Documente Academic

Documente Profesional

Documente Cultură

Current Probe Fixture Instruction Manual

Încărcat de

enticoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Current Probe Fixture Instruction Manual

Încărcat de

enticoDrepturi de autor:

Formate disponibile

A.H.

Systems Current Probe Fixture

Current Probe Fixture

Instruction Manual

A.H. Systems inc. – January 2017 1

REV B

A.H. Systems Current Probe Fixture

TABLE OF CONTENTS

INTRODUCTION 3

GENERAL INFORMATION 4

TEST METHODS 5

SAFETY 7

FIGURES 8

FORMULAS 10

MAINTENANCE 11

WARRANTY 12

A.H. Systems inc. – January 2017 2

REV B

A.H. Systems Current Probe Fixture

INTRODUCTION

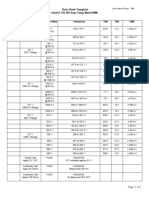

figure 1

Mechanical Outline

Model Frequency

Number Range A B C D E Weight

CPF-630 20 Hz – 500 MHz 2.75” 4.72” 0.625” 10.25” 5.72” 9.25 lbs.

CPF-631 400 MHz – 1.5 GHz 2.75” 4.72” 1.25” 10.25” 5.72” 10.5 lbs.

A.H. Systems inc. – January 2017 3

REV B

A.H. Systems Current Probe Fixture

GENERAL INFORMATION

INTENDED PURPOSES

This equipment is intended for general laboratory use in a wide variety of

industrial and scientific applications, and designed to be used in the

process of generating, controlling and measuring high levels of

electromagnetic Radio Frequency (RF) energy. It is the responsibility of

the user to assure that the device is operated in a location which will

control the radiated energy such that it will not cause injury and will not

violate regulatory levels of electromagnetic interference.

GENERAL DESCRIPTION

The current probe fixture is composed of an electrically short section of

trough transmission line. The short section permits the measurement of

current in the center conductor of the line, while the current probe is

clamped around the center conductor. The fixture's output terminal is

terminated in a 50 receiver, spectrum analyzer or RF voltmeter. A

measurement of the voltage developed by this RF voltmeter permits the

calculation of current flowing in the center conductor. The trough is large

enough to permit the current probe to be clamped around the center

conductor, with the outer conductor of the trough extending around the

current probe's outer shield.

A mechanical outline of the fixture and a typical injection probe mounted in

the fixture is shown in Figure 1. This fixture is useable over the frequency

range of 10 kHz to 400 MHz.

BROADBAND CURRENT PROBES (MONITOR PROBES)

During the equipment test a broadband current probe (monitoring probe) is

clamped around the same wire or wire bundle that the injection probe is

clamped around. The broadband current probe shall be calibrated for the

test frequencies and cable of operating with 1 ampere of RF current. The

broadband current probe shall be located approximately 5 cm from the

injection current probe.

INJECTION CURRENT PROBES

Injection current probes must be capable of injecting the specified current

levels into the circuit under test. Each probe has its own technical

description and model number, and each has its own individual technical

literature.

A.H. Systems inc. – January 2017 4

REV B

A.H. Systems Current Probe Fixture

TEST METHODS

PROBES AND TEST FIXTURES

In order to carry out a Bulk Current Injection Test, the following probes

and fixture will be required:

Calibration Test Fixture

Broadband Current Probes (Monitor Probes)

Injection Current Probes

TEST METHOD FOR PRECALIBRATION

Due to the occurrence of large variable circuit impedance’s and resonances

in cables, a calibration fixture is used to establish the forward power into the

injection probe, which develops defined currents in the calibration fixture.

The limits of current are established in a "Precalibration Test Set Up". This

test configuration is shown in Figure 2.

PRECALIBRATION TEST PROCEDURE

This test procedure consists of precalibration to establish the levels of

forward power necessary to generate the specification limits while clamped

onto the calibration fixture.

The precalibration is described in the following, and should be carried out

first.

1) The injection probe will be clamped in the calibration fixture as shown in

Figure 2.

2) The calibration fixture will be terminated in a 50 ohm, 50 watt RF load at

one end and a 50 ohm receiver 30 dB attenuator will be required to protect

the receiver or spectrum analyzer. The VSWR of the terminations at both

ends of the calibration fixture will be less than 1.2:1 over the frequency

range of the test.

3) The injection probe receives signal levels from the signal generator and

power amplifier. The limits of injected current in the calibrating fixture are

precalibrated for two levels of current magnitude:

A.H. Systems inc. – January 2017 5

REV B

A.H. Systems Current Probe Fixture

a) An accept/reject level of current which should not cause a

malfunction in the equipment under test.

b) A level of current which will cause a malfunction in the

equipment under test, without creating permanent damage to

it, or the specification level.

4) Precalibration Procedure Steps

a) Increase the test signal to the injection probe until the

accept/reject level of current is flowing in the calibration

fixture.

b) Record the forward power and reverse power necessary to

generate the accept/reject level of current.

c) Increase the test signal until the specification levels of current

are achieved.

d) Record the forward power and reverse power necessary to

generate the specification levels of current.

e) Repeat steps 1-4 over the required frequency range. The

calibration frequency range can extend from 10 kHz to 400

MHz.

f) The forward power in steps 1-4 identifies the total power from

the amplifier required to achieve the necessary current levels.

The reverse power permits the ability to 1) establish the

VSWR of injection probe, 2) the power forward - power

reverse establishes the net power delivered to the load

attached to the calibration fixture.

g) The test report shall document steps 1-4 data.

INJECTION OF CURRENT INTO EQUIPMENT CABLES PROCEDURE

The equipment test shall be applied to individual wires and entire cables as

required by the specifications.

A test procedure will be prepared that identifies each wire and cable to be

tested.

In all cases of injected current, the test configuration used shall be as

shown in Figure 3.

The broadband current probe shall be placed at the specified distance from

the injection probe. This distance is approximately 5 cm for most

specifications.

EQUIPMENT PROCEDURE TEST STEPS

1) Carry out the Precalibration Procedure Steps again in this test

configuration and record the current from the broadband current probe.

A.H. Systems inc. – January 2017 6

REV B

A.H. Systems Current Probe Fixture

2) At each test frequency, increase the signal level until a malfunction

occurs or until the specification current level is measured by the broadband

current probes.

Record the following:

Current from the Broadband Current Probe

Forward power injected

Reverse power injected

3) Repeat this test for all frequencies necessary. Measure enough

frequencies to be sure that all susceptibility levels have been determined.

4) At frequencies where the equipment under test shows susceptibility,

reduce the signal levels until the susceptibility stops. Record the same data

as in step 2.

SAFETY

Caution during all of these tests is advised. High RF voltages and currents

are being generated during these tests. Personnel conducting tests should

not come in contact with any exposed metallic items of the test setup.

Use extreme care when clamping current probes around uninsulated

conductors. It is advised to de-energize the test item during assembly and

disassembly of the test setup. Place all conductors passing through the

aperture of probes in the center of the aperture for additional voltage

breakdown protection. Do not permit the uninsulated current probe

connector and cable connectors to come in contact with the ground plane or

other adjacent conductors.

A.H. Systems inc. – January 2017 7

REV B

A.H. Systems Current Probe Fixture

Figure 2

Precalibration of Injection Current Probe

A.H. Systems inc. – January 2017 8

REV B

A.H. Systems Current Probe Fixture

Figure 3

Test Configuration for Current Injection

A.H. Systems inc. – January 2017 9

REV B

A.H. Systems Current Probe Fixture

ANTENNA FORMULAS AND CALCULATIONS

A specific Transfer Impedance Factor is associated with each frequency. This number is

to be subtracted from the receiver reading in order to convert to dBuA

dBA = dBV (from Receiver) - Transfer Impedance (dB) + cable Loss (dB)

EXAMPLE:

Assume that the frequency of interest is 80 KHz and we need to find the current at

this frequency. Connect the probe per figure 1

Frequency: 80 KHz

Transfer Impedance: -2.76 dB ohms

Cable Loss: 0.1dB

Receiver Reading: -33.0dBuV

dBA = dBV (from Receiver) - Transfer Impedance (dB) + cable Loss (dB)

dBA = -33.0 - -2.76 + - 0.1

dBA = -30.34

When injecting current:

Injection current (dB) = Input current (dB) - Insertion loss (dB) - Cable loss

Maximum power rating : 100 Watts for 30 minutes

Do not handle injection probe while testing is in progress.

Hazardous voltages may be present.

A.H. Systems inc. – January 2017 10

REV B

A.H. Systems Current Probe Fixture

MAINTENANCE

To ensure reliable and repeatable long-term performance, annual

re-calibration of your current probe by A.H. Systems experienced

technicians is recommended. Our staff can recalibrate almost any

type or brand of antenna.

For more information about our calibration services or to place an

order for antenna calibration visit our website at

http://www.AHSystems.com or call 1(818) 998-0223.

A.H. Systems inc. – January 2017 11

REV B

A.H. Systems Current Probe Fixture

WARRANTY INFORMATION

A.H. Systems Inc., warrants that our Antennas, Sensors and Probes will be free from

defects in materials and workmanship for a period of three (3) years. All other products

delivered under contract will be warranted for a period of two (2) years. A.H. Systems'

obligation under this warranty shall be limited to repairing or replacing, F.O.B.

Chatsworth, California, each part of the product which is defective, provided that the

buyer gives A.H. Systems notice of such defect within the warranty period commencing

with the delivery of the product by A.H. Systems.

The remedy set forth herein shall be the only remedy available to the buyer, and in no

event shall A.H. Systems be liable for direct, indirect, incidental or consequential

damages.

This warranty shall not apply to any part of the product which, without fault of A.H.

Systems has been subject to alteration, failure caused by a part not supplied by A.H.

Systems, accident, fire or other casualty, negligence, misuse or normal wear of

materials.

Except for the warranty set forth above, there are no other warranties, expressed or

implied, with respect to the condition of the product or it's suitability for the use intended

for them by the buyer.

For prompt service, please contact our service department for a Return Material

Authorization Number before shipping equipment back to us.

A.H. Systems inc. – January 2017 12

REV B

S-ar putea să vă placă și

- Method Statement For Protection TestingDocument4 paginiMethod Statement For Protection TestingAfanda Rodgers100% (3)

- Aws d1.1 Ut Inspection ProcedureDocument17 paginiAws d1.1 Ut Inspection ProcedureMohanadÎncă nu există evaluări

- T&C ManualDocument65 paginiT&C ManualKarthikeyan S100% (1)

- RFT ProcedureDocument9 paginiRFT ProcedureKuppan SrinivasanÎncă nu există evaluări

- Method of Statement For Power Cables: Owner/Client Consultant ContractorDocument7 paginiMethod of Statement For Power Cables: Owner/Client Consultant ContractorPandrayar MaruthuÎncă nu există evaluări

- A High-Voltage Reference Testbed For The Evaluation ofDocument2 paginiA High-Voltage Reference Testbed For The Evaluation ofYolandaIbáñezÎncă nu există evaluări

- Rangel PowerDocument4 paginiRangel PowerPixel ShicÎncă nu există evaluări

- PotM 2020 12 CommissioningSub Harmonic Proteciton IED Using CMC 356 ENUDocument13 paginiPotM 2020 12 CommissioningSub Harmonic Proteciton IED Using CMC 356 ENUprakashÎncă nu există evaluări

- A Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusDocument7 paginiA Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusAmanda MeloÎncă nu există evaluări

- 700 Series AC Dielectric Test SetsDocument7 pagini700 Series AC Dielectric Test SetsKhoilnÎncă nu există evaluări

- 6606 Issue 3 Cathodic Protection Potential SurveyDocument4 pagini6606 Issue 3 Cathodic Protection Potential SurveyFethi BELOUISÎncă nu există evaluări

- ANSI SCTE 06 2009 Composite Distortion Measurements (CSO & CTB)Document10 paginiANSI SCTE 06 2009 Composite Distortion Measurements (CSO & CTB)Angel AhumadaÎncă nu există evaluări

- A Custom Vibration Test Fixture Using SubwooferDocument11 paginiA Custom Vibration Test Fixture Using SubwooferDaniel ObataÎncă nu există evaluări

- Draft Format - Method Statement of Commissioning NURSE CALLDocument12 paginiDraft Format - Method Statement of Commissioning NURSE CALLmohammed naseer uddinÎncă nu există evaluări

- Api Ut 1Document6 paginiApi Ut 1Ricardo Andres Santamaria Torres100% (1)

- HR Wallingford-009 - Wave - GaugeDocument2 paginiHR Wallingford-009 - Wave - GaugeSutanto HadiÎncă nu există evaluări

- Ultrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Document26 paginiUltrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Taufik SantosoÎncă nu există evaluări

- UT Lesson7 08 12Document58 paginiUT Lesson7 08 12Gulfam HussainÎncă nu există evaluări

- XLPE PD DetectionDocument4 paginiXLPE PD DetectionClaysius DewanataÎncă nu există evaluări

- Saep 150Document13 paginiSaep 150Abdullah100% (1)

- Solar PanalDocument5 paginiSolar PanalShankar SwamiÎncă nu există evaluări

- IEEE 43 (Testing Insulation Rotating Machine)Document4 paginiIEEE 43 (Testing Insulation Rotating Machine)Kukuh WidodiÎncă nu există evaluări

- Test Instruments - Exams-1 MedicalDocument12 paginiTest Instruments - Exams-1 MedicalJon Alvin M SelisanaÎncă nu există evaluări

- IS-2071, Part-2Document29 paginiIS-2071, Part-2Himansu Sekhar JenaÎncă nu există evaluări

- UOW019 - Tech Note 14 - AW - Screen PDFDocument14 paginiUOW019 - Tech Note 14 - AW - Screen PDFmorrissubhashÎncă nu există evaluări

- E1106-12 Método de Prueba Estándar para La Calibración Primaria de Sensores de Emisión Acústica1Document13 paginiE1106-12 Método de Prueba Estándar para La Calibración Primaria de Sensores de Emisión Acústica1fredy lopezÎncă nu există evaluări

- Considerations ForDocument9 paginiConsiderations Forkiyong namÎncă nu există evaluări

- High-Speed Digital Test & Measurement: Chris Allen (Callen@eecs - Ku.edu)Document21 paginiHigh-Speed Digital Test & Measurement: Chris Allen (Callen@eecs - Ku.edu)mikeshinoda2011Încă nu există evaluări

- Paut Total ProcedureDocument25 paginiPaut Total ProcedureMassimo Fumarola100% (1)

- A Low Power Bioimpedance Module For Wearable Systems: SciencedirectDocument4 paginiA Low Power Bioimpedance Module For Wearable Systems: SciencedirectDmitriyÎncă nu există evaluări

- RFT ProcedureDocument9 paginiRFT ProcedurevikramÎncă nu există evaluări

- Partial Discharge Measurement and Monitoring On High Voltage XLPE CablesDocument14 paginiPartial Discharge Measurement and Monitoring On High Voltage XLPE CableskarakoukasÎncă nu există evaluări

- Micro Resistance Tester Based On AC Constant Current ExcitationDocument6 paginiMicro Resistance Tester Based On AC Constant Current ExcitationFor GosÎncă nu există evaluări

- UntitledDocument105 paginiUntitledUlises Almeida CruzÎncă nu există evaluări

- Evaluation of A Vibration Text Fixture: Everaldo de Barros and Carlos D'andrade SoutoDocument5 paginiEvaluation of A Vibration Text Fixture: Everaldo de Barros and Carlos D'andrade SoutoTaqweem ZahraÎncă nu există evaluări

- Control Engineering and AutomationDocument2 paginiControl Engineering and AutomationaltanshnetÎncă nu există evaluări

- State and Explain Barkhausen's Criteria For Sustained Oscillation 1Document5 paginiState and Explain Barkhausen's Criteria For Sustained Oscillation 1Ayush NinaweÎncă nu există evaluări

- Astm F 528 - 99Document7 paginiAstm F 528 - 99o_l_0Încă nu există evaluări

- Profitest100s IIDocument8 paginiProfitest100s IIKirilÎncă nu există evaluări

- Calibration Steps Using Ultrasonic Flaw DetectorDocument7 paginiCalibration Steps Using Ultrasonic Flaw DetectorShahazad ShaikÎncă nu există evaluări

- HV&HC Test Techniques PDFDocument4 paginiHV&HC Test Techniques PDFChristian RuedaÎncă nu există evaluări

- The Oxford Polytechnic: Log SheetDocument9 paginiThe Oxford Polytechnic: Log SheetAnonymous EayGj0Încă nu există evaluări

- Cigre 2010 - On-Site Commissioning Test and Diagnostics ofDocument7 paginiCigre 2010 - On-Site Commissioning Test and Diagnostics ofAnonymous F71F47EnKÎncă nu există evaluări

- The Use of Multiple Sensors For The On-Line Partial Discharge Measurement of High Voltage Electrical EquipmentDocument5 paginiThe Use of Multiple Sensors For The On-Line Partial Discharge Measurement of High Voltage Electrical EquipmentShailesh ChettyÎncă nu există evaluări

- NOTES 4 Sensors For Vibration MeasurementDocument77 paginiNOTES 4 Sensors For Vibration MeasurementmanishpaliÎncă nu există evaluări

- Teledyne LeCroy - Current ProbesDocument2 paginiTeledyne LeCroy - Current ProbesDeepa DevarajÎncă nu există evaluări

- PD Analysis by NattrassDocument14 paginiPD Analysis by NattrassmuhammadmusakhanÎncă nu există evaluări

- CIGRE - Paris-Application of Partial Discharge Diagnostic Technique On High Voltage Cable Sealing EndsDocument9 paginiCIGRE - Paris-Application of Partial Discharge Diagnostic Technique On High Voltage Cable Sealing EndsKarthik SriramakavachamÎncă nu există evaluări

- The Practical Measurement Setup of Dpi Method Above 1 GHZ For IcsDocument4 paginiThe Practical Measurement Setup of Dpi Method Above 1 GHZ For IcsIbeth CarbajalÎncă nu există evaluări

- Capacitive Slot Coupler For On-Line Partial Discharge Monitoring of Stator Winding InsulationDocument6 paginiCapacitive Slot Coupler For On-Line Partial Discharge Monitoring of Stator Winding InsulationDaniel Rafael DzuculeÎncă nu există evaluări

- GT CISPR25 v1.8Document55 paginiGT CISPR25 v1.8江玉樹Încă nu există evaluări

- Paper - QUALITATIVE ANALYSIS OF PARTIAL DISCHARGE RADIO FREQUENCY EMISSION PROPAGATION IN MEDIUM VOLTAGE METAL CLAD SWITCHGEARDocument10 paginiPaper - QUALITATIVE ANALYSIS OF PARTIAL DISCHARGE RADIO FREQUENCY EMISSION PROPAGATION IN MEDIUM VOLTAGE METAL CLAD SWITCHGEARNguyen Vu Nhat HaÎncă nu există evaluări

- Boonton Radio Corporation - The Notebook 12Document8 paginiBoonton Radio Corporation - The Notebook 12Luiz Roberto PascotteÎncă nu există evaluări

- 1482389591final - Dilectric Impulse Tester HV Probeoscilloscope TENDER FINALDocument9 pagini1482389591final - Dilectric Impulse Tester HV Probeoscilloscope TENDER FINALGowri GaneshÎncă nu există evaluări

- Abb Keca 80 D85Document7 paginiAbb Keca 80 D85Laurentiu CatalinÎncă nu există evaluări

- Ansi Scte 04-2007Document9 paginiAnsi Scte 04-2007liuyx866Încă nu există evaluări

- SAT PROCEDURE FOR MV SWGR PANELS - PdfToWordDocument4 paginiSAT PROCEDURE FOR MV SWGR PANELS - PdfToWordAmr ElkadyÎncă nu există evaluări

- Electrical Spectrum and Network Analyzers: A Practical ApproachDe la EverandElectrical Spectrum and Network Analyzers: A Practical ApproachÎncă nu există evaluări

- Operational Amplifier Circuits: Analysis and DesignDe la EverandOperational Amplifier Circuits: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (2)

- Berkeley Nucleonics 745Document33 paginiBerkeley Nucleonics 745enticoÎncă nu există evaluări

- Pxie-5650/5651/5652: Calibration ProcedureDocument31 paginiPxie-5650/5651/5652: Calibration ProcedureenticoÎncă nu există evaluări

- Current Probe Calibration PGD 2014 02 06 2Document3 paginiCurrent Probe Calibration PGD 2014 02 06 2enticoÎncă nu există evaluări

- TB 9-4935-251-50-7Document9 paginiTB 9-4935-251-50-7enticoÎncă nu există evaluări

- ProcsDocument10 paginiProcsenticoÎncă nu există evaluări

- ATEQ OMICRON ADSE744 USER MANUAL PITOT STATIC TESTER - CompressedDocument89 paginiATEQ OMICRON ADSE744 USER MANUAL PITOT STATIC TESTER - CompressedenticoÎncă nu există evaluări

- Sda Om eDocument397 paginiSda Om eenticoÎncă nu există evaluări

- Iso 3696-1987Document8 paginiIso 3696-1987enticoÎncă nu există evaluări

- Ransburg 76652 01 - 04Document24 paginiRansburg 76652 01 - 04enticoÎncă nu există evaluări

- ProcsDocument10 paginiProcsenticoÎncă nu există evaluări

- Agilent B1500A: Semiconductor Device AnalyzerDocument202 paginiAgilent B1500A: Semiconductor Device AnalyzerenticoÎncă nu există evaluări

- Smiqb OperatingManual V2 en 11Document424 paginiSmiqb OperatingManual V2 en 11enticoÎncă nu există evaluări

- Doble-Tdr9000 DatasheetDocument4 paginiDoble-Tdr9000 DatasheetenticoÎncă nu există evaluări

- CSA8000 Series Communications Signal Analyzers & TDS8000 ...Document456 paginiCSA8000 Series Communications Signal Analyzers & TDS8000 ...enticoÎncă nu există evaluări

- CVSDFDDocument1 paginăCVSDFDenticoÎncă nu există evaluări

- CJDS98 EN ManualDocument47 paginiCJDS98 EN ManualenticoÎncă nu există evaluări

- EN60601 2 25 (2015) e - CodifiedDocument9 paginiEN60601 2 25 (2015) e - CodifiedenticoÎncă nu există evaluări

- Anritsu OSLN50-1Document20 paginiAnritsu OSLN50-1enticoÎncă nu există evaluări

- Vscan Vivax 101167693Document1 paginăVscan Vivax 101167693enticoÎncă nu există evaluări

- Lecroy SDA 6000A ME180Document5 paginiLecroy SDA 6000A ME180enticoÎncă nu există evaluări

- BK PRECISION 251x - ManualDocument159 paginiBK PRECISION 251x - ManualenticoÎncă nu există evaluări

- Dokumen - Tips Metrel MD 9226 Online Shop Fuer Mess Und Metrel MD 9226 Trms Acdc CurrentDocument56 paginiDokumen - Tips Metrel MD 9226 Online Shop Fuer Mess Und Metrel MD 9226 Trms Acdc CurrententicoÎncă nu există evaluări

- Archived Ni 445x 455x Calibration ProcedureDocument42 paginiArchived Ni 445x 455x Calibration ProcedureenticoÎncă nu există evaluări

- Modelling of Impact Falling Ball Test Response On Solid and Engineered Wood Flooring of Two Eucalyptus SpeciesDocument20 paginiModelling of Impact Falling Ball Test Response On Solid and Engineered Wood Flooring of Two Eucalyptus SpeciesenticoÎncă nu există evaluări

- Ni Pci-4451 - 4452 - 4453 - 4454Document122 paginiNi Pci-4451 - 4452 - 4453 - 4454enticoÎncă nu există evaluări

- Ideal Industries 61-702 DatasheetDocument2 paginiIdeal Industries 61-702 DatasheetenticoÎncă nu există evaluări

- User Instruction Manual Self Retracting Lifelines: Instructions For The Following Series ProductsDocument40 paginiUser Instruction Manual Self Retracting Lifelines: Instructions For The Following Series ProductsenticoÎncă nu există evaluări

- Datacom/DDS Module: Sunrise TelecomDocument2 paginiDatacom/DDS Module: Sunrise TelecomenticoÎncă nu există evaluări

- OTC Family of Battery Testers: Sabre HPDocument4 paginiOTC Family of Battery Testers: Sabre HPenticoÎncă nu există evaluări

- Racal - Dana 9008: Automatic Modulation MeterDocument2 paginiRacal - Dana 9008: Automatic Modulation MeterenticoÎncă nu există evaluări

- E85005-0132 - Io Series Submittal Guide PDFDocument51 paginiE85005-0132 - Io Series Submittal Guide PDFgndurangoÎncă nu există evaluări

- University of Engineering and Technology Electrical Technology Lab Experiment # 10: Norton's TheoremDocument3 paginiUniversity of Engineering and Technology Electrical Technology Lab Experiment # 10: Norton's TheoremMuhammad AliÎncă nu există evaluări

- BE3252 QB Unit4Document2 paginiBE3252 QB Unit4rkanthimathi86Încă nu există evaluări

- Infineon SAA - XC866 DS v01 - 05 enDocument114 paginiInfineon SAA - XC866 DS v01 - 05 enpatricio andradeÎncă nu există evaluări

- Ed - 2Document54 paginiEd - 2JaiÎncă nu există evaluări

- Operating System Full and Final NotesDocument5 paginiOperating System Full and Final NotesUrja DhabardeÎncă nu există evaluări

- Module 4 CMOS LogicDocument18 paginiModule 4 CMOS LogicJessie Tess TolentinoÎncă nu există evaluări

- Week 4 Monitoring SystemsDocument19 paginiWeek 4 Monitoring SystemskongÎncă nu există evaluări

- LSK389 Dual Monolithic JFETDocument14 paginiLSK389 Dual Monolithic JFETattapapaÎncă nu există evaluări

- Datasheet Growatt Syn 50 XH 30 Apx EnglishDocument2 paginiDatasheet Growatt Syn 50 XH 30 Apx EnglishTihomir KocijanovicÎncă nu există evaluări

- Landis+Gyr E550: Industrial & CommercialDocument6 paginiLandis+Gyr E550: Industrial & CommercialDylan GomezÎncă nu există evaluări

- Biasing and Transfer Characteristic of Mach-Zehnder Modulator (MZM) 1Document12 paginiBiasing and Transfer Characteristic of Mach-Zehnder Modulator (MZM) 1Ranjan KumarÎncă nu există evaluări

- Introduction To Computer Architecture and Network Tutorial 4.1 - Computer Component - Part 1: HardwareDocument3 paginiIntroduction To Computer Architecture and Network Tutorial 4.1 - Computer Component - Part 1: HardwareTumblr AshwinÎncă nu există evaluări

- Chapter 07Document47 paginiChapter 07Muhammad AzharÎncă nu există evaluări

- Lenovo V110-15ISK - Wistron LV115 LV114NOWATER Esquematico LenovoDocument105 paginiLenovo V110-15ISK - Wistron LV115 LV114NOWATER Esquematico LenovoMiguel MillanÎncă nu există evaluări

- Black Hole and Selective Forwarding Attack Detection and Prevention in WSN 2017Document6 paginiBlack Hole and Selective Forwarding Attack Detection and Prevention in WSN 2017Seid MohammedÎncă nu există evaluări

- Performance Analysis and Monitoring of V PDFDocument23 paginiPerformance Analysis and Monitoring of V PDFIvan CuadrosÎncă nu există evaluări

- Sports & IT MPPSC Test PDF in Hindi by Kothari (For More Book - WWW - GKTrickHindi.com)Document14 paginiSports & IT MPPSC Test PDF in Hindi by Kothari (For More Book - WWW - GKTrickHindi.com)Pankaj S ChandelÎncă nu există evaluări

- Llora Nena Wah: Resistors Transistors Capacitors Parts ListDocument1 paginăLlora Nena Wah: Resistors Transistors Capacitors Parts ListRichard SeixasÎncă nu există evaluări

- FieryOption Supported FierysDocument4 paginiFieryOption Supported Fierysondemandprint100% (1)

- HC900 DataDocument24 paginiHC900 DatamoisesÎncă nu există evaluări

- Mega65 BookDocument1.279 paginiMega65 BookgoogleÎncă nu există evaluări

- GENERAL PURPOSE SOLID STATE RELAY Application Note (EN) Ver1.0Document4 paginiGENERAL PURPOSE SOLID STATE RELAY Application Note (EN) Ver1.0Luis HuanqqueÎncă nu există evaluări

- Beamng DxdiagDocument39 paginiBeamng DxdiagVika GoguaÎncă nu există evaluări

- 2119945r2 MPPU DiagnosticsDocument99 pagini2119945r2 MPPU DiagnosticsLuciano GoncalvesÎncă nu există evaluări

- This Study Resource WasDocument4 paginiThis Study Resource WasDinesh tallaparthiÎncă nu există evaluări

- User'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedDocument48 paginiUser'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedBelghennou Hadj AliÎncă nu există evaluări

- 08 PV1800 VPM 1Document1 pagină08 PV1800 VPM 1Moh AwadÎncă nu există evaluări

- Fuse Terminal Block - 1500VDocument1 paginăFuse Terminal Block - 1500VSEO BDMÎncă nu există evaluări

- Micro Controller Based Solar ChargerDocument24 paginiMicro Controller Based Solar Chargerbalu54100% (2)