Documente Academic

Documente Profesional

Documente Cultură

Engineering Excellence Ross Multi-Shaft Mixers (Production Models)

Încărcat de

Juan PerezDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engineering Excellence Ross Multi-Shaft Mixers (Production Models)

Încărcat de

Juan PerezDrepturi de autor:

Formate disponibile

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Engineering

Hauppauge, New York 11788

www.mixers.com Excellence

TTh

hee W

Woorrlld

d LLeea

addeerr iin

nMMiix

xiin

ngga

annd

dBBlleen

nddiin

ngg TTeecch

hnno

ollo

oggy

y

Multi-Shaft Mixers

Ross Dual-Shaft Mixers

and Triple-Shaft Mixers

Production Models

100-gallon and 200-gallon Dual-Shaft Mixers Sanitary 10-gallon VersaMix Triple-Shaft Mixer

(CDA Models) (VMC Model)

Page 1 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

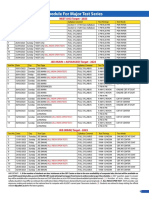

STANDARD CAPACITIES

Maximum working capacity of standard Dual-Shaft Mixers (CDA Models):

10, 50, 100, 200, 500, 1000, 1500, 2000, and 3000 gallons

Maximum working capacity of standard Dual- and Triple-Shaft Mixers

(VersaMix VMC and VM Models): 10, 15, 40, 100, 200, 300, 400, 500,

600, 750, 1000, 1500, 2000 and 3000 gallons

10-gallon Triple-Shaft Mixer Sanitary 15-gallon VersaMix 40-gallon Dual-Shaft VMC

200-gallon CDA Mixer 600-gallon Fixed Tank Mixer 1000-gallon Dual-Shaft Mixer

Page 2 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

GENERAL FEATURES

For change-can designs, an air/oil hydraulic lift raises/lowers the stirrer blades in/out of

the vessel. A 100-125-psig air supply is required on standard models.

Custom

VMC CDA

Alternative lift options offered on certain models: Motorized hydraulic lift and reverse

hydraulic lift (which raises/lowers the mix can instead of the blades).

Limit switches prevent mixer operation while in the raised/non-mixing position or when

the mix can is removed.

Atmospheric, vacuum and/or internal pressure design. Built-in vacuum pump, piping and

controls can be supplied.

Change-can Multi-Shaft Mixers enable the use of multiple vessels for semi-continuous

operation. The process can be broken down into mixing, discharging, cleaning and

preparation. Thus, multiple vessels can be used to extend the production capacity of a

single mixer. One vessel would be under the mixer while another would be in the

discharge or clean-up stage, and still another would be the loading area being charged

with raw materials for the next run.

Fixed-tank designs are commonly offered on Multi-Shaft Mixers with a working capacity

of 300 gallons and larger.

Page 3 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

Change-can

Multi-Shaft Mixers

may be supplied with

two or more

interchangeable

vessels to maximize

throughput. Each

vessel may be

dedicated to a

particular recipe to

simplify clean-up and

product changeover.

For large mixers

(300-gallons and

up), a dual-post

lift design

provides complete

access to the

agitators and

vessel.

The fixed-tank

design is the most

economical option.

Hinged covers and

large access ports

enable periodic

maintenance and

cleaning.

Page 4 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

MATERIALS OF CONSTRUCTION

Stainless steel type 304 or 316 wetted parts polished to 80-grit finish.

Options: 150 to 240 grit finish, electropolish, mirror finish, passivation.

Choice of elastomers (lip seals, mechanical seals and O-rings):

Viton

Silicone

Teflon-encapsulated silicone

Buna-N

Neoprene

Kalrez

Other material options:

Hastelloy Alloy C-276 contact parts

Bushing for the rotor/stator mixer may be

made of bronze, solid Teflon, glass-filled

Teflon or Stellite

Hardened stainless steel 440C rotor and stator

Polyetheretherketone (PEEK) or ultra-high

molecular weight polyethylene (UHMW-PE)

disperser blade

Custom Dual-Shaft

Coating options for the anchor agitator and mix Mixer equipped with a

PEEK High Speed

vessel internal surfaces:

Disperser and a Two-Wing

Aluminum oxide Anchor Agitator

Teflon completely coated with

Nylon black Teflon PFA, a

Kynar perfluoroalkoxy copolymer

resin with a high level of

Teflon sidewall and bottom scrapers on the inertness. The wetted

surfaces of the stainless

anchor agitator.

steel vessel, cover and

charge ports are all PFA-

Non-stainless steel exterior surfaces are painted

coated as well to prevent

with off-white, two-part epoxy coating or any metal ion contamination.

customer-preferred paint.

Page 5 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

MIXER COVER OPTIONS

Thermoprobe CIP spray nozzles Sight/charge ports

Pneumatic valves Tank light Sanitary pressure gauge

Vacuum/pressure Hinged feed port Tri-clamp nozzles Viscosity probe

transducer

Page 6 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

AGITATOR OPTIONS

Multi-Shaft Mixers are highly customizable and equipped with independently-driven

agitators in many different combinations and styles. Below are some popular configurations.

Two-wing anchor and Three-wing anchor and Dished-bottom anchor Anchor and two disperser

disperser blade disperser blade and two disperser blades blades with “slinger”

Two-wing anchor and Anchor with helical Three-wing anchor and Anchor, disperser and

dual-blade turbine flights and a disperser rotor/stator mixer rotor/stator mixer

Triple-shaft mixer with Helical-style anchor, Anchor with scrapers, Anchor agitator with

Solids/Liquid Injection adjustable disperser blade dual-blade disperser and downthrust propellers and

Manifold (SLIM) System and rotor/stator mixer rotor/stator mixer two disperser shafts

Page 7 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

AGITATOR FEATURES AND DRIVE OPTIONS

SLIM SYSTEM

Position of saw-tooth blade(s) along the high speed

shaft can be made adjustable. The Solids/Liquid Injection

Interchangeable disperser blade and rotor/stator. Manifold (SLIM) System is an

option offered on Multi-Shaft

Sidewall and bottom scrapers attached to the anchor.

Mixers equipped with a

Variable Frequency Drive design with TEFC or rotor/stator attachment. As it

explosion-proof constant-torque motors. reaches operating speed, the

Motors, safety switches and other electrical items are SLIM rotor generates a

factory-wired to a junction box. powerful vacuum; the solids

inlet valve is opened and

High horsepower/heavy-duty models available.

powders are quickly drawn

sub-surface, at precisely the

SEALING ARRANGEMENTS point where intense mixing

takes place. The SLIM is

Standard: Single mechanical seals with Viton recommended for powders

O-rings, carbon vs. silicon carbide faces. with a tendency to form

Optional: Double mechanical seals, dry-running gas- tough lumps or “fish eyes”

such as gums, fumed silica

lubricated seals for sanitary applications, liquid-cooled

and other thickeners.

seals with heat exchanger and pump.

Triple-Shaft Mixer with liquid- Gas-purged double mechanical In sanitary systems, gas controls and

cooled sealing arrangement seals are plumbed to a common regulators for dry-running agitator

suitable for long intervals of manifold. Source of clean seals may be encased in a stainless

high-temperature processing. compressed nitrogen is required. steel panel with view window.

Page 8 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

MIX CAN

Precision-machined upper flange sets the can in perfect alignment with the cover.

Vessel clamps can be supplied to further secure the mix can and cover during mixing.

Optional heating/cooling jacket, sidewall thermowell and insulation.

Many choices of flush discharge valves: ball valves, Y-valves, cove plugs, etc.

Non-sparking casters with brakes, lift trunnions and/or forklift channels.

Mixer base and vessel may be raised to provide anywhere from 6” to 24" clearance

between the discharge opening and floor.

ROSS DISCHARGE SYSTEM

Utilized for fast and easy transfer of

non-flowable viscous products out of the

mix vessel.

Requires a Ross Mix Can suitable for use

with a Discharge System.

Floor-mounted or elevated design.

Stainless steel platen with Viton

sealing O-ring.

Platen is activated by means of a self-

contained hydraulic power unit (constant

volume or constant pressure design).

Two-hand safety controls for raising and

lowering the platen.

A Discharge System consists of a platen that is

lowered hydraulically into the mix vessel. The

platen is fitted with an O-ring which rides

against the vessel wall. As the platen pushes

down on the batch, sidewall surfaces are

wiped clean. Viscous product which would not

normally flow by gravity alone is quickly

forced out through the vessel’s bottom valve or

through the top of the platen.

Page 9 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

SOME EXAMPLES OF CUSTOM DESIGNS AND FEATURES

Designed for a high-purity electronic application,

this Dual-Shaft Mixer with recirculation filter system

is vacuum-rated and chemically-inert. Operators

control and monitor the agitators, recirculation

pump, recipe menu, temperature, vacuum level and

data acquisition from a 10” color touch screen.

All-stainless

steel Dual-Shaft

Mixer with

custom two-wing

anchor agitator

and disperser.

The support

frame with

This 100-gallon VersaMix is equipped with locking casters is

a three-wing anchor agitator; high speed designed for

disperser; SLIM rotor/stator mixer designed complete

for sub-surface powder induction; multiple portability.

feed ports with pneumatic

ball valves; jacketed

vessel; level sensor;

vacuum/pressure

transmitter; clean-in-place

rotary spray nozzles;

magnetic iron trap on the

discharge piping; and a

transfer pump assembly

that can measure viscosity

and density to verify that

the batch is complete and

within spec. The entire Triple-Shaft Mixers with

system is explosion-proof interchangeable vessels which double as

and automated via pre- mobile holding tanks. Custom lids with

programmed PLC controls. air-driven propellers are also supplied.

Page 10 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

Charles Ross & Son Company

710 Old Willets Path

P.O. Box 12308

Hauppauge, New York 11788

www.mixers.com

Documentation Package includes:

Operation, Installation and Maintenance Manual.

As-Built Approved Drawings.

Electrical Control Panel Drawings and Schematics.

Parts Lists and Assembly Drawings.

All Vendor Literature for major components (motor, reducer, bearings, etc.).

Final Ross Fabrication/Pre-Shipment Inspection Reports with operational test results.

One complete copy of the documentation package furnished in a Ross binder.

OTHER OPTIONAL SERVICES

Validation Package. In addition to the basic Documentation Package, the following

may also be provided, as applicable:

Product-wetted Surfaces Material Certificates Certification of Type of Welding

Elastomer Material Certificates U1 Report (ASME)

Certification of Surface Finish Welder Qualifications

Certification of Passivation Vessel Calculations (ASME)

Certification of Electropolish

Factory Acceptance Testing (FAT) at Ross plant prior to shipment.

Start-up/training assistance at the customer’s facility.

Page 11 of 11

Phone: 631-234-0500 - Fax: 631-234-0691 - E-mail: mail@mixers.com

S-ar putea să vă placă și

- Wemco Product OverviewDocument24 paginiWemco Product OverviewAkilesh AravindakshanÎncă nu există evaluări

- 100 Series: Affordable High Pressure Water JettingDocument4 pagini100 Series: Affordable High Pressure Water JettingCarlos Alberto Aguilera MendezÎncă nu există evaluări

- Caustic Soda Mix Tank PsDocument2 paginiCaustic Soda Mix Tank PsDaniel Pandapotan MarpaungÎncă nu există evaluări

- OBERDORFER S923 Spec SheetDocument2 paginiOBERDORFER S923 Spec SheetJavier GarciaÎncă nu există evaluări

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 paginiRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezÎncă nu există evaluări

- Model J-352-LS: SpecificationsDocument2 paginiModel J-352-LS: SpecificationsjiaozhongxingÎncă nu există evaluări

- Bomba Series 100Document4 paginiBomba Series 100Edwing William Salhuana MendozaÎncă nu există evaluări

- Pressures To 20,000 PSI Flows To 10.3 GPM Power 100 HP: FeaturesDocument2 paginiPressures To 20,000 PSI Flows To 10.3 GPM Power 100 HP: FeaturesLuis VazquezÎncă nu există evaluări

- Liqua-Blaster 100 Series BrochureDocument4 paginiLiqua-Blaster 100 Series BrochurejleonosÎncă nu există evaluări

- Espec - Tec.bombas Lowara DL A 60HzDocument39 paginiEspec - Tec.bombas Lowara DL A 60HzpapashoÎncă nu există evaluări

- Water WastewaterDocument20 paginiWater WastewaterterryjoseeÎncă nu există evaluări

- Three Way ValvesDocument8 paginiThree Way ValvesWalter JosephÎncă nu există evaluări

- OBERDORFER S930 Spec SheetDocument2 paginiOBERDORFER S930 Spec SheetJavier GarciaÎncă nu există evaluări

- M J251 SpecDocument2 paginiM J251 SpecjiaozhongxingÎncă nu există evaluări

- Bombas CornellDocument12 paginiBombas CornellGabo Cabezas NaranjoÎncă nu există evaluări

- ETP QueriesDocument6 paginiETP Queriespurchase1.gindÎncă nu există evaluări

- Trailer: Superior Construction. Excellent Performance. Rely On Our ExperienceDocument2 paginiTrailer: Superior Construction. Excellent Performance. Rely On Our ExperienceMilton PeñaÎncă nu există evaluări

- Severn 8300 A4 8pg Bro V1.1 EMAILDocument8 paginiSevern 8300 A4 8pg Bro V1.1 EMAILYelena ObyazovaÎncă nu există evaluări

- Progressing Cavity Pumps: Colfax AmericasDocument12 paginiProgressing Cavity Pumps: Colfax AmericasKhairil AjjaÎncă nu există evaluări

- Series PWS10T: Pure WaterDocument4 paginiSeries PWS10T: Pure WaterWattsÎncă nu există evaluări

- HD 7/11-4 Cage Classic DescriptionDocument2 paginiHD 7/11-4 Cage Classic DescriptionadnansirajÎncă nu există evaluări

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocument4 paginiOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccÎncă nu există evaluări

- Technical Data Sheet: Performa 560Document10 paginiTechnical Data Sheet: Performa 560Diego NavaÎncă nu există evaluări

- LM22509Document2 paginiLM22509Diogo LinharesÎncă nu există evaluări

- Legacy Fuel Pumps & Systems - Gilbarco Veeder RootDocument2 paginiLegacy Fuel Pumps & Systems - Gilbarco Veeder Rootgilbarcomarketing1230% (2)

- Brochure Ajax Vibratory Equipment Catalog PDFDocument85 paginiBrochure Ajax Vibratory Equipment Catalog PDFTheLizardKingÎncă nu există evaluări

- Válvulas Modelo CTDocument5 paginiVálvulas Modelo CTOdlanier José MendozaÎncă nu există evaluări

- Humboldt Catalog #7Document240 paginiHumboldt Catalog #7Wagdi Alhajj100% (1)

- Blowers TS R: Everest Twin Lobe Rotary Air BlowersDocument1 paginăBlowers TS R: Everest Twin Lobe Rotary Air Blowersankitsaxena123Încă nu există evaluări

- Taco 1400Document4 paginiTaco 1400sas999333Încă nu există evaluări

- Q2017025JH Petrobras 550 HP Heli-Portable RigDocument29 paginiQ2017025JH Petrobras 550 HP Heli-Portable RigRobertoVitorianoÎncă nu există evaluări

- Westco PumpDocument8 paginiWestco PumpWorapat PuttakasemÎncă nu există evaluări

- 001-232500-0 2.7 Filtration EquipmentDocument34 pagini001-232500-0 2.7 Filtration Equipmentmolinach100% (1)

- PCE 2015 CatalogDocument96 paginiPCE 2015 CatalogMatoÎncă nu există evaluări

- Stolle Rotary End Liners 0Document2 paginiStolle Rotary End Liners 0JavierÎncă nu există evaluări

- SPX-Plenty Mixer PDFDocument24 paginiSPX-Plenty Mixer PDFkingathur26681100% (1)

- HD 7/11-4 Cage Classic DescriptionDocument2 paginiHD 7/11-4 Cage Classic DescriptionadnansirajÎncă nu există evaluări

- Severe Service ValveDocument16 paginiSevere Service ValvesekharsamyÎncă nu există evaluări

- 450-Series 2016Document4 pagini450-Series 2016David BahenaÎncă nu există evaluări

- 2000 HP National 1320 Drilling Rig (FILEminimizer)Document5 pagini2000 HP National 1320 Drilling Rig (FILEminimizer)Pedro RiveraÎncă nu există evaluări

- en-IDDocument23 paginien-IDEsa MuliaÎncă nu există evaluări

- CC Marine 2013-14 Catalogue - PumpsDocument94 paginiCC Marine 2013-14 Catalogue - PumpsGregGGH100% (1)

- Models OF817-8H, OF817-12H, OF1019-20H and OF1465-75H Specification SheetDocument2 paginiModels OF817-8H, OF817-12H, OF1019-20H and OF1465-75H Specification SheetWattsÎncă nu există evaluări

- Multivac Stainless Steel Instrument Manual20160810 enDocument13 paginiMultivac Stainless Steel Instrument Manual20160810 enpepeÎncă nu există evaluări

- m1433 6in Sand FighterDocument2 paginim1433 6in Sand Fighterwpt_meÎncă nu există evaluări

- Hoer CT Valve 2Document5 paginiHoer CT Valve 2Tu PhamÎncă nu există evaluări

- Chcokfast ManualDocument202 paginiChcokfast ManualRavi SelvarajanÎncă nu există evaluări

- Dunham Bush Package UnitsDocument8 paginiDunham Bush Package UnitsStephanie StewartÎncă nu există evaluări

- API Vertical FlowayDocument8 paginiAPI Vertical FlowayRaja RamachandranÎncă nu există evaluări

- LSP LowSpeedHighPressurePumps E00522Document7 paginiLSP LowSpeedHighPressurePumps E00522Sigit PramonoÎncă nu există evaluări

- Fast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPDocument2 paginiFast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPFrederik CañabiÎncă nu există evaluări

- Stolle Optimus Can WasherDocument2 paginiStolle Optimus Can WasherLópez LuisÎncă nu există evaluări

- Sotera Diaphragm Pumps (DV Motor)Document8 paginiSotera Diaphragm Pumps (DV Motor)Imran Shahzad KhanÎncă nu există evaluări

- Tanque de HidroterapiaL-105-SDocument2 paginiTanque de HidroterapiaL-105-SVictor EspinozaÎncă nu există evaluări

- Lamella 012517Document2 paginiLamella 012517workingÎncă nu există evaluări

- E BOA CompactorDocument2 paginiE BOA CompactormuhammadnainÎncă nu există evaluări

- Aljac Catg On Closed SamplerDocument2 paginiAljac Catg On Closed SamplervuongÎncă nu există evaluări

- Geotextiles and Geomembranes HandbookDe la EverandGeotextiles and Geomembranes HandbookT.S. IngoldEvaluare: 5 din 5 stele5/5 (1)

- Forecasting PDFDocument194 paginiForecasting PDFJuan PerezÎncă nu există evaluări

- Best Plants KPIDocument64 paginiBest Plants KPIJuan PerezÎncă nu există evaluări

- One Point LessonsDocument26 paginiOne Point LessonsJuan PerezÎncă nu există evaluări

- Quick Kaizen PDFDocument5 paginiQuick Kaizen PDFJuan PerezÎncă nu există evaluări

- 5S Guide: Learn How A Simple Organizational Strategy Can Transform Your BusinessDocument25 pagini5S Guide: Learn How A Simple Organizational Strategy Can Transform Your Businessတိုး ေဝ ေအာင္Încă nu există evaluări

- Chapter Two: 4.1 The Structured Paradigm Versus The Object-Oriented ParadigmDocument43 paginiChapter Two: 4.1 The Structured Paradigm Versus The Object-Oriented ParadigmAmanuel DereseÎncă nu există evaluări

- BCA 605 Practical File CompletedDocument15 paginiBCA 605 Practical File CompletedEr Niraj SinghÎncă nu există evaluări

- Cisco Packet TracerDocument15 paginiCisco Packet Tracerrqi11Încă nu există evaluări

- Pronunciation NEWDocument7 paginiPronunciation NEWTrần Minh ThànhÎncă nu există evaluări

- Question Bank For Unix ProgrammingDocument2 paginiQuestion Bank For Unix ProgrammingNongmaithem DinamaniÎncă nu există evaluări

- Web result with site links: ఈనాడు: Telugu News - Latest Telugu News - Breaking ..Document3 paginiWeb result with site links: ఈనాడు: Telugu News - Latest Telugu News - Breaking ..VamsiÎncă nu există evaluări

- The Schmidt-Rubin Series of Swiss RiflesDocument11 paginiThe Schmidt-Rubin Series of Swiss RiflesquirxiÎncă nu există evaluări

- 7 - ConcurrencyControlDocument99 pagini7 - ConcurrencyControlmodyxstarÎncă nu există evaluări

- And Classroom Surveillance: Prepared By: John Ernest J. BunuanDocument8 paginiAnd Classroom Surveillance: Prepared By: John Ernest J. BunuanHu T. BunuanÎncă nu există evaluări

- Ejma 2015Document306 paginiEjma 2015Azima Zalfa AuliyakÎncă nu există evaluări

- MCQ Part3Document13 paginiMCQ Part3Spiderspider2021Încă nu există evaluări

- ASTM D 2161 Standard Practice For Conversion of Kinematic Viscosity To Saybolt Universal Viscosity or To Saybolt Furol ViscosityDocument26 paginiASTM D 2161 Standard Practice For Conversion of Kinematic Viscosity To Saybolt Universal Viscosity or To Saybolt Furol ViscositySAURABHÎncă nu există evaluări

- Formulary - Aerodynamic Design of Turbomachinery: PV NRT, H HDocument2 paginiFormulary - Aerodynamic Design of Turbomachinery: PV NRT, H HZhifengÎncă nu există evaluări

- Certified Ref September 2018Document98 paginiCertified Ref September 2018Jake SalagubangÎncă nu există evaluări

- UntitledDocument54 paginiUntitledMudug Primary and secondary schoolÎncă nu există evaluări

- Mts InfoDocument2 paginiMts InfoscrbddÎncă nu există evaluări

- Exception Handling in JavaDocument2 paginiException Handling in JavamanoharÎncă nu există evaluări

- STARWATCH TIME PRO - MSSQL English (20091026)Document259 paginiSTARWATCH TIME PRO - MSSQL English (20091026)Abdalhakeem AlturkyÎncă nu există evaluări

- Plasma Cut Series: Operator ManualDocument20 paginiPlasma Cut Series: Operator ManualprisilliawongÎncă nu există evaluări

- Usbee Suite ManualDocument152 paginiUsbee Suite ManualJortonÎncă nu există evaluări

- UPS-GER 60kVA 0.8Pf 380V50Hz STR Out380V50Hz RangeDocument22 paginiUPS-GER 60kVA 0.8Pf 380V50Hz STR Out380V50Hz Rangeines lichihebÎncă nu există evaluări

- DBA Lab Ass 2Document10 paginiDBA Lab Ass 2Tao CacheÎncă nu există evaluări

- Introduction To HazidDocument29 paginiIntroduction To Hazidafan nur arifÎncă nu există evaluări

- First City Providential College: Brgy. Narra, Francisco Homes Subd., City of San Jose Del Monte, BulacanDocument10 paginiFirst City Providential College: Brgy. Narra, Francisco Homes Subd., City of San Jose Del Monte, BulacanAlyssa YutigaÎncă nu există evaluări

- Electrical Power and Energy Systems: Browh Serge Tekpeti, Xiaoning Kang, Xinghua HuangDocument14 paginiElectrical Power and Energy Systems: Browh Serge Tekpeti, Xiaoning Kang, Xinghua HuangashishÎncă nu există evaluări

- UX LawsDocument2 paginiUX LawsChayatal BangladeshÎncă nu există evaluări

- Chap 6 Verification and ValidationDocument33 paginiChap 6 Verification and ValidationmigadÎncă nu există evaluări

- Enhancement of Time-Based One-Time Password For 2-Factor AuthenticationDocument6 paginiEnhancement of Time-Based One-Time Password For 2-Factor AuthenticationInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Undergraduate-Prospectus SsuetDocument141 paginiUndergraduate-Prospectus SsuetRuman AnwarÎncă nu există evaluări