Documente Academic

Documente Profesional

Documente Cultură

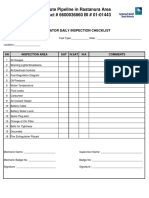

Section C, Exhibit 1 - Example Equipment Inspection Checklists

Încărcat de

Arturo Ramos AlvezoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section C, Exhibit 1 - Example Equipment Inspection Checklists

Încărcat de

Arturo Ramos AlvezoDrepturi de autor:

Formate disponibile

EQUIPMENT DAILY CHECKLIST AND SAFETY INSPECTION FORM

NOTE: This form is not to be used for inspections of mobile/overhead cranes, powered industrial trucks, or aerial lifts. For inspections of such equipment,

use FBP-OS-PRO-00025-F05 (for mobile/overhead cranes), FBP-OS-PRO-00057-F01 (for powered industrial trucks), or FBP-WM-PRO-00061-F07 (for

aerial lifts)

Section 1

Location / Project: Contractor: FBP or ______________________

Contact Name: Contact Phone: ________________

Section 2 – Check Type of Equipment Inspecting

Backhoe Trackhoe Loader Skid Steer Manufacturer

Generator Compressor Welding Machine Dozer Model Number

Tractor Roll-off Truck Other (specify) ______________________ Serial Number

• Place a check (√) mark in the box to indicate inspection is complete and is satisfactory.

• Mark “P” in box where Problem is found and make further comments on next page, if necessary.

• Report all items in need of repair to the Supervisor at the time of inspection.

• Mark N/A for items which do not apply.

Section 3 – Mark as Directed Above

Inspection Item / Day of Week Mon Tue Wed Thu Fri Sat Sun

Worker Badge Number

Worker Initials

Date

Hour Meter Reading

Structural Damage – none apparent

Tires / Tracks – condition acceptable

Load Chart – available/readable

Glass / Mirrors – clean/clear; unobstructed

Electrical Connections (generators)

Hydraulic Hoses – good condition/no leaks

Check Valves - functional

Lubrication – adequate amount

Fluid Levels – adequate amounts/no leaks

Engine Oil - level/appearance good

Cooling Water – adequate amount/no leaks

Operating Manual - available

Fire Extinguisher – present, charged, dated

Seat Belts – functional/latch properly

Operating Controls - functional

Horn / Gauges - functional

Lights and Reflectors – clean/functional

Windshield Wipers - functional

Air Systems - functional

Steering Mechanism - functional

Brakes - functional

Backup Alarm - functional

Kill Switch (if available) - functional

Roll-off Truck Cable – no single strand

broken; no kinks; no stretching; clamps tight

FBP-OS-PRO-00025-F01, Rev. 3 Page 1 of 2

EQUIPMENT DAILY CHECKLIST AND SAFETY INSPECTION FORM

Section 4 - Briefly explain items having problems

Date Repairs Date Repaired

Comments:

Section 5 – Supervisor and Safety Representative Concurrence

To be signed by the Superintendent and Safety Representative in the event deficiencies are discovered. All Equipment

Daily Checklists and Safety Inspection Forms shall be filed with the Work Control Organization.

__________________________________________________________________ ________________

Print/Signature of Supervisor Date

__________________________________________________________________ ________________

Print/Signature of Safety Representative Date

FBP-OS-PRO-00025-F01, Rev. 3 Page 2 of 2

INBOUND EQUIPMENT SAFETY INSPECTION FORM

Section 1 – Inspection Performed by Qualified Personnel Only

Location / Project Date

Equipment Inspected By Contractor

Section 2 – Check Type of Equipment Inspecting

Crane Forklift Backhoe Track Hoe Manufacturer

Tractor Loader Skid Steer Aerial Lift Model Number

Drill Rig Dozer Loader Scissors Lift Serial Number

Welding Machine > 35 hp Generator > 35 hp Compressor > 35 hp OSHA Annual Date

Last Maintenance Date

NOTE: Do NOT record this inspection sheet into the Central Equipment Database

Contact Name

for equipment not expected to be onsite greater than 30 days.

Contact Phone

Section 3 – General Categories to Inspect

Pass Fail N/A Pass Fail N/A

Tires / Tracks / Drive Chains Aux. Hook and Ball

Leaking Fluids Present Main Hook and Block

Hydraulic Hoses in Good Condition Boom / Mask / Cylinders

Lights and Mirrors Anti Two Block

Structural Damage Present Wedge Socket Plus Cable Length (6 x Diameter)

Computer Aids / Operator Controls Brakes

Roll Over Protection Emergency Flares and Triangles

Seat Belt Latches Properly Fork Lift Assembly Bolts

Fire Extinguisher with Current Inspection Operators Manual Present and Load Chart

Glass Condition Record of Last Performed Maintenance

Back Up Alarm / Bi-directional C of C Not Having Counterfeit Material

Kill Switch Periodic Inspection

Horn DOT Annual Inspection

Operator Controls OSHA Annual Inspection (if required)

Labels, Voltage & Hand Signal Chart, e.g. Generator Circuit Breaker is Open (Off) Position

Wire Rope Generator has no Electrical Primary Feed or Secondary

Outriggers Load Cables Connected

Section 4 – Fuel Type Diesel Use permitted in the X-744G and X-326 Facilities

Gasoline Use permitted in the X-326 Facilities

Propane NOT PERMITTED TO BE USED INSIDE ANY SITE FACILITIES

Electric Use permitted in X-326, X-345, and X-744G Facilities

Other TO BE EVALUATED BY THE LPP CAT II FACILITY MANAGER

Section 5 – Comments

Inbound Equipment Safety Inspection Forms shall be provided to Contracts and a copy to Work Control.

Additional checklist specific to the equipment may be used and attached to this checklist.

FBP-OS-PRO-00025-F02, Rev. 1 Page 1 of 2

INBOUND EQUIPMENT SAFETY INSPECTION FORM

Section 6 – Qualified Radiological Control Technician acceptance for equipment receiving (Inbound)

Yes No N/A Print name: Signature:

Section 7 –Qualified Person (Leased Equipment Manager)

Yes No Equipment

Print name: Signature:

Accepted

Inbound Equipment Safety Inspection Forms shall be provided to Contracts and a copy to Work Control.

Additional checklist specific to the equipment may be used and attached to this checklist.

FBP-OS-PRO-00025-F02, Rev. 1 Page 2 of 2

OUTBOUND EQUIPMENT SAFETY INSPECTION FORM

Section 1 – Inspection Performed by Qualified Personnel Only

Location / Project Date

Equipment Inspected By Contractor

Section 2 – Check Type of Equipment Inspecting

Crane Forklift Backhoe Track Hoe Manufacturer

Tractor Loader Skid Steer Aerial Lift Model Number

Drill Rig Dozer Loader Scissors Lift Serial Number

Welding Machine > 35 hp Generator > 35 hp Compressor > 35 hp Contact Name

Contact Phone

NOTE: Do NOT record this inspection sheet into the Central Equipment Database

for equipment not expected to be onsite greater than 30 days.

Section 3 – General Categories to Inspect

Pass Fail N/A Pass Fail N/A

Tires / Tracks / Drive Chains Aux. Hook and Ball

Leaking Fluids Present Main Hook and Block

Hydraulic Hoses in Good Condition Boom / Mask / Cylinders

Lights and Mirrors Anti Two Block

Structural Damage Present Wedge Socket Plus Cable Length (6 x Diameter)

Computer Aids / Operator Controls Brakes

Roll Over Protection Emergency Flares and Triangles

Seat Belt Latches Properly Fork Lift Assembly Bolts

Fire Extinguisher with Current Inspection Operators Manual Present and Load Chart

Glass Condition Record of Last Performed Maintenance

Back Up Alarm / Bi-directional C of C Not Having Counterfeit Material

Kill Switch Periodic Inspection

Horn DOT Annual Inspection

Operator Controls OSHA Annual Inspection (if required)

Labels, Voltage & Hand Signal Chart, e.g. Generator Circuit Breaker is Open (Off) Position

Wire Rope Generator has no Electrical Primary Feed or

Outriggers Secondary Load Cables Connected

Section 4 – Fuel Type

Section 5 - Comments

Section 6 – Leased Equipment Manager

Yes No Equipment

Print name: Signature:

Accepted

FBP-OS-PRO-00025-F04, Rev. 1

S-ar putea să vă placă și

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 paginăTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- 9.5 Forklift Daily InspectionDocument1 pagină9.5 Forklift Daily InspectionArshad MahmoodÎncă nu există evaluări

- Bull Dozer Daily Inspection ChecklistDocument1 paginăBull Dozer Daily Inspection ChecklistMartine Otieno100% (2)

- Excavator ChecklistDocument1 paginăExcavator ChecklistEleonor MaderazoÎncă nu există evaluări

- BACKHOE Checklist-WeeklyDocument1 paginăBACKHOE Checklist-WeeklyChaudhary Wasim Murtaza100% (1)

- Backhoe ChecklistDocument1 paginăBackhoe ChecklistSajid Hussain100% (1)

- Generator Daily Inspection ChecklistDocument1 paginăGenerator Daily Inspection ChecklistMd Azizul MawlaÎncă nu există evaluări

- Form-093-Dump Truck Safety ChecklistDocument2 paginiForm-093-Dump Truck Safety Checklistshamroz khan100% (2)

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 paginăSwitchgear Inspection Checklist: Section A - Customer Data20082012Încă nu există evaluări

- Daily Montly Checklist 04JUN2007Document9 paginiDaily Montly Checklist 04JUN2007tomiÎncă nu există evaluări

- Asphalt Paver Inspection Form (Pre-Hired & Pre-Used)Document2 paginiAsphalt Paver Inspection Form (Pre-Hired & Pre-Used)Hendra Arya PratamaÎncă nu există evaluări

- Truck Load-Out ChecklistDocument3 paginiTruck Load-Out ChecklistIsaac Anthony100% (2)

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 paginăDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- Editable Inspection Checklist For Heavy Equipment PDFDocument1 paginăEditable Inspection Checklist For Heavy Equipment PDFchassas0% (1)

- Excavator Inspection ChecklistDocument1 paginăExcavator Inspection ChecklistArsalan Ahmad100% (2)

- Daily Inspection ChecklistsDocument59 paginiDaily Inspection Checklistsibrahim100% (1)

- Equipment Inspection Checklist NewDocument57 paginiEquipment Inspection Checklist Newakbar zulazmi100% (1)

- Diesel Generator Inspection ChecklistDocument1 paginăDiesel Generator Inspection ChecklistCandra Wae Lah100% (3)

- ATTACH 3 LOG SHEET UpdatedDocument12 paginiATTACH 3 LOG SHEET UpdatedHedi Ben MohamedÎncă nu există evaluări

- Dewatering PumpDocument14 paginiDewatering PumpparthaÎncă nu există evaluări

- Fuel Truck Operator's Daily ChecklistDocument1 paginăFuel Truck Operator's Daily ChecklistTFattah0% (1)

- Bobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityDocument1 paginăBobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityMuhammad Farooq Awan100% (5)

- Heavy Equipment Inspection Checklist PDFDocument3 paginiHeavy Equipment Inspection Checklist PDFSajid HussainÎncă nu există evaluări

- Daily Inspection Checklist For ExcavatorDocument1 paginăDaily Inspection Checklist For ExcavatorMaheshwor Man JoshiÎncă nu există evaluări

- PPM Task Sheet - MPGSDocument4 paginiPPM Task Sheet - MPGSJacobÎncă nu există evaluări

- Road Grader Daily Inspection by OperatorDocument1 paginăRoad Grader Daily Inspection by OperatorNasrullah Khan Yousafzai100% (1)

- Form Inspection Premob - Quarterly (1) - 2Document26 paginiForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniÎncă nu există evaluări

- Front End Loader Pre Use Inspection SUP 142 e en 16 077Document2 paginiFront End Loader Pre Use Inspection SUP 142 e en 16 077Mahmoud Taher El Khorzaty100% (1)

- Generator Inspection ChecklistDocument2 paginiGenerator Inspection Checklistramakrishna6667% (3)

- Light Vehicle Inspection ChecklistDocument4 paginiLight Vehicle Inspection Checklistzelda1022Încă nu există evaluări

- SKC Engineers and Contractors Private Limited: Heavy Equipment Daily ChecklistDocument1 paginăSKC Engineers and Contractors Private Limited: Heavy Equipment Daily ChecklistMohammed AffrozeÎncă nu există evaluări

- Grinder Checklist2Document3 paginiGrinder Checklist2jovyÎncă nu există evaluări

- Transit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksDocument1 paginăTransit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksRísês ÃfrözÎncă nu există evaluări

- Weekly Fuel Tanker Inspection ChecklistDocument2 paginiWeekly Fuel Tanker Inspection ChecklistRabbanÎncă nu există evaluări

- 02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPDocument8 pagini02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPB&R HSE BALCO SEP SiteÎncă nu există evaluări

- Catalogo Chaglin YZ12HDDocument4 paginiCatalogo Chaglin YZ12HDIwa RizaÎncă nu există evaluări

- Crane ChecklistDocument1 paginăCrane Checklistsajin0% (1)

- Borang Pemeriksaan Air KompressorDocument1 paginăBorang Pemeriksaan Air KompressorAndara Asifa YudianaÎncă nu există evaluări

- Daily Checklist For DGDocument2 paginiDaily Checklist For DG7Days Facility ManagementÎncă nu există evaluări

- Risk Assessment For Weigh Bridge.Document1 paginăRisk Assessment For Weigh Bridge.erkarthik8550% (4)

- Excavator Check SheetDocument1 paginăExcavator Check SheetTaslimah Ali88% (8)

- Heavy Lift Activity Checklist: Lifting & Erection of Fin Fan CoolerDocument3 paginiHeavy Lift Activity Checklist: Lifting & Erection of Fin Fan Coolerbrecht1980Încă nu există evaluări

- Absolute Rules DeclarationDocument1 paginăAbsolute Rules DeclarationThandabantu MagengeleleÎncă nu există evaluări

- Safety & HealthDocument1 paginăSafety & HealthМарк Артём Лимот АпаллаÎncă nu există evaluări

- Electrical System Safety Rules (Esr) - OETCDocument108 paginiElectrical System Safety Rules (Esr) - OETCRayar Dhanasekar100% (1)

- Truck and Trailer DriversDocument2 paginiTruck and Trailer DriversaymenmoatazÎncă nu există evaluări

- Temporary Building and Porta Cabin Safety Inspection ChecklistDocument3 paginiTemporary Building and Porta Cabin Safety Inspection ChecklistHabib ur rahman0% (1)

- Bar Cutting MachineDocument1 paginăBar Cutting Machinesaurav roy100% (1)

- 010 Electrical Tool & EquipmentDocument2 pagini010 Electrical Tool & EquipmentWahyu Endra PurwantoÎncă nu există evaluări

- Excavator Daily Inspection ChecklistDocument1 paginăExcavator Daily Inspection ChecklistMalefane Cortez TlatlaneÎncă nu există evaluări

- Dump Truck Monthly Inspection ChecklistDocument1 paginăDump Truck Monthly Inspection ChecklistJoy BD100% (1)

- Dump Truck Monthly Inspection ChecklistDocument1 paginăDump Truck Monthly Inspection ChecklistJoy BDÎncă nu există evaluări

- 10 - Cherry Picker Inspection ChecklistDocument1 pagină10 - Cherry Picker Inspection Checklistsanjeev kumarÎncă nu există evaluări

- L - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistDocument1 paginăL - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistEdhz Bilog100% (1)

- 4 Plant & Equipment Checklist - Docx-1Document2 pagini4 Plant & Equipment Checklist - Docx-1REHAN IQBALÎncă nu există evaluări

- Boom Truck Inspection by Operator-MonthlyDocument1 paginăBoom Truck Inspection by Operator-MonthlyChaudhary Wasim MurtazaÎncă nu există evaluări

- Shovel ChecklistDocument2 paginiShovel Checklistjamal motaÎncă nu există evaluări

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistDocument3 paginiJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaÎncă nu există evaluări

- Maintenance Record - Equipment/machineryDocument3 paginiMaintenance Record - Equipment/machineryNicholas DICKÎncă nu există evaluări

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- Generator Load Recording SheetDocument1 paginăGenerator Load Recording SheetArturo Ramos Alvezo100% (2)

- Everlasting God - Lincoln BrewsterDocument1 paginăEverlasting God - Lincoln BrewsterArturo Ramos AlvezoÎncă nu există evaluări

- Pdf03-Generator Set Operation Monitoring Log SheetDocument1 paginăPdf03-Generator Set Operation Monitoring Log SheetArturo Ramos Alvezo100% (1)

- The Blessing: Intro: BRIDGE 1 - Hannah (Hign Tone)Document2 paginiThe Blessing: Intro: BRIDGE 1 - Hannah (Hign Tone)Arturo Ramos AlvezoÎncă nu există evaluări

- Equipment Monitoring ChecklistDocument1 paginăEquipment Monitoring ChecklistArturo Ramos AlvezoÎncă nu există evaluări

- Great Are You LordDocument1 paginăGreat Are You LordArturo Ramos AlvezoÎncă nu există evaluări

- Angels We Have HeardDocument1 paginăAngels We Have HeardArturo Ramos AlvezoÎncă nu există evaluări

- Cover The EarthDocument1 paginăCover The EarthArturo Ramos AlvezoÎncă nu există evaluări

- Into The Deep: Intro: Verse I: Instrumental (2x)Document1 paginăInto The Deep: Intro: Verse I: Instrumental (2x)Arturo Ramos AlvezoÎncă nu există evaluări

- Job Description Building MainDocument3 paginiJob Description Building MainArturo Ramos AlvezoÎncă nu există evaluări

- Again I Say RejoiceDocument1 paginăAgain I Say RejoiceArturo Ramos AlvezoÎncă nu există evaluări

- Moving Closer Chords (Ver 3) by Never The Strangers at Ultimate-GuitarDocument2 paginiMoving Closer Chords (Ver 3) by Never The Strangers at Ultimate-GuitarArturo Ramos AlvezoÎncă nu există evaluări

- Most Player: (Recipient Name)Document1 paginăMost Player: (Recipient Name)Arturo Ramos AlvezoÎncă nu există evaluări

- Creator King (1 of 2) : Mary MacleanDocument0 paginiCreator King (1 of 2) : Mary MacleanArturo Ramos AlvezoÎncă nu există evaluări

- Calculator SolutionsDocument42 paginiCalculator SolutionsArturo Ramos AlvezoÎncă nu există evaluări

- Hold ONDocument7 paginiHold ONArturo Ramos AlvezoÎncă nu există evaluări

- Delta WyeDocument4 paginiDelta WyeArturo Ramos AlvezoÎncă nu există evaluări

- DasdaDocument1 paginăDasdaArturo Ramos AlvezoÎncă nu există evaluări

- Flaws of Ra 8749Document1 paginăFlaws of Ra 8749Arturo Ramos AlvezoÎncă nu există evaluări

- Alternator ProtectionDocument6 paginiAlternator ProtectionArturo Ramos AlvezoÎncă nu există evaluări

- India X-Ray Service ManualDocument160 paginiIndia X-Ray Service ManualMurali100% (8)

- Electrical Cable Heads: ApplicationsDocument3 paginiElectrical Cable Heads: ApplicationsDiego Cordero100% (1)

- 3 Storey 3 Bedroom Apartment Building (OSEI BREFO)Document78 pagini3 Storey 3 Bedroom Apartment Building (OSEI BREFO)NORTSEN ALBERT100% (1)

- TG043 Figure8 Install GuideDocument14 paginiTG043 Figure8 Install Guidemazen zaloudÎncă nu există evaluări

- p103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemDocument9 paginip103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemAnandu AshokanÎncă nu există evaluări

- 000000000001001849Document544 pagini000000000001001849Dante Filho100% (1)

- Concrete Cable-Stayed BridgesDocument60 paginiConcrete Cable-Stayed BridgesSelim TurkyilmazÎncă nu există evaluări

- 2.1. Technical Specification For OPGW NZ (91271A (Rev.3) )Document9 pagini2.1. Technical Specification For OPGW NZ (91271A (Rev.3) )Samiksha BhattacharyaÎncă nu există evaluări

- Is 4240-1984 Glossary of Conveyors Terms and DefinitionsDocument117 paginiIs 4240-1984 Glossary of Conveyors Terms and DefinitionsJohn0% (1)

- Electrical Taps, Splices and JointsDocument17 paginiElectrical Taps, Splices and JointsMark PalomaresÎncă nu există evaluări

- Manual de Partes Torre Allmand Nlpro IIDocument87 paginiManual de Partes Torre Allmand Nlpro IINabor Ibañez SilvaÎncă nu există evaluări

- s757 O-47 6j7122001 Deck MachineryDocument287 paginis757 O-47 6j7122001 Deck MachineryLeo Micheal YamonÎncă nu există evaluări

- GORBEL Freestanding Jib Crane - ManualDocument20 paginiGORBEL Freestanding Jib Crane - Manualaiyubi2100% (1)

- NSL Loler MatrixDocument1 paginăNSL Loler MatrixBrian McIntoshÎncă nu există evaluări

- Maintenance Practices - IIDocument27 paginiMaintenance Practices - IIrashmiameÎncă nu există evaluări

- 02 Wire Rope StrandDocument36 pagini02 Wire Rope StrandBreno Jasser Cordeiro Rodrigues100% (1)

- Kelvin Hughes X-Band 12Kw Upmast Transceiver: Installation InstructionsDocument40 paginiKelvin Hughes X-Band 12Kw Upmast Transceiver: Installation InstructionsNaviÎncă nu există evaluări

- ERECTION METHOD STATEMENT Part 2Document6 paginiERECTION METHOD STATEMENT Part 2joseph chewÎncă nu există evaluări

- Crane Safety and Awareness: Internal Use OnlyDocument99 paginiCrane Safety and Awareness: Internal Use Onlydsn_sarmaÎncă nu există evaluări

- Blockwork Accessories CatalogueDocument53 paginiBlockwork Accessories CatalogueTejinder KumarÎncă nu există evaluări

- Wirelock ManualDocument27 paginiWirelock Manualmujeebtalib100% (1)

- Turn Buckle Safety WireDocument1 paginăTurn Buckle Safety WireJohn Adrian RoceroÎncă nu există evaluări

- Cleaning and Corrosion 12-19Document17 paginiCleaning and Corrosion 12-19July TadeÎncă nu există evaluări

- Liftket - ManualDocument40 paginiLiftket - ManualMetCES100% (1)

- Industrial Cable List Price - 17th August 2021Document6 paginiIndustrial Cable List Price - 17th August 2021Mohan BabuÎncă nu există evaluări

- Air Ducting ManualDocument34 paginiAir Ducting ManualDimSolÎncă nu există evaluări

- Wciagniki Linowe SH AngielskiDocument68 paginiWciagniki Linowe SH AngielskiSandu Paraschiv-DorinÎncă nu există evaluări

- Sae J1067-2020Document9 paginiSae J1067-2020يحي عامرÎncă nu există evaluări

- MUSE ED Elevator: Installation ManualDocument16 paginiMUSE ED Elevator: Installation ManualMoises PerelloÎncă nu există evaluări

- Preliminary Design of Cable Stayed Bridge Using Influence Line PDFDocument103 paginiPreliminary Design of Cable Stayed Bridge Using Influence Line PDFnebaÎncă nu există evaluări