Documente Academic

Documente Profesional

Documente Cultură

Joining: Piping and Plumbing Fittings

Încărcat de

Jitendra BhatewaraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Joining: Piping and Plumbing Fittings

Încărcat de

Jitendra BhatewaraDrepturi de autor:

Formate disponibile

Joining[edit]

Main article: Piping and plumbing fittings

Pipes are commonly joined by welding, using threaded pipe and fittings; sealing the connection

with a pipe thread compound, Polytetrafluoroethylene (PTFE) Thread seal tape, oakum, or PTFE

string, or by using a mechanical coupling. Process piping is usually joined by welding using a TIG

or MIG process. The most common process pipe joint is the butt weld. The ends of pipe to be

welded must have a certain weld preparation called an End Weld Prep (EWP) which is typically

at an angle of 37.5 degrees to accommodate the filler weld metal. The most common pipe thread

in North America is the National Pipe Thread (NPT) or the Dryseal (NPTF) version. Other pipe

threads include the British standard pipe thread (BSPT), the garden hose thread (GHT), and

the fire hose coupling (NST).

Copper pipes are typically joined by soldering, brazing, compression fittings, flaring,

or crimping. Plastic pipes may be joined by solvent welding, heat fusion, or elastomeric sealing.

If frequent disconnection will be required, gasketed pipe flanges or union fittings provide better

reliability than threads. Some thin-walled pipes of ductile material, such as the smaller copper or

flexible plastic water pipes found in homes for ice makers and humidifiers, for example, may be

joined with compression fittings.

A HDPE ring main that has been joined with an Electrofusion Tee.

Underground pipe typically uses a "push-on" gasket style of pipe that compresses a gasket into a

space formed between the two adjoining pieces. Push-on joints are available on most types of

pipe. A pipe joint lubricant must be used in the assembly of the pipe. Under buried conditions,

gasket-joint pipes allow for lateral movement due to soil shifting as well as expansion/contraction

due to temperature differentials.[11] Plastic MDPE and HDPE gas and water pipes are also often

joined with Electrofusion fittings.

Large above ground pipe typically uses a flanged joint, which is generally available in ductile iron

pipe and some others. It is a gasket style where the flanges of the adjoining pipes are bolted

together, compressing the gasket into a space between the pipe.

Mechanical grooved couplings or Victaulic joints are also frequently used for frequent

disassembly and assembly. Developed in the 1920s, these mechanical grooved couplings can

operate up to 120 pounds per square inch (830 kPa) working pressures and available in

materials to match the pipe grade. Another type of mechanical coupling is a flareless tube fitting

(Major brands include Swagelok, Ham-Let, Parker); this type of compression fitting is typically

used on small tubing under 2 inches (51 mm) in diameter.

When pipes join in chambers where other components are needed for the management of the

network (such as valves or gauges), dismantling joints are generally used, in order to make

mounting/dismounting easier.

Fittings and valves[edit]

Copper pipe fittings

Fittings are also used to split or join a number of pipes together, and for other purposes. A broad

variety of standardized pipe fittings are available; they are generally broken down into either a

tee, an elbow, a branch, a reducer/enlarger, or a wye. Valves control fluid flow and regulate

pressure. The piping and plumbing fittings and valves articles discuss them further.

S-ar putea să vă placă și

- Alert Codes 30GTNDocument4 paginiAlert Codes 30GTNJose Suriel86% (7)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDe la EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerEvaluare: 5 din 5 stele5/5 (1)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDe la EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (6)

- Ascs To The Acr Standard Training Course Handouts - 2016 0 PDFDocument143 paginiAscs To The Acr Standard Training Course Handouts - 2016 0 PDFNhel AlvaroÎncă nu există evaluări

- Steel PipeDocument1 paginăSteel PipeJitendra BhatewaraÎncă nu există evaluări

- Hdpe Pipe Joining SystempdfDocument10 paginiHdpe Pipe Joining Systempdfmai huy tânÎncă nu există evaluări

- HDPE Lining Case StudyDocument9 paginiHDPE Lining Case StudymujeebscribdÎncă nu există evaluări

- DuctDocument14 paginiDuctSalehAfadlehÎncă nu există evaluări

- Gas Purging Optimizes Root WeldsDocument3 paginiGas Purging Optimizes Root Weldsta_binhaaaÎncă nu există evaluări

- General PipingDocument42 paginiGeneral PipingSHANE MABUGAYÎncă nu există evaluări

- RioPipeline2017 2396 Ibp 2396 17 JLR White Paper RiDocument8 paginiRioPipeline2017 2396 Ibp 2396 17 JLR White Paper RiJose Anisio SilvaÎncă nu există evaluări

- Pipe Fitting - WikipediaDocument5 paginiPipe Fitting - Wikipediaramthecharm_46098467Încă nu există evaluări

- SS Pipe Weld PurgingDocument5 paginiSS Pipe Weld Purging888ddbÎncă nu există evaluări

- Piping and Plumbing FittingDocument21 paginiPiping and Plumbing FittingC.yrillÎncă nu există evaluări

- Pipe and Pipe JointsDocument11 paginiPipe and Pipe Jointsنور جمال عبدالحليمÎncă nu există evaluări

- Pipe (Material) : Pipe Is A Hollow Cylinder of Material. It Differs FromDocument5 paginiPipe (Material) : Pipe Is A Hollow Cylinder of Material. It Differs FromSyed Aftab AhmedÎncă nu există evaluări

- Shell and Tube Ref - AnandDocument6 paginiShell and Tube Ref - Anand7761430Încă nu există evaluări

- Heat ExchangerDocument6 paginiHeat ExchangeralokbdasÎncă nu există evaluări

- Refinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketDocument19 paginiRefinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketAlbertoÎncă nu există evaluări

- Piping JointsDocument25 paginiPiping JointstowiwaÎncă nu există evaluări

- Piping and Plumbing Fittings PDFDocument5 paginiPiping and Plumbing Fittings PDFmichol201450% (4)

- HDPE PipeDocument6 paginiHDPE PipeNaeemÎncă nu există evaluări

- PipesDocument12 paginiPipesYasas LiyanageÎncă nu există evaluări

- Underground Piping Systems: Column Engineer'S NotebookDocument5 paginiUnderground Piping Systems: Column Engineer'S Notebook08017Fandi Ari MaulanaÎncă nu există evaluări

- 2 General Piping System and Lay OutDocument43 pagini2 General Piping System and Lay OutJonah Lyn AsendidoÎncă nu există evaluări

- Info On HDPE PipesDocument49 paginiInfo On HDPE PipesH.V. Patil100% (1)

- Pipa PEDocument374 paginiPipa PEservodinamarÎncă nu există evaluări

- Methods and Types of Joints and ConnectionDocument31 paginiMethods and Types of Joints and ConnectionIamKish Tipono ValenciaÎncă nu există evaluări

- Introduction To Piping SystemDocument9 paginiIntroduction To Piping SystemMohamed Al-OdatÎncă nu există evaluări

- R.S.W. Building Technology - 4 "Plumbing Materials": Urdaneta City UniversityDocument12 paginiR.S.W. Building Technology - 4 "Plumbing Materials": Urdaneta City UniversityDAWFWFÎncă nu există evaluări

- Weldings On PipeDocument4 paginiWeldings On PipeImran AkhtarÎncă nu există evaluări

- Threaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20Document3 paginiThreaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20abhay_patil_22Încă nu există evaluări

- 01 Piping ComponentsDocument23 pagini01 Piping Componentshwang2100% (1)

- A Complete Guide To Using Plumbing Fittings For Joining PVCDocument28 paginiA Complete Guide To Using Plumbing Fittings For Joining PVCJosh Vincent RanqueÎncă nu există evaluări

- Cylinder Circular Cross-Section: Pipe Installation On A Street inDocument8 paginiCylinder Circular Cross-Section: Pipe Installation On A Street inMohit BauskarÎncă nu există evaluări

- IndustrialDocument22 paginiIndustrialArnz BibosoÎncă nu există evaluări

- Fittings Are Used in Pipe and Plumbing Systems ToDocument28 paginiFittings Are Used in Pipe and Plumbing Systems ToSidra LiaquatÎncă nu există evaluări

- Heat Exchanger Types and SelectionDocument31 paginiHeat Exchanger Types and Selectionmehul10941Încă nu există evaluări

- Hot TappingDocument12 paginiHot TappingSmith JasonÎncă nu există evaluări

- Hot Tapping CalculationsDocument19 paginiHot Tapping Calculationsna270791dia100% (1)

- Piping and Plumbing FittingDocument25 paginiPiping and Plumbing Fittingignatus lupapuloÎncă nu există evaluări

- Column Plant LayoutDocument7 paginiColumn Plant Layoutsteepa22Încă nu există evaluări

- Basic Construction of Shell & Tube Heat ExchangersDocument12 paginiBasic Construction of Shell & Tube Heat ExchangerslatshareÎncă nu există evaluări

- Asme Power PresentationDocument8 paginiAsme Power PresentationBardya SamiÎncă nu există evaluări

- TEMA Terminology:: o o o o oDocument5 paginiTEMA Terminology:: o o o o oNathanianÎncă nu există evaluări

- Condenser and Heat Exchanger Tube RestorationDocument6 paginiCondenser and Heat Exchanger Tube RestorationspalaniyandiÎncă nu există evaluări

- Manual Uponor MeltawayDocument12 paginiManual Uponor MeltawayUPOTERMÎncă nu există evaluări

- Study of Carbon Steel Pipes 2013Document26 paginiStudy of Carbon Steel Pipes 2013Deepak Ramchandani100% (1)

- PIPE and TubesDocument11 paginiPIPE and TubesnamÎncă nu există evaluări

- From Wikipedia, The Free Encyclopedia: Process Duct WorkDocument17 paginiFrom Wikipedia, The Free Encyclopedia: Process Duct WorkB DASÎncă nu există evaluări

- Pneumatic FittingsDocument7 paginiPneumatic FittingsZakir MunirÎncă nu există evaluări

- Pneumatic FittingsDocument7 paginiPneumatic FittingsZakir MunirÎncă nu există evaluări

- Piping BasicsDocument3 paginiPiping BasicsWinston RajÎncă nu există evaluări

- Types of Piping JointsDocument4 paginiTypes of Piping Jointsravish kumarÎncă nu există evaluări

- Heat Exchanger Glossary of TermsDocument3 paginiHeat Exchanger Glossary of Termsusman_hafeez86Încă nu există evaluări

- Heat ExchangerDocument22 paginiHeat ExchangerYashwant SinghÎncă nu există evaluări

- A.C DuctsDocument15 paginiA.C DuctsMustafam98Încă nu există evaluări

- Pipe FittingsDocument16 paginiPipe FittingsMuhammad Qaisar Khan100% (1)

- Ducts DetailsDocument8 paginiDucts DetailsfayasÎncă nu există evaluări

- TEMA Basics of Construction - 07 10Document8 paginiTEMA Basics of Construction - 07 10Zeeshan SajidÎncă nu există evaluări

- Why HDPE PipeDocument3 paginiWhy HDPE PipeRaphael LawÎncă nu există evaluări

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Aryan Invasion Theory: in Popular CultureDocument1 paginăAryan Invasion Theory: in Popular CultureJitendra BhatewaraÎncă nu există evaluări

- Death: The Buddha and His DhammaDocument2 paginiDeath: The Buddha and His DhammaJitendra BhatewaraÎncă nu există evaluări

- The Statue of B. R. Ambedkar in The Parliament of India (Left) The Portrait of B. R. Ambedkar in The Central Hall of The Parliament House (Right)Document2 paginiThe Statue of B. R. Ambedkar in The Parliament of India (Left) The Portrait of B. R. Ambedkar in The Central Hall of The Parliament House (Right)Jitendra BhatewaraÎncă nu există evaluări

- Works: Dr. Babasaheb AmbedkarDocument2 paginiWorks: Dr. Babasaheb AmbedkarJitendra BhatewaraÎncă nu există evaluări

- Marriage: Ramabai Neuropathic Pain Insulin Homoeopathic Medicines Sharada Kabir Savita AmbedkarDocument2 paginiMarriage: Ramabai Neuropathic Pain Insulin Homoeopathic Medicines Sharada Kabir Savita AmbedkarJitendra BhatewaraÎncă nu există evaluări

- Opposition To Untouchability: Studies at The London School of EconomicsDocument2 paginiOpposition To Untouchability: Studies at The London School of EconomicsJitendra BhatewaraÎncă nu există evaluări

- Poona Pact: Kalaram Temple Movement Kalaram Temple NashikDocument1 paginăPoona Pact: Kalaram Temple Movement Kalaram Temple NashikJitendra BhatewaraÎncă nu există evaluări

- Procurement Tender Details: BackDocument3 paginiProcurement Tender Details: BackJitendra BhatewaraÎncă nu există evaluări

- Sharad Pawar: Citation NeededDocument1 paginăSharad Pawar: Citation NeededJitendra BhatewaraÎncă nu există evaluări

- Post-Secondary Education: Elphinstone High School ArrangedDocument1 paginăPost-Secondary Education: Elphinstone High School ArrangedJitendra BhatewaraÎncă nu există evaluări

- Early Life: Bhimrao Ramji Ambedkar (14 April 1891 - 6 December 1956) Was An IndianDocument1 paginăEarly Life: Bhimrao Ramji Ambedkar (14 April 1891 - 6 December 1956) Was An IndianJitendra BhatewaraÎncă nu există evaluări

- Click Here For More DetailsDocument1 paginăClick Here For More DetailsJitendra BhatewaraÎncă nu există evaluări

- JM 3Document1 paginăJM 3Jitendra BhatewaraÎncă nu există evaluări

- Procurement Tender Details: BackDocument3 paginiProcurement Tender Details: BackJitendra BhatewaraÎncă nu există evaluări

- Mechanical Systems: Power Actuators System of MechanismsDocument1 paginăMechanical Systems: Power Actuators System of MechanismsJitendra BhatewaraÎncă nu există evaluări

- Etymology: Middle French Latin Greek Doric IonicDocument1 paginăEtymology: Middle French Latin Greek Doric IonicJitendra BhatewaraÎncă nu există evaluări

- History: Hand Axe WinchesterDocument2 paginiHistory: Hand Axe WinchesterJitendra BhatewaraÎncă nu există evaluări

- Infection Fatality Rate (IFR)Document1 paginăInfection Fatality Rate (IFR)Jitendra BhatewaraÎncă nu există evaluări

- Cases: Tested For COVID-19Document1 paginăCases: Tested For COVID-19Jitendra BhatewaraÎncă nu există evaluări

- The Six Types of Simple MachinesDocument1 paginăThe Six Types of Simple MachinesJitendra BhatewaraÎncă nu există evaluări

- Hiring Of: Neethipudi - Chaitanya@ongc - Co.in Mantri - Kirtesh@ongc - Co.in Ankit.s@gspc - inDocument1 paginăHiring Of: Neethipudi - Chaitanya@ongc - Co.in Mantri - Kirtesh@ongc - Co.in Ankit.s@gspc - inJitendra BhatewaraÎncă nu există evaluări

- Epidemiology: COVID-19 Pandemic by Country and TerritoryDocument1 paginăEpidemiology: COVID-19 Pandemic by Country and TerritoryJitendra BhatewaraÎncă nu există evaluări

- Deaths: Main Articles: and Further InformationDocument2 paginiDeaths: Main Articles: and Further InformationJitendra BhatewaraÎncă nu există evaluări

- Catalog Air Cooled Screw Chiller TASD AC1Document12 paginiCatalog Air Cooled Screw Chiller TASD AC1Luis BermudezÎncă nu există evaluări

- PP-12-PT: Standard FeaturesDocument4 paginiPP-12-PT: Standard Featuresmember1000Încă nu există evaluări

- Thermex Installation Operation Manual PDFDocument9 paginiThermex Installation Operation Manual PDFMarkÎncă nu există evaluări

- Bouygues Construction Nigeria Limited: Weld History SheetDocument5 paginiBouygues Construction Nigeria Limited: Weld History SheetnwohaÎncă nu există evaluări

- Atr Airconditioning System MarzoDocument4 paginiAtr Airconditioning System MarzoBENoÎncă nu există evaluări

- R-114 Job Aid PDF-XXL FDBM Dual Evaporator RefrigeratorDocument68 paginiR-114 Job Aid PDF-XXL FDBM Dual Evaporator Refrigeratormacj510Încă nu există evaluări

- ESET 212 LECTURE - Week 7Document41 paginiESET 212 LECTURE - Week 7eglits4170Încă nu există evaluări

- Fire Alarm Valve E3 ReliableDocument4 paginiFire Alarm Valve E3 ReliableMKOZERDEM100% (1)

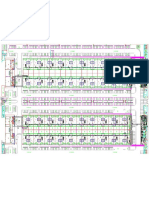

- AL-MUHAIDIB UGTP FINAL ModelDocument1 paginăAL-MUHAIDIB UGTP FINAL ModelIzaaz AhamedÎncă nu există evaluări

- MEP Production RatesDocument5 paginiMEP Production Ratesahmed HOSNYÎncă nu există evaluări

- The New Home Appliance 2017-2018 GrundigDocument130 paginiThe New Home Appliance 2017-2018 Grundigphilip davisÎncă nu există evaluări

- Ug36 - Ug46Document5 paginiUg36 - Ug46ALEXISORTIZ20Încă nu există evaluări

- 1.5HP Panasonic Csu13vkh 1Document4 pagini1.5HP Panasonic Csu13vkh 1MizizHÎncă nu există evaluări

- Sarjana Site Visit Schedule For CPPDocument53 paginiSarjana Site Visit Schedule For CPPSanjay GuptaÎncă nu există evaluări

- ISOCode ListDocument135 paginiISOCode ListRashid MalikÎncă nu există evaluări

- Air Conditioner Standard Series: SpesifikasiDocument5 paginiAir Conditioner Standard Series: SpesifikasiAndie NoegrohoÎncă nu există evaluări

- Test, Inspection, Permit, FeeDocument3 paginiTest, Inspection, Permit, FeeKevinNavidadÎncă nu există evaluări

- Introduction To Hydraulic System in The Construction Machinery - Copy ALIDocument2 paginiIntroduction To Hydraulic System in The Construction Machinery - Copy ALImahadÎncă nu există evaluări

- Pages From ASHRAE Standard 62.1Document1 paginăPages From ASHRAE Standard 62.1Ahmed NabilÎncă nu există evaluări

- PEL INSTALLMENT RATE UPDATE 09-March-2021-1Document3 paginiPEL INSTALLMENT RATE UPDATE 09-March-2021-1RD DaskaÎncă nu există evaluări

- Revised PPT For Online Lecture 5 HVAC-IntroductionDocument14 paginiRevised PPT For Online Lecture 5 HVAC-IntroductionAmey DeshmukhÎncă nu există evaluări

- 40VCT CatalogDocument2 pagini40VCT CatalogSreejil RaveendranÎncă nu există evaluări

- Belimo Model Number Change Dec 2014Document3 paginiBelimo Model Number Change Dec 2014Huỳnh VũÎncă nu există evaluări

- VRF VS Chiller: Technical ManagerDocument38 paginiVRF VS Chiller: Technical ManagerJhon Lewis Pino100% (1)

- Edfmt391744 FXBQ P FXBPQ PDocument48 paginiEdfmt391744 FXBQ P FXBPQ PandreÎncă nu există evaluări

- Machine Drawing (3) - ModelDocument1 paginăMachine Drawing (3) - ModelHamad GulÎncă nu există evaluări

- Refrigeration and Air Conditioning ThesisDocument4 paginiRefrigeration and Air Conditioning Thesisfc4b5s7r100% (1)

- ASHRAE STANDARD 15 Applied To Packaged, Split and VRF Systems PDFDocument6 paginiASHRAE STANDARD 15 Applied To Packaged, Split and VRF Systems PDFhabebeÎncă nu există evaluări