Documente Academic

Documente Profesional

Documente Cultură

f4g02613 Ver2 050220 FINAL

Încărcat de

Sekar NaikDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

f4g02613 Ver2 050220 FINAL

Încărcat de

Sekar NaikDrepturi de autor:

Formate disponibile

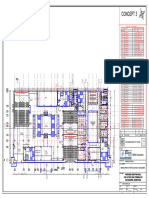

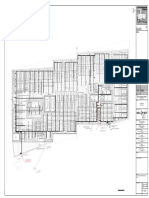

ASHOK COMPUTERISED DRAWING DI

ALTERATIONS

SUFFIX

GRADE

FIRST ANGLE PROJECTION -

DO NOT CHANGE MANUALLY ER

+

TE

DA

#2 #1

214 0,2

- SNO.1 BRACKET PROFILE 0062684 1 #1

#2 MODIFIED 06.11.19

LEYLAND

ABOVE THIS LINE - WELDING

TO BE AVOIDED

+ 23,5 - 9(4 HOLES THRU)ADDED

- BOM ADDED & NOTES

UPDATED

- DIMN 221.2 0.2,25.3 0.2,

29.6 0.2, 13.7 0.2,

R1

0 33.7 0.3,63.7 0.3,

83.7 0.3, 106.7 0.3,

#2 137.4, 182.6, 247.3,

22,2 269.8 0.5, 292.3 0.5,

8,9

160 0.5 ADDED

- DIMN 234 0.3, 54.5,

#2

15

120.5 0.3, 39.2,34.70.2

CHANGED TO 234 0.5,

54.5 0.3, 120.5 0.5,

9,5

73.3 0.3,34.7 0.3

- DIMN 234 0.3, (166),140

DELETED

- WEIGHT UPDATED

13,4 0,2

exclusive property of ASHOK LEYLAND Ltd, and must not be used,

- BRACKET PROFILE 1 #2

This drawing is strictly private and confidential. It is the

MODIFIED

copied or reproduced in part or whole without the company's

RIB TO BE - RIB DETAILS ADDED

WELDED - THICKNESS CHANGED

EACH NUT TO BE

WELDED AT 3 PLACES

B + +82,7 #2

FROM 10(0/-0.2) TO

6(0/-0.2)

22,5 0,2 0,2 - DIMN 221 0.2 CHANGED

TO 214 0.2

- DIMN 27.5, 86.7 0.2

CHANGED TO 23.5,

M8X1.25 NUT - EACH NUT TO

82.7 0.2

BE ASSEMBLED AT 4 HOLES

+

- DIMN 120.5 0.5

0,8 A

+

CHANGED TO 116.5 0.5

0,8 B - DIMN 24.5, 54.5 0.3,

67 0.3 ADDED

- BOM AND DEVELOPED

R1

#2 Sno.3 RIB VIEW, WEIGHT UPDATED

0

1 DEVELOPED VIEW:

R1

90

116,5 0,5

- DIMN 316.6, 168.2,

0

CHANGED TO 315.6, 170.2,

46,5 3D VIEW FOR REFERENCE - DIMN 50.5, 14 0.3,

+

105.5 ADDED

0,5 15,5

written permission

10 - DIMN 29.6 0.2, 30.7 0.3,

34.7 0.3,137.4,182.6,

#2 #1

WELDED 269.8 0.5, 292.3 0.5

CHANGED TO 24.6 0.2,

54,5 0,3

3 34.7 0.3,26.8 0.3,

THICK

A 140.4,187.6, 268.80.5,

10

30

2 90 291.3 0.5

R1

6-0,2

0

0

24,5

#1

#1 NOTES:

#2

#2

1. SPECIFIC SYMBOLS ON DRAWING:

+ 0,8 A

#X REVISION NOTE

#1 #2

160 0,5 46,5

#2

( ) REFERENCE DIMENSION

67 0,3

< > FIXTURE DIMENSION

#2 DEVELOPED VIEW BASIC DIMENSION

#2

315,6

2. CLEANLINESS REQUIREMENT:

11,5 0,2

#2

170,2 MAXIMUM PERMISSIBLE WEIGHT OF DEBRIS IN

3 (4 SLOTS) 0 MILLIGRAMS (0.001g) RETAINED ON A 5µm FILTER

R1

R4 4 S

#2

+ 50,5 VALUE <= 13 mg

,5 LO

R5

1,5 (4 SLOTS)

TY TS

CLEANLINESS AS PER ALS.011.60 STANDARD

P

25,3 0,2

3. SURFACE PROTECTION AS PER ALS 268.03, CLASS D

26,8 0,3

0,4

ASHOK LEYLAND LTD.

TECHNICAL CENTRE VELLIVOYALCHAVADI

#1

4. EDGE CONDITIONS SHOWN ACC. TO ISO 13715:2000-06-15.

73,3 0,3

6,5 R10

24,6 0,2

34,7 0,3

29,6 0,2

#2 #1

(4 HOLES THRU) R5 5. GEOMETRIC TOLERANCES ACC.TO ISO1101:1983

&

#2

ISO 5459:1981-11

#1

#1

#2

#1

6. FREE FROM BURRS.

R5 7. UNMENTIONED DIMENSION REFER 3D MODEL

#1

R3

+13

14 0,3

(4

0,2 13,7 0,3

R5

8. NUT-HEXAGON WELD NUT AS PER

X)

#1

33,7 0,3 IS 8856-1991- M8 X 1.25

#2

#1

63,7 0,3 9. REFER ALS 276.02 FOR WELDING

#1

83,7 0,3

#2 105,5

DRAWING NOT VALID WITHOUT

EDGE CONDITION ALPLM WATERMARK IN THIS SPACE

#1 106,7 0,3 -0.1

-0.3

#2 #1

140,4

SURFACE FINISH 3 RIB IS 2062 E250 Gr A 1 DRAWN / CHECKED / MED APPROVAL/ APPROVED / STDS APP. /

#2 #1

187,6 DATE DATE DATE DATE DATE

#1

247,3 ( ) 2 NUT M8 X 1.25 REFER NOTES 4

GSK/

08.09.2019

GP/

08.09.2019

GKS/

08.09.2019

NAS/

08.09.2019

XXXX /

XXXX

MATERIAL

#2 #1

268,8 0,5 1 BRACKET S235 JR DIN EN 10025 DR FE - 410W-A-IS 2062 1

REFER DWG

#2 #1

291,3 0,5 HEAT TREATMENT

#2 #1 SL.NO DESCRIPTION MATERIAL QTY

--

UNLESS OTHERWISE SPECIFIED

BILL OF MATERIALS REMARKS

+ IMPORTANT CHARACTERISTIC

TOLERANCES REFER IS:2102 ; MEDIUM FOR MACHINING AND COARSE FOR FABRICATION

ASHOK

FABRICATED COMPONENTS TO BE DEGREASED, DESCALED. APPLY ZINC PHOSPHATE, APPLY EPOXY PRIMER

(10) SPECIAL INSTRUCTIONS/NOTE:

APPEARENCE ITEM ER-DIN DATE N6 BSVI

SURFACE AND APPLY ENAMEL TO MEET 300 HRS OF SALT SPRAY LIFE WHEN TESTED AS PER ASTM B117 YES NO 0060973 12.09.2019 DESCRIPTION

C CRITICAL CHARACTERISTIC (0)

PROTECTION (UNDER PELLICULAR CORROSION <= 2 mm. NO BLISTERING IS ALLOWED.)

MACHINED SURFACE TO BE APPLIED WITH RUST PREVENTIVE OIL TO IS: 1154

FINISHED WEIGHT (APPROX) REF PART NO: ---

AIR INTAKE PIPE SUPPORT BRACKET

% 100% INSPECTION CHARACTERISTIC (0) #2 #1 0.77 kg S/A PART NO: ---- PART

SURFACE FINISH AS PER METRIC SCREW THREADS SHALL CONFORM TO THE LIMITS

AND TOLERANCES SPECIFIED IN THE CURRENT IS:4218

SHARP EDGES TO BE REMOVED

DIMENSIONS ARE IN mm

S SAFETY CHARACTERISTIC (0)

AVERAGE OUTGOING QUALITY LIMIT AS 60PPM

SCALE SUPERSEDES --- NO. F4G02613 #2

IS: 3073 (CLA VALUE) CLASS 6g EXTERNAL OR 5H INTERNAL. DO NOT SCALE DRAWING 1 1

LEYLAND THIS DRAWING SHEET CONTAINS 10 KEY CHARACTERISTICS 1:1 SPEC NO: ---- SHEET NO.

--------

OF

-------- A1

S-ar putea să vă placă și

- City of Birmingham: Structures Ready For DemolitionDocument1 paginăCity of Birmingham: Structures Ready For DemolitionErin Edgemon25% (4)

- 5 - WQU - 622 CTSP - M5 - CompiledContentDocument34 pagini5 - WQU - 622 CTSP - M5 - CompiledContentJoe NgÎncă nu există evaluări

- Pre Stressed Concrete Solved ProblemsDocument17 paginiPre Stressed Concrete Solved ProblemsJefferson T. Ignacio75% (28)

- Exciter Field - Cat GeneratorDocument5 paginiExciter Field - Cat Generatorwagner_guimarães_10% (1)

- CADCAM PortfolioDocument5 paginiCADCAM PortfolioGuhan MÎncă nu există evaluări

- Eamco DMJ RS SD 001Document1 paginăEamco DMJ RS SD 001libin513Încă nu există evaluări

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 paginig214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevÎncă nu există evaluări

- ENR 6. 1-3 07 OCT 21 AI P-Cuba: CE AN ICODocument2 paginiENR 6. 1-3 07 OCT 21 AI P-Cuba: CE AN ICOMendel Piorno CharchabalÎncă nu există evaluări

- MRS, FlorenceDocument1 paginăMRS, Florencemagoobe reaganÎncă nu există evaluări

- Cipageran Peta CitraDocument1 paginăCipageran Peta Citrarullybandung100% (1)

- Karya Desain: Detail Ranka AtapDocument1 paginăKarya Desain: Detail Ranka AtapKukuh HidayatÎncă nu există evaluări

- Ec2-02a Second Floor Auxiliary LayoutDocument1 paginăEc2-02a Second Floor Auxiliary LayoutSEDFREY DELA CRUZÎncă nu există evaluări

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 paginăG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaÎncă nu există evaluări

- Platform ADocument1 paginăPlatform ACosmescu AnaÎncă nu există evaluări

- Ad-90.0-E-02054-Pdf Small Power & LightingDocument1 paginăAd-90.0-E-02054-Pdf Small Power & LightingmcaslamÎncă nu există evaluări

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 paginiG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevÎncă nu există evaluări

- Asc Eamco DMJ Rs SD 001Document1 paginăAsc Eamco DMJ Rs SD 001libin513Încă nu există evaluări

- Existing Drain LevelsDocument1 paginăExisting Drain LevelsNaveen NagisettiÎncă nu există evaluări

- Ec1-09 - Utility Room Fdas LayoutDocument1 paginăEc1-09 - Utility Room Fdas LayoutSEDFREY DELA CRUZÎncă nu există evaluări

- Transmission Network July, 2021 NEA-ModelDocument1 paginăTransmission Network July, 2021 NEA-ModelSuraj DahalÎncă nu există evaluări

- A-707-Signage Locations Overall Ground FloorDocument1 paginăA-707-Signage Locations Overall Ground FloorEmmanuel InfanteÎncă nu există evaluări

- 07-Rajasthani Ghat KDocument1 pagină07-Rajasthani Ghat KVinod Kumar GaurÎncă nu există evaluări

- A-805-Reflected Ceiling - Mosque - First FloorDocument1 paginăA-805-Reflected Ceiling - Mosque - First FloorEmmanuel InfanteÎncă nu există evaluări

- Industrial Area: Administration BuildingDocument1 paginăIndustrial Area: Administration BuildingAnas TawfiqÎncă nu există evaluări

- N SHEET NO:9/14: Fire Extinguishers ListDocument1 paginăN SHEET NO:9/14: Fire Extinguishers ListDasari VenkateshÎncă nu există evaluări

- Plantas Baixas PDFDocument1 paginăPlantas Baixas PDFCelimorMoreiraÎncă nu există evaluări

- Side Elevation View: Casing SupportDocument2 paginiSide Elevation View: Casing SupportCARRILLO GRANDEZ BRANDON GEINSTEINÎncă nu există evaluări

- 1909-01-28C HV, LV TELE & AREA LIGHTING RETICULATION LAYOUT & CO-ORDINATED DRAWING (Phase3) A0Document1 pagină1909-01-28C HV, LV TELE & AREA LIGHTING RETICULATION LAYOUT & CO-ORDINATED DRAWING (Phase3) A0n0188741wÎncă nu există evaluări

- 2nd FLR - PlanDocument1 pagină2nd FLR - PlanManjunatha A.RÎncă nu există evaluări

- #Isomap-Arnaud Velten 2007Document1 pagină#Isomap-Arnaud Velten 2007Etherikal Commander100% (2)

- Desague (1) - Planta GeneralDocument1 paginăDesague (1) - Planta Generalkristian MéndezÎncă nu există evaluări

- Planta Potabilizadora Y Reservorio 100 M3 - "Andamayo": ViracoDocument1 paginăPlanta Potabilizadora Y Reservorio 100 M3 - "Andamayo": ViracoRichard Henry Peñaranda PachoÎncă nu există evaluări

- Ir - CTCR - STR - La - M2 - 1004 - Initial Vertical Pile Load TestDocument1 paginăIr - CTCR - STR - La - M2 - 1004 - Initial Vertical Pile Load TestCTC RLY (Photos)Încă nu există evaluări

- 01 Plano de Ubicacion Edu. SLDocument1 pagină01 Plano de Ubicacion Edu. SLElwis ApazaÎncă nu există evaluări

- Buffet Area: Seating 90Document5 paginiBuffet Area: Seating 90Karun RijalÎncă nu există evaluări

- Ad 90.0 e 02061 PDF Earthing Details B 4Document1 paginăAd 90.0 e 02061 PDF Earthing Details B 4mcaslamÎncă nu există evaluări

- As App Vs Rev Foot1675404512947Document2 paginiAs App Vs Rev Foot1675404512947Fadi AlatrashÎncă nu există evaluări

- CA Haypress Valley 20180907 TM GeoDocument1 paginăCA Haypress Valley 20180907 TM GeoMichael SmethurstÎncă nu există evaluări

- Elt - Villgio - 0505Document1 paginăElt - Villgio - 0505Leandro JampietreÎncă nu există evaluări

- Mapas Hidrogeologica RJDocument1 paginăMapas Hidrogeologica RJChen Kuang HsiaoÎncă nu există evaluări

- 03 150000 4200000005 Ace Mec DRG 005204 - 02Document1 pagină03 150000 4200000005 Ace Mec DRG 005204 - 02Anas TawfiqÎncă nu există evaluări

- SM-105 Smoke SchematicDocument1 paginăSM-105 Smoke SchematicMohd AbidÎncă nu există evaluări

- MESIAS TERRENO-ModelDocument1 paginăMESIAS TERRENO-ModelAnderson LuceroÎncă nu există evaluări

- Potongan Bangunan MallDocument1 paginăPotongan Bangunan Mallkuze007Încă nu există evaluări

- T5 B2 LayoutDocument1 paginăT5 B2 Layoutsatyam.pulkam7490Încă nu există evaluări

- Chachu Majra: Sector - 66 BetaDocument1 paginăChachu Majra: Sector - 66 Betapujan77Încă nu există evaluări

- Dimensions Table Elastometric BearingDocument1 paginăDimensions Table Elastometric BearingDMRÎncă nu există evaluări

- 01 - Food Court - First Floor - 231011 - 172531Document1 pagină01 - Food Court - First Floor - 231011 - 172531shubham BaliyanÎncă nu există evaluări

- DMH5Document1 paginăDMH5Keyvin dela CruzÎncă nu există evaluări

- DDDDDDDDDDocument1 paginăDDDDDDDDDNideesh RobertÎncă nu există evaluări

- Electricas-02 IEDocument1 paginăElectricas-02 IEDANIEL MARDOQUEO QUISPE MEZAÎncă nu există evaluări

- External - SITE-WORK-PROCESS (002) - 1Document1 paginăExternal - SITE-WORK-PROCESS (002) - 1verbat007Încă nu există evaluări

- VO Back Flow AD Ref 4-1Document15 paginiVO Back Flow AD Ref 4-1wiwitoke3Încă nu există evaluări

- CCTV Location - MAINGATEDocument1 paginăCCTV Location - MAINGATEAdi PriyapurnatamaÎncă nu există evaluări

- PLDM Plumbing FCD PlanDocument34 paginiPLDM Plumbing FCD PlanNon Etabas GadnatamÎncă nu există evaluări

- Peta RencanaDocument1 paginăPeta Rencana1paradox229Încă nu există evaluări

- Nep SD BW 217 23 002Document1 paginăNep SD BW 217 23 002مصطفى خضرÎncă nu există evaluări

- Two-Way Mobility Adams & Forsyth Streets: City of Jacksonville NotesDocument133 paginiTwo-Way Mobility Adams & Forsyth Streets: City of Jacksonville NotesJJÎncă nu există evaluări

- Project Title Project Owner Note Scale: As Shown Sheet Contents Sheet NoDocument1 paginăProject Title Project Owner Note Scale: As Shown Sheet Contents Sheet NoLorena TanÎncă nu există evaluări

- Approve For Ref Lighting Power LayoutsDocument2 paginiApprove For Ref Lighting Power LayoutsSaahil KhaanÎncă nu există evaluări

- 2019-565 Fire Protection ReviewDocument23 pagini2019-565 Fire Protection ReviewMohamed AlbanaÎncă nu există evaluări

- D O E-ModelDocument1 paginăD O E-Modelsiul.cogÎncă nu există evaluări

- Instant Assessments for Data Tracking, Grade 1: Language ArtsDe la EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsÎncă nu există evaluări

- Ready to Go Guided Reading: Question, Grades 1 - 2De la EverandReady to Go Guided Reading: Question, Grades 1 - 2Încă nu există evaluări

- Module 3 Q2 Gen Chem IIDocument10 paginiModule 3 Q2 Gen Chem IIMengieÎncă nu există evaluări

- Prediction TheoryDocument90 paginiPrediction TheoryJuliusSerdeñaTrapalÎncă nu există evaluări

- Power Electronics Circuits Devices and Applications by Muhammad H RashidDocument602 paginiPower Electronics Circuits Devices and Applications by Muhammad H RashidSuhas K Sri SaiÎncă nu există evaluări

- Sr. Grand Test Key and HintsDocument7 paginiSr. Grand Test Key and HintsM JEEVARATHNAM NAIDUÎncă nu există evaluări

- WS-Problems Solved by Quadratic EquationsDocument1 paginăWS-Problems Solved by Quadratic EquationsNorul AzimÎncă nu există evaluări

- EE2202 Electromagnetic Theory Lecture NotesDocument125 paginiEE2202 Electromagnetic Theory Lecture NoteskanjaiÎncă nu există evaluări

- Oracle Ebs InstallationDocument22 paginiOracle Ebs InstallationMr. JalilÎncă nu există evaluări

- Opc Da Client ManualDocument29 paginiOpc Da Client ManualantoÎncă nu există evaluări

- Hypothesis Testing in Stata PDFDocument9 paginiHypothesis Testing in Stata PDFMarisela FuentesÎncă nu există evaluări

- Thông Gió Cho T - Pdfslide - Net - Electrical-Cabinet-Vbcm-The-Electrical-Cabinet-Ventilation-Serves-To-MaintainDocument26 paginiThông Gió Cho T - Pdfslide - Net - Electrical-Cabinet-Vbcm-The-Electrical-Cabinet-Ventilation-Serves-To-MaintainThành PhạmÎncă nu există evaluări

- Civl432 Bridge Design SummaryDocument5 paginiCivl432 Bridge Design SummarySheikh Mizanur RahmanÎncă nu există evaluări

- Engine Overhaul : Group 11BDocument80 paginiEngine Overhaul : Group 11BДмитрий100% (1)

- Java Programming For BSC It 4th Sem Kuvempu UniversityDocument52 paginiJava Programming For BSC It 4th Sem Kuvempu UniversityUsha Shaw100% (1)

- Notation Composer 3 Users GuideDocument690 paginiNotation Composer 3 Users GuideSvedot MakedonecÎncă nu există evaluări

- An Experimental and Statistical Study of Olfactory PreferencesDocument7 paginiAn Experimental and Statistical Study of Olfactory Preferencesjungseong parkÎncă nu există evaluări

- Bombardier Global 7500 Pilots AcronymsDocument18 paginiBombardier Global 7500 Pilots AcronymsGourav DasÎncă nu există evaluări

- Crop Productivity Aroma Profile and Antioxidant Activity in Pelargonium Graveolens L-H-R Under inDocument7 paginiCrop Productivity Aroma Profile and Antioxidant Activity in Pelargonium Graveolens L-H-R Under inNo VivoÎncă nu există evaluări

- Cable Net StructuresDocument18 paginiCable Net StructuresRimon GawandeÎncă nu există evaluări

- ISUOG Basic Training: Fetal Biometry - Dating, Assessing Size & Estimating Fetal WeightDocument33 paginiISUOG Basic Training: Fetal Biometry - Dating, Assessing Size & Estimating Fetal WeightRolando DiazÎncă nu există evaluări

- Diego 1Document22 paginiDiego 1acs_spÎncă nu există evaluări

- Student Personal Prescriptive Path 2Document29 paginiStudent Personal Prescriptive Path 2api-377332228Încă nu există evaluări

- Fork LiftDocument4 paginiFork Lifttamer goudaÎncă nu există evaluări

- L05 - DumitriuDocument9 paginiL05 - DumitriuLouisaMjjÎncă nu există evaluări

- Tutorial DistillationDocument3 paginiTutorial DistillationManu Indivare Nundoolall100% (1)

- Fuse Link KDocument6 paginiFuse Link KABam BambumÎncă nu există evaluări