Documente Academic

Documente Profesional

Documente Cultură

Development of Nonwoven Fabric From Recycled Fibers 2165 8064 1000289

Încărcat de

Ronak JoshiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Development of Nonwoven Fabric From Recycled Fibers 2165 8064 1000289

Încărcat de

Ronak JoshiDrepturi de autor:

Formate disponibile

Science Sharma and Goel, J Textile Sci Eng 2017, 7:2

ile &

xt DOI: 10.4172/2165-8064.1000289

urnal of Te

En

Journal of Textile Science & Engineering

gineering

Jo

ISSN: 2165-8064

Research Article

Research Article Open Access

Development of Nonwoven Fabric from Recycled Fibers

Sharma R1* and Goel A2

1

Department of Home Science, Dayalbagh Educational Institute Agra, Uttar Pradesh, India

2

Department of Clothing and Textiles, G. B. Pant University of Agriculture and Technology, Pantnagar, Uttarakhand, India

Abstract

“Nothing is waste until and unless we know how to use it”.

Recycling is a way to process, the used materials (waste) into new products to prevent waste of potentially useful

materials. Textile waste recycling becomes more important phenomenon; bearing in mind the limited availability of

resources to produce natural fibers as well as fossil raw materials to make synthetic fibres. Recycled textile waste

can be further converted in the form of fiber for filling, recycled yarn, recycled woven fabric, recycled nonwoven

fabrics etc. Therefore the present study has been conducted to prepare nonwoven fabric by using recycled cotton

and polyester fibers.

Keywords: Nonwoven; Recycling; Waste textiles;, Needle punching Objectives of the Study

Introduction Major objective of the present research is to develop a nonwoven

fabric made-up of recycled cotton fiber (RCF) and recycled polyester

Recycling is a way to process, the used materials (waste) into new fiber (RPF) blend which gives a new approach of recycled fiber

products to prevent waste of potentially useful materials. It reduces application. Another objective of the present paper is to test the

the consumption of fresh raw materials, energy usage, air pollution various properties of developed nonwoven fabrics to analyze the best

created mainly from incineration, water pollution and land pollution proportion.

mainly from land filling. Recycling is a key component of modern waste

reduction and is the third component of the "Reduce, Reuse, Recycle Material and Methods

and Recover" (4R’s) waste hierarchy.

The present invention provides nonwoven fabric prepared with

Cotton and polyester fibre have long been dominant fibres in the recycled cotton and recycled polyester blended fibers with such a

textile industry. Low quality grey fibres or low value textile wastes unique texture and properties which makes it suitable for preparing

predominantly consist of cotton and polyester fibers. These fibres could the various household and commercial products out of it [6-10].

not be used directly in the apparel industry but have a high potential

in the manufacturing of recycled woven and nonwovens fabrics that a) Raw material used for nonwoven fabric: Two recycled

are quite promising materials in the current market. Use of recovered fibers, cotton and polyester were selected for the preparation of

synthetic fibrous waste is particularly attractive as the processing nonwoven fabrics. Cotton and polyester both fibers were most widely

characteristics of properly recovered synthetic do not differ much from used fiber in clothing and other textile industry, may be this was the

those of original synthetic staple and cut filaments [1-10]. reason that most of the textile waste comprised of these two fibers.

Cotton and polyester fibers have long been dominant fibers in the b) Physical properties of recycled fibers: In the present

textile industry. Low quality greige fabrics or low value textile wastes investigation, selected fibers were tested in terms of fiber length,

predominantly consist of cotton and polyester fibers. Saravanan [1] tenacity, crimp, fineness, elongation, diameter, moisture content and

microscopic appearance by using standard test procedures. Testing

explained that the scope of the waste from cotton industry extends its

was necessary as the fiber properties directly affect the properties of

products to upholstery cloth, cover cloths, blanket, towels, shirting,

developed nonwoven fabric. Before testing recycled cotton and recycled

quilts, underwear, carpet, industrial roller cloth, electric cabling,

polyester, fibers were kept in standard conditions for 24 h i.e., 27°C

hosiery and in the manufacture of asbestos yarn, paper, linoleum temperature and 65% RH. It was done to avoid deviation in results.

and regenerated fibres. It has been reported that, the total amount of

waste generated in India is about 80,000 to 85,000 tons per annum and c) Preparation of nonwoven fabric by recycled fiber:

this obviously needs proper treatment apart from disposal as landfill. Nonwoven fabrics were prepared in three ratios (70:30, 50:50 and

Similarly Claudio [2] reported that with the rise in production in the 70:30) of recycled cotton and recycled polyester fibers by using needle

punching method. The needle punch nonwoven blended recycled

fashion industry, demand for man-made fibers, especially polyester, has

nearly doubled in the last 15 years [3-5].

Hence visualizing the ready availability of recycled cotton fiber and *Corresponding author: Sharma R, Assistant Professor, Department of

recycled polyester fibers and their profusion, they were selected to be Home Science, Dayalbagh Educational Institute Agra,Uttar Pradesh, India; Tel:

05622801545; E-mail: dr.rachnasharma12@gmail.com

processed into nonwoven fabrics. A good quality nonwoven fabric can

be formulated by using needle punching technique. The present study Received February 28, 2016; Accepted April 05, 2017; Published April 10, 2017

emphasis selection, testing, blending of recycled cotton and polyester Citation: Sharma R, Goel A (2017) Development of Nonwoven Fabric from

fibers in various ratios for preparation of needle punched nonwoven Recycled Fibers. J Textile Sci Eng 6: 289. doi: 10.4172/2165-8064.1000289

fabric. This article prominence the analysis of best ratios for the Copyright: © 2017 Sharma R, et al. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

preparation of blended nonwoven fabric by using recycled cotton fibers

use, distribution, and reproduction in any medium, provided the original author and

and recycled polyester fibers. source are credited.

J Textile Sci Eng, an open access journal Volume 7 • Issue 2 • 1000289

ISSN: 2165-8064

Citation: Sharma R, Goel A (2017) Development of Nonwoven Fabric from Recycled Fibers. J Textile Sci Eng 6: 289. doi: 10.4172/2165-8064.1000289

Page 2 of 3

cotton and recycled polyester was prepared by passing through the second loom where the web gets needle punched successively to get the

various steps are discussed below. middle density nonwoven fabric of recycled fibers. In this process of

needle punching the fiber web is passed through there needle punching

Blending looms, so that the more compressed nonwoven fabric can be developed

Recycled cotton and recycled polyester fibers were blended [16-18].

manually in three different ratios to prepare web for nonwoven fabrics.

Calendaring

Blending ratios are of 30:70, 50:50 and 70:30 i.e., in first ratio 30%

recycled cotton and 70% recycled polyester then equal amount of each Calendering is a finishing process used on nonwoven where fabric

fiber 50% recycled cotton and 50% recycled polyester. Another ratio is passed under hot rollers at high temperatures and pressures. The

comprises 30% recycled polyester and 70% recycled cotton [11-15]. fabric runs through rollers that polish the surface and make the fabric

smoother and more lustrous. High temperatures and pressure are used

Carding as well. Fabrics that go through the calendering process feel thin, glossy

Carding machine, Vijay Textiles (M/C AQQ1Q4) was employed and papery. For the present study 180°C temperature was kept for

in the present research work. It consists of seven rollers covered with upper roller and 170°C was kept for lower roller. The needle punching

iron spikes of different length and thickness in each roller. Fiber mass and calendering process was carried out separately for each kind of

was placed evenly on lattice of carding machine. This machine worked recycled blended fiber samples.

as to make web of fibers and also it removes dust and other impurities. Physical properties of blended nonwoven fabrics

Carding machine helped in straightening and parallelization of the

fibers into thin web known as lap. To make a good quality non-woven The physical properties of all the developed fabrics were tested.

fabric, this is very essential to card fibers properly to prepare even web. Tests were carried out to evaluate fabric weight (g/m2), fabric thickness

(mm), bending length, abrasion loss (per cent), tensile strength (g/

Web feeding cm2), elongation (per cent) of the prepared non-woven samples, as per

their applicability.

Layers of recycled cotton and recycled polyester web were feed

into the needle punching machine by means of web feeder. Web feeder Result and Discussion

prevents the layers to get deformed.

a) Physical properties of experimental fibers

Pre needling punching loom

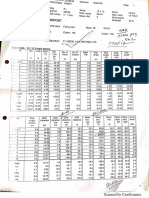

The results of the comparable physical properties of experimental

The fluffy layers of fiber web were then fed through a series of fibers are presented in Table 1.

needle punching machine to interlace various layers using low needle

density. It was a preliminary 3D interlacing to entangle fibers. Through b) Physical properties of blended nonwoven fabrics: The physical

this process the fluffy mass of fibers web get slightly compact. properties of all the developed fabrics were tested. Results are discussed

characteristic wise as under fabric weight as it is apparent from Table

Needle punching

2 that the fabric weight for blend of cotton and polyester nonwoven

The pre punched layered web of blended fibers (each separately) fabric 30:70, 50:50, 70:30 was 188, 200, 190 g/m2 respectively.

was delivered by means of conveyer belt and rollers through two needle

punching looms placed back to back. Fabric passed from first loom to i. Fabric thickness: Thickness of blended nonwoven fabrics in all

Sl. No. Properties RCF RPF

1 Length (mm) 21.50 66.80

2 Tenacity (g/denier) 2.73 4.46

3 Elongation (%) 6.3 19.41

4 Fiber fineness/count (dtex) 1.577 3.92

5 Crimp No/inch 2/inch 6/inch

6 Diameter (microns) 16.75 24.29

RCF: Recycled Cotton Fiber; RPF: Recycled Polyester Fiber.

Table 1: Physical properties of experimental fibers.

Fabric properties Fabric direction Nonwoven fabric ratio

30:70 (RC:RP) 50:50 (RC:RP) 70:30 (RC:RP)

Fabric weight g/m2 - 188 200 190

Fabric Thickness mm - 1.86 2.60 2.75

Busting strength kg/cm2 - 7.00 6.8 3.56

Abrasion resistance (percent weight loss) - 1.42 0.52 0.34

Tensile strength MD 16.84 14.60 3.60

(kg/cm2) CD 23.6 21.49 7.80

Fabric elongation (%) MD 36 35.00 44.11

CD 30 32 37

Bending Length (cm) MD 4.10 4.50 3.50

CD 6.90 5.3 5

RC: Recycled Cotton; RP: Recycled Polyester; MD: Machine Direction; CD: Cross Direction.

Table 2: Physical properties of developed nonwoven fabric samples.

J Textile Sci Eng, an open access journal Volume 7 • Issue 2 • 1000289

ISSN: 2165-8064

Citation: Sharma R, Goel A (2017) Development of Nonwoven Fabric from Recycled Fibers. J Textile Sci Eng 6: 289. doi: 10.4172/2165-8064.1000289

Page 3 of 3

three ratios i.e., 30:70 (C:P), 50:50, (C:P) 70:30 (C:P) was found to be appropriate properties of this combination make it suitable ecofriendly

1.86 mm, 2.60 mm, 2.75 mm respectively. fabric for use in various applications of textiles.

ii. Bursting strength: Bursting strength was acquired as 7 kg/cm2 References

in 30:70 cotton polyester blend, 6.80 kg/cm2 in 50:50 cotton polyester 1. Saravanan K (2011) Environment protection by textile recycling. The Indian

ratios and 3.56 kg/cm2 in 70:30 cotton polyester blend. Textile Journal.

iii. Abrasion resistance: Abrasion loss of the fabric prepared from 2. Claudio L (2007) Waste Couture: Environmental Impact of the Clothing

recycled cotton & recycled polyester blend having 30:70 (C:P), 50:50 Industry. Environ Health Prospect 115: 449-454.

(C:P), and 70:30 (C:P) ratio was recorded as 0.34%, 0.52% and 1.42% 3. Anonymous (2012) What is textile recycling.

respectively. 4. Anonymous (2013) Cotton Recycling en.wikipedia.org/wiki/Cotton recycling.

iv. Tensile strength: Table 2 depicts that blended nonwoven fabric 5. Blackburn RS (2009) Sustainable Textiles: Life Cycle and Environmental

samples of recycled cotton with recycled polyester fiber were also Impact. Woodhead publishing ltd 14.

tested for tensile strength and maximum tensile strength was observed 6. Booth JE (1996) Principles of Textile Testing. (5thedn), New Delhi. CBS

in blended nonwoven fabric prepared with 30:70 ratio of cotton and publishers and distributors 609.

polyester i.e., 16.84 kg/cm2 in machine direction and 23.60 kg/cm2 in 7. Chiparus (2004) Bagasse fiber for production of nonwoven materials. Thesis

cross direction followed by 50:50 ratio of cotton and polyester i.e., Ph.D Textile Science, Louisiana State University.

14.60 kg/cm2 in machine direction and 21.49 kg/cm2 in cross direction 8. Council for Textile Recycling (1997) Don't Overlook Textiles! from info house

and 70:30 ratio of cotton and polyester i.e., 3.60 kg/cm2 in machine – United States PDF.

direction and in 7.80 g/cm2 cross direction. 9. Debnath CR, Roy AN (1999) Needle punched nonwoven. Indian Textile Journal

108: 34-37.

v. Elongation: Non-woven fabric blend in 30:70 ratio (recycled

cotton with recycled polyester) shows 36% elongation in machine 10. Domina T, Koch K (1997) The Textile Waste Lifecycle. Clothing and Textiles

direction and 30% in cross direction followed by 50:50 and 70:30 Research Journal 15: 96-102.

ratio i.e., 35 and 32% & 44.11 and 37 in machine and cross directions 11. Hawley JM (2006) Textile Recycling: A system perspective. In: Wang Y ed.

respectively. Recycling in Textiles, Woodhead Publishing Ltd, Cambridge, UK 11-13.

12. Gramsch S (2013) ITWM Research News.

vi. Bending length: Values of bending length of cotton/polyester

blended samples in 30:70, 50:50, 70:30 ratios was observed 4.10 cm, 13. Maity S, Singha K (2012) Structure-Property Relationships of Needle-Punched

Nonwoven Fabric. Frontiers in Science 2: 226-234

4.50 cm and 3.50 cm in machine direction and 6.90 cm, 5.3 cm and 5

cm in cross direction respectively as shown in Table 2. 14. Ravishankar G (2013) Durables to Disposables - Are we ready for a phase

change?.

Summary and Conclusion 15. Sharma R, Goel A (2015) Status of Textiles Recycling and Waste Utilization

in Amroha District. International Journal of Basic and Applied Agriculture

Comparison of properties was done to obtain best blended Research 13: 112-116.

nonwoven fabric among all ratios. It can be concluded that best

16. Silva E (2013) Recycled polyester and its physical properties: Literature

proportion of nonwoven blended fabric on the basis of physical Review. TMS 762 physical properties phd FPS-NCSU: 28.

properties was 30:70 cotton and polyester blend. We claim this blended

nonwoven fabric as best combination of recycled cotton and polyester 17. Wang Y (2006) Recycling in Textiles. Woodhead publishing ltd CRC press: 148.

fibers for the preparation of this fabric. Highest tensile strength and 18. Wang Y (2010) Fiber and textile waste utilization. Springer: 135-143.

J Textile Sci Eng, an open access journal Volume 7 • Issue 2 • 1000289

ISSN: 2165-8064

S-ar putea să vă placă și

- The Bread Lover's Bread Machine CookbookDocument921 paginiThe Bread Lover's Bread Machine CookbookRicardo Yasuo Hirano93% (14)

- Developing The Leader Within You by John CDocument7 paginiDeveloping The Leader Within You by John CRonak JoshiÎncă nu există evaluări

- Personality TestDocument24 paginiPersonality Testapi-3827604100% (4)

- Belgian Ale by Pierre Rajotte (1992)Document182 paginiBelgian Ale by Pierre Rajotte (1992)Ricardo Gonzalez50% (2)

- Wolfe Edwin Episodes With GurdjieffDocument20 paginiWolfe Edwin Episodes With Gurdjieffzzanko100% (3)

- Marshall Goldsmith - 20 Bad HabitsDocument1 paginăMarshall Goldsmith - 20 Bad HabitsLucky Duck100% (2)

- Management StoriesDocument95 paginiManagement StoriesRonak Joshi100% (1)

- X KiltDocument60 paginiX KiltHennot Do NorteÎncă nu există evaluări

- Electrical Conductivity Measurement of Fibers & YarnsDocument8 paginiElectrical Conductivity Measurement of Fibers & YarnsAhmad SamerÎncă nu există evaluări

- Textiles - Textile Production DiderotDocument248 paginiTextiles - Textile Production DiderotThe 18th Century Material Culture Resource Center80% (5)

- A Review of Spun Bond Process : Hosun Lim, PH.DDocument13 paginiA Review of Spun Bond Process : Hosun Lim, PH.DmamunÎncă nu există evaluări

- Technical TextilesDocument60 paginiTechnical TextilesBebi WakaÎncă nu există evaluări

- Determinants of Demand & Changes in DemandDocument15 paginiDeterminants of Demand & Changes in DemandSrishti AggarwalÎncă nu există evaluări

- Textile and Appreal Study PDFDocument80 paginiTextile and Appreal Study PDFShivam Devansh100% (1)

- Supply Chain Management in Big BazaarDocument25 paginiSupply Chain Management in Big Bazaarabhijit05582% (11)

- Dyeing and Printing Process in Textile IndustryDocument30 paginiDyeing and Printing Process in Textile IndustryMushahid Ali100% (3)

- Revenue Management at Prego Italian RestaurantDocument17 paginiRevenue Management at Prego Italian RestaurantAvishek PaulÎncă nu există evaluări

- Cotton Knitted FabricsDocument7 paginiCotton Knitted FabricsAmitÎncă nu există evaluări

- B-Plan - Mobile Retail StoreDocument31 paginiB-Plan - Mobile Retail StorePlaban Roy100% (1)

- 21 Indispensable Qualities of A LeaderDocument11 pagini21 Indispensable Qualities of A LeaderAaron MannÎncă nu există evaluări

- Fibers Filament August 2013Document25 paginiFibers Filament August 2013Nikesh Shah100% (1)

- Project ReportDocument23 paginiProject ReportAbhishek AgarwalÎncă nu există evaluări

- Sanam Textile Mills (Company Profile)Document4 paginiSanam Textile Mills (Company Profile)mohsinnadirÎncă nu există evaluări

- Non WovenDocument9 paginiNon WovenIbrahim Khalil100% (1)

- Knits DenimDocument8 paginiKnits DenimRonak JoshiÎncă nu există evaluări

- Denim Jeans ManufacturingDocument20 paginiDenim Jeans Manufacturingjpsingh75Încă nu există evaluări

- NEEW Generation Smart TextileDocument13 paginiNEEW Generation Smart Textileabdulkhaliqmohd46Încă nu există evaluări

- 71FD2d01 Xian Knit Kimono Jacket 3 PagDocument3 pagini71FD2d01 Xian Knit Kimono Jacket 3 Paganca_dinca100% (1)

- Swot AlibabaDocument6 paginiSwot AlibabavianywidillaÎncă nu există evaluări

- Block Printing Process in IndiaDocument14 paginiBlock Printing Process in IndiaKavya 45Încă nu există evaluări

- PorosityDocument30 paginiPorosityPawan KumarÎncă nu există evaluări

- Nestle Case StudyDocument12 paginiNestle Case StudyMieder van Loggerenberg87% (47)

- Knitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Document5 paginiKnitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Pradeep AhireÎncă nu există evaluări

- My Family Should KnowDocument11 paginiMy Family Should KnowRonak Joshi100% (7)

- Textile Industry in RajasthanDocument3 paginiTextile Industry in RajasthanManish Kumar JangirÎncă nu există evaluări

- Investigation of Wicking PropertiesDocument7 paginiInvestigation of Wicking PropertiesJuan CubasÎncă nu există evaluări

- E Textile Article ReviewDocument5 paginiE Textile Article ReviewDeekshithaÎncă nu există evaluări

- Textile Internship Exposure - Jaya Shree Textiles - Aditya BirlaDocument15 paginiTextile Internship Exposure - Jaya Shree Textiles - Aditya BirlaSaptarshi BagchiÎncă nu există evaluări

- Wicking: (Revised 1-1-09) BTC Innovations, LLC, 731 W Wynnewood RD, Unit #20, Ardmore, PA 19003Document11 paginiWicking: (Revised 1-1-09) BTC Innovations, LLC, 731 W Wynnewood RD, Unit #20, Ardmore, PA 19003Muthu ManickamÎncă nu există evaluări

- Garima 1Document82 paginiGarima 1Parshant GargÎncă nu există evaluări

- Satveer Project ReportDocument102 paginiSatveer Project ReportAbhinav AshishÎncă nu există evaluări

- Green TextilesDocument29 paginiGreen TextilesGauri NagpalÎncă nu există evaluări

- Morarjee 1Document46 paginiMorarjee 1Anand SinghÎncă nu există evaluări

- Indian Textile Bookslist 2019Document12 paginiIndian Textile Bookslist 2019DINKER MAHAJANÎncă nu există evaluări

- Summer Training Project of Textile Industry"manjinder Singh"Document89 paginiSummer Training Project of Textile Industry"manjinder Singh"manjinder1933% (3)

- Erp in TextileDocument15 paginiErp in TextileHarun VenkatÎncă nu există evaluări

- Textile Design Internship DocumentDocument96 paginiTextile Design Internship DocumentswathiÎncă nu există evaluări

- SCM of GO COLORSDocument15 paginiSCM of GO COLORSNamanJain100% (1)

- Non Woven Filter Market in IndiaDocument11 paginiNon Woven Filter Market in Indiakalyani dynamicsÎncă nu există evaluări

- Kara Wipes Project FinalDocument46 paginiKara Wipes Project FinalSoumik SettÎncă nu există evaluări

- Waterless DyeingDocument2 paginiWaterless DyeingChaitali Debnath100% (1)

- Datatex: Drawbacks in Existing SystemsDocument22 paginiDatatex: Drawbacks in Existing SystemsIndranil Saha100% (1)

- Non Woven Bag Word 1Document11 paginiNon Woven Bag Word 1Bhimsen100% (1)

- Singeing & Desizing. 2Document15 paginiSingeing & Desizing. 2Chayon Sarkar Bappy100% (1)

- BalticFashion Rapport Smarttextiles PDFDocument34 paginiBalticFashion Rapport Smarttextiles PDFvahidÎncă nu există evaluări

- SRCFEB20 Exhibitor List 11-19-2020 PDFDocument10 paginiSRCFEB20 Exhibitor List 11-19-2020 PDFSrishty RanaÎncă nu există evaluări

- Sarla Fabric Pvt. Ltd. InternshipDocument58 paginiSarla Fabric Pvt. Ltd. InternshipAkshay SinghÎncă nu există evaluări

- Bio-Degratable Plastic BagDocument13 paginiBio-Degratable Plastic BagVickesh MalkaniÎncă nu există evaluări

- Alok IndustriesDocument37 paginiAlok IndustriesHitesh Kumar100% (1)

- Textile Traning ReportDocument62 paginiTextile Traning ReportSanjeev Singh0% (1)

- Index: TopicDocument36 paginiIndex: TopicAliArababadiÎncă nu există evaluări

- Product Specification of Terry TowelsDocument2 paginiProduct Specification of Terry TowelsAbhishek SrivastavaÎncă nu există evaluări

- Jute BagsDocument20 paginiJute Bagsbig johnÎncă nu există evaluări

- CatalogueDocument20 paginiCatalogueDivya AnandÎncă nu există evaluări

- TukacadDocument17 paginiTukacadajay kalangiÎncă nu există evaluări

- Recent Development in Textile IndustryDocument48 paginiRecent Development in Textile IndustryShrikant Gadge0% (2)

- Sportech in Technical TextileDocument6 paginiSportech in Technical TextileRadiika Balamurugan100% (1)

- Textiles: Hosiery/ Knitwear ProcessingDocument20 paginiTextiles: Hosiery/ Knitwear ProcessingShripadÎncă nu există evaluări

- Jute Market Scan - 171210Document102 paginiJute Market Scan - 171210KrishnaRaoÎncă nu există evaluări

- Catalogue Textile ENDocument20 paginiCatalogue Textile ENMelita ArifiÎncă nu există evaluări

- 06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme TreatmentDocument10 pagini06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme Treatmentleosun halariÎncă nu există evaluări

- Project ReportDocument79 paginiProject ReportRam Kumaran Ganeshan100% (1)

- Arvind Textiles Internship ReportDocument107 paginiArvind Textiles Internship ReportDipan SahooÎncă nu există evaluări

- 1 s2.0 S2666790821003013 MainDocument8 pagini1 s2.0 S2666790821003013 MainImran shaownÎncă nu există evaluări

- Investigation of The Quality Properties of Open-End Spun Recycled Yarns Made From Blends of Recycled Fabric Scrap Wastes and Virgin Polyester FibreDocument12 paginiInvestigation of The Quality Properties of Open-End Spun Recycled Yarns Made From Blends of Recycled Fabric Scrap Wastes and Virgin Polyester FibreJJ SerraltaÎncă nu există evaluări

- Innovative Energy ResearchDocument4 paginiInnovative Energy ResearchAzumaÎncă nu există evaluări

- Comparison of Recycle Yarn To VirginDocument9 paginiComparison of Recycle Yarn To VirginParvesh Khurana100% (1)

- Optimization of The Tencel Cotton and Polyester Recycled Polyester Blended Knitted Fabrics To Replace CVC FabricDocument13 paginiOptimization of The Tencel Cotton and Polyester Recycled Polyester Blended Knitted Fabrics To Replace CVC Fabricsiddiqui4303379Încă nu există evaluări

- Sustainable Innovations in Recycled TextilesDe la EverandSustainable Innovations in Recycled TextilesÎncă nu există evaluări

- HR Manual PDFDocument62 paginiHR Manual PDFMD IMRAN RAJMOHMADÎncă nu există evaluări

- Cotton PDFDocument124 paginiCotton PDFRonak JoshiÎncă nu există evaluări

- The Circle of InnovationDocument10 paginiThe Circle of InnovationRonak JoshiÎncă nu există evaluări

- Textile Wastewater TreatmentDocument21 paginiTextile Wastewater TreatmentRonak JoshiÎncă nu există evaluări

- Efluent Treatment in DenimDocument30 paginiEfluent Treatment in DenimRonak JoshiÎncă nu există evaluări

- Efluent Treatment in DenimDocument30 paginiEfluent Treatment in DenimRonak JoshiÎncă nu există evaluări

- Mercerization of Cotton Yarn Fibers. Optimization of Caustic Soda Concentration Via Degree of Mercerization, Dyability and Mechanical PropertiesDocument5 paginiMercerization of Cotton Yarn Fibers. Optimization of Caustic Soda Concentration Via Degree of Mercerization, Dyability and Mechanical PropertiesOlajumoke AnikeÎncă nu există evaluări

- Turkish Journal of Fisheries and Aquatic Sciences 7: 97-103 (2007)Document7 paginiTurkish Journal of Fisheries and Aquatic Sciences 7: 97-103 (2007)sujeshrajaÎncă nu există evaluări

- The Effective Executive by DruckerDocument14 paginiThe Effective Executive by DruckerSantosh SumÎncă nu există evaluări

- Geckoboard: Make Your Most Important Metrics VisibleDocument8 paginiGeckoboard: Make Your Most Important Metrics VisibleRonak JoshiÎncă nu există evaluări

- Kaggle: Your Machine Learning and Data Science CommunityDocument7 paginiKaggle: Your Machine Learning and Data Science CommunityRonak JoshiÎncă nu există evaluări

- QuotesDocument3 paginiQuotesgova_iconÎncă nu există evaluări

- Panchtantra StoriesDocument18 paginiPanchtantra StoriesShriram KelkarÎncă nu există evaluări

- Oscar Wilde's Short StoriesDocument42 paginiOscar Wilde's Short StoriesAndersonSmithÎncă nu există evaluări

- TrSi0143066220620170239Document1 paginăTrSi0143066220620170239Ronak JoshiÎncă nu există evaluări

- Gujarat Technological UniversityDocument1 paginăGujarat Technological UniversityRonak JoshiÎncă nu există evaluări

- TrSi0116842100220200253Document1 paginăTrSi0116842100220200253Ronak JoshiÎncă nu există evaluări

- 9ar 542Document2 pagini9ar 542Ronak JoshiÎncă nu există evaluări

- Creating Our FutureDocument1 paginăCreating Our FutureRonak JoshiÎncă nu există evaluări

- The Burn Test To Identify Textile FibersDocument2 paginiThe Burn Test To Identify Textile FibersRonak JoshiÎncă nu există evaluări

- 10ar 544Document3 pagini10ar 544Ronak JoshiÎncă nu există evaluări

- Speciality Yarn E BrochureDocument9 paginiSpeciality Yarn E BrochureRonak JoshiÎncă nu există evaluări

- New Textiles Projects in Andhra PradeshDocument2 paginiNew Textiles Projects in Andhra PradeshPradeep RajasekeranÎncă nu există evaluări

- Financial Accounting, 5e: Weygandt, Kieso, & KimmelDocument31 paginiFinancial Accounting, 5e: Weygandt, Kieso, & KimmelAuora BiancaÎncă nu există evaluări

- Introductions: Key VocabularyDocument11 paginiIntroductions: Key Vocabularytucurina100% (1)

- Article No.: Spl019: Tank Top White YO!Document3 paginiArticle No.: Spl019: Tank Top White YO!hmsohag100% (1)

- TB Chapter 12Document20 paginiTB Chapter 12Elisa TrisnaÎncă nu există evaluări

- 5-Aircraft Fabric Covering TextDocument2 pagini5-Aircraft Fabric Covering TextJecah Angelu S. SaquianÎncă nu există evaluări

- Module 2 Lesson 1-Tools and Materials Used in EmbroideryDocument7 paginiModule 2 Lesson 1-Tools and Materials Used in EmbroideryRoderick Viloria MiloÎncă nu există evaluări

- Paknsave: Operation Management and MethodsDocument10 paginiPaknsave: Operation Management and MethodsSameer ShaikhÎncă nu există evaluări

- Shimano Clipless Pedal Service Manua PDFDocument1 paginăShimano Clipless Pedal Service Manua PDFJose Luis GutierrezÎncă nu există evaluări

- CIDOC Fact Sheet No2Document3 paginiCIDOC Fact Sheet No2Bethany PalmerÎncă nu există evaluări

- Thesis Clothing GreeceDocument5 paginiThesis Clothing Greecefjebwgr4100% (2)

- Sample CH 01Document29 paginiSample CH 01Ali Akbar0% (1)

- Competition On Bottled Water IndustryDocument6 paginiCompetition On Bottled Water IndustryJestin C. Sto TomasÎncă nu există evaluări

- Adidas MPRDocument41 paginiAdidas MPRAdewitiya Singh100% (1)

- What You Need: Makes 2 Pint JarsDocument2 paginiWhat You Need: Makes 2 Pint JarsnyomchenÎncă nu există evaluări

- Industrial ProductsDocument3 paginiIndustrial Productsalishah64Încă nu există evaluări

- Module 2Document3 paginiModule 2jessafesalazarÎncă nu există evaluări

- User'S Guide Dq-643: Setting The TimeDocument2 paginiUser'S Guide Dq-643: Setting The TimeknockcontrolÎncă nu există evaluări