Documente Academic

Documente Profesional

Documente Cultură

Magnum 3416 SC: Product Information

Încărcat de

Dridi BadredineDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Magnum 3416 SC: Product Information

Încărcat de

Dridi BadredineDrepturi de autor:

Formate disponibile

Product Information

MAGNUM 3416 SC

Natural Plus ABS Resins

The mass (continuous process) ABS MAGNUM* 3416 SC is a resin Applications

technology of Dow ensures an ABS with very high heat resistance and • Automotive interior and exterior

resin that combines excellent pro- excellent processing characteristics. applications

cessability with a stable light base • Dashboard components

colour that is ideal for self-colouring. • Consoles

• Pillar covers

• Taillight housings

• Household appliances

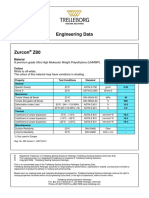

Properties (1) Test Method Value

ISO ASTM DIN

Physical Properties

Density, kg/m3 1183B D-792-B 53479-B 1050

Bulk density, kg/m3 60 D-1895 53468 650

Melt flow rate (230°C/3.8 kg), g/10 min. 1133 D-1238 53735-N 2.2

Melt flow rate (220°C/ 10 kg), g/10 min. 1133 D-1238 53735-U 7.0

Thermal Properties

Vicat softening point (50 °C/h, 5 kg), °C 306B D-1525-A 53460 108

Vicat softening point (120 °C/h, 1 kg), °C 306A D-1525-B 119

HDT, annealed (120 °C/hr, 1.82 MPa), °C 75/A D-648 53461-A 108

Mechanical Properties

Charpy notched, kJ/m2 23°C 179/2C 53453 12

0°C 179/2C 53453 10

–20°C 179/2C 53453 9

–40°C 179/2C 53453 7

Charpy unnotched, kJ/m 23°C

2 179/2D 53453 No break

–40°C 179/2D 53453 No break

Izod notched, kJ/m2 23°C 180/1A 17

Tensile yield, 100 mm/min., MPa DIS527/D D-638-M 53455-6-3 51

Tensile elongation, % DIS527/D D-638-M 53455-6-3 25

Tensile modulus, 1 mm/min., MPa DIS527/A 53455-t-3 2400

Flexural strength, 1 mm/min., MPa 178 D-790-M 53452 76

Flexural modulus, 3 point, MPa 178 D-790-M-A 53457-B3 2500

Flexural modulus, 4 point, MPa D-790-M-B 53457-B4 2700

Shear modulus, MPa 23 °C 537 D-4065 53445 960

Rockwell hardness, R-scale 2039/2 D-785B 88

Ball indentation 2039 53456 100

Flammability Ratings

Flame class rating (2,3) all colours HB

Special Properties

UV stability, 300 hrs (4)

(1) Typical properties, not to be construed as specification limits.

(2) This numerical flame-spread rating is not intended to reflect hazards presented by material under actual fire conditions.

(3) UL ratings are given for the density reduction range 0–15 % (see UL listing for details).

(4) UV stability is colour-dependent.

* Trademark of The Dow Chemical Company See “Safety and Handling Considerations”

Dow Plastics is a business unit of Dow Europe S.A. Page 1 of 2 CH 264-044-E-897

Safety and Handling Considerations

Material Safety Data (MSD) sheets for Use safety glasses. If there is a potential for Environment

MAGNUM ABS resins are available from Dow exposure to particles which could cause Generally speaking, in the environment lost

Plastics, a business unit of Dow Europe S.A. mechanical injury to the eye, wear chemical pellets are not a problem except under un-

MSD sheets are provided to help customers goggles. If vapour exposure causes eye dis- usual circumstances – when they enter the

satisfy their own handling, safety and dispos- comfort, use a full-face respirator. No other marine environment. They are inert and be-

al needs, and those that may be required by precautions other than clean body-covering nign in terms of their physical environmental

locally applicable health and safety regula- clothing should be needed for handling impact, but if ingested by waterfowl or

tions such as OSHA (USA), MAK (Germany) MAGNUM ABS resins. Use gloves with insu- aquatic life, they may mechanically cause ad-

or WHMIS (Canada). MSD sheets are upgrad- lation for thermal protection, when needed. verse effects. Spills should be minimised and

ed regularly, therefore, please request and they should be cleaned up when they happen.

review the most current MSD sheet before Combustibility

Plastics should not be discarded into the

handling or using any product. MAGNUM ABS resins will burn, and once ocean or any other body of water.

The following comments are general and ignited, may burn rapidly under the right con-

apply only to MAGNUM ABS resins as suppli- ditions of heat and oxygen supply. Do not Product Stewardship

ed. Various additives and processing aids permit dust to accumulate. Dust layers can The Dow Chemical Company has a funda-

used in fabrication and other materials used be ignited by spontaneous combustion mental concern for all who make, distribute

in finishing steps have their own safe use pro- or other ignition sources. When suspended and use its products, and for the environment

file and must be investigated separately. in air, dust can pose an explosion hazard. in which we live. This concern is the basis

Dense black smoke is produced when prod- of our Product Stewardship philosophy by

Hazards and Handling Precautions uct burns. Toxic fumes are released in fire which we assess the health and environ-

MAGNUM ABS resins have a very low degree situations. mental information on our products and then

of toxicity and under normal conditions of Fire fighters should wear positive-pressure, take appropriate steps to protect employee

use should pose no unusual problems from self-contained breathing apparatus and full and public health and the environment. Our

ingestion, eye or skin contact. However, protective equipment. Water or water fog are Product Stewardship programme rests with

caution is advised when handling, storing, the preferred extinguishing media. Foam, every individual involved with Dow products

using or disposing of these resins and good alcohol resistant foam, carbon dioxide, or dry from the initial concept and research to the

housekeeping and controlling of dusts are chemicals may also be used. Soak thoroughly manufacture, sale, distribution, and disposal

necessary for safe handling of product. with water to cool and prevent re-ignition. of each product.

Workers should be protected from the pos-

sibility of contact with molten resin during Disposal Customer Notice

fabrication. DO NOT DUMP INTO ANY SEWERS, ON THE Dow encourages its customers and potential

Handling and fabrication of plastic resins can GROUND, OR INTO ANY BODY OF WATER. users of Dow products to review their appli-

result in the generation of vapours and dusts. For unused or uncontaminated material, cations for such products from the standpoint

Dusts resulting from sawing, filing and sand- the preferred options include sending to a of human health and environmental quality.

ing of plastic parts in post-moulding opera- licensed recycler, reclaimer, incinerator or To help ensure that Dow products are not

tions may cause irritation to eyes and upper other thermal destruction device. For used or used in ways for which they are not intended

respiratory tract. In dusty atmospheres, use contaminated material, the disposal options or tested, Dow personnel will assist custom-

an approved dust respirator. remain the same, although additional evalua- ers in dealing with ecological and product

Granules or beads may present a slipping haz- tion is required (see, for example, in the USA safety considerations. Your Dow sales repre-

ard. Good general ventilation of the polymer 40 CFR, Part 261, “Identification and Listing sentative can arrange the proper contacts.

processing area is recommended. Processing of Hazardous Waste”). All disposal methods Dow literature, including Material Safety Data

may release fumes which may include poly- must be in compliance with Federal, State/ sheets, should be consulted prior to the use

mer fragments and other decomposition prod- Provincial and local laws and regulations. of Dow products. These are available from

ucts. Fumes can be irritating. At temperatures As a service to its customers, Dow can pro- the nearest Dow sales office.

exceeding melt temperature, polymer frag- vide lists of companies which recycle, re-

ments can occur. Good general ventilation process, or manage chemicals or plastics,

should be sufficient for most conditions. and companies that manage used drums.

Local exhaust ventilation may be necessary Contact the nearest Dow sales office for

for some operations. further details.

Notice: The information and data contained herein do not constitute sales specifications. The product properties may be changed without no-

tice. No liability, warranty or guarantee of product performance is created by this document. It is the Buyer’s responsibility to determine whether

Dow products are appropriate for Buyer’s use and to ensure that Buyer’s workplace and disposal practices are in compliance with applicable

laws and regulations. No freedom from any patents or other industrial or intellectual property rights is granted or to be inferred. (August 1997)

We don’t succeed unless you do.

Printed in Switzerland * Trademark of The Dow Chemical Company CH 264-044-E-897

Page 2 of 2 Studer AG

S-ar putea să vă placă și

- Climate Change in The Philippines PDFDocument44 paginiClimate Change in The Philippines PDFlipÎncă nu există evaluări

- Ia Masonry 17Document8 paginiIa Masonry 17Alliah Jane DelfinÎncă nu există evaluări

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingDocument2 paginiSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoÎncă nu există evaluări

- 1354 Nigeria Country SuDocument48 pagini1354 Nigeria Country Sudharmendra_kanthariaÎncă nu există evaluări

- Eyes of Nye - Human PopulationDocument3 paginiEyes of Nye - Human Populationmakenziee j .Încă nu există evaluări

- Weed Eater XT-112 ManualDocument8 paginiWeed Eater XT-112 Manual9iuyt100% (1)

- ABPK2203 Perception and Emotion Module PDFDocument147 paginiABPK2203 Perception and Emotion Module PDFPhoebeilsie RaimiÎncă nu există evaluări

- Introduction CavitationDocument19 paginiIntroduction CavitationArturoÎncă nu există evaluări

- DP03HDocument1 paginăDP03HDiadam SharmaÎncă nu există evaluări

- TDS LC670 Eng 220216Document1 paginăTDS LC670 Eng 220216AthonioMourinhoÎncă nu există evaluări

- Polypropylene: Sub-Group Description Applications ProcessDocument2 paginiPolypropylene: Sub-Group Description Applications ProcessJulio GarcíaÎncă nu există evaluări

- LG Chem TDS SP988 EnglishDocument1 paginăLG Chem TDS SP988 EnglishSérgio BarbosaÎncă nu există evaluări

- Property ComparisonDocument2 paginiProperty Comparisondiadam07Încă nu există evaluări

- H T NH A Lldpe 1002en TdsDocument1 paginăH T NH A Lldpe 1002en TdsChu ChuÎncă nu există evaluări

- Product Data: Titanpro For ThermoformingDocument1 paginăProduct Data: Titanpro For ThermoformingFarah99hanÎncă nu există evaluări

- ELITE 5401G: Blown Film ResinDocument2 paginiELITE 5401G: Blown Film ResinEndayenew MollaÎncă nu există evaluări

- PP PP9074MED DatasheetDocument1 paginăPP PP9074MED DatasheetDiogo SouzaÎncă nu există evaluări

- Lldpe - LL7410D PDSDocument1 paginăLldpe - LL7410D PDSchinchotarngÎncă nu există evaluări

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pagini9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupÎncă nu există evaluări

- High Density Polyethylene HS5407: Descrip OnDocument1 paginăHigh Density Polyethylene HS5407: Descrip OnJosiola MariledoÎncă nu există evaluări

- TDS Co-3-X 27 03 2018 (003) - 1687274055Document2 paginiTDS Co-3-X 27 03 2018 (003) - 1687274055KSXÎncă nu există evaluări

- En Akraplast Brochure AkrathermDocument2 paginiEn Akraplast Brochure AkrathermPrabartak DasÎncă nu există evaluări

- DMH 401 POM Black: Mechanical, Physical and Thermal PropertiesDocument1 paginăDMH 401 POM Black: Mechanical, Physical and Thermal Propertiessetiadi pratondoÎncă nu există evaluări

- Pa6 GF15 - Basf Ultramid B3eg3Document2 paginiPa6 GF15 - Basf Ultramid B3eg3armandoÎncă nu există evaluări

- Hdpe Me8000 (En)Document1 paginăHdpe Me8000 (En)Judith Casstañeda AgurtoÎncă nu există evaluări

- Durolon HFR 1910Document2 paginiDurolon HFR 1910elrolo3000Încă nu există evaluări

- Ficha Tecnica Abs Tairilac Ag12a0Document1 paginăFicha Tecnica Abs Tairilac Ag12a0Rula SiuÎncă nu există evaluări

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 paginiULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezÎncă nu există evaluări

- Elix ABS M220: Technical InformationDocument3 paginiElix ABS M220: Technical InformationDiegoTierradentroÎncă nu există evaluări

- PP TI4005P2 BraskemDocument1 paginăPP TI4005P2 BraskemJulio GarcíaÎncă nu există evaluări

- Ficha Técnica Hdpe (Sabic)Document2 paginiFicha Técnica Hdpe (Sabic)Luis LiraÎncă nu există evaluări

- Sé Etec: ApplicationsDocument1 paginăSé Etec: ApplicationsMohit MohataÎncă nu există evaluări

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 paginiStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoÎncă nu există evaluări

- Styro Lution Tds 400900240714Document3 paginiStyro Lution Tds 400900240714vrjrÎncă nu există evaluări

- TDS BB120 Eng 220216Document1 paginăTDS BB120 Eng 220216QcÎncă nu există evaluări

- Zurcon Z80 PDFDocument1 paginăZurcon Z80 PDFLuz SmithÎncă nu există evaluări

- Technyl Star S 218 V30 BK 31NDocument3 paginiTechnyl Star S 218 V30 BK 31Nratz23695Încă nu există evaluări

- Sabic BM 1052Document2 paginiSabic BM 1052ifahÎncă nu există evaluări

- Sabic Lldpe MG200024: PolymersDocument2 paginiSabic Lldpe MG200024: PolymersYoshie IwaiÎncă nu există evaluări

- Polypropylene: Sub-Group Description ApplicationsDocument1 paginăPolypropylene: Sub-Group Description ApplicationsJulio GarcíaÎncă nu există evaluări

- Y25GRDocument1 paginăY25GRPiyush A JoshiÎncă nu există evaluări

- Styrolution TDS400900250546Document2 paginiStyrolution TDS400900250546prabhat singhÎncă nu există evaluări

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 paginiLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúÎncă nu există evaluări

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 paginăSABIC® PP - 5271K - Global - Technical - Data - SheetjituniÎncă nu există evaluări

- TDS Mafill CRHT6344Document1 paginăTDS Mafill CRHT6344marcohang00Încă nu există evaluări

- SABIC® HDPE - P6006 - Global - Technical - Data - SheetDocument2 paginiSABIC® HDPE - P6006 - Global - Technical - Data - Sheetjemish limbaniÎncă nu există evaluări

- Pmma-Lg Pmma Ih 830a (Natural)Document1 paginăPmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesÎncă nu există evaluări

- GM5340PRK enUS ASTMDocument2 paginiGM5340PRK enUS ASTMDuongthithuydungÎncă nu există evaluări

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealÎncă nu există evaluări

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroÎncă nu există evaluări

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument1 paginăSABIC® HDPE - P6006AD - Global - Technical - Data - SheetNaren RawatÎncă nu există evaluări

- LUPOX TE5100: Description ApplicationDocument2 paginiLUPOX TE5100: Description Applicationhugo santiago chavez godoyÎncă nu există evaluări

- TecamidDocument2 paginiTecamidTejas HuddarÎncă nu există evaluări

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 paginăRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiÎncă nu există evaluări

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument2 paginiSABIC® HDPE - P6006AD - Global - Technical - Data - SheetThouraya Hbs100% (1)

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 paginiTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkÎncă nu există evaluări

- PA6G MoSDocument1 paginăPA6G MoSjhax90Încă nu există evaluări

- Hdi0653u1 Enus AstmDocument1 paginăHdi0653u1 Enus AstmJonathan GuadarramaÎncă nu există evaluări

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 paginiLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverÎncă nu există evaluări

- PolycarbonateDocument2 paginiPolycarbonateAdnan KhanÎncă nu există evaluări

- PolycarbonateDocument2 paginiPolycarbonateROHIT SHARMAÎncă nu există evaluări

- PolycarbonateDocument2 paginiPolycarbonatepuvitta sudeshilaÎncă nu există evaluări

- PP - Braskem - CP 442 XP PDFDocument1 paginăPP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosÎncă nu există evaluări

- ELITE 5400G: Blown Film ResinDocument2 paginiELITE 5400G: Blown Film ResinEndayenew MollaÎncă nu există evaluări

- Astm Property IM17VDocument2 paginiAstm Property IM17VSaketh VandeÎncă nu există evaluări

- Ref 12Document12 paginiRef 12Tiago BaraÎncă nu există evaluări

- A3233q48 140313 V01 enDocument15 paginiA3233q48 140313 V01 enfreezsoli4576Încă nu există evaluări

- Prolift 430R: Opener ForDocument12 paginiProlift 430R: Opener ForNatasha GlennÎncă nu există evaluări

- Exer7 Isolation and Detection of Salmonella in Foods PostlabDocument26 paginiExer7 Isolation and Detection of Salmonella in Foods PostlabFrances Grace OrdoñezÎncă nu există evaluări

- Project Documentation Part 2Document42 paginiProject Documentation Part 2Lorena LanchoÎncă nu există evaluări

- Marketing Midterm - Mohamed Serageldin - PEPSIDocument14 paginiMarketing Midterm - Mohamed Serageldin - PEPSIHossam SamyÎncă nu există evaluări

- Haynes 230 Alloy: Principal FeaturesDocument28 paginiHaynes 230 Alloy: Principal FeaturesMatheus DominguesÎncă nu există evaluări

- German Cars-Mercedes-S-Class-W222Document10 paginiGerman Cars-Mercedes-S-Class-W222DorusÎncă nu există evaluări

- Marble-Hand (II) CDocument8 paginiMarble-Hand (II) CmohammedetaÎncă nu există evaluări

- Technical Data Sheet R404A ENGLISH PDFDocument4 paginiTechnical Data Sheet R404A ENGLISH PDFjane.yuchen8283100% (1)

- Randomization List H2B de (M A W)Document25 paginiRandomization List H2B de (M A W)Elaine SantosÎncă nu există evaluări

- Work 2dos - Indigenous and Piñata-6 NovDocument1 paginăWork 2dos - Indigenous and Piñata-6 NovDoris50% (2)

- RM50HG 12SDocument3 paginiRM50HG 12SAbu Bakr M. SaeedÎncă nu există evaluări

- Vizzini Et Al 2024 - 240131 - 201545Document82 paginiVizzini Et Al 2024 - 240131 - 201545aedsp2Încă nu există evaluări

- Linear Programming AssignementDocument5 paginiLinear Programming AssignementHuzaifaÎncă nu există evaluări

- Brooklyn Brochure 21aprilDocument14 paginiBrooklyn Brochure 21aprilRiya AgrawalÎncă nu există evaluări

- Fluke Diagnostics Treatment PosterDocument1 paginăFluke Diagnostics Treatment PosterKarezza BacenaÎncă nu există evaluări

- Hydraulic Cylinder - Mill TypeDocument28 paginiHydraulic Cylinder - Mill TypeLe Van TamÎncă nu există evaluări

- Detection of NMI in SteelDocument13 paginiDetection of NMI in SteelShahidÎncă nu există evaluări

- NVC Catalogue Issue 05 September 2021.Document112 paginiNVC Catalogue Issue 05 September 2021.StampinusStephanoÎncă nu există evaluări

- Environmental Sustainability in The Food-Energy-Water-Health NexusDocument10 paginiEnvironmental Sustainability in The Food-Energy-Water-Health NexusPutri Alya KrisnamurtiÎncă nu există evaluări

- Body and Trim (Exterior)Document17 paginiBody and Trim (Exterior)Woong-Sub Lee0% (1)

- Working Paper 2010Document76 paginiWorking Paper 2010Javed LatifÎncă nu există evaluări