1)

- The Cyanide Canary: A True Story of InjusticeDe la EverandThe Cyanide Canary: A True Story of InjusticeEvaluare: 4 din 5 stele4/5 (52)

- Introduction to Ecology and Environmental Laws in IndiaDe la EverandIntroduction to Ecology and Environmental Laws in IndiaÎncă nu există evaluări

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksDe la EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksÎncă nu există evaluări

- Slow Violence and the Environmentalism of the PoorDe la EverandSlow Violence and the Environmentalism of the PoorEvaluare: 4 din 5 stele4/5 (5)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDe la EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionEvaluare: 3 din 5 stele3/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionDe la Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionÎncă nu există evaluări

- Principles of direct and superior responsibility in international humanitarian lawDe la EverandPrinciples of direct and superior responsibility in international humanitarian lawÎncă nu există evaluări

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaDe la EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaEvaluare: 4 din 5 stele4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldDe la EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldEvaluare: 5 din 5 stele5/5 (1)

- Environmental Justice: Issues, Policies, and SolutionsDe la EverandEnvironmental Justice: Issues, Policies, and SolutionsÎncă nu există evaluări

- Environmental Justice in New Mexico: Counting CoupDe la EverandEnvironmental Justice in New Mexico: Counting CoupÎncă nu există evaluări

- Introduction to Ecology and Environmental Laws in IndiaDe la EverandIntroduction to Ecology and Environmental Laws in IndiaÎncă nu există evaluări

- Busted!: Drug War Survival Skills and True Dope DDe la EverandBusted!: Drug War Survival Skills and True Dope DEvaluare: 3.5 din 5 stele3.5/5 (7)

- Down to the Wire: Confronting Climate CollapseDe la EverandDown to the Wire: Confronting Climate CollapseEvaluare: 4.5 din 5 stele4.5/5 (8)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawDe la EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawEvaluare: 4 din 5 stele4/5 (334)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontDe la EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontEvaluare: 4.5 din 5 stele4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsDe la EverandEnvironmental Education in Practice: Concepts and ApplicationsÎncă nu există evaluări

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksDe la EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksÎncă nu există evaluări

- Debunking Creation Myths about America's Public LandsDe la EverandDebunking Creation Myths about America's Public LandsÎncă nu există evaluări

- Obstacles to Environmental Progress: A U.S. perspectiveDe la EverandObstacles to Environmental Progress: A U.S. perspectiveÎncă nu există evaluări

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933De la EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Încă nu există evaluări