Documente Academic

Documente Profesional

Documente Cultură

JSA Road Crossing With Casing

Încărcat de

Moaatazz Nouisri0 evaluări0% au considerat acest document util (0 voturi)

63 vizualizări6 paginiTitlu original

JSA Road crossing with casing.docx

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

63 vizualizări6 paginiJSA Road Crossing With Casing

Încărcat de

Moaatazz NouisriDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 6

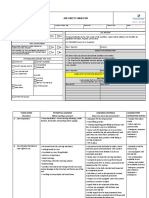

JOB SAFETY ANALYSIS

Ref: C5+– JSA- 006

Facility / Site:……………………………………………… Location within Site:…………………….. Permit No:……………………. Permit Type: ……………… Date:…………………….

Task Description: Road Crossing with casing

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: Company:

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company:

FALL RESTRAINT COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify):

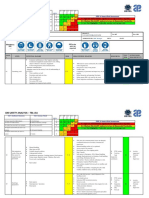

TASKS/STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

1. Permitting work Work condition not safe PTW system

Procedures and tasks not clear All necessary permissions and authorization Tool Box Talk

Lack of supervisory shall be obtained from the relevant Inspection

Miscommunication Authorities concerned before starting any Certificates

Not correct PPE worn work.

Equipment not inspected and certified HSE team to assess continuously the

conditions of work in the assigned area

Toolbox talks

Competency of personnel and supervisory for

the activity

Define hierarchy and reporting flowcharts

Define proper PPE to be used for the work

Check inspection certificates of equipment for

the job.

2. Mobilization and Driving Collision with other vehicles. Travel at suitable speed for the surface Trainings

Overturning vehicle with driving off road. conditions and respect speed limits. Certifications

Driving fatigue In-field journey Management Plan

Drivers to receive a course in Desert defensive

driving prior to mobilization to project

location

The use of mobile phones (including hands

free) is not permitted whilst the vehicle is in

motion

Seatbelt On all the time driving

3. Site Preparation collusion with other gear and vehicle Communicate the deviation drawing and Trained First aiders

Blocked road without adequate traffic signs notify staff onsite onsite

unmaintained deviation (bypass) road Define the adequate traffic signs (arrow Emergency

Traffic accident deviation, speed limit, stop, blocked road) Response Plan

Traffic signs bad placed/defined Block the road with adequate barriers (with Traffic laws

red fence) and signals

Proper placement of signs

Restrict the work area.

TBT in place

Adequate PPE for all personnel

Appropriate layout and maintenance of the

road deviation

4. Checking equipment Punch point / hand injuries Smart grip / 3 points of contact when climbing Trained First aiders

Personnel Injury onto machines onsite

Falling from machine Use containment cans/ plastic covers to Emergency

Slipping from ladder prevent spills Response Plan

Diesel / oil spill Wear dust mask when cleaning air filter

Electric shock Adequate equipment, certified will be used Ambulance ready

Breathing dust from filters Competent persons will perform the job to intervene in case

Waring must be done only after turning off of emergency

the power and confirming there is no

Evacuation car on

electricity to prevent electrification.

work site covering

Equipment check list should be made for all

POB working in the

new equipment coming to site

area.

Ensure the respiratory equipment such as air

line hose pressure regulator, filter is free from

defect.

Weekly equipment check list should be made

and kept at engine

Wear proper PPE

Use proper ladders / steps to go on top

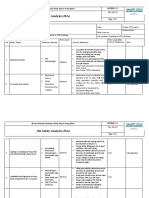

5. Excavation Damaged buried facilities Dedicated team for the manual digging Trained First aiders

Person fall in the trench Provide locate documentation (as-built, maps, onsite

Dust goes in respiratory system drawing…) to ensure that the locations of all Emergency

Mishandled or poorly placed material buried facilities have been determined. Response Plan

Excavated material or other objects falling on Ensure that copies of locate documentation

workers are on site at all times during the ground Ambulance ready

Personnel hit by excavator or wheel loader disturbance. to intervene in case

Mobile equipment incident due to unstable Install stakes and warning tape around trench of emergency

adjacent structures Ground personnel to wear high visibility

Evacuation car on

Workers go down in the trench while trenching jackets

work site covering

Back injury when working with shovel under bad Inspect trenches at the start of each day.

POB working in the

posture Remove debris and excavated soil near

area.

Personnel trip / falling hazards due to excavated excavation site

material Wear respiratory mask if working downwind

Excavator tilting due to bad ground stability (mud, Place excavated material at safe distance from

sand…) the trench

Never walk under and beside excavator

loader, wheel loader or machines

Be aware of nearby vehicles and mobile

equipment causing soil to vibrate

Do not go down in the trench while excavating

the trench

Wear correct safety boots and mind steps / do

not rush

Check the stability of the ground below the

excavator

Keep safe distance between the heavy

equipment and the trench edges (2m).

Do not go down in the trench while excavating

Wear correct safety boots and mind steps / do

not rush

Watch for venomous animals and wear safety

boots and leather gloves

Avoid hand and fingers injuries.

Safety signs in place.

Goal posts to avoid collision with overhead

power lines.

Banksman permantly presence in mandatory.

Area Underground utilities maps.

6. Pipe casing lowering in Equipment / structure damage by Excavator/ Side- Competent personnel shall be designated for Fire extinguishers

boom when moving the operation Emergency

Punch point / hand or finger injuries due to All equipment inspected (daily internal Response Plan

releasing lifting pipe inspection, and 3th party inspection) and Ambulance ready

Person crushed against objects by Excavator/ Side- confiscate any defective equipment to intervene in case

boom Banksman to guide the engines movement of emergency

Person foot crush by Excavator/ Side-boom chain Never stand under suspended loads Evacuation car on

Personnel injury/Death or structure damage by Do not exceed the SWL of the Excavator/ Side- work site covering

boom or rope boom POB working in the

Personnel injury or structure damage by backload Have good communication / visibility with the area.

due to excavator rotation Excavator/ Side-boom operator

Excavator/ Side-boom tilting due to bad ground Never insert hand / finger in between the pipe

stability (mud, sand…) and slings

falling load Wear leather gloves and avoid punch points

Correct use of hand signals for lifting

Trained First aiders onsite

Adequate PPE for all personnel

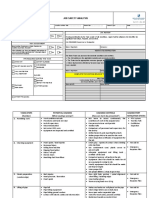

7. Holiday test Personnel injuries Proper PPE must be worn First Aid Kit

Electrification/electrocution TBT in place Emergency

Electrical sparks causing fire Proper safety signs Response Plan

Equipment damage by high voltage Check the holiday detector, and substitute if Ambulance ready

any damage (loose connection and frayed to intervene in case

cables) of emergency

Only competent person must use the holiday Evacuation car on

detector work site covering

Ensure that supply is kept off during POB working in the

intervention on the pipe area.

Personnel must use insulate adequate hand

gloves to protect from electricity shocks.

8. Coating/coating repairs Worker insert his hand in the heating area Inspect tools before use First Aid Kit

Torch applied accidentally to face Watch for ground personnel while operating Fire extinguishers

Body or parts burned by the torch flame the heating machine Emergency

Compressed gas bottles explosion Clear area from personnel before spotting the Response Plan

Fire catching to equipment heater MSDS

Manual lifting / moving of gas bottles causing back Do not approach heater during operation, Ambulance ready

injuries, tripping hazards never insert hand in between heaters to intervene in case

Chemical contact with skin Buddy system, have a working plan according of emergency

Chemical contact with eyes to flame direction Evacuation car on

Chemical pouring on the coverall or clothes Wear face shield and leather gloves work site covering

Chemical spill on the ground Handle bottles correctly, keep fire away from POB working in the

Fire catching chemicals gas bottles area

Have fire extinguisher in place

Team carrying loads over 25 Kg

Keep gas bottles at standing position

Wear chemical gloves / plastic gloves long

sleeves

Wear face shield or safety goggles

Rinse eyes immediately with fresh water

Refer to MSDS for immediate actions

Wear plastic coveralls / Tyvex coveralls

Avoid spill of chemicals, proceed carefully

Keep fire away from chemicals, never smoke

Warning signs in place

Keep safe distance from trench

9. Cleaning &Housekeeping • Equipment and tools remain on site • Training for good work practices to be held on Plastic bags

• Slip trip and fall site waste bins

• Trash left in the work place • TBT in place before job, housekeeping issue to

be mentioned in all TBT

• After working day, team leader must ensure

cleaning, inspecting equipment and good

housekeeping.

• Waste management plan is in force during

project

• Waste to be removed in time as per

CONTRACTOR waste management plan

10. Working in ROW Biological hazards such as reptiles Use of proper PPE Emergency

Personal Fatigue / Heat stress Insure periodic rest time for work force. response plan

Personnel missing or lost in the desert Dedicated rest area sun-shielded (medical treatment

Close supervision + ambulance)

Personnel Protests

Communication means

Assess the situation as quick as possible and

announcing the state of the emergency

(Emergency or Alert).

At any security or terrorist threats call first the

ERT leader mentioned in emergency contact

list.

Name Position Date Signed

Prepared By

Checked By

Approved By

S-ar putea să vă placă și

- Job Safety Analysis: Required References Jsa ReviewDocument5 paginiJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (1)

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 paginiJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- JSA - Repair-Coating and Finition Work THDocument3 paginiJSA - Repair-Coating and Finition Work THKhorbi AbdeltifÎncă nu există evaluări

- Kimanis Power Project: Job Safety AnalysisDocument9 paginiKimanis Power Project: Job Safety Analysissimonsitompul25Încă nu există evaluări

- Erection JsaDocument52 paginiErection JsaMd Danish Raza100% (2)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 paginiProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 paginiPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungÎncă nu există evaluări

- Jsa For Installation of Bracket in Phase 1Document4 paginiJsa For Installation of Bracket in Phase 1Mohammed Minhaj100% (1)

- JSA For Scaffolding Erection and Dismentling at Process AreaDocument5 paginiJSA For Scaffolding Erection and Dismentling at Process Areanoahlungu96Încă nu există evaluări

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 paginiSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Jsa - Hot TappingDocument15 paginiJsa - Hot TappingAmadeo Sabanal0% (1)

- Method Statement For Cable & TerminationDocument6 paginiMethod Statement For Cable & TerminationRajuÎncă nu există evaluări

- JSA For Flare Pit Area Including Night WorksDocument4 paginiJSA For Flare Pit Area Including Night WorksMohammed MinhajÎncă nu există evaluări

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 paginiJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanÎncă nu există evaluări

- JSA For Piping-Hydro TestDocument10 paginiJSA For Piping-Hydro TestMuthu AlaguRajÎncă nu există evaluări

- TRA-Street Light Foundation Installation WorkDocument5 paginiTRA-Street Light Foundation Installation WorkbinunalukandamÎncă nu există evaluări

- JSA For Foundation Concrete RepairDocument6 paginiJSA For Foundation Concrete RepairOvais FarooqÎncă nu există evaluări

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 paginiULSADO-JSA - Installation of Temporary Fence GateKelvin TanÎncă nu există evaluări

- Confined Space Entry For Painting Inside PontoonDocument4 paginiConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathÎncă nu există evaluări

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 paginiPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponÎncă nu există evaluări

- Jsa Insulation WorkDocument20 paginiJsa Insulation WorkazerÎncă nu există evaluări

- HIRA 013 Working Over Water.Document2 paginiHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument5 paginiJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriÎncă nu există evaluări

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 paginiEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- JSA For Road BarrierDocument3 paginiJSA For Road BarrierMohammed MinhajÎncă nu există evaluări

- CSM by AramcoDocument3 paginiCSM by AramcoSharifullahÎncă nu există evaluări

- JSA-001 Earth Works & Civil WorksDocument5 paginiJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 paginăProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanÎncă nu există evaluări

- Jsa For Civil Confined Space EntryDocument11 paginiJsa For Civil Confined Space EntryAmit SinghÎncă nu există evaluări

- Jha New - PWHTDocument6 paginiJha New - PWHTSalam AlkataluniÎncă nu există evaluări

- Daily JSA - Fence Post InstallationDocument5 paginiDaily JSA - Fence Post Installationshoaib akhtarÎncă nu există evaluări

- Pre Commissioning Electrical EquipmentDocument4 paginiPre Commissioning Electrical Equipmentmohammed a hseÎncă nu există evaluări

- JSA - CivilDocument5 paginiJSA - CivilRajuÎncă nu există evaluări

- EMP - Environmental Risk RegisterDocument23 paginiEMP - Environmental Risk RegisterNaveen ChaudharyÎncă nu există evaluări

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 paginiJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- JSA Install Automatic Parking GateDocument6 paginiJSA Install Automatic Parking GateMarhendraÎncă nu există evaluări

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 paginiJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- JSA 02-03 Vertical Borehole and Anode Bed InstallationDocument5 paginiJSA 02-03 Vertical Borehole and Anode Bed InstallationHaleemUrRashidBangash50% (2)

- Cold Cutting PDFDocument9 paginiCold Cutting PDFAshraf BottaniÎncă nu există evaluări

- Brazing (Oxygen and Acetylene)Document6 paginiBrazing (Oxygen and Acetylene)My Zain100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 paginăJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseÎncă nu există evaluări

- Doku - Pub Risk-AssessmentDocument10 paginiDoku - Pub Risk-AssessmentUlviyye ElesgerovaÎncă nu există evaluări

- Marafiq Risk Assessment 02Document5 paginiMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- Work at Height ProcedureDocument36 paginiWork at Height ProcedureShams JogÎncă nu există evaluări

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 paginijsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnÎncă nu există evaluări

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 paginiHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834100% (1)

- ARK JSA Manual Excavation A 3Document9 paginiARK JSA Manual Excavation A 3REMYAÎncă nu există evaluări

- JSA For Coating and Raping Activity in TankDocument7 paginiJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatÎncă nu există evaluări

- JSA Manual Excavation and Cable LayingDocument3 paginiJSA Manual Excavation and Cable Layingimran100% (1)

- Bolt Torquing Risk Assessment (Generic)Document5 paginiBolt Torquing Risk Assessment (Generic)kaleeswaran sÎncă nu există evaluări

- JSA OF Fabrication and Installation Work ApproviedDocument3 paginiJSA OF Fabrication and Installation Work Approviedsakthi venkatÎncă nu există evaluări

- 011 Duct Lifter SWMSDocument2 pagini011 Duct Lifter SWMSJ JohnsonÎncă nu există evaluări

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pagini13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Reliance Project Management System 10080-1-HSEF-CHK-CN-001: M/s Shanti Construction (Guj) PVT LTDDocument25 paginiReliance Project Management System 10080-1-HSEF-CHK-CN-001: M/s Shanti Construction (Guj) PVT LTDdrparihary100% (1)

- Jsa - Duck Bank InstallationDocument10 paginiJsa - Duck Bank InstallationAmadeo Sabanal100% (1)

- 63 Risk Assesments Testing and Pre-Commissioning WorksDocument18 pagini63 Risk Assesments Testing and Pre-Commissioning WorksEngr.Syed Amjad100% (3)

- Safe Work Methode For HDD BoringDocument1 paginăSafe Work Methode For HDD Boringiwansalma100% (3)

- Job Safety Analysis: Required References Jsa ReviewDocument4 paginiJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- Job Safety Analysis: Required References Jsa ReviewDocument3 paginiJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (1)

- HVAC Fans Initial Energisation Battery RoomDocument3 paginiHVAC Fans Initial Energisation Battery RoomMajdiSahnounÎncă nu există evaluări

- Hsse Requirements Trakcing RegisterDocument4 paginiHsse Requirements Trakcing RegisterMoaatazz NouisriÎncă nu există evaluări

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pagini120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- Daily HSE Report 22-12-2018Document117 paginiDaily HSE Report 22-12-2018Moaatazz NouisriÎncă nu există evaluări

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 paginiDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriÎncă nu există evaluări

- Daily Hsse Report 04 - 05 - 12 - 2018Document19 paginiDaily Hsse Report 04 - 05 - 12 - 2018Moaatazz NouisriÎncă nu există evaluări

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 paginiJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Daily Hsse Report 04 - 05 - 12 - 2018Document19 paginiDaily Hsse Report 04 - 05 - 12 - 2018Moaatazz NouisriÎncă nu există evaluări

- Daily Hsse Report 27 - 28-11-2018Document12 paginiDaily Hsse Report 27 - 28-11-2018Moaatazz NouisriÎncă nu există evaluări

- JSA-070 Desert Road TripDocument4 paginiJSA-070 Desert Road TripMoaatazz NouisriÎncă nu există evaluări

- 120021-Hse-003 - Waste Management PlanDocument21 pagini120021-Hse-003 - Waste Management PlanMoaatazz NouisriÎncă nu există evaluări

- JSA-002 Civil WorksDocument6 paginiJSA-002 Civil WorksMoaatazz NouisriÎncă nu există evaluări

- JSA-003 Fence InstallationDocument5 paginiJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- JSA-001 Earth Works & Civil WorksDocument5 paginiJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- JSA-020 Fence InstallationDocument4 paginiJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- 120025-Hse-001 Company Hse Management PlanDocument19 pagini120025-Hse-001 Company Hse Management PlanMoaatazz NouisriÎncă nu există evaluări

- 04 - Organisation ChartDocument1 pagină04 - Organisation ChartMoaatazz NouisriÎncă nu există evaluări

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pagini220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriÎncă nu există evaluări

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 paginiJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Job Safety Analysis - Civil WorksDocument7 paginiJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 120025-Hse-002 Company Hse Project StandardsDocument25 pagini120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- 119026-HSE-003 HSE StandardsDocument27 pagini119026-HSE-003 HSE StandardsMoaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- CV QAQC Manager-W.DORRI PDFDocument6 paginiCV QAQC Manager-W.DORRI PDFMoaatazz NouisriÎncă nu există evaluări

- CV Project Manager-M.Ammar PDFDocument6 paginiCV Project Manager-M.Ammar PDFMoaatazz NouisriÎncă nu există evaluări

- Iwcf Section OneDocument20 paginiIwcf Section OnesuifengniliuÎncă nu există evaluări

- Complaint Handling Policy of CBECDocument52 paginiComplaint Handling Policy of CBECharrypotter1Încă nu există evaluări

- 213-Article Text-620-1-10-20201118Document6 pagini213-Article Text-620-1-10-20201118Arlin FebriantiÎncă nu există evaluări

- Sample Resume FinalDocument2 paginiSample Resume FinalSyed Asad HussainÎncă nu există evaluări

- MS Word Lecture NotesDocument11 paginiMS Word Lecture NotesMoguriÎncă nu există evaluări

- Helicoil Plus en 0100Document56 paginiHelicoil Plus en 0100Khổng MạnhÎncă nu există evaluări

- Kathrein 739624Document2 paginiKathrein 739624anna.bÎncă nu există evaluări

- The Dell Direct Model: What It Means For Customers (Users) : - ProsDocument12 paginiThe Dell Direct Model: What It Means For Customers (Users) : - ProsAbhinandan MattelaÎncă nu există evaluări

- Dove Case Study QNA: Presented - Rachna JoshiDocument7 paginiDove Case Study QNA: Presented - Rachna JoshiGo2 MummaÎncă nu există evaluări

- History and Development of StatisticsDocument4 paginiHistory and Development of Statisticsjosedenniolim96% (27)

- 1LA7070-4AB10-Z A11 Datasheet en PDFDocument1 pagină1LA7070-4AB10-Z A11 Datasheet en PDFKraponis TylnessÎncă nu există evaluări

- BUSINESS PROPOSAL-dönüştürüldü-2Document15 paginiBUSINESS PROPOSAL-dönüştürüldü-2Fatah Imdul UmasugiÎncă nu există evaluări

- Business PlanDocument20 paginiBusiness PlanRona BautistaÎncă nu există evaluări

- Ruling The CountrysideDocument9 paginiRuling The Countrysiderajesh duaÎncă nu există evaluări

- MSW - 1 - 2016 Munisicpal Solid Waste Rules-2016 - Vol IDocument96 paginiMSW - 1 - 2016 Munisicpal Solid Waste Rules-2016 - Vol Inimm1962Încă nu există evaluări

- Huawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221Document2 paginiHuawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221nuttylÎncă nu există evaluări

- Tia-Eia-Is 801-1 - 2001Document148 paginiTia-Eia-Is 801-1 - 2001John UrdanetaÎncă nu există evaluări

- Ats1811 MLDocument16 paginiAts1811 MLWathÎncă nu există evaluări

- ManualDocument36 paginiManual2009tamerÎncă nu există evaluări

- Chats: Dini-Ay TriciaDocument1 paginăChats: Dini-Ay Triciaaiyana sopiaudaundoÎncă nu există evaluări

- 110Q Pump Catalog SheetDocument2 pagini110Q Pump Catalog SheetJohnÎncă nu există evaluări

- Package Contents: Ariadni DivaDocument4 paginiPackage Contents: Ariadni DivaShadi AbdelsalamÎncă nu există evaluări

- Degree 21-22 INTERNSHIPDocument4 paginiDegree 21-22 INTERNSHIPkoushik royalÎncă nu există evaluări

- Urban Jungle 8Document3 paginiUrban Jungle 8Angel Medez GonzalezÎncă nu există evaluări

- India's Information Technology Sector: What Contribution To Broader Economic Development?Document32 paginiIndia's Information Technology Sector: What Contribution To Broader Economic Development?Raj KumarÎncă nu există evaluări

- LC1D40008B7: Product Data SheetDocument4 paginiLC1D40008B7: Product Data SheetLê Duy MinhÎncă nu există evaluări

- Circuito Eléctrico Bomba de Freno VochoDocument1 paginăCircuito Eléctrico Bomba de Freno Vochosvelaib100% (1)

- Sharp AR-C172M ServiceM EN PDFDocument308 paginiSharp AR-C172M ServiceM EN PDFpiaggio_nrgÎncă nu există evaluări

- Theories of International TradeDocument33 paginiTheories of International Tradefrediz79Încă nu există evaluări

- Why CPVC Pipes FailDocument12 paginiWhy CPVC Pipes FailNikita Kadam100% (1)