Documente Academic

Documente Profesional

Documente Cultură

NAWPPL-BIMS-NPPL-000-HS-PLA-00003 - 000 - HSSE Bridging Document

Încărcat de

Moaatazz NouisriTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NAWPPL-BIMS-NPPL-000-HS-PLA-00003 - 000 - HSSE Bridging Document

Încărcat de

Moaatazz NouisriDrepturi de autor:

Formate disponibile

Contractor: Engineering: Project: Company:

NAWARA PROJECT

(PIPELINE)

Contract n°: OTP/PP/189 OMV/BIMS EPCC PPL

Contractor doc. n°: Engineering doc. n°: Job n°: P13IT02472 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS- NAWPPL-BIMS-NPPL-000-HS-PLA-

PLA-00003

Sheet 1 of 35 1 00003

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

000 08.04.2015 Issued for OMV use/construction MK RBL MCI

C03 24.03.2015 Issued for OMV Approval MK RBL MCI C

C02 25.02.2015 Issued for OMV Review MK RBL MCI C

C01 05.12.2014 Issued for OMV Review MK ABK MCI E

Rev. Date REVISION TITLE PREPARED CHECKED APPROVED COMPANY

This document is the property of ETAP & OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP & OMV.

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 2 of 35 00003

INDEX

0 Introduction ...................................................................................................................................4

0.1 Scope ....................................................................................................................................4

0.2 Purpose of the document .......................................................................................................6

0.3 Definitions and Abbreviations.................................................................................................7

0.4 Referenced Documents .........................................................................................................8

0.5 Project HSSE Policy ..............................................................................................................8

0.6 HSSE Objectives, Plans & Performance Standards ...............................................................8

1 Contractor ORGANIZATION, ROLE & responsibilities ................................................................10

1.1 HSSE Organisation and Reporting Responsibilities Chart ...................................................10

1.1.1 HSSE Resources ..........................................................................................................10

1.2 HSE Responsibility Senior Management..............................................................................10

1.2.1 Project Manager ...........................................................................................................10

1.2.2 Deputy project Manager................................................................................................11

1.2.3 Construction Manager ..................................................................................................11

1.2.4 HSSE Manager .............................................................................................................12

1.2.5 Site HSSE Manager......................................................................................................12

1.2.6 HSSE Coordinator ........................................................................................................13

1.2.7 PTW Coordinator ..........................................................................................................14

1.2.8 HSSE Instructor/Trainer ................................................................................................16

1.2.9 HSSE Supervisors ........................................................................................................17

1.2.10 HSSE Officers ..............................................................................................................18

1.2.11 Medical Staff (Doctor / Nurse) .......................................................................................18

1.2.12 Superintendent / Supervisor .........................................................................................19

1.2.13 Security Officers ...........................................................................................................19

1.2.14 Project employees & Subcontractors ............................................................................20

1.2.15 Provision of HSE Specialists .........................................................................................20

2 MANAGEMENT OF SUBCONTRACTORS .................................................................................21

3 HSE COMMUNICATION.............................................................................................................22

3.1 Communication in case of emergency .................................................................................23

3.2 External Links ......................................................................................................................23

4 HSE Meeting...............................................................................................................................24

4.1 Site induction .......................................................................................................................24

4.2 COMPANY/CONTRACTOR HSE Meetings .........................................................................24

4.2.1 CONTRACTOR HSE Meeting.......................................................................................25

4.2.2 Tool Box Talks meetings..............................................................................................25

5 HSE ProMOTION AND AWARNESS ..........................................................................................25

6 HSSE TRAINING ........................................................................................................................26

6.1 HSSE Induction ...................................................................................................................26

6.2 Specialised Training ............................................................................................................26

7 HSSE LEGISLATION AND STANDARDS ..................................................................................26

7.1 Applicable HSE legislation ...................................................................................................26

7.2 HSE Standards ....................................................................................................................27

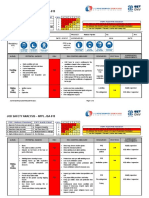

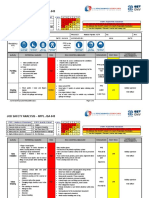

8 HAZARD AND EFFECT MANAGEMENT ...................................................................................27

8.1 Methods and Procedures for Hazards and Effect Management ...........................................27

8.2 Methods and Procedures for Hazards and Effect Management ...........................................27

9 PLANNING AND PROCEDURES ...............................................................................................28

9.1 Plan for development and implementation ...........................................................................28

9.2 HSSE procedures ................................................................................................................29

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 3 of 35 00003

9.2.1 Medical Planning and Procedures ................................................................................30

9.2.2 Environmental Planning Procedure ...............................................................................30

9.3 Work Permit System ............................................................................................................30

9.3.1 Implementation of Work Permit System ........................................................................30

9.4 Management, control & use of Hazardous Substances ........................................................30

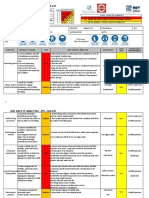

9.5 PPE requirements................................................................................................................30

10 EMERGENCY RESPONSE ....................................................................................................32

11 ROAD TRANSPORT ...............................................................................................................32

12 IMPLEMENTATION AND PERFORMANCE MONITORING ....................................................33

12.1 HSE Performance ................................................................................................................33

12.2 Accident/Incident Investigation.............................................................................................33

13 AUDIT AND MANAGEMENT REVIEW ....................................................................................33

13.1 Project HSE Audits ..............................................................................................................33

13.2 Management Review ...........................................................................................................33

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 4 of 35 00003

0 INTRODUCTION

0.1 Scope

The objective of the Nawara Development Project is to recover the associated and non-associated

gas reserves from the Nawara Concession, separate and pre-treat the fluids from 9 wells, gathered

them in Central Processing Facility (CPF), convert them into a commercial condensate and pre-

treated gas. Export the condensate via 10 km pipeline into the existing

TRAPSA pipeline, and export the gas via a new 374 km pipeline to Gabes. At Gabes, the gas will be

treated in a dedicated Liquefied Petroleum Gas (LPG) extraction facility to commercial specification

required for end user consumption. In Gabes, the gas will be conditioned in a Gas Treatment PLANT

(GTP) into commercial products (C1/C2, C3, C4 & C5), and sold to the end users: STEG, SNDP and

TRAPSA. The Nawara concession (528 km 2 ), part of the Jenein Sud Exploration permit (1992 km 2

), see Figure 1.1, is located in the Governorate of Tataouine, in the Southern Desert of Tunisia.

Nawara concession is owned by ETAP, the Tunisian National Oil COMPANY (50% share) and OMV

Tunisia (50% share). It extends from flat and stony surface in the south east to heavy and mobile

sand dunes in the North West. The discoveries and prospects within the Nawara concession are

considered to be relatively small and independent structures in the Acacus A formation.

Figure 1.1 Jenein Sud Exploration Area

Figure 1.2 below is a satellite view of the block area showing the Nawara concession, the well and

CPF locations, Hammouda Block Valve Station and pipeline and TRAPSA pipeline.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 5 of 35 00003

Figure 1.3 below is a satellite image showing the 374 km pipeline starting from Nawara

location to Gabes Industrial area where the GTP will be located.

Figure 1.3: Satellite Image, Pipeline Route to Gabes from HBVS

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 6 of 35 00003

0.2 Purpose of the document

This document has been developed by and oulines all activities for which CONTRACTOR and

SUBCONTRACTOR are responsible and accountable.

This document will include as a minimum:

Alignment of CONTRACTOR with OMV HSEE Policy

Alignment with requirements of the 12 elements of the OMV HSSE Management system

intentions, expectations, objectives and metrics.

CONTRACTOR HSSE organization to support OMV Group HSSE objectives and management

system with respect to EPCC activities

Clear Identification of roles and responsibilities in contractor organization.

Alignment of hazard identification and assessment with corresponding suitable and appropriate

preventive and mitigation actions including full accountability with respect to EPCC

Clearly identify the health, security, safety, environmental and Community Relations procedures

and actions that contractor shall maintain with respect to EPCC.

Inspection and audit process to demonstrate alignment with OMV Group 12 elements of HSSE

Management System

This document is a live document and could be updated upon company request.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 7 of 35 00003

0.3 Definitions and Abbreviations

TERM DEFINITION

COMPANY / ETAP & OMV

OWNER

COMPANY Is the party which carries out the detailed engineering, construction

management, supplies materials, equipment and services to perform

the duties as specified by the CONTRACTOR / OWNER;

COMPANY means the member and/or members appointed or designated by

Representative COMPANY in charge for the Double joint supervision on site as its

duly authorised representative to deal with CONTRACTOR with

respect to the CONTRACT

Contact Directory A list of team members and key players in a crisis. The list should

include home phone numbers, cell phone numbers, e-mail address,

etc.

CONTRACT is an agreement having a lawful object entered into voluntarily by

two or more parties, each of whom intends to create one or more

legal obligations between them

CONTRACTOR Entity (and its legal successors in title) named as CONTRACTOR in

the CONTRACTOR purchase order and/or the Contract awarded to

the CONTRACTOR to perform specific services and/or works

Crisis Is an actual or potential threat to the CONTRACTOR’s long-term

ability to do business due to the impact on reputation, legal /

financial liabilities and the ability to operate.

Emergency Is a situation from an incident, which has already taken place, but

has the potential to escalate further and cause additional damage to

human life, environment, assets, investment and reputation of

CONTRACTOR

Incident Is a physical act that threatens human life, environment or property.

Job Safety Risk assessment tools used to identify and control workplace

Analysis (JSA) hazards which helps integrate accepted safety and health principles

and practices into a particular task or job operation..

PROJECT NAWARA Pipeline Project

Quality Control A document that defines specific elements or processes of the

Plan (QCP) scope of work that require to be inspected;

Rescue Is the process of recovering of persons following their evacuation or

escape from the installation, and rescuing of persons near the

installation and taking such persons to a place of safety

Risk assessment Is the determination of quantitative or qualitative value of risk related

to a concrete situation and a recognized threat (also called hazard).

Quantitative risk assessment requires calculations of two

components of risk:, the magnitude of the potential loss (L), and the

probability (p) that the loss will occur.

SUBCONTRACTOR Entity (and its legal successors in title) named as

SUBCONTRACTOR in the CONTRACTOR purchase order and/or

the CONTRACT awarded to the SUBCONTRACTOR to perform

specific services and/or works.

Work Method A document that defines the methods to be used for the execution of

Statement (WMS) a certain activity;

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 8 of 35 00003

0.4 Referenced Documents

Document Number Document Title

NAWPPL-BIMS-NPPL-000-HS-PLA-00001 HSSE Management Plan

NAWPPL-BIMS-NPPL-000-HS-PLA-00005 Environmental Management Plan

NAWPPL-BIMS-NPPL-000-HS-PM-00009 Logistic Plan

NAWPPL-BIMS-NPPL-000-PM-CHA-00001 Organization Chart

NAWPPL-BIMS-NPPL-000-HS-PLA-00002 Information Security Plan

NAWPPL-BIMS-NPPL-000-HS-PLA-00004 Final Security Plan

NAWPPL-BIMS-NPPL-000-HS-PLA-00006 Final Emergency Response Plan

NA-OTP-PMT-0803-PM-TND-006310-Rev001 Exhibit J HSSE Requirements

NA-OTP-PMT-0803-PM-TND-006310-A01 Attachment 1 to EXHIBIT J Minimum

COMPANY HSSE expectations in EPCC

NA-OTP-PMT-0803-PM-TND-006310-A02 Attachment 2 to EXHIBIT J Construction

Site Rules

NA-OTP-PMT-0803-PM-TND-006310-A03 Attachment 3 to EXHIBIT J Environmental

Management Plan

NA-OTP-PMT-0805-HS-PLA-008 HSSE Management Plan for „EXECUTE“

0.5 Project HSSE Policy

CONTRACTOR is committed to the provision of a safe and health-working environment with the clear

target of an Accident & Incident Free workplace, by the application of well planned and executed

during realization of Nwara Pipeline Project.

A project specific HSSE policy shall be developed in line with the following:

The COMPANY and CONTRACTOR HSSE Management System

National and Local authorities Requirements

0.6 HSSE Objectives, Plans & Performance Standards

CONTRACTOR will establish, maintain and monitor measurable and achievable HSEC performance

objectives consistent with COMPANY and the project HSSE policy.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 9 of 35 00003

These objectives reflect our responsibilities, legislative requirements and project HSSE policy

commitments. They are:

All incidents are preventable;

All hazards will be identified, assessed and either eliminated or controlled;

Compliance with legislative requirements;

Compliance with approved industry best practice, applicable standards and codes;

Actively promote a safety culture that places HSSE ahead of all other objectives;

Engage in consultation with all stakeholders on relevant HSSE issues;

Develop and maintain a strategy for continuous improvement;

Provide effective competency based training;

Provide resources including personnel, systems and equipment;

Report HSSE outcomes through industry wide statistics, HSSE alerts and bulletins; and

Provide effective rehabilitation programs where necessary.

Our HSE key performance objectives include both leading and lagging HSSE performance indicators.

These are measurable and achievable and will be communicated to all personnel during induction and

weekly safety meetings to ensure an understanding of and participation in achieving these objectives.

In addition specific Key Performance Indicators and Leading Performance Indicators will be identified

in liaison with the COMPANY and monitored throughout against project performance.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 10 of 35 00003

1 CONTRACTOR ORGANIZATION, ROLE & RESPONSIBILITIES

1.1 HSSE Organisation and Reporting Responsibilities Chart

1.1.1 HSSE Resources

To ensure the success of the project HSSE MS, CONTRACTOR has a structure, which ensures that:

The Senior Management supports the formal management of the project;

There are sufficient managerial resources to support the Project HSSE processes;

There are sufficient specialist resources to co-ordinate the implementation of the HSSE plan

All workers feel that they play an active role in the HSSE process;

The responsibilities of the project key figures involved in implementing the Health, Safety and

Environment Management System are described in below.

The project HSSE organisation is detailed in NAWPPL-BIMS-NPPL-000-HS-PLA-00001 HSSE

Management Plan & NAWPPL-BIMS-NPPL-000-PM-CHA-00001 Organization Chart.

1.2 HSE Responsibility Senior Management

The following describes the project HSSE team organization and responsibilities during operations.

1.2.1 Project Manager

Reports to Supervisory Board

Demonstrate a total commitment to HSSE. Lead by example

Assist with development and implementation of the HSSE-Management system

Ensure the provision of adequate resources for the execution of this HSSE-

Management system

Monitoring all project activities. Ensures that all components of the HSSE Management

system are implemented and maintained

Ensure the workplace safety performance is regularly audited, reviewed and inspected

to allow an evaluation of the site safety performance against policies, objectives and

targets for the purpose of identifying opportunities for improvement

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 11 of 35 00003

Complete understanding of all statutory safety requirements applicable to the scope of

work

Ensure that HSSE issues are on the agenda for all site meetings

Ensure all stakeholders are kept informed and consulted regarding HSSE issues

1.2.2 Deputy project Manager

Is second in charge of the project under the Project Manager. The deputy's job is to assist the

project manager to get the project done within a total commitment to HSSE

Reports to PM and he substitute him during the rotation time for each decisions / activities upon

consultation with him.

1.2.3 Construction Manager

Reports to Site Manager

Demonstrate a total commitment to HSSE. Lead by example

Implement, maintain and adhere to the HSSE Management system

Establish and maintain a safe workplace

Ensures HSSE Management system is implemented with various construction activities

and operations

Monitoring all construction activities

Familiarity with statutory safety requirements applicable to the scope of work

Ensuring training resources are available to meet training requirements

Counsel employees in breach of site HSSE- requirements

Assist with workplace safety audits, reviews and inspections

Assist with incident investigations as required

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 12 of 35 00003

1.2.4 HSSE Manager

Reports to Project Manager

Manage & monitor all project HSSE activities

Provide support to site HSE Team

Co-ordinate the implementation of the HSSE-Management system

Ensure that an effective Emergency Response Plan is established and maintained

Provide advice to supervision on the development of Project Specific Procedures and Job Risk

Analysis (JSA)

Identify all training requirements

Carry out Internal Audits and assist with External Audits

Carry out incident investigations as required

Ensure all risk control measures are detailed in the Construction Hazard Register and referenced

in JSA

Implement and maintain a database of all incidents, workplace audits, inspections, reviews,

hazard observations and injury management programs.

Implement and maintain an up to date Action Tracking Register for demonstrating continual

improvement in the HSSE Management system.

1.2.5 Site HSSE Manager

Implement Rules and Work instructions of HSSE Management Plan and procedures in

accordance with the project requirements for daily work on Site

check that all equipment is approved in compliance with the local and company law/regulations

and is safe for use and serves notice on the subject matter in case of non-compliance

check that the protective personnel equipment utilised by personnel is in good condition and is

compatible with health and welfare

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 13 of 35 00003

check that during the execution of all phases of work, hygiene and safety rules are applied and

serve notice in case of non-compliance

inform all personnel about health and safety rules by means of brochures, notices,

meetings etc. via Introduction-/Tool Box Meetings

ensure the adoption of safe working practices

regular reporting to HSSE Project Manager

Safety instructions to subcontractors before starting of works and preparation of safety passes

Investigate and report incidents/ accidents

Analysis of incidents/ accidents and development of mitigate actions on Site

Attend regular management meetings (if additionally required to HSSE Manager)

Participation in weekly Construction Meetings

Assessment of safety behaviour in terms of safety incentive program and award of incentives

Ensure and control of Last Minute Risk Assessment

Reporting of Near-Miss Accidents and preparation of preventive action reports

1.2.6 HSSE Coordinator

Coordinate HSE team under direction of HSSE Manager.

Recommend safe working practices in the industry and construction sites.

Provide assistance to HSSE site manager as directed.

Formally conduct HSE meetings with project team and subcontractors as necessary.

Provide advice, administration, support and responses necessary to assist site management to fulfil

their safety responsibilities in accordance with legal requirements and Company’s safety policies in

order to maintain safe working conditions for employees and site facilities.

Ensure Risk Assessments, Inductions, HSE Procedures, applicable technical standards are known with

site personnel and are well understood;

Identify and report any areas that require support from the HSSE Manager to that entity.

Pay special attention to HSSE management of (major) Sub-Contractors.

Ensure actions for the site from HSSE meetings, Audits,

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 14 of 35 00003

Inspections and other instructions are implemented.

Inform HSE Manager of needs for improvements in procedures, training, instruction, information

materials and/or equipment, etc.

Conduct audits and inspections in order to measure the degree of compliance with legislation,

regulations, procedures and instructions.

Assist HSE team in performing Risk Assessments, when required.

Conduct and take part in regular meeting and communication with representatives of Client &

Subcontractor with regard to Health, Safety & Environmental issues.

Responsibility for ensuring that all activities comply with applicable Health, Safety and Environmental

requirements, and that personnel are not subjected to situations of unacceptable risk.

Participating in any external or internal audits which may be conducted.

Monitor and control the application of Emergency and Contingency Plans.

Work with Managers and Supervisors to update training requirements, in conformity with job

requirements;

1.2.7 PTW Coordinator

Permit to Work issues

Provides technical expertise to develop and upgrade procedures, guidelines and standards and

implements Permit to Work for Compagny as required

Provides technical expertise for development and implementation of Permit to Work training

programs Provides, assists and participates in Permit to Work training of workforce

Encourages Safe working practice and safety culture at all times.

Provides guidance and assistance to all signatory authorities using the Permit to Work system

Provides coaching, mentors training and assistance to all users of the Permit to Work system

Reviews all permits, associated certificates and documents to ensure compliance to the Permit to

Work rules, procedures and regulations. Notifies PTW signatories of conflicting work activities

Reviews process, mechanical, electrical isolations to ensure correct isolation standard and

procedures Ensures all Permit to Work and Isolation registers are true, audited and kept up to date

Conducts Permit to Work meetings to ensure review and signing by signatories ready for permit

issue

Performs inspection, auditing of permits, associated certificates and documents to ensure

compliance to the requirements, standards and rules of the Permit to Work system

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 15 of 35 00003

Participates in incident investigations

Assists with administration of Key Performance Indicators (KPI)

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 16 of 35 00003

1.2.8 HSSE Instructor/Trainer

Development and delivery of HSSE courses in consistency with employee’s individual development

plan

Planning and scheduling of delivery of HSSE courses.

Plan & implement effective use of resources for the Training Program.

Liaise with other on-job training staff to ensure full compatibility of on-job & off-job training, meet

with them regularly, & visit locations where trainees are receiving on-job training.

Ensure consistency of training activities & documentation across all company disciplines.

Monitor trainee progress & implement corrective action as necessary.

Prepare monthly written reports on program & trainees progress.

Develop ideas and create HSE courses.

Plan/carry out/support local HSSE activities to agreed budgets and timescales, and integrate HSSE

efforts with other Company activities.

Monitor and report HSSE activities and provide relevant reports and information.

Communicate, liaise, using appropriate methods to facilitate the development of HSSE training

activates.

Attend and present external and internal HSSE meetings with other company personnel’s.

Undertake such further duties as required to facilitate or enhance Company HSE training activities.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 17 of 35 00003

1.2.9 HSSE Supervisors

Set an example by personal application of HSSE principles and practices.

Conduct weekly inspections of each work unit using an approved checklist.

Conduct pre-use equipment HSE inspections of major equipment using an approved Checklist.

Supervise critical procedures where timing and access allows.

Participate in reporting of hazards, coordinates hazard reporting and development of action plans.

Take immediate corrective action in situations where imminent serious or major unsafe acts or

conditions exist.

Monitor the compliance of planning and control of daily HSSE meetings, feasibility and validity of

Emergency Plan.

Compliance with all training activities, drills, safety programmes, etc., set out in in the HSSE Plan.

Participate and report in investigation of accidents / incidents, analysis of causes and development

of action plans using the COMPANY format.

Maintain and report accident/incident statistics on a monthly basis using a COMPANY prescribed

method.

Participate in and assist in coordination and evaluation of various emergency drills.

Participate in development of action plans resulting from evaluation of drills.

Monitor action plans resulting from inspections, hazard reporting, emergency drills, and accident /

incident investigations.

Report deviation.

Monitor personal protective equipment usage and advise management when replacements are

needed.

CONTRACTOR’s HSSE performance report on completion of project. The report should document

all reportable incidents or near misses, mention the steps taken to improve HSE performance,

problems encountered which prevented any of the operation’s HSSE objectives from being

realised; and should be supported by photographs.

Review all aspects of the site activities, including vehicles, to ensure that local, national

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 18 of 35 00003

1.2.10 HSSE Officers

Assist with the implementation of the HSSE strategy of the CONTRACTOR.

Implement a best practice on site

Assist HSSE supervisor in the design of HSSE Training

Maintain all the required documentation, operational checks and reports for each location of the site;

Carryout Daily Inspection and write reports.

participate in the investigation of incidents/accidents and near misses

Audit work being performed with ''Safe Work Permit”

Assist with the implementation of Job Safety Analysis, Safe Systems of Work and inspect job site activ

ities.

To attend site HSSE meetings and lead HSSE Toolbox meetings

Review and analyze accidents and near miss incidents and making corrective action recommendatios.

Assist and Conduct emergency response exercises and drills; ensuring the highest

level of preparedness in any emergency, also to record such drills, providing recommendations for em

ergency response improvements.

Assist with Site risk management workshops.

1.2.11 Medical Staff (Doctor / Nurse)

To give first aid and medical assistance on site and in clinic.

To maintain equipment and medical supplies in accordance with national and COMPANY

standards

To maintain effective communication

To maintain confidential medical reports in accordance with national and COMPANY

standards

To reviewed and maintained on a regular basis the First Aid Kit(s) content.

To ensure correct medical waste disposal

To cooperate on site to training sessions concerning first aid procedures

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 19 of 35 00003

1.2.12 Superintendent / Supervisor

Report to the respective managers / contractors

All members of line management shall ensure that work under their control is executed in a safe

manner and shall lead by example

Monitor workplace activities

Conduct specific area safety briefing and ensure that PPE has been issued prior to commencement of

work

Assist with and review all JSA’s / Work Method statements to ensure that items in Hazard Register are

identified for respective work areas under their control

Ensure that Tool Box, Safety & Job Start Meetings for respective work areas are conducted

Investigate and compile incident reports for respective work areas

Carry out regular workplace HSSE Management system inspections

Counsel personnel identified failing to adhere to the site safety requirements

1.2.13 Security Officers

Secures premises and personnel by patrolling property; monitoring surveillance equipment; inspecting

site, equipment, and access points; permitting entry.

Obtains help by sounding alarms.

Prevents losses and damage by reporting irregularities; informing violators of policy and procedures;

restraining trespassers.

Controls traffic by directing drivers.

Completes reports by recording observations, information, occurrences, and surveillance activities;

interviewing witnesses; obtaining signatures.

Maintains environment by monitoring and equipment controls.

Maintains organization's stability and reputation by complying with legal requirements.

Ensures operation of equipment by completing preventive maintenance requirements; following

manufacturer's instructions; troubleshooting malfunctions; calling for repairs; evaluating new

equipment and techniques.

Contributes to team effort by accomplishing related results as needed.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 20 of 35 00003

1.2.14 Project employees & Subcontractors

Take reasonable care to ensure their actions do not cause detrimental effects to themselves or others.

Become conversant with, and follow systems and procedures on site. (Applicable to all employees)

Comply to the best of their ability with specific safety requirements / procedures and guidelines

disseminated through the project induction’s and participate in JSA’s, Safety, Job-Start meetings and

site instructions

Stop any observed unsafe acts and not commence tasks until hazards are reduced to as low a risk as

is reasonably practical

Be pro-active towards achieving project goals and targets, and encourage team mates to follow safety

practices

Correctly use and maintain the equipment and PPE supplied

Ensure the correct tools and equipment is used and maintained in a good condition

Warn other employees of known hazards

Report to their Supervisor, all accidents, incidents including near hits and any defects in plant or

equipment – immediately

Be responsible for daily housekeeping in own working area

Report all observed Hazards both positive and negative and HSSE Incidents to the responsible

Supervisor or HSE Team as soon as is practicable

Subcontractors and their employees shall at all times when on site, be accountable to the Construction

Manager and shall comply with this HSSE Management system and all relevant site and statutory

regulations applicable to the scope of work;

1.2.15 Provision of HSE Specialists

The CONTRACTOR recognises that in certain cases and for specialised activities within HSE there is

a need to source independent specialists. When specialist’s services required, these services can

arrange either from local consultancy organisations or from Corporate Office.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 21 of 35 00003

2 MANAGEMENT OF SUBCONTRACTORS

Sub-contractors carry out some of the activities of CONTRACTOR. In that case CONTRACTOR staff

is mainly involved in specifying the work to be done, and managing the execution by the sub-

contractor.

The project manager is responsible for ensuring that HSE is managed by subcontractors in a way that

is compatible with COMPANY and CONTRACTOR system.

The requirement related to the selection and management of Subcontractors is implemented in the

following principal phases:

Pre-qualification

Submittal of project HSE requirements;

Analysis of Subcontractor HSE Programmes

Management at the work site

Co-ordination Safety Meetings

Monitoring of Safe Working Procedures implementation;

Appointement of qualified HSE personnel at training;

Implementation of training programme;

Emergency Response Procedures;

Control of Personal Protective Equipment use.

HSE selection and Approval of Sub-contractor are detailed in NAWPPL-BIMS-NPPL-000-HS-PRO-

009.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 22 of 35 00003

3 HSE COMMUNICATION

Effective communication is essential between COMPANY and CONTRACTOR for the development of

HSE culture within the organization, as well as to ensure that the objectives, HSE performance

requirements, responsibilities are clearly understood. This will be implemented through:

Dissemination of CONTRACTOR HSE Policy to all personnel, and instruction on its use;

Distribution of HSE Safety Notices, periodic health and safety briefing notes, etc on a regular basis

Promoting open communications between management and workforce on safety matters;

Ensuring health and safety issues are included on the agenda at COMPANY and CONTRACTOR

management meetings;

Promoting hygiene, health and safety awareness by disseminating information such as accident and

injury statistics, and articles which have a direct impact upon the health, hygiene and safety of

the workforce; sharing HSE experience and best practices;

Weekly safety meetings. A safety committee will be established for the project covering onshore

construction activities. The committee will address health, safety and environmental issues, which

are identified during the project;

On the job instructions (toolbox meeting);

Effective signs indicating hazards and escape routes;

Management visits to site.

The HSE communication Between COMPANY and CONTRACTOR shall have visible lines for :

Effective flow of consultation;

Information;

Correspondence;

Reports.

Internal lines of communication shall provide for :

Work site co-ordination

Co-ordination between Corporate and Line Management.

External lines of communication shall provide for :

COMPANY

Local authorities and communities, governmental authorities in order to be aware of any changes in

HSE legislation, standards and initiatives which may influence HSE activities;

Subcontractors and services

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 23 of 35 00003

Any type of HSE communication implementation shall be recorded appropriately (records of HSE

meetings, management site visits etc). The specific procedure shall be included in the HSe

procedures manuals to be developed after contract award.

All HSE concerns shall be seriously considered and reported through the lines of

Communication in an open manner. During the entire project activities local languages will be

incorporated into the Communications mediums necessary to ensure full comprehension.

Encouraging, capturing and implementing employee’s Health, Safety and Environmental

recommendations are accomplished using incentive schemes, Safety Campaign Programs, Safety

suggestion boxes, performance evaluation, etc

3.1 Communication in case of emergency

The objective of emergency communication is to ensure that any emergency affecting the place

of operational activities, is dealt with in an efficient and professional manner so that the safety of

personnel is not compromised in any way, the environmental pollution risks are prevented or

minimized and that all other losses which may arise from emergencies are prevented or

minimized.

A Specific Emergency Response Plan NAWPPL-BIMS-NPPL-000-HS-PL-00006 is issued to detail

written arrangements and procedures, which specify the actions to be taken in the event of an

emergency that may occur during the course of operational activities.

Each Section of the Specific Emergency Response Plan provide instructions and relevant

checklists, which should be utilized to assist in incident management.

3.2 External Links

CONTRACTOR will establish clear procedures to communicate national, local governmental

departments, non-governmental organizations, media and general public. These procedures shall be

put in place to disseminate the project information pertaining to HSE issues and for promptly respond

to governmental and local inquires concerns and complaints.

The HSSE Manager will also ensure that all safety signs are similarly printed in Arabic and English. All

HSE procedure, instruction, posters and information’s will be sent to the site.

HSE communication will be detailed in NAWPPL-BIMS-NPPL-000-HS-PRO-00012 Consultation and

Communication at site.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 24 of 35 00003

4 HSE MEETING

HSE Meeting is convened to ensure that health and safety issues are formally presented and

discussed collectively at all pipeline sites construction sites encompass each shift, which will be

convened and chaired by the Construction Manager.

All department Heads shall also attend the meetings. CONTRACTOR will report all type of HSE

meeting to the COMPANY as per the Appendix: HSE Monitoring program.

4.1 Site induction

Immediately after employment of new personnel or assignment of personnel to project, will attend an

HSE Induction training organized at project site by competent HSE instructor in order to ensure that all

employees are aware of general project work related HSE awareness.

CONTRACTOR will ensure all Subcontractor companies employees have undergone safety induction

training prior to commence work activities in compliance with COMPANY HSE training requirements.

4.2 COMPANY/CONTRACTOR HSE Meetings

COMPANY and CONTRACTOR will mutually promote the arrangements of several HSE meetings. In

addition to the typical safety meetings attended by the Project Senior personnel, the following can be

considered example of meeting to be arranged throughout the project duration :

Specific HSE workshop to address certain important issue (i.e PTW, HARC, simultaneous operations,

transportation and journey management, etc)

Periodic “working together meetings” to be attended by representatives from COMPANY,

CONTRACTOR and the Main Sub-Contractors

Regular HSE Meetings attended by Project Management, CONTRACTOR HSE Manager and

COMPANY Representatives.

The detailed schedule for the above HSE meetings are defined in the preliminary HSSE plan

NAWPPL-BIMS-NPPL-000-HS-PL-00001.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 25 of 35 00003

4.2.1 CONTRACTOR HSE Meeting

A H weekly HSE meeting will be organised between Construction Manager, Site HSE Manager and

Senior Representatives from each Subcontractor companies employed in the project. The main of the

meeting is to ensure a proper co-ordination between the entities involved in the Project in order to

enhance the safety at site level.

4.2.2 Tool Box Talks meetings

All Supervisors and Safety Inspector of the CONTRACTOR are to lead the daily individual meetings

for working crews. This is to ensure that every worker is quite conscious of his duties and hazards,

answer any questions, initiate discussions. Inspect the safety conditions of all mechanical equipment,

materials stored and proposed work manner. They shall also discuss the accidents and deficiencies, if

any that occurred in the previous days.

5 HSE PROMOTION AND AWARNESS

CONTRACTOR will encourage that an appropriate communication techniques will be used to make

project personnel aware of HSE issues and to consider any language/ literacy problems.

CONTRACTOR recognizes the importance of HSE Performance boards and shall provide HSE

performance boards at all offices/sites. The performance boards shall highlight the project and

individual major subcontractor statistical as is applicable to the Contract and the main HSE

performance target for the COMPANY.

CONTRACTOR recognizes the importance of fair and equal recognition of good practice concerning

the application of often complicated and precise workplace management procedures. CONTRACTOR

HSSE department will apply a generous meritorious HSE incentive program throughout the works

execution.

CONTRACTOR believes that a good method for promotion of HSE is implemented including safety

incentive scheme, which will be developed for duration of the entire project.

HSE Incentive Schemes Procedure will be developed.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 26 of 35 00003

6 HSSE TRAINING

6.1 HSSE Induction

The induction training will be performed on all new arrivals to the project within the first day on site.

Immediately after employment of new personnel or assignment of personnel to a Project, HSE

Instructor shall carry out an HSE induction in order to ensure that all people are Aware of safety rules

and policies for the project. As far as is practicable, the HSE induction shall be given in the language

of the personnel undergoing the training.

CONTRACTOR will ensure all Subcontractor employees have undergone safety induction training

prior to commence work activities in compliance with COMPANY HSE Training requirements.

6.2 Specialised Training

In addition to safety induction, CONTRACTOR will ensure the following types of specialized training to

all necessary employees during the course of project as per COMPANY training requirements.

The CONTRACTOR HSSE Manager will regularly assess the requirements of specialized HSE

training to all employees as per COMPANY requirements.

A training Matrix is being developed as per COMPANY HSE Training Requirements.

Details are stated in the HSSE Management Plan NAWPPL-BIMS-NPPL-000-HS-PLA-00001.

7 HSSE LEGISLATION AND STANDARDS

7.1 Applicable HSE legislation

CONTRACTOR will take all necessary and reasonable steps to identify and apply the legislative

requirements.

CONTRACTOR will develop and maintain a register of all applicable and adopted laws, regulations,

codes, standards and permit conditions applicable to the project.

Legal requirements will be detailed in a specific Procedure Identification and Management of HSE

Legislation and according to NA-OTP-PMT-0805-HS-STA-0101 HSSE legal Compliance procedure.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 27 of 35 00003

7.2 HSE Standards

CONTRACTOR utilizes accepted regulatory as a minimum to protect the health and safety of all

personnel working in construction, and any others who may be affected by the project activities.

CONTRACTOR considers the management of HSE a High priority, and the acceptance of the

COMPANY and applicable Tunisian Laws and regulations is part of the equation.

8 HAZARD AND EFFECT MANAGEMENT

8.1 Methods and Procedures for Hazards and Effect Management

HSE risk management forms an integral part of all phases of a project and at a level

commensurate with the size, manning requirements and complexity of the project.

In order to manage all HSE matters and on site specificity, CONTRACTOR will provide a complete

documentation system based on database coming from past pipeline construction projects in

TUNISIA.

CONTRACTOR’s HSE procedures will be written on a first step by the HSSE Manager when he will be

nominated and in a second time these procedures shall be up-dated as necessary following

completion of risks assessment and reassessment of these risks against the time, trouble, difficulty

and cost of achieving it.

Hazards and Effects Management Process is managed by a set of Hazard identification and Loss

Control procedures.

These procedures shall be developed in compliance with COMPANY Hazard/Risk Management

requirements.

Details are stated in the doc. NAWPPL-BIMS-NPPL-000-HS-PRO-0004 Risk Assessment.

8.2 Methods and Procedures for Hazards and Effect Management

CONTRACTOR Risk Assessment procedure NAWPPL-BIMS-NPPL-000-HS-0004 Risk Assessment.

addresses all the hazards which may arise during the typical operation performed on project.

Within the overall assessment CONTRACTOR monitors and ensures proper working condition and

environment through the analysis of:

Work task;

Effects of dust and fumes;

Noise from machinery and equipment;

Vibration from mechanical tools;

Effect of temperature extremes;

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 28 of 35 00003

Ergonomic hazards;

Radiological hazard;

Harmful substances;

Particular attention is paid for the control of personnel exposure to the noise at work.

CONTRACTOR shall comply with Tunisian Legislation and COMPANY standards on noise protection

and perform periodical medical check-ups for exposed personnel, perform noise assessment in the

working location, issue specific training and hearing protectors (PPE).

Additionally, suitable and sufficient workplace facilities will be provided, these include:

Hygiene and welfare provisions

Cleanliness of premises

Good housekeeping of entry and exit routes

Ergonomic and comfort of employees

Good lighting standards

In addition to this, COMPANY’s procedures such as Quantitative Risk Analysis and Permit to Work

System procedure shall be implemented during the unloading of pipes in the port.

9 PLANNING AND PROCEDURES

9.1 Plan for development and implementation

The HSE management system for the Project is derived directly from the Corporate HSE procedures

and CONTRACTOR system, including HSE management plans, procedures, and instructions

demonstrated to be effective on similar project. Once adapted to Nawara Pipeline Project, these will

establish consistent and comprehensive project planning, execution and monitoring for all phases of

project development.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 29 of 35 00003

9.2 HSSE procedures

A set of HSE Procedures will be developed for the construction activities. They are formulated in a

way that may be also used as training tools for the personnel and as training tools for the personnel

and as reference for Tool Box meetings and Job Safety Analysis.

The HSE Procedures applies to the all construction site directly performed or supervised by

CONTRACTOR Project Management.

Refer to Appendix 2 : List of safe working Procedure for pipeline construction.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 30 of 35 00003

9.2.1 Medical Planning and Procedures

As described in more details above, each employee involved in Project activities will undergo pre-

employment and periodical medial fitness examinations.

Infectious diseases prevention shall be achieved through strict hygiene surveillance.

9.2.2 Environmental Planning Procedure

Each employee involved in Project activities will attend Environmental awareness training as a part of

their induction training (mandatory). Concerned project employees will also receive specialised

training in environmental protection measures such as Oil spill clean up, Material Safety Data Sheet.

Details will be stated in the NAWPPL-BIMS-NPPL-ENV-PLN-0001 Environmental Plan.

9.3 Work Permit System

9.3.1 Implementation of Work Permit System

A work permit authorises specific works to be conducted in a restricted area. This serves record that

establishes steps that have been taken to ensure safe working conditions in the area.

In this Project, when required, application for CONTRACTOR Work Permit will be made in advance

NAWPPL-BIMS-NPPL-000-HS-PRO-00013 (as per COMPANY requirements). Except at location

where working under COMPANY total supervision and control such as the port, in this case the

CONTRACTOR will adopt the COMPANY’s work Permit system.

9.4 Management, control & use of Hazardous Substances

Management, control and use of hazardous substances shall comply with all applicable Tunisian

regulations. CONTRACTOR will develop a specific procedure NAWPPL-NPPL-000-HS-PRO-00022

Chimical Management Procedure.

9.5 PPE requirements

PPE includes protective clothing, body protection, safety harnesses and high visibility clothing.

The procedure covers the supply and use of:

Head protection

Eye protection

Hearing protection

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 31 of 35 00003

Respiratory protection

Hand and foot protection

Details about PPE requirements will be stated in the document NAWPPL-BIMSI-NPPL-000-HS-PRO-00011

PPE procedure.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 32 of 35 00003

10 EMERGENCY RESPONSE

A specific Emergency Response Plan NAWPPL-BIMS-NPPL-000-HS-PLN-000006 will be issued to

detail written arrangements and procedures, which specify the actions to be taken in the event of an

emergency that may occur during the course of the construction activities.

Each selection of the Specific Emergency Plan provides instructions and relevant checklists, wich

should be utilized to assist in incident management. Emergency plans cover most operations, i.e

Oil spill

Structural/equipment failure,

Fire / explosion

Escape of gas,

Loss of radioactive source.

Accidents refer to person and vehicle, MEDEVAC, sudden death, repatriation of a body. Security risks

procedures concern criminal acts, loss of property, kidnap, ransom, etc

11 ROAD TRANSPORT

Travel risks to personnel shall be effectively managed and all travels shall be undertaken in a safe

manner.

In Early Works, COMPANY’s Journey Management System is implemented for all journeys within the

project. Once CONTRACTOR’s journey management system is approved, so it shall be used.

Any non-desirable event in the Journey process shall be reported and investigated and the person in

charge should be provided with details for further investigation.

All vehicles will be equipped with IVMS as per COMPANY requirements.

Details are stated in the NAWPPL-BIMS-NPPL-000-HS-PRO-00006 Drivers, Vehicles and journey

Management Procedure.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 33 of 35 00003

12 IMPLEMENTATION AND PERFORMANCE MONITORING

12.1 HSE Performance

The Project Manager shall be responsible in reporting all Accident/incident, personnel injuries,

casualties, damage and fires to COMPANY and to the Local Authorities (when required).

CONTRACTOR will report, to the COMPANY of project HSE Performance, weekly and monthly basis.

Project Manger together with HSSE Manager shall ensure the submission of Health and Safety

Statistic to COMPANY as per the COMPANY requirement.

As mentioned in section 2.12.3 of the HSSE Plan, CONTRACTOR has system in place for monitoring

re-active and proactive performance indicators .

12.2 Accident/Incident Investigation

All accidents, incidents and near-misses shall be classified, investigated and reported systematically in

accordance with the COMPANY suggested Accident/Incident Reporting and Investigation System.

Details will be stated in the document NAWPPL-BIMS-NPPL-000-HS-00010 Accident/Incident

Investigation & Reporting procedure.

13 AUDIT AND MANAGEMENT REVIEW

The following approach will be forced during the Project execution.

13.1 Project HSE Audits

The HSE Manager will carry out regular audits ( monthly basis) to ensure the required health, safety,

and environmental policies, procedures, and work practices are in place, and are working effectively.

All actions as a result of audits will be followed up and close out.

The findings of the HSE audits will be communicated to the CONTRACTOR project Management for

review and, where required, improving the HSE management system.

13.2 Management Review

The CONTRACTOR project management team will assess the project’s HSE performance at regular

intervals and issue formal reports. The findings of these reviews will form basis for improvement plans

and action to enhance the HSE system.

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 34 of 35 00003

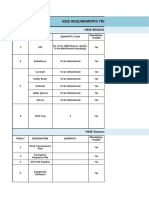

Appendix 1 List of HSSE delivrables.

NAWPPL-BIMS-NPPL-000-HS-

PLA-00001 HSSE Plan

NAWPPL-BIMS-NPPL-000-HS-

PLA-00003 HSSE Bridging Document

NAWPPL-BIMS-NPPL-000-HS-

PLA-00004 Final Security Plan

NAWPPL-BIMS-NPPL-000-HS-

PLA-00006 Final Emergency Response Plan

NAWPPL-BIMS-NPPL-000-HS-

PRO-00001 Pipeline lifting, transport& storage Procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00002 SAFE PIPELINE HANDLING, TRANSPORT AND STORAGE PROCEDURE_Dissa

NAWPPL-BIMS-NPPL-000-HS-

PRO-00003 Ksar Ghilen Emergency response procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00004 CONVOY_MOVEMENTS _PROCEDURE

NAWPPL-BIMS-NPPL-000-HS- KSAR GHILENE SAFE PIPELINE HANDLING TRANSPORTATION AND

PRO-00005 STORAGE PROCEDURE

NAWPPL-BIMS-NPPL-000-HS-

PRO-00006 DRIVERS VEHICLES AND JOURNEY MANAGEMENT PROCEDURE

NAWPPL-BIMS-NPPL-000-HS-

PRO-00007 Safety training procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00008 Risk Assesment procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00009 Tagging & Isolation Procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00010 Incident Reporting & Investigation procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00011 Personnel protective Equipment procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00012 HAZARD reporting procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00013 Manual Handling procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00014 Review, Audits and Inspections procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00015 Trenching/Excavation Safety procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00016 Electrical Safety procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00017 Work permits procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00018 Confined Space procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00019 Hand and Power tools procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00020 Welding & Cutting Safety procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00021 Crane & Lifting Safety procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00022 Chemical management procedure

NAWPPL-BIMS-NPPL-000-HS-

PRO-00023 Working at height procedure

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

NAWARA PROJECT (PIPELINE)

HSSE Bridging Document

Contractor doc. n°: Engineering doc. n°: Rev.: A01 C01 C02 C03 000 Company doc. n°:

NAWPPL-BIMS-NPPL-000-HS-PLA- NAWPPL-BIMS-NPPL-000-HS-PLA-

00003 Sheet 35 of 35 00003

NAWPPL-BIMS-NPPL-000-HS-

PRO-00024 Abrasive Blasting procedure

NAWPPL-BIMS-NPPL-000-HS-PLA-00003_000_HSSE Bridging Document

Summary of Comments on: NAWPPL-BIMS-

NPPL-000-HS-PLA-00003 _

C03_HSSE_Bridging_Document

Pages: Authors: OMV Comments: BIMS Responses:

Author: mohamed11 Subject: Highlight Date:

Page: 6 08/04/2015 09:37:12 please add a sentence stating that:

this document is an live document and could

done.

be updated upon company request.

the C04 to be issued for use shall contain that.

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 paginiDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- JSA-003 Fence InstallationDocument5 paginiJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Daily HSE Report 22-12-2018Document117 paginiDaily HSE Report 22-12-2018Moaatazz NouisriÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hsse Requirements Trakcing RegisterDocument4 paginiHsse Requirements Trakcing RegisterMoaatazz NouisriÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pagini120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- JSA-070 Desert Road TripDocument4 paginiJSA-070 Desert Road TripMoaatazz NouisriÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- 120021-Hse-003 - Waste Management PlanDocument21 pagini120021-Hse-003 - Waste Management PlanMoaatazz NouisriÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- CV QAQC Manager-W.DORRI PDFDocument6 paginiCV QAQC Manager-W.DORRI PDFMoaatazz NouisriÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- JSA-002 Civil WorksDocument6 paginiJSA-002 Civil WorksMoaatazz NouisriÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- JSA-020 Fence InstallationDocument4 paginiJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- JSA-001 Earth Works & Civil WorksDocument5 paginiJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Job Safety Analysis - Civil WorksDocument7 paginiJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 paginiJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 120025-Hse-002 Company Hse Project StandardsDocument25 pagini120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pagini220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriÎncă nu există evaluări

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 paginiReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 120025-Hse-001 Company Hse Management PlanDocument19 pagini120025-Hse-001 Company Hse Management PlanMoaatazz NouisriÎncă nu există evaluări

- Instrument & Control Engineering Head: Curriculum Vitae PirecoDocument2 paginiInstrument & Control Engineering Head: Curriculum Vitae PirecoMoaatazz NouisriÎncă nu există evaluări

- Attachment 4.1.1Document16 paginiAttachment 4.1.1Moaatazz NouisriÎncă nu există evaluări

- CV Project Manager-M.Ammar PDFDocument6 paginiCV Project Manager-M.Ammar PDFMoaatazz NouisriÎncă nu există evaluări

- JSA-017 Lifting With Forklift 2Document4 paginiJSA-017 Lifting With Forklift 2Moaatazz NouisriÎncă nu există evaluări

- JSA-017 Lifting With ForkliftDocument3 paginiJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameDocument1 pagină4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameMoaatazz NouisriÎncă nu există evaluări

- CV Civil & Structural Head-O.RAJEHDocument2 paginiCV Civil & Structural Head-O.RAJEHMoaatazz NouisriÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- CV Business Adm Mgr-S.DridiDocument2 paginiCV Business Adm Mgr-S.DridiMoaatazz NouisriÎncă nu există evaluări

- JSA-019 Manual WeldingDocument5 paginiJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- JSA-018 Lifting With Mobile CraneDocument5 paginiJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- JSA-049 LVS Equipment & Material InstallationDocument10 paginiJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriÎncă nu există evaluări

- JSA-049 Valves & Support Installation and DismantlingDocument4 paginiJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Tool Box Talk - 14 Working at HeightsDocument2 paginiTool Box Talk - 14 Working at HeightsMoaatazz NouisriÎncă nu există evaluări

- Department of Education: Weekly Learning PlanDocument8 paginiDepartment of Education: Weekly Learning PlanChristian Kim Caguioa IIÎncă nu există evaluări

- Profmed Schedule of BenefitsDocument48 paginiProfmed Schedule of BenefitsJesiel Romero RodotaÎncă nu există evaluări

- A Comparison of Emergence Delirium Scales Following General Anesthesia in ChildrenDocument8 paginiA Comparison of Emergence Delirium Scales Following General Anesthesia in ChildrenNongnapat KettungmunÎncă nu există evaluări

- Eldi OilDocument6 paginiEldi OilNatalija68Încă nu există evaluări

- 02 Adler Human Nature PDFDocument62 pagini02 Adler Human Nature PDFJulaiza MontegrandeÎncă nu există evaluări

- Narayan Hrudalaya Case Study AnalysisDocument5 paginiNarayan Hrudalaya Case Study Analysisdarshak kansagraÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ijccm 13 173Document34 paginiIjccm 13 173Tricia Jane OpinaldoÎncă nu există evaluări

- (창사글) '인공지능 의료진단' 논문Document215 pagini(창사글) '인공지능 의료진단' 논문yangjiwon041111Încă nu există evaluări

- Annotated Bibliography 1Document2 paginiAnnotated Bibliography 1api-509555528Încă nu există evaluări