Documente Academic

Documente Profesional

Documente Cultură

TGM 2.6.6 Cargo Care During Voyage

Încărcat de

Boris PetrovicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TGM 2.6.6 Cargo Care During Voyage

Încărcat de

Boris PetrovicDrepturi de autor:

Formate disponibile

TGM 2.6.

6 Cargo care during voyage

Valid for: Revision: 0 Date: 2017-12-01

Thome Ship Management (TSM)

Author: Reviewed by: Approved by:

Tanker Department Marine Manager COO Tanker

Contents

1 Application..................................................................................................................1

2 Purpose......................................................................................................................1

3 Responsibilities...........................................................................................................1

4 Cargo handling and operational tests during voyage......................................................1

5 Operational checks for tank vessel during sea passage..................................................2

1 APPLICATION

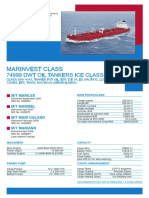

This document applies to all officers onboard fully managed tanker vessels.

2 PURPOSE

The purpose of this document is to specify cargo care procedures during voyage.

3 RESPONSIBILITIES

Chief Officer- Overall in charge.

Deck Officers- To assist chief officer as required.

Chief Engineer- Overall in charge for availability of machinery required for cargo care.

Watch Keepers- Assist chief officer & deck officers

4 CARGO HANDLING AND OPERATIONAL TESTS DURING VOYAGE

Cargo Heating – Refer to TGM 2.6.8 – Cargo Heating

Preventing Vapour Loss

Monitor escape of cargo vapour by checking PV valves.

Ensure all hatch lids, ullage ports and other tank openings are gas tight.

Maintain inert gas blanket on cargo throughout voyage using the inert gas system as

necessary.

Keep tanks under a good positive pressure at all times.

Prevention of grade contamination by cargo vapour - Cargoes of different vapour

pressure carried with a common venting system can lead to contamination.

Page 1 of 4 TGM 2.6.6 Cargo care during voyage Rev 0 of 2017-12-01

Isolate the venting systems for the two grades if possible.

Use the individual PV valves (if fitted), for pressure control.

Follow any specific instructions from charterers.

Pre-arrival checks, tests and inspections - Carry out following tests, inspections and

checks during the laden passage, before arrival at discharge port.

Water Dips - Make a full set of water cuts for cargo tanks and maintain records.

Hydraulic systems

o Activate hydraulic system and check for leakage.

o Ensure that the motors are working properly.

o Check operation of valves.

o Check operation of high and low pressure alarms, low oil level and auto stop/start

systems.

o Overhaul portable hydraulic hand pumps if necessary.

Inert gas system – Refer to TGM 2.6.7 – Inert gas system

Note:

-The time for conducting pre-arrival tests may depend on the trade of the vessel but generally

carry out tests at not less than 3 days before arrival.

-This ensures plenty of time to rectify any defects discovered during the tests.

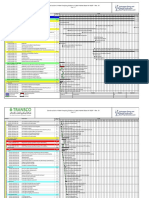

5 OPERATIONAL CHECKS FOR TANK VESSEL DURING SEA PASSAGE

Carry out below checks/controls during sea passage based on nature of cargoes carried .

Note:

Report any abnormality to the master for necessary corrective action.

Daily check of pump room

o Check hydrocarbon gas to detect cargo leakage.

o Bilge sounding to detect water leakages.

Control of valves

o Cargo segregation or mixing or contamination

o Tagging of valves - When the vessel is carrying more than one grade, tag the

valves of each grade by different colour.

Avoid inadvertent access or operation of valves

Keeping the cargo control room and/or hydraulic room locked.

Use ‘Lock out – Tag out’ procedure to identify and isolate the grades.

Segregation of venting lines to avoid vapour contamination

o In case of common venting lines, keep tank isolation valves shut.

o Check inert gas pressure regularly.

o Lock tank isolation valves to avoid inadvertent operation.

Page 2 of 4 TGM 2.6.6 Cargo care during voyage Rev 0 of 2017-12-01

Note:

Chief Officer should have the keys to the I.G. isolation valve locks.

Cargo tanks level

o Investigate any variation in the tank level immediately.

Cargo tank or line pressure

o Monitor and maintain cargo tank/line pressure within design limits to avoid

structural damage.

Caution:

Structural damage of tanks / lines can lead to serious pollution.

Top up inert gas if tank pressures fall below 100 mmwg.

In case the pressure increases, it may have to vent off using mast riser or PV valves.

Note:

In case of releasing toxic vapours, refer to TGM 2.13.1 A13 Hazardous vapour release.

o Cargo lines also suffer over and under pressurization due to increase or fall in the

temperature of the cargo in the line.

o Release line pressure one by one, by crack opening the drop valve and the

goose neck valve to the cargo tank.

Cargo temperature

o For heated cargoes, follow heating instruction given by the shipper.

Note:

Heating instruction will specify voyage/discharge temperatures and maximum temperature rise

per day.

o Maintain daily cargo temperature record.

o If in hot climate e.g. warm seawater and sun warming up the deck, a more

frequent check may be necessary.

o If temperature starts rising to dangerous level, put cooling systems into

operation.

o For cooling circulate cold fresh water in the heating coils, and/or flush deck by

ambient seawater.

Inspection of cargo lines

o If loaded with multiple grades do not pressure test the cargo lines, nor try out

the cargo pumps.

o If vessel is regularly involved in multiple grade loading, then pressure test the lines

and try out of cargo pumps during tank cleaning.

Gas detection and sounding of empty tanks adjacent to cargo tanks

o On vessels without fixed gas detection systems or fixed gas detection

system without recorders for void and ballast spaces within the cargo tank

area, regularly monitored for hydrocarbon content with portable equipment.

Page 3 of 4 TGM 2.6.6 Cargo care during voyage Rev 0 of 2017-12-01

o Include sounding and ullaging of the empty spaces to detect cargo or water

leakages.

o Monitor non-cargo spaces within the cargo tank area should as follows:

1. Soonest after each loading operation

2. Everyday during loaded passage and immediately prior to arrival at port

3. Prior ballasting

4. In unusual event such as grounding, collision, contact damage, after a period

of very heavy weather or any other unforeseen operational problems

5. Every third day during ballast passage (sounding or ullaging only)

o When on short coastal voyages, which make the above regulations impractical

to follow, visual inspection of the tanks or the ballast water is a suitable alternative

measure.

o Record the test results.

o During voyage, gas-monitor all void spaces every day and record results.

Page 4 of 4 TGM 2.6.6 Cargo care during voyage Rev 0 of 2017-12-01

S-ar putea să vă placă și

- Maritime Technical EnglishDocument49 paginiMaritime Technical EnglishMahdi Bordbar100% (27)

- Cheng Gong CG956G Service ManualDocument76 paginiCheng Gong CG956G Service ManualDanilo Marin90% (10)

- Chevron Vetting RequirementsDocument2 paginiChevron Vetting Requirementsady sto100% (1)

- Breaking of Tow Line Checklist - Attachment XLIVDocument3 paginiBreaking of Tow Line Checklist - Attachment XLIVFaiqah AzmirÎncă nu există evaluări

- Dangerous & Difficult Bulk Cargoes - Best Practice and The IMSBC CodeDocument12 paginiDangerous & Difficult Bulk Cargoes - Best Practice and The IMSBC CodeRadu GeorgeÎncă nu există evaluări

- Guide To Vetting Proceed 2017 - Part81 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part81 PDFQuang Hòa Lưu100% (1)

- Sample Ballast Water Record Book CompletedDocument9 paginiSample Ballast Water Record Book Completedsanthosh shetty100% (2)

- USCG Inspection Self ChercklistDocument5 paginiUSCG Inspection Self ChercklistVipin JainÎncă nu există evaluări

- 3) Project ScheduleDocument7 pagini3) Project ScheduleunnicyriacÎncă nu există evaluări

- DM0557 CR Injector Repair Parts OSNDocument4 paginiDM0557 CR Injector Repair Parts OSNbogdanxp2000100% (1)

- 15 Important Points To Consider For Efficient Tanker Ship OperationsDocument13 pagini15 Important Points To Consider For Efficient Tanker Ship OperationsDaniel Castillo100% (1)

- A Complete Guide of Loading TDI Onboard A Chemical TankerDocument19 paginiA Complete Guide of Loading TDI Onboard A Chemical TankerKunal Singh100% (1)

- Grain Cargo Care ChecklistDocument5 paginiGrain Cargo Care ChecklistEfren RojasÎncă nu există evaluări

- Tech 32c MSC Manya S PlakidaDocument24 paginiTech 32c MSC Manya S PlakidajudesonÎncă nu există evaluări

- Vetting Inspectors.Document5 paginiVetting Inspectors.Pavel ViktorÎncă nu există evaluări

- PUBS Loss Prevention Gangways - 0719 1Document23 paginiPUBS Loss Prevention Gangways - 0719 1karaflass100% (1)

- Shipboard Marine Pollution Emergency Plan (Smpep)Document44 paginiShipboard Marine Pollution Emergency Plan (Smpep)capt_wal1137Încă nu există evaluări

- SIRE 2.0 Guidance Document TableDocument1 paginăSIRE 2.0 Guidance Document TableValerson CarvalhoÎncă nu există evaluări

- Gas Tanker Operating Manual VMS/GAS/01: COPY NO.Document118 paginiGas Tanker Operating Manual VMS/GAS/01: COPY NO.Bui Duy ThanhÎncă nu există evaluări

- Cargo Line Clearance Safe Procedure For Chemical TankersDocument8 paginiCargo Line Clearance Safe Procedure For Chemical TankersJeet SinghÎncă nu există evaluări

- Guide To Vetting Proceed 2017 - Part71 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part71 PDFQuang Hòa LưuÎncă nu există evaluări

- Appendix 12 - IMO Ship Shore Safety Checklist FormDocument4 paginiAppendix 12 - IMO Ship Shore Safety Checklist FormCharalampos BarÎncă nu există evaluări

- Code 17 DeficienciesDocument18 paginiCode 17 DeficienciescapmanirajÎncă nu există evaluări

- Ecdis FailureDocument2 paginiEcdis FailureAndrei CondruzÎncă nu există evaluări

- Tmsa 2014Document39 paginiTmsa 2014Alcides Hermoza MejiaÎncă nu există evaluări

- US Environmental Protection Agency National Pollution Discharge Elimination System Vessel General PermitDocument37 paginiUS Environmental Protection Agency National Pollution Discharge Elimination System Vessel General PermitHarbinder SinghÎncă nu există evaluări

- Panamax Cargo Hold Cleaning Manual Rev00Document36 paginiPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanÎncă nu există evaluări

- Grain Stability Manual: Diamond 53 - Handymax Bulk Carrier M/S Spar ScorpioDocument173 paginiGrain Stability Manual: Diamond 53 - Handymax Bulk Carrier M/S Spar ScorpioDinchak RRAH100% (2)

- Damage Control Plan PDFDocument21 paginiDamage Control Plan PDFasdsddsÎncă nu există evaluări

- FG15 Vetting Findings 2023Document8 paginiFG15 Vetting Findings 2023Ante IvkovicÎncă nu există evaluări

- Cargo Switching ManualDocument53 paginiCargo Switching ManualНиколай Ника100% (1)

- Passage Plan Flow Chart 2Document1 paginăPassage Plan Flow Chart 2Кирилл Ананченко100% (2)

- Asian VettingDocument13 paginiAsian Vettingkhaled1160Încă nu există evaluări

- ISGOTT 6 Breakdown of POI For InspectorsDocument4 paginiISGOTT 6 Breakdown of POI For InspectorsSam BÎncă nu există evaluări

- Standard P&a ManualDocument16 paginiStandard P&a ManualVasant Kumar VarmaÎncă nu există evaluări

- Imbsc CodeDocument8 paginiImbsc CodeNeeraj SÎncă nu există evaluări

- MSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)Document6 paginiMSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)CaptShivraj ManeÎncă nu există evaluări

- VIQ 7 - Knowlwdge Based Questions For Both Ratings and Officers - Oil Tankers PDFDocument2 paginiVIQ 7 - Knowlwdge Based Questions For Both Ratings and Officers - Oil Tankers PDFFaisal Karim ShazibÎncă nu există evaluări

- Light and Smoke Signal: Warning DisposalDocument1 paginăLight and Smoke Signal: Warning Disposalariesyiha100% (1)

- Monitoring of Cargo During VoyageDocument29 paginiMonitoring of Cargo During VoyageYap JoshuaÎncă nu există evaluări

- AIMPA - Marine Pilots' Journal - August 2020 Year 1 - Issue 1Document16 paginiAIMPA - Marine Pilots' Journal - August 2020 Year 1 - Issue 1Capt Gajanan KaranjikarÎncă nu există evaluări

- 10 B Bulk Cargo Transfer Check List FormDocument6 pagini10 B Bulk Cargo Transfer Check List Formasdasd0% (1)

- Guide To Vetting Proceed 2017 - Part78 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part78 PDFQuang Hòa LưuÎncă nu există evaluări

- Solas Training Manual PartivDocument25 paginiSolas Training Manual PartivCarlton AfreddyÎncă nu există evaluări

- Bridge 130 Deep Sea NavigationDocument1 paginăBridge 130 Deep Sea NavigationMiha MihaelaÎncă nu există evaluări

- Guide To Vetting Proceed 2017 - Part74 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part74 PDFQuang Hòa LưuÎncă nu există evaluări

- Survey Planning Questionnaire For Oil Tanker - CASDocument4 paginiSurvey Planning Questionnaire For Oil Tanker - CASrays100% (1)

- Vetting Preparation FinalDocument36 paginiVetting Preparation Finalnsa.paceÎncă nu există evaluări

- Gmi Ps200 Multi Gas Detector DatasheetDocument3 paginiGmi Ps200 Multi Gas Detector DatasheetEyu Allaga Abanto-Busayong VegafriaÎncă nu există evaluări

- Microsoft Power Point - Session 4 Secondary Venting (Compatibility Mode)Document31 paginiMicrosoft Power Point - Session 4 Secondary Venting (Compatibility Mode)paulholl100% (3)

- 340 Att.1 Ballast Water Management ChecklistDocument2 pagini340 Att.1 Ballast Water Management Checklistwaleed yehiaÎncă nu există evaluări

- GMP - UniverseDocument27 paginiGMP - UniverseShahid Ali SyedÎncă nu există evaluări

- Check List 84 - BALLASTING, DeballastingDocument1 paginăCheck List 84 - BALLASTING, Deballastingprakash7kÎncă nu există evaluări

- Passenger Ship Outbreak Management Manual AppendixDocument82 paginiPassenger Ship Outbreak Management Manual AppendixNestor Matus100% (1)

- Bridge 100 Full Away SituationDocument1 paginăBridge 100 Full Away SituationMiha MihaelaÎncă nu există evaluări

- Inerting of Cargo TanksDocument20 paginiInerting of Cargo TanksFlexi100% (1)

- What Is Deck Water Seal On Tanker and Its Types in DetailDocument5 paginiWhat Is Deck Water Seal On Tanker and Its Types in DetailRose AriantiÎncă nu există evaluări

- Marine Cargo OperationDocument15 paginiMarine Cargo OperationJohn Raj100% (1)

- 8.04 Carriage of Coal in BulkDocument49 pagini8.04 Carriage of Coal in BulkRoken Zgoul100% (2)

- OIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsDocument3 paginiOIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsShoaib100% (2)

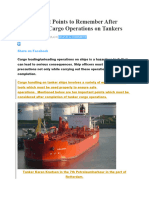

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument5 pagini10 Important Points To Remember After Completing Cargo Operations On TankerscassandraÎncă nu există evaluări

- Risk Watch Vol 09 1 PDFDocument4 paginiRisk Watch Vol 09 1 PDFkahl983Încă nu există evaluări

- They Can't Stop Enjoy Flying: Keep Things SimpleDocument3 paginiThey Can't Stop Enjoy Flying: Keep Things SimpleBoris PetrovicÎncă nu există evaluări

- The Crossing CeremonyDocument4 paginiThe Crossing CeremonyNuţu DumitrelÎncă nu există evaluări

- TGM 2.1.5 Cargo GearDocument8 paginiTGM 2.1.5 Cargo GearBoris PetrovicÎncă nu există evaluări

- SIGNS OF THE TIMES - Hieromonk Seraphim RoseDocument19 paginiSIGNS OF THE TIMES - Hieromonk Seraphim RoseAlina-Mihaela Miki100% (1)

- The Crossing Ceremony CertificateDocument1 paginăThe Crossing Ceremony CertificateBoris PetrovicÎncă nu există evaluări

- Ex Meridian: First Point of AriesDocument3 paginiEx Meridian: First Point of AriesBoris PetrovicÎncă nu există evaluări

- SIGNS OF THE TIMES - Hieromonk Seraphim RoseDocument19 paginiSIGNS OF THE TIMES - Hieromonk Seraphim RoseAlina-Mihaela Miki100% (1)

- Making Tissue TubesDocument2 paginiMaking Tissue TubesBoris PetrovicÎncă nu există evaluări

- Build A Simple Pitch GageDocument2 paginiBuild A Simple Pitch GageBoris PetrovicÎncă nu există evaluări

- Flying On Partial MotorsDocument1 paginăFlying On Partial MotorsBoris PetrovicÎncă nu există evaluări

- Plastic Films and How To Cover With ThemDocument3 paginiPlastic Films and How To Cover With ThemBoris PetrovicÎncă nu există evaluări

- How To Make A Flight LogDocument3 paginiHow To Make A Flight LogBoris PetrovicÎncă nu există evaluări

- ASTM TablesDocument25 paginiASTM TablesBoris PetrovicÎncă nu există evaluări

- Winning Indoor Designs Free Flight - The National Free Flight SocietyDocument93 paginiWinning Indoor Designs Free Flight - The National Free Flight Societylxndr20Încă nu există evaluări

- PrimarySeries enDocument2 paginiPrimarySeries enBoris PetrovicÎncă nu există evaluări

- For MuleDocument5 paginiFor MuleBoris PetrovicÎncă nu există evaluări

- Comments On DefinitionsDocument2 paginiComments On DefinitionsBoris PetrovicÎncă nu există evaluări

- Marilee Maribel Mari Ugland MariannDocument1 paginăMarilee Maribel Mari Ugland MariannBoris PetrovicÎncă nu există evaluări

- ASTM Tables Usage & Procedure of CalculationsDocument5 paginiASTM Tables Usage & Procedure of CalculationsJaspreet SinghÎncă nu există evaluări

- Draught Survey - A Guide To Good PracticeDocument71 paginiDraught Survey - A Guide To Good Practicemsk5in100% (3)

- VOC PlanDocument132 paginiVOC PlanBoris PetrovicÎncă nu există evaluări

- Ice NacigationDocument330 paginiIce NacigationBoris Petrovic100% (3)

- Working ECDIS Procedure - Answers ###Document13 paginiWorking ECDIS Procedure - Answers ###Boris Petrovic83% (6)

- Duznosti TrecegDocument4 paginiDuznosti TrecegBoris PetrovicÎncă nu există evaluări

- The Final Word - How To Seduce Any Woman You WantDocument9 paginiThe Final Word - How To Seduce Any Woman You WantBoris Petrovic100% (1)

- Safety ValvesDocument65 paginiSafety Valvesserturkbudak_3448365Încă nu există evaluări

- TC220 Manual Tenico V1.15Document147 paginiTC220 Manual Tenico V1.15Ivan Villena ChumanÎncă nu există evaluări

- 08 Special Lubrication Systems PDFDocument7 pagini08 Special Lubrication Systems PDFSugiharto RichardÎncă nu există evaluări

- L100N6 Parts BookDocument13 paginiL100N6 Parts BookAllidlah Imam SofiyanÎncă nu există evaluări

- EDTO Pre-Departure Service Check SheetDocument7 paginiEDTO Pre-Departure Service Check SheetThax NgeÎncă nu există evaluări

- Draught Beer Quality Manual - 2nd Edition 2012 (Brewers Assoc)Document82 paginiDraught Beer Quality Manual - 2nd Edition 2012 (Brewers Assoc)Joaquin IgnacioÎncă nu există evaluări

- Management of Change: Did You Know?Document1 paginăManagement of Change: Did You Know?baaziz2015Încă nu există evaluări

- DB6-10 Oim R15Document19 paginiDB6-10 Oim R15Vũ Đình QuangÎncă nu există evaluări

- R55-75N Manual Operación PDFDocument32 paginiR55-75N Manual Operación PDFJose NavasÎncă nu există evaluări

- Us-Vps-0674-En Vps All Eng Clean Fuel Rail Procedure Guide 1Document2 paginiUs-Vps-0674-En Vps All Eng Clean Fuel Rail Procedure Guide 1api-477120514Încă nu există evaluări

- Reciprocating Compressor Optimum Design and Manufacturing With Respect To Performance Reliability and CostDocument6 paginiReciprocating Compressor Optimum Design and Manufacturing With Respect To Performance Reliability and Costnnandha100% (1)

- M-101-17. Catalogo ImprimadorDocument137 paginiM-101-17. Catalogo ImprimadorPabloMatiasCÎncă nu există evaluări

- Boiler Maintenance and Safety Study GuideDocument10 paginiBoiler Maintenance and Safety Study GuideKapila2zÎncă nu există evaluări

- Burners and Torches: National Handtorch Type 3A BlowpipeDocument14 paginiBurners and Torches: National Handtorch Type 3A Blowpipefrenzy personÎncă nu există evaluări

- P Qac Pro 200 38257 DDDDocument64 paginiP Qac Pro 200 38257 DDDBadiÎncă nu există evaluări

- Valve - Manual Override PDFDocument2 paginiValve - Manual Override PDFGeorge_Wabag_2014Încă nu există evaluări

- 742 762 Control 255 Performa Series Valves Service Manual 3000440Document48 pagini742 762 Control 255 Performa Series Valves Service Manual 3000440Ousmane BAÎncă nu există evaluări

- Cfm56-3 Comp IdxDocument54 paginiCfm56-3 Comp IdxDiniswari AlrinoÎncă nu există evaluări

- 1316323815-Fabius GS ManualDocument312 pagini1316323815-Fabius GS ManualJose De Abreu100% (1)

- Hydratec BlainDocument4 paginiHydratec Blaincoco MPÎncă nu există evaluări

- Ok RH31LT HP200LP HP200LPWF Operating Instruction With BrochureDocument32 paginiOk RH31LT HP200LP HP200LPWF Operating Instruction With Brochurehandoyo_eko20017573Încă nu există evaluări

- BA DUO 008 02 16 EN DUODOS 15 EN - Part9Document2 paginiBA DUO 008 02 16 EN DUODOS 15 EN - Part9alang_businessÎncă nu există evaluări

- Heating Control ManualDocument12 paginiHeating Control ManualPuszta BalázsÎncă nu există evaluări

- ECS 15-3-1 - 2 - 80099e80Document8 paginiECS 15-3-1 - 2 - 80099e80Florin Daniel AnghelÎncă nu există evaluări

- E2152 7 05 01 - Stellantriebe PDFDocument17 paginiE2152 7 05 01 - Stellantriebe PDFJs WilyÎncă nu există evaluări

- York BoilerDocument2 paginiYork Boilertaweng11Încă nu există evaluări

- Manual Service Clamp Cascade PDFDocument230 paginiManual Service Clamp Cascade PDFXAV G2Încă nu există evaluări